A BWM-TOPSIS Hazardous Waste Inventory Safety Risk Evaluation

Abstract

1. Introduction

1.1. Inventory Management

1.2. Methodology

2. Index System Construction

2.1. Factor Analysis

- (1)

- Inventory equipment has a certain useful life. Because of the dangers associated with hazardous waste, the longer the equipment is used, the greater the inventory risk and the higher the need for equipment maintenance. Therefore, both service life and equipment maintenance factors affect inventory safety.

- (2)

- Generally, specialized knowledge, management ability and practical experience can reflect the ability to solve problems in the hazardous waste management. Therefore, management level such as education and professional behavior are also factors that affect inventory safety.

- (3)

- The National Hazardous Waste List issued by China in 2016 classified hazardous waste into 50 categories, formulated a Hazardous Waste Identification Index to identify unclear hazardous waste and classified the hazardous characteristics: causticity, toxicity, flammability, reactivity and infectivity. Therefore, both the quantity and hazardous waste characteristics are factors that affect inventory safety.

- (4)

- A hazardous waste inventory risk assessment should first consider the operational safety associated with hazardous waste warehousing, storage (packaging and the storage method) and removal, all of which affect inventory safety.

2.2. Identification and Screening of Indicators

2.2.1. Inventory Equipment

- (1)

- The technical life of inventory equipment is related to its use time; that is, the longer the equipment is used, the greater is the risk. Therefore, to determine the risk, the ratio of the use time of each device to the service life of the device was first calculated, and then the arithmetic average method used to calculate the average number as a criterion, with the larger the ratio, the greater the risk.

- (2)

- Equipment maintenance can be divided into annual maintenance frequency and equipment maintenance timeliness, the criteria for which are:

- Annual maintenance frequency is the number of times the equipment was quality tested and the operating apparatus checked each year.

- Equipment maintenance timeliness is the time interval between instrument failure and successful maintenance.

2.2.2. Management Level

- (1)

- The academic qualifications of the inventory staff were divided from low to high from basic education to college education, after which the percentage of college education was used as the criterion, as it was assumed that the higher is the education, the higher is the management level.

- (2)

- Because it is difficult to quantify professional knowledge, management capabilities, or practical experience, this paper defines professionals as persons who have been engaged in hazardous waste management related work for more than three years. The percentage of professionals in the staff was used to measure the professionalism of the inventory management personnel. It was assumed that the higher is the percentage, the higher is the possibility of effective inventory management.

2.2.3. Nature of Hazardous Waste

- (1)

- The greater is the quantity of hazardous waste stored, the higher are the safety requirements for the inventory and the greater is the risk. Therefore, the daily average quantity of hazardous waste was used as the criterion with the measurement unit being the tonne.

- (2)

- The hazardous waste characteristics were classified into five types: corrosive, toxic, flammable, reactive and infectious. The more types of hazardous waste characteristics there are in an inventory, the more difficult it is to manage and the larger the safety risks; therefore, the hazardous waste characteristic types were used as the criteria.

2.2.4. Operations

- (1)

- The primary issue to be considered in the hazardous waste inventory is safety. The hazardous waste inventory packaging should be intact and free of leaks; therefore, the packaging quality was taken as a criterion.

- (2)

- Hazardous waste operations during storage are also a major safety factor, which means that it was necessary to consider the different hazardous waste storage methods and the possibilities of chemical reactions between the hazardous waste. Therefore, the criteria were:

- Storage method: The selection of different storage methods for different types of hazardous wastes.

- Separation operation: The separation of hazardous waste that has a risk of chemical reactions.

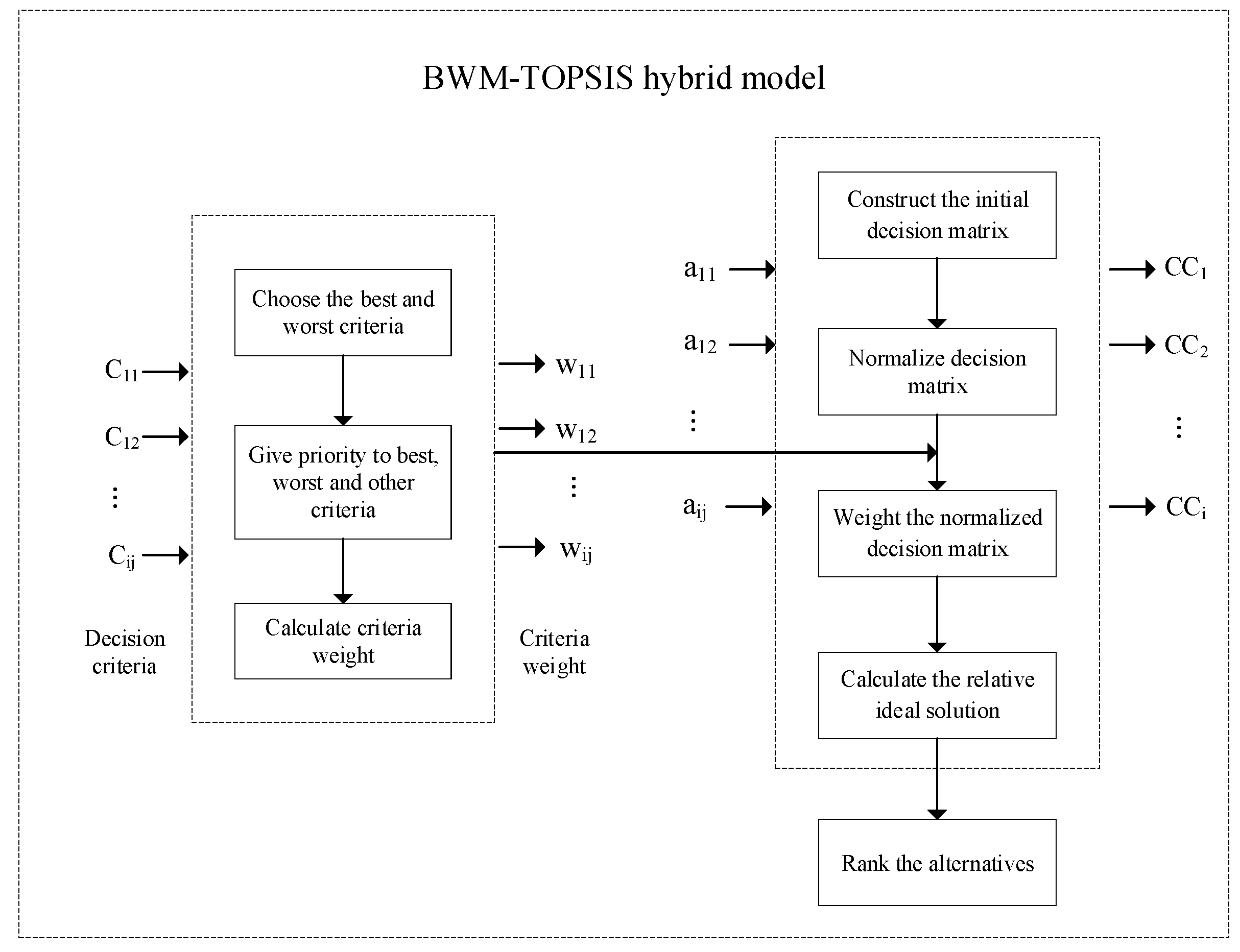

3. BWM and TOPSIS for Risk Evaluation

3.1. BWM Calculation of Criteria Weights

s.t.∑jwj = 1

wj ≥ 0, for all j

3.2. TOPSIS for Ranking the Alternatives

4. Case Analysis

4.1. Case Enterprise

4.2. Calculating the Criteria Weights Using BWM

4.3. Ranking the Case Companies Using TOPSIS

4.4. Discussion

5. Conclusions

- (1)

- A novel risk evaluation index system for hazardous waste inventory was constructed to assist companies reduce the risk of hazardous waste inventory and improve the level of inventory management of hazardous waste.

- (2)

- For the first time, this study used the BWM-TOPSIS model to evaluate the inventory risk and develop a new decision-making framework for hazardous waste inventory risk evaluation.

- (3)

- A new inventory management method was proposed from a safe production perspective to improve the scientificity of hazardous waste inventory management, reduce the risk of hazardous waste inventory management and provide a scientific management basis for decision makers.

- (1)

- This paper selects equipment, management level, nature of hazardous waste and operations to establish the risk evaluation criteria. However, these criteria were all on-site factors and no off-site factors were considered, such as effects on nearby residents and nature reserves. Therefore, future research could consider adding off-site factors to the inventory risk evaluation model. In this assumption, considering the damage of hazardous waste to the surrounding environment, the warehouse location of the waste-producing companies may become a key factor affecting the evaluation results.

- (2)

- The hazardous waste inventory risk evaluation model used an expert scoring method to quantify the operational criteria, which could be considered somewhat subjective. Therefore, the next step could be to consider adding fuzzy theory to increase the objectivity of the model. The limit of this hypothesis is that experts need to understand fuzzy theory, and this limit can be overcome by introducing language variables to allow experts to directly choose qualitative data.

Author Contributions

Funding

Conflicts of Interest

References

- Xu, L.; Deng, Y.; Mancl, K. Environmental disaster risk reduction-oriented centralized treatment of hazardous wastes: A novel approach for production-distribution decision optimization in China. Int. J. Disaster Risk Reduct. 2019, 40. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.Y. Facts Related to August 12, 2015 Explosion Accident in Tianjin, China. Process Saf. Prog. 2015, 34, 313–314. [Google Scholar] [CrossRef]

- Das, A.; Mazumder, T.N.; Gupta, A.K. Pareto frontier analyses based decision making tool for transportation of hazardous waste. J. Hazard. Mater. 2012, 227–228, 341–352. [Google Scholar] [CrossRef] [PubMed]

- Samanlioglu, F. A multi-objective mathematical model for the industrial hazardous waste location-routing problem. Eur. J. Oper. Res. 2013, 226, 332–340. [Google Scholar] [CrossRef]

- Aydemir-Karadag, A. A profit-oriented mathematical model for hazardous waste locating-routing problem. J. Clean. Prod. 2018, 202, 213–225. [Google Scholar] [CrossRef]

- Rabbani, M.; Heidari, R.; Farrokhi-Asl, H.; Rahimi, N. Using metaheuristic algorithms to solve a multi-objective industrial hazardous waste location-routing problem considering incompatible waste types. J. Clean. Prod. 2018, 170, 227–241. [Google Scholar] [CrossRef]

- Rabbani, M.; Heidari, R.; Yazdanparast, R. A stochastic multi-period industrial hazardous waste location-routing problem: Integrating NSGA-II and Monte Carlo simulation. Eur. J. Oper. Res. 2019, 272, 945–961. [Google Scholar] [CrossRef]

- Gautam, P.; Kumar, S.; Lokhandwala, S. Advanced oxidation processes for treatment of leachate from hazardous waste landfill: A critical review. J. Clean. Prod. 2019, 237, 117639. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; You, J.; Yu, P.; Li, X.; Xue, G.; Chen, H.; Xu, X.; van Agtmaal, S.; Alvarez, P.J.J. Hazardous waste dewatering and dry mass reduction through hydrophobic modification by a facile one-pot, alkali-assisted hydrothermal reaction. Water Res. 2019, 155, 225–232. [Google Scholar] [CrossRef]

- Tang, L.; Tang, C.; Xiao, J.; Zeng, P.; Tang, M.; Wang, Z.; Zhang, Z. A cleaner process for lead recovery from lead-containing hazardous solid waste and zinc leaching residue via reducing-matting smelting. J. Clean. Prod. 2019, 241, 118328. [Google Scholar] [CrossRef]

- Zeng, J.; Yue, Y.; Gao, Q.; Zhang, J.; Zhou, J.; Pan, Y.; Qian, G.; Tang, J.; Ruan, J. Co-treatment of hazardous wastes by the thermal plasma to produce an effective catalyst. J. Clean. Prod. 2019, 208, 243–251. [Google Scholar] [CrossRef]

- Zhang, Y.; Gan, T.; Hu, H.; Cai, X.; Huang, Z.; Liang, X.; Yin, Y.; Qin, Y.; Feng, Z. Effective treatment and utilization of hazardous waste sulfuric acid generated from alkylation by lignocellulose ester-catalyzed oxidative degradation of organic pollutants. J. Hazard. Mater. 2019, 380, 120892. [Google Scholar] [CrossRef] [PubMed]

- Duong, L.N.K.; Wood, L.C.; Wang, W.Y.C. A Multi-criteria Inventory Management System for Perishable & Substitutable Products. Procedia Manuf. 2015, 2, 66–76. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, G.; Li, K.W. Efficient aircraft spare parts inventory management under demand uncertainty. J. Air Transp. Manag. 2015, 42, 101–109. [Google Scholar] [CrossRef]

- Najafi, M.; Ahmadi, A.; Zolfagharinia, H. Blood inventory management in hospitals: Considering supply and demand uncertainty and blood transshipment possibility. Oper. Res. Health Care 2017, 15, 43–56. [Google Scholar] [CrossRef]

- Saha, E.; Ray, P.K. Modelling and analysis of inventory management systems in healthcare: A review and reflections. Comput. Ind. Eng. 2019, 137, 106051. [Google Scholar] [CrossRef]

- Cho, W.-J.; Chang, S.-H.; Park, H.-H. Uncertainty analysis of safety assessment for high-level radioactive waste repository. Waste Manag. 1992, 12, 45–54. [Google Scholar] [CrossRef]

- Louis, G.; Shih, J.-S. A flexible inventory model for municipal solid waste recycling. Socio-Econ. Plan. Sci. 2007, 41, 61–89. [Google Scholar] [CrossRef]

- Mes, M.; Schutten, M.; Rivera, A.P. Inventory routing for dynamic waste collection. Waste Manag. 2014, 34, 1564–1576. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, G.H.; He, L. A multi-echelon supply chain model for municipal solid waste management system. Waste Manag. 2014, 34, 553–561. [Google Scholar] [CrossRef]

- Zhao, J.; Ke, G.Y. Incorporating inventory risks in location-routing models for explosive waste management. Int. J. Prod. Econ. 2017, 193, 123–136. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Tavana, M. An extension of the Electre I method for group decision-making under a fuzzy environment. Omega Int. J. Manag. Sci. 2011, 39, 373–386. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K.P. Multiple Attribute Decision Making: Method and Applications; Springer: New York, NY, USA, 1981. [Google Scholar]

- Forgionne, G.A.; Kohli, R.; Jennings, D. An AHP analysis of quality in AI and DSS journals. Omega Int. J. Manag. Sci. 2002, 30, 171–183. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; Albin, S.L. A hierarchical method for evaluating products with quantitative and sensory characteristics. IIE Trans. 2001, 33, 1081–1092. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N. Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega Int. J. Manag. Sci. 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Briggs, T.; Kunsch, P.L.; Mareschal, B. Nuclear waste management—An application of the multicriteria PROMETHEE methods. Eur. J. Oper. Res. 1990, 44, 1–10. [Google Scholar] [CrossRef]

- Queiruga, D.; Walther, G.; Gonzalez-Benito, J.; Spengler, T. Evaluation of sites for the location of WEEE recycling plants in Spain. Waste Manag. 2008, 28, 181–190. [Google Scholar] [CrossRef]

- Boran, F.E.; Genc, S.; Kurt, M.; Akay, D. A multi-criteria intuitionistic fuzzy group decision making for supplier selection with TOPSIS method. Expert Syst. Appl. 2009, 36, 11363–11368. [Google Scholar] [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A multi-criteria decision making approach for location planning for urban distribution centers under uncertainty. Math. Comput. Model. 2011, 53, 98–109. [Google Scholar] [CrossRef]

- Dagdeviren, M. Decision making in equipment selection: An integrated approach with AHP and PROMETHEE. J. Intell. Manuf. 2008, 19, 397–406. [Google Scholar] [CrossRef]

- Kaya, T.; Kahraman, C. Multicriteria renewable energy planning using an integrated fuzzy VIKOR & AHP methodology: The case of Istanbul. Energy 2010, 35, 2517–2527. [Google Scholar] [CrossRef]

- Kandakoglu, A.; Celik, M.; Akgun, I. A multi-methodological approach for shipping registry selection in maritime transportation industry. Math. Comput. Model. 2009, 49, 586–597. [Google Scholar] [CrossRef]

- Herman, M.W.; Koczkodaj, W.W. A Monte Carlo study of pairwise comparison. Inf. Process. Lett. 1996, 57, 25–29. [Google Scholar] [CrossRef]

- You, P.; Guo, S.; Zhao, H.; Zhao, H. Operation Performance Evaluation of Power Grid Enterprise Using a Hybrid BWM-TOPSIS Method. Sustainability 2017, 9, 2329. [Google Scholar] [CrossRef]

- Nestico, A.; Somma, P. Comparative Analysis of Multi-Criteria Methods for the Enhancement of Historical Buildings. Sustainability 2019, 11, 4526. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Chen, S.; Diao, W. Establishing indices for groundwater contamination risk assessment in the vicinity of hazardous waste landfills in China. Environ. Pollut. 2012, 165, 77–90. [Google Scholar] [CrossRef]

- Schroer, S.; Modarres, M. An event classification schema for evaluating site risk in a multi-unit nuclear power plant probabilistic risk assessment. Reliab. Eng. Syst. Saf. 2013, 117, 40–51. [Google Scholar] [CrossRef]

- Hsu, W.-K.K.; Huang, S.-H.S.; Tseng, W.-J. Evaluating the risk of operational safety for dangerous goods in airfreights—A revised risk matrix based on fuzzy AHP. Transp. Res. Part D Transp. Environ. 2016, 48, 235–247. [Google Scholar] [CrossRef]

- Gumus, A.T. Evaluation of hazardous waste transportation firms by using a two step fuzzy-AHP and TOPSIS methodology. Expert Syst. Appl. 2009, 36, 4067–4074. [Google Scholar] [CrossRef]

- Trucco, P.; Cagno, E.; Ruggeri, F.; Grande, O. A Bayesian Belief Network modelling of organisational factors in risk analysis: A case study in maritime transportation. Reliab. Eng. Syst. Saf. 2008, 93, 845–856. [Google Scholar] [CrossRef]

- Glickman, T.S.; Erkut, E. Assessment of hazardous material risks for rail yard safety. Saf. Sci. 2007, 45, 813–822. [Google Scholar] [CrossRef][Green Version]

- Escher, B.I.; Baumgartner, R.; Koller, M.; Treyer, K.; Lienert, J.; McArdell, C.S. Environmental toxicology and risk assessment of pharmaceuticals from hospital wastewater. Water Res. 2011, 45, 75–92. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.-C.; Chen, M.-S. Risk assessment and quality improvement of liquid waste management in Taiwan University chemical laboratories. Waste Manag. 2018, 71, 578–588. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, J. Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega-Int. J. Manag. Sci. 2016, 64, 126–130. [Google Scholar] [CrossRef]

- Mi, X.; Tang, M.; Liao, H.; Shen, W.; Lev, B. The state-of-the-art survey on integrations and applications of the best worst method in decision making: Why, what, what for and what’s next? Omega Int. J. Manag. Sci. 2019, 87, 205–225. [Google Scholar] [CrossRef]

- Wang, E. Benchmarking whole-building energy performance with multi-criteria technique for order preference by similarity to ideal solution using a selective objective-weighting approach. Appl. Energy 2015, 146, 92–103. [Google Scholar] [CrossRef]

| Country | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|---|---|---|

| Armenia | 435,398 | 462,896 | 470,506 | 579,050 | 576,419 | 555,077 | 615,471 | 543,232 |

| Austria | 1,472,864 | … | 1,065,888 | … | 1,272,288 | … | 1,260,953 | … |

| Belarus | 918,200 | 943,196 | 1,322,792 | 1,415,421 | 1,723,975 | 1,207,798 | 1,626,610 | 1,668,060 |

| China | 15,867,550 | 34,312,200 | 34,652,400 | 31,568,900 | 36,335,200 | 39,761,100 | 53,473,000 | 69,368,896 |

| Denmark | 1,224,795 | … | 1,216,905 | … | 1,715,907 | … | 2,010,740 | … |

| Germany | 19,931,452 | … | 21,983,896 | … | 21,812,660 | … | 23,039,154 | … |

| Iceland | 8,304 | … | 16,263 | … | 36,250 | … | 47,857 | … |

| Italy | 8,543,415 | … | 8,987,032 | … | 8,877,164 | … | 9,706,964 | … |

| Kyrgyzstan | 5,806,792 | 10,152,943 | 4,930,216 | 7,957,260 | 10,223,015 | 10,498,943 | 12,377,486 | 12,648,247 |

| Poland | 1,491,845 | … | 1,737,024 | … | 1,681,037 | … | 1,917,134 | … |

| Singapore | 434,000 | 432,600 | 280,500 | 332,800 | 411,180 | 446,870 | 478,990 | 471,450 |

| First-Level Influencing Factors | Secondary Influencing Factors | Related Literature |

|---|---|---|

| Equipment | Equipment usage time | Li et al. established an evaluation index system for groundwater pollution near hazardous waste landfills, which had landfill management field equipment maintenance as an influencing factor, which had two indicators: routine maintenance frequency and the equipment repair and replacement timeliness [38]. Schroer and Modarres considered the same equipment components in their multi-unit nuclear power plant probabilistic risk assessment and pointed out that the design, installation and maintenance of these components were almost the same, which made them susceptible to traditional common cause failures [39]. Hsu et al. studied the operational safety risk factors for dangerous goods air cargo and included the lack of equipment in the customs operations as a risk factor [40]. |

| Equipment maintenance | ||

| Management level | Education | Li et al. included landfill management employee competence as an important factor affecting groundwater when establishing groundwater pollution risk assessment indicators and used the percentage of professionals in the staff to measure the human impact of daily landfill operations [38]. Hsu et al. included the lack of qualified and experienced inspectors in customs operations as a risk factor for air cargo dangerous goods [40]. Gumus used an improved Delphi method to identify eight evaluation criteria for hazardous waste shipping, which included the ability to solve problems [41]. Trucco et al. integrated human factors and organizational factors into a risk analysis for marine transportation and pointed out that passenger and crew behaviors were affected by management and organizational structures [42]. |

| Professional | ||

| The nature of hazardous waste | Quantity | Li et al. included the nature of waste filtrate as an influencing factor in groundwater pollution risk in a groundwater pollution risk assessment index near hazardous waste landfills, with the most important of these being the chemical composition of the leachate [38]. When developing a quantitative railway station risk assessment, Glickman and Erkut included the risks associated with the receipt and storage of dangerous goods tankers, which in this case involved six different chemicals. For each dangerous substance, an average monthly quantity and the hazards that required the most attention were specified [43]. Escher et al. correlated drug toxicity data with predicted concentrations in different wastewater streams when developing an environmental toxicology and risk assessment for drugs in hospital wastewater to assess the overall potential risks in different situations [44]. |

| Hazardous characteristics | ||

| Operation | Pack | Schroer and Modarres examined human dependence in a probabilistic risk assessment for a multi-unit nuclear power plant, finding that the lack of monitoring, maintenance and cleaning operations could increase the potential risks [39]. Hsu et al. considered operations such as insufficient packaging and the failure to regulate cargo unloading as dangerous factors in the risk assessment of air cargo dangerous goods [40]. Ho and Chen counted the list of laboratory accidents that had occurred at Taiwan University since 2000 and prioritized 10 potential risk factors based on the number of risk priorities: the use of funnels or drain pans for waste liquid collection, decentralized storage, container materials and other operational factors [45]. |

| Criteria | Sub-Criteria | Definition |

|---|---|---|

| Equipment | Equipment usage time | Equipment usage time percentage |

| Annual maintenance frequency | number of times the equipment is quality tested and operating apparatus checked each year | |

| Timeliness of maintenance | the time interval between instrument failure and successful maintenance. | |

| Management level ( | College education percentage | University graduates as a percentage of all warehouse management staff |

| Professional percentage | Proportion of risk management related professionals in all warehouse management staff | |

| Nature of hazardous waste | Quantity | Daily average hazardous waste quantity |

| Hazardous waste characteristics | Hazardous waste characteristics: corrosive, toxic, flammable, reactive and infectious | |

| Operation | Packing quality | Packaging must be intact |

| Storage method | Different storage methods for different types of hazardous waste | |

| Separation operation ( | Separation of hazardous waste that has potential chemical reactions |

| aBW | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Consistency Index (Max ξ) | 0.00 | 0.44 | 1.00 | 1.63 | 2.30 | 3.00 | 3.73 | 4.47 | 5.23 |

| Primary Criteria | Primary Criteria Weight | Sub-Criteria | Sub-Criteria Weight | Total Weight | Ranking |

|---|---|---|---|---|---|

| Equipment usage time | 0.615 | 0.041 | 8 | ||

| Equipment | 0.067 | Annual maintenance frequency | 0.308 | 0.021 | 9 |

| Maintenance timeliness | 0.077 | 0.005 | 10 | ||

| Management | 0.125 | College education percentage | 0.333 | 0.042 | 7 |

| level | Professional percentage | 0.667 | 0.083 | 4 | |

| Nature of hazardous | 0.200 | Quantity | 0.750 | 0.150 | 3 |

| Waste | Hazardous waste characteristics | 0.250 | 0.050 | 6 | |

| Packing quality | 0.622 | 0.378 | 1 | ||

| Operation | 0.608 | Storage method | 0.287 | 0.174 | 2 |

| Separation operation | 0.091 | 0.055 | 5 |

| Enterprise 1 | Enterprise 2 | Enterprise 3 | Enterprise 4 | |

|---|---|---|---|---|

| Equipment usage time | 0.643 | 0.514 | 0.112 | 0.327 |

| Annual maintenance frequency | 10 | 5 | 1 | 12 |

| Maintenance timeliness | 1 | 7 | 7 | 3 |

| College education percentage | 0.25 | 0.333 | 0.429 | 0.714 |

| Professional percentage | 0.167 | 0.286 | 0.14 | 0.238 |

| Quantity | 3.6 | 5.7 | 4.3 | 8.2 |

| Hazardous waste characteristics | 3 | 4 | 4 | 5 |

| Packing quality | 3.8 | 4.2 | 3.8 | 4.6 |

| Storage method | 4.2 | 4 | 3.8 | 2.8 |

| Separation operation | 2.4 | 2 | 2.8 | 1.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, F.; Li, Y.; Lin, H.; Miao, J.; Liang, X. A BWM-TOPSIS Hazardous Waste Inventory Safety Risk Evaluation. Int. J. Environ. Res. Public Health 2020, 17, 5765. https://doi.org/10.3390/ijerph17165765

Deng F, Li Y, Lin H, Miao J, Liang X. A BWM-TOPSIS Hazardous Waste Inventory Safety Risk Evaluation. International Journal of Environmental Research and Public Health. 2020; 17(16):5765. https://doi.org/10.3390/ijerph17165765

Chicago/Turabian StyleDeng, Fumin, Yanjie Li, Huirong Lin, Jinrui Miao, and Xuedong Liang. 2020. "A BWM-TOPSIS Hazardous Waste Inventory Safety Risk Evaluation" International Journal of Environmental Research and Public Health 17, no. 16: 5765. https://doi.org/10.3390/ijerph17165765

APA StyleDeng, F., Li, Y., Lin, H., Miao, J., & Liang, X. (2020). A BWM-TOPSIS Hazardous Waste Inventory Safety Risk Evaluation. International Journal of Environmental Research and Public Health, 17(16), 5765. https://doi.org/10.3390/ijerph17165765