Exertion Perception When Performing Cutting Tasks in Poultry Slaughterhouses: Risk Assessment of Developing Musculoskeletal Disorders

Abstract

:1. Introduction

2. Method

2.1. Participants

2.2. Instruments

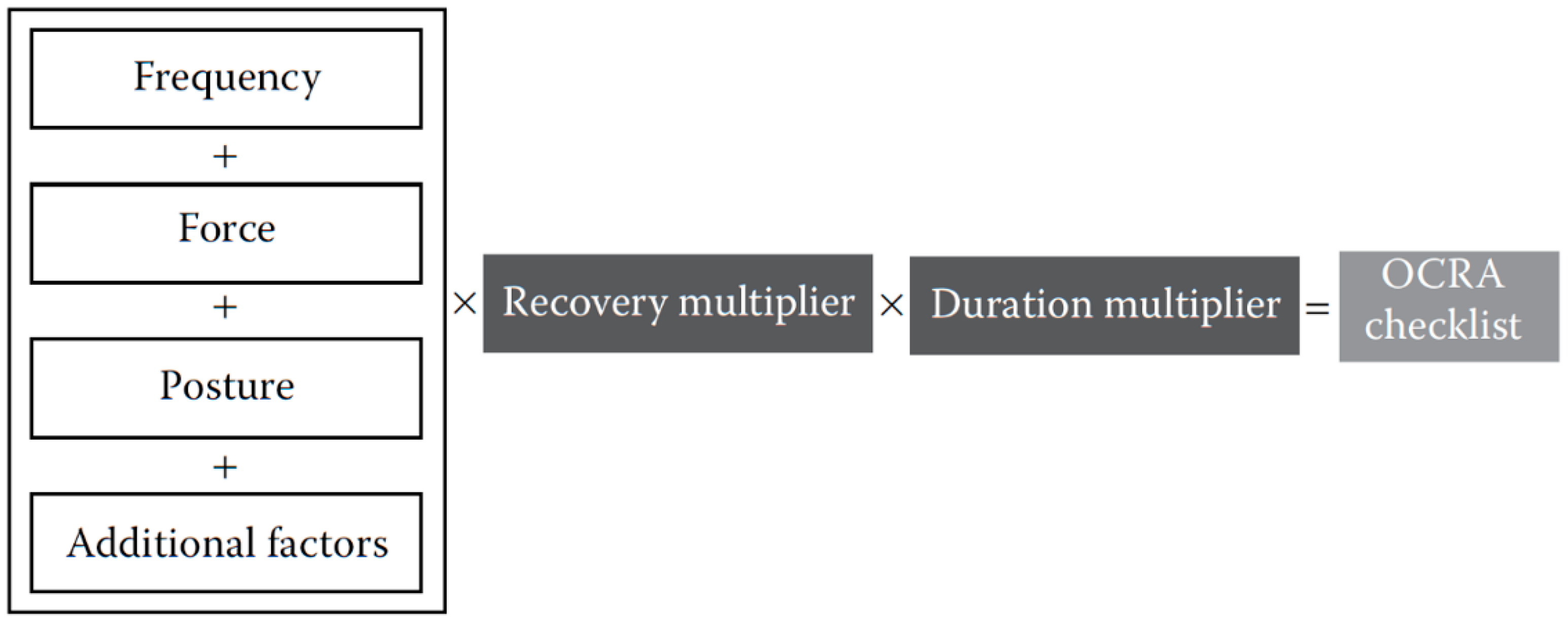

2.3. OCRA Checklist Method

2.3.1. Action Frequency Factor

2.3.2. Force Factor

2.3.3. Awkward Posture Factor

2.3.4. Additional Risk Factors

2.3.5. Recovery Multiplier

2.3.6. Duration Multiplier

2.4. Knife Sharpness Evaluation

2.5. Statistics

3. Results

4. Discussion

Strengths and Limitations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ABPA. Associação Brasileira de Proteína Animal. Relatório Anual 2020. 2020. Available online: http://abpa-br.org/wp-content/uploads/2020/05/abpa_relatorio_anual_2020_portugues_web.pdf (accessed on 23 June 2020).

- Brasil, Ministério da Fazenda. Anuário Estatístico da Previdência Social-2018. 2018. Available online: http://www.previdencia.gov.br/dados-abertos/dados-abertos-previdencia-social/ (accessed on 12 March 2020).

- OSHA, Occupational Safety and Health Administration. Prevention of Musculoskeletal Injuries in Poultry Processing. 2013. Available online: https://www.osha.gov/Publications/OSHA3213.pdf/ (accessed on 1 March 2020).

- Toulouse, G.; Richard, J.G. Slaughterhouses. In International Encyclopedia of Ergonomics and Human Factors; Karwowski, W., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2006; pp. 2772–2775. [Google Scholar]

- Colombini, D.; Occhipinti, E. Risk Analysis and Management of Repetitive Actions: A Guide for Applying the OCRA System (Occupational Repetitive Actions), 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ramsey, J.G.; Musolin, K.; Mueller, C. Health Hazard Evaluation Report: Evaluation of Carpal Tunnel Syndrome and Other Musculoskeletal Disorders among Employees at a Poultry Processing Plant; HHE 2014-0040-3232; U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health: Cincinnati, OH, USA, 2015. Available online: https://www.cdc.gov/niosh/hhe/reports/pdfs/2014-0040-3232.pdf (accessed on 18 May 2020).

- Ricco, M.; Signorelli, C. Personal and occupational risk factors for carpal tunnel syndrome in meat processing industry workers in Northern Italy. Med. Pr. 2017, 68, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Buckle, P.W. Fortnightly review: Work factors and upper limb disorders. BMJ 1997, 315, 1360–1363. [Google Scholar] [CrossRef] [PubMed]

- Dianat, I.; Haslegrave, C.M.; Stedmon, A.W. Using pliers in assembly work: Short and long task duration effects of gloves on hand performance capabilities and subjective assessments of discomfort and ease of tool manipulation. Appl. Ergon. 2012, 43, 413–423. [Google Scholar] [CrossRef] [PubMed]

- Ramos, E.; Reis, D.C.; Tirloni, A.S.; Moro, A.R.P. Thermographic analysis of the hands of poultry slaughterhouse workers exposed to artificially cold environment. Procedia Manuf. 2015, 3, 4252–4259. [Google Scholar] [CrossRef] [Green Version]

- Tirloni, A.S.; Reis, D.C.D.; Dias, N.F.; Moro, A.R.P. The Use of Personal Protective Equipment: Finger Temperatures and Thermal Sensation of Workers’ Exposure to Cold Environment. Int. J. Environ. Res. Public Health 2018, 15, 2583. [Google Scholar] [CrossRef] [Green Version]

- Tirloni, A.S.; Reis, D.C.; Borgatto, A.F.; Moro, A.R.P. Association between perception of bodily discomfort and individual and work organisational factors in Brazilian slaughterhouse workers: A cross-sectional study. BMJ Open 2019, 9, e022824. [Google Scholar] [CrossRef] [Green Version]

- McGorry, R.W.; Young, S.L.; Murphy, P.; Brogmus, G. Experimental appraisal of a manual task evaluator. Int. J. Ind. Ergon. 2000, 25, 265–274. [Google Scholar] [CrossRef]

- Juul-Kristensen, B.; Fallentin, N.; Hansson, G.Å.; Madeleine, P.; Andersen, J.H.; Ekdahl, C. Physical workload during manual and mechanical deboning of poultry. Int. J. Ind. Ergon. 2002, 29, 107–115. [Google Scholar] [CrossRef]

- Waddell, D.E.; Wyvill, C.; Gregor, R.J. Upper extremity kinetics in poultry processing: A comparison between two different cutting tasks. J. Appl. Biomech. 2003, 19, 169–177. [Google Scholar] [CrossRef]

- Pontonnier, C.; de Zee, M.; Samani, A.; Dumont, G.; Madeleine, P. Strengths and limitations of a musculoskeletal model for an analysis of simulated meat cutting tasks. Appl. Ergon. 2014, 45, 592–600. [Google Scholar] [CrossRef] [Green Version]

- Murphy, P.; McGorry, R.; Teare, P.; Brogmus, G. Design and performance of a manual task evaluator. Int. J. Ind. Ergon. 2000, 25, 257–264. [Google Scholar] [CrossRef]

- McGorry, R.W. A system for the measurement of grip forces and applied moments during hand tool use. Appl. Ergon. 2001, 32, 271–279. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dempsey, P.G.; O’Brien, N.V. The effect of workstation and task variables on forces applied during simulated meat cutting. Ergonomics 2004, 47, 1640–1656. [Google Scholar] [CrossRef] [PubMed]

- McGorry, R.W.; Dowd, P.C.; Dempsey, P.G. A technique for field measurements of knife sharpness. Appl. Ergon. 2005, 36, 635–640. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dowd, P.C.; Dempsey, P.G. The effect of blade finish and blade edge angle on forces used in meat cutting operations. Appl. Ergon. 2005, 36, 71–77. [Google Scholar] [CrossRef]

- Dempsey, P.G.; McGorry, R.W. Investigation of a Pork Shoulder Deboning Operation. J. Occup. Environ. Hyg. 2004, 1, 167–172. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dempsey, P.G.; Casey, J.S. The Effect of Force Distribution and Magnitude at the Hand-Tool Interface on the Accuracy of Grip Force Estimates. J. Occup. Rehabil. 2004, 14, 255–266. [Google Scholar] [CrossRef]

- Borg, G.A.V. Psychophysical bases of perceived exertion. Med. Sci. Sports Exerc. 1982, 14, 377–381. [Google Scholar] [CrossRef]

- McGorry, R.W.; Lin, J.; Dempsey, P.G.; Casey, J.S. Accuracy of the Borg CR10 Scale for Estimating Grip Forces Associated with Hand Tool Tasks. J. Occup. Environ. Hyg. 2010, 7, 298–306. [Google Scholar] [CrossRef]

- Tirloni, A.S.; Reis, D.C.; Dias, N.F.; Moro, A.R.P. Evaluation of Worker Satisfaction with the Use of Hand Tools in a Poultry Slaughterhouse. In Advances in Physical Ergonomics & Human Factors; Goonetilleke, R., Karwowski, W., Eds.; Springer: Cham, Switzerland, 2019; pp. 476–488. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dowd, P.C.; Dempsey, P.G. Cutting moments and grip forces in meat cutting operations and the effect of knife sharpness. Appl. Ergon. 2003, 34, 375–382. [Google Scholar] [CrossRef]

- Savescu, A.; Cuny-Guerrier, A.; Wild, P.; Reno, G.; Aublet-Cuvelier, A.; Claudon, L. Objective assessment of knife sharpness over a working day cutting meat. Appl. Ergon. 2018, 68, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Karltun, J.; Vogel, K.; Bergstrand, M.; Eklund, J. Maintaining knife sharpness in industrial meat cutting: A matter of knife or meat cutter ability. Appl. Ergon. 2016, 56, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Vogel, K.; Karltun, J.; Eklund, J.; Engkvist, I.-L. Improving meat cutters’ work: Changes and effects following an Intervention. Appl. Ergon. 2013, 44, 996–1003. [Google Scholar] [CrossRef] [PubMed]

- Brasil, Ministério do Trabalho, Secretaria de Inspeção do Trabalho. Manual de Auxílio na Interpretação e Aplicação da Norma Regulamentadora nº 36: Segurança e Saúde no Trabalho em Empresas de Abate e Processamento de Carnes e Derivados. 2017. Available online: https://sit.trabalho.gov.br/portal/images/manuais/manualNR36.pdf/ (accessed on 30 March 2020).

- Couto, H.A. Ergonomia Aplicada ao Trabalho: Conteúdo Básico: Guia Prático; ERGO: Belo Horizonte, Brazil, 2007. [Google Scholar]

- Colombini, D.; Occhipinti, E. Método Ocra Para Análise e a Prevenção do Risco por Movimentos Repetitivos: Manual Para a Avaliação e a Gestão do Risco; Escola Ocra Brasiliana: Curitiba, Brazil, 2014. [Google Scholar]

- Hinkle, D.E.; Wiersman, W.; Jurs, S.G. Applied Statistics for the Behavioral Sciences, 5th ed.; Houghton Mifflin: Boston, MA, USA, 2003. [Google Scholar]

- Reis, D.C.; Ramos, E.; Reis, P.F.; Hembecker, P.K.; Gontijo, L.A.; Moro, A.R.P. Assessment of risk factors of upper-limb musculoskeletal disorders in poultry slaughterhouse. Procedia Manuf. 2015, 3, 4309–4314. [Google Scholar] [CrossRef] [Green Version]

- Reis, D.C.; Moro, A.R.P.; Ramos, E.; Reis, P.F. Upper Limbs Exposure to Biomechanical Overload: Occupational Risk Assessment in a Poultry Slaughterhouse. In Advances in Physical Ergonomics and Human Factors, 1st ed.; Goonetilleke, R., Karwowski, W., Eds.; Springer International Publishing: Orlando, FL, USA, 2016; pp. 275–282. [Google Scholar] [CrossRef]

- Reis, D.C.; Tirloni, A.S.; Ramos, E.; Moro, A.R.P. G3-2-Assessment of Risk Factors of Upper-limb Musculoskeletal Disorders in a Chicken Slaughterhouse. Jpn. J. Ergon. 2017, 53, S458–S461. [Google Scholar] [CrossRef] [Green Version]

- Reis, D.C.; Tirloni, A.S.; Moro, A.R.P. Risk Assessment of Upper Limb Musculoskeletal Disorders in a Poultry Slaughterhouse. In Advances in Safety Management and Human Factors; Arezes, P., Ed.; Springer: Cham, Switzerland, 2020; pp. 265–272. [Google Scholar] [CrossRef]

- Dias, N.F.; Tirloni, A.S.; Reis, D.C.; Moro, A.R.P. Risk of slaughterhouse workers developing work-related musculoskeletal disorders in different organizational working conditions. Int. J. Ind. Ergon. 2020, 76, 102929. [Google Scholar] [CrossRef]

- Brasil, Ministério do Trabalho. Norma Regulamentadora NR- 36–Segurança e Saúde no Trabalho Em Empresas de Abate e Processamento de Carnes e Derivados. Brasil: Portaria MTE n° 555, de 18 de Abril de. 2013. Available online: http://trabalho.gov.br/images/Documentos/SST/NR/nr-36-atualizada-2018-II.pdf/ (accessed on 10 March 2020).

- Kilbom, A. Repetitive work of the upper extremity: Part II—The scientific basis (knowledge base) for the guide. Int. J. Ind. Ergon. 1994, 14, 59–86. [Google Scholar] [CrossRef]

- Colombini, D.; Occhipinti, E. Risultati della valutazione del rischio e do danno em gruppi di lavoratori esposti, em diversi comparti lavorativi, a movimenti e sforzi ripetuti degli arti superiori. Med. Lav. 2004, 95, 233–246. [Google Scholar]

- Reis, D.C.; Tirloni, A.S.; Ramos, E.; Dias, N.F.; Moro, A.R.P. Risk Assessment of Repetitive Movements of the Upper Limbs in a Chicken Slaughterhouse. In Proceedings of the 20th Congress of the International Ergonomics Association; Bagnara, S., Tartaglia, R., Albolino, S., Alexander, T., Fujita, Y., Eds.; Springer: Cham, Switzerland, 2019; pp. 323–329. [Google Scholar]

- Ruiz, R.C.; Kupek, E.; Menegon, F.A.; Ruiz, P.G.M. Roteiro para a ação. Revista Proteção 2017, 311, 60–67. [Google Scholar]

- Szabo, R.L.; Radwin, R.G.; Henderson, C.J. The influence of knife dullness on poultry processing operator exertions and the effectiveness of periodic. AIHAJ 2001, 62, 428–433. [Google Scholar] [CrossRef]

- Pinetti, A.C.H.; Buczek, M.D.R.M. Ergonomic Work Analysis in a Brazilian poultry slaughterhouse cutting room. In Proceedings of the 19th Triennial Congress of the IEA, Melbourne, Australia, 9–14 August 2015; pp. 1–7. [Google Scholar]

- Tirloni, A.S.; Reis, D.C.; Santos, J.B.; Reis, P.F.; Barbosa, A.; Moro, A.R.P. Body discomfort in poultry slaughterhouse workers. Work 2012, 4, 2420–2425. [Google Scholar] [CrossRef] [Green Version]

- Tirloni, A.S.; Reis, D.C.; Ramos, E.; Moro, A.R.P. Association of bodily discomfort with occupational risk factors in poultry slaughterhouse workers. DYNA 2017, 84, 49–54. [Google Scholar] [CrossRef]

- Willms, K.; Wells, R.; Carnahan, H. Glove attributes and their contribution to force decrement and increased effort in power grip. Hum. Factors 2009, 51, 797–812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tirloni, A.S.; Reis, D.C.; Ramos, E.; Moro, A.R.P. Thermographic evaluation of the hands of pig slaughterhouse workers exposed to cold temperatures. Int. J. Environ. Res. Public Health 2017, 14, 838. [Google Scholar] [CrossRef] [PubMed]

- Dias, N.F.; Tirloni, A.S.; Reis, D.C.; Moro, A.R.P. Effect of Job Rotation on the Risk of Developing UL-WMSDS in Poultry Slaughterhouse Workers. Braz. J. Poult. Sci. 2019, 21, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Arvidsson, I.; Balogh, I.; Hansson, G.A.; Ohlsson, K.; Akesson, I.; Nordander, C. Rationalization in meat cutting–consequences on physical workload. Appl. Ergon. 2012, 43, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

| Description | Slaughterhouse 1 | Slaughterhouse 2 | Slaughterhouse 3 | Total |

|---|---|---|---|---|

| Total workers (n) | 2300 | 1130 | 3100 | 6530 |

| Workers in productive area | 1600 | 930 | 2500 | 5030 |

| Participants (n) | 19 | 36 | 46 | 101 |

| Chickens slaughtered daily | 300,000 | 115,000 | 280,000 |

| 0 | 0.5 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Missing | Extremely light | Very light | Light | Moderate | Moderate + | Hard (heavy) | Hard + | Very hard | Very hard + | Very hard ++ | Extremely hard (almost max.) |

| Borg Scale | Fraction of the Time and Force Factor | ||||

|---|---|---|---|---|---|

| The working activity requires: | <1/3 of time | ≈1/3 of time | ≈1/2 of time | ≈2/3 of time | ≈all the time |

| MODERATE FORCE (score 3–4) | 1 | 2 | 4 | 6 | 8 |

| peaks of 1–2 s every 10 min | ≈1% of time | ≈5% of time | ≈10% of time or more | - | |

| INTENSE FORCE (score 5–6-7) | 4 | 8 | 16 | 24 | - |

| Almost MAXIMAL FORCE (score 8 or more) | 6 | 12 | 24 | 32 | - |

| Slaughterhouses | Tasks (18) | Cycle Time (s) | Technical Actions/Cycle | Technical Actions/min | Frequency Factor | Time/One Action | n (%) Workers | OCRA Checklist—Sharp Knife | OCRA Checklist—Dull Knife | OCRA Score Increase (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Cleaning breast | 15.3 | 16.7 | 65.5 | 9 | 0.92 | 10 (53) | 25.81 ± 2.0 | 46.55 ± 13.29 | 80.4 |

| Deboning leg—bone 1 | 10.1 | 14.7 | 87.3 | 10 | 0.69 | 4 (21) | 25.93 ± 2.28 | 41.75 ± 13.52 | 61.0 | |

| Deboning leg—bone 2 | 8.7 | 12.8 | 88.3 | 10 | 0.68 | 5 (26) | 27 ± 1.91 | 39.22 ± 13.52 | 44.9 | |

| 2 | Removing neck | 2.6 | 2 | 46.2 | 5 | 1.30 | 1 (3) | 22.77 † | 48.07 † | 111.1 |

| Removing back | 4.6 | 3 | 39.1 | 4 | 1.53 | 1 (3) | 24.04 † | 24.04 † | 0.0 | |

| Deboning whole leg | 16.4 | 23 | 84.1 | 10 | 0.71 | 16 (44) | 26.88 ± 2.91 | 51.23 ± 10.63 | 90.6 | |

| Cutting Kakugiri | 14.8 | 21 | 85.1 | 10 | 0.70 | 2 (6) | 20.87 ± 1.79 | 24.67 ± 0 | 18.2 | |

| Cleaning breast | 17.9 | 16 | 53.6 | 7 | 1.12 | 6 (17) | 18.13 ± 3.72 | 42.59 ± 11.29 | 134.9 | |

| Cleaning breast—automatic | 6.1 | 7 | 68.9 | 10 | 0.87 | 6 (17) | 25.72 ± 1.31 | 45.12 ± 17.94 | 75.4 | |

| Removing wing | 4.7 | 6 | 76.6 | 10 | 0.78 | 3 (8) | 24.04 ± 3.31 | 36.69 ± 13.83 | 52.6 | |

| Deboning sassami | 5.5 | 4 | 43.6 | 5 | 1.38 | 1 (3) | 20.24 † | 48.07 † | 137.5 | |

| 3 | Removing wing | 2.1 | 3 | 85.7 | 10 | 0.70 | 6 (13) | 25.3 ± 3.23 | 53.55 ± 17.62 | 111.7 |

| Deboning back | 40 | 50 | 75 | 10 | 0.80 | 1 (2) | 21.51 † | 49.34 † | 129.4 | |

| Removing breast/removing condemnations # | 5 | 5 | 60 | 8 | 1.00 | 9 (20) | 22.49 ± 0.84 | 30.08 ± 12.36 | 33.7 | |

| Cleaning breast | 5.4 | 5.6 | 62.2 | 8 | 0.96 | 11 (24) | 21.16 ± 2.54 | 41.4 ± 14.94 | 95.7 | |

| Cleaning leg | 12.4 | 12.4 | 60 | 8 | 1.00 | 17 (37) | 22.55 ± 2.38 | 45.91 ± 14.28 | 103.6 | |

| Chicken slaughter # | 2.9 | 1 | 20.7 | 0 | 2.90 | 1 (2) | 12.65 † | 13.92 † | 10.0 | |

| Removing back | 3.6 | 4 | 66.7 | 9 | 0.90 | 1 (2) | 27.83 † | 22.66 † | 100.0 | |

| Range | 3 to 8 tasks/slaughterhouses | 2.1 to 40 | 1 to 50 | 20.7 to 88.3 | 0 to 10 | 0.68 to 2.90 | 101 | 12.65 to 29.10 | 13.92 to 64.52 | 0 to 137.5 |

| Average ± SD | - | 10.6 ± 5.9 | 12.4 ± 7.7 | 69.1 ± 13.3 | 8.7 ± 1.5 | 0.91 ± 0.25 | - | 23.79 ± 3.10 | 43.57 ± 13.51 | 83.7 ± 30.3 |

| Borg Scale (Score) | Sharpness Conditions | |

|---|---|---|

| Sharp (%) | Dull (%) | |

| 0.5 | 12 | - |

| 1 | 25 | - |

| 2 | 50 | 2 |

| 3 | 12 | 18 |

| 4 | 1 | 16 |

| 5 | - | 33 |

| 6 | - | 17 |

| 7 | - | 10 |

| 8 | - | 5 |

| Force Factor | ||

| 0 | 37 | - |

| 1 | 6 | 1 |

| 2 | 45 | 8 |

| 4 | 12 | 27 |

| 24 | - | 59 |

| 32 | - | 5 |

| Risk Level | OCRA Checklist Score | Incidence of UL-WMSDs (%) | Sharpness Conditions (n) | |

|---|---|---|---|---|

| Sharp | Dull | |||

| Acceptable | <7.5 | < 5.3 | 0 | 0 |

| Borderline or very low | 7.6–11 | 5.3–8.4 | 0 | 0 |

| Low | 11.1–14 | 8.4–10.8 | 1 | 1 |

| Moderate | 14.1–22.5 | 10.8–21.5 | 30 | 1 |

| High | >22.5 | >21.5 | 70 | 99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tirloni, A.S.; dos Reis, D.C.; Tirloni, S.F.; Moro, A.R.P. Exertion Perception When Performing Cutting Tasks in Poultry Slaughterhouses: Risk Assessment of Developing Musculoskeletal Disorders. Int. J. Environ. Res. Public Health 2020, 17, 9534. https://doi.org/10.3390/ijerph17249534

Tirloni AS, dos Reis DC, Tirloni SF, Moro ARP. Exertion Perception When Performing Cutting Tasks in Poultry Slaughterhouses: Risk Assessment of Developing Musculoskeletal Disorders. International Journal of Environmental Research and Public Health. 2020; 17(24):9534. https://doi.org/10.3390/ijerph17249534

Chicago/Turabian StyleTirloni, Adriana Seára, Diogo Cunha dos Reis, Salvador Francisco Tirloni, and Antônio Renato Pereira Moro. 2020. "Exertion Perception When Performing Cutting Tasks in Poultry Slaughterhouses: Risk Assessment of Developing Musculoskeletal Disorders" International Journal of Environmental Research and Public Health 17, no. 24: 9534. https://doi.org/10.3390/ijerph17249534

APA StyleTirloni, A. S., dos Reis, D. C., Tirloni, S. F., & Moro, A. R. P. (2020). Exertion Perception When Performing Cutting Tasks in Poultry Slaughterhouses: Risk Assessment of Developing Musculoskeletal Disorders. International Journal of Environmental Research and Public Health, 17(24), 9534. https://doi.org/10.3390/ijerph17249534