Individual Fit Testing of Hearing-Protection Devices Based on Microphones in Real Ears among Workers in Industries with High-Noise-Level Manufacturing

Abstract

:1. Introduction

2. Methods

2.1. Test Facility and Equipment

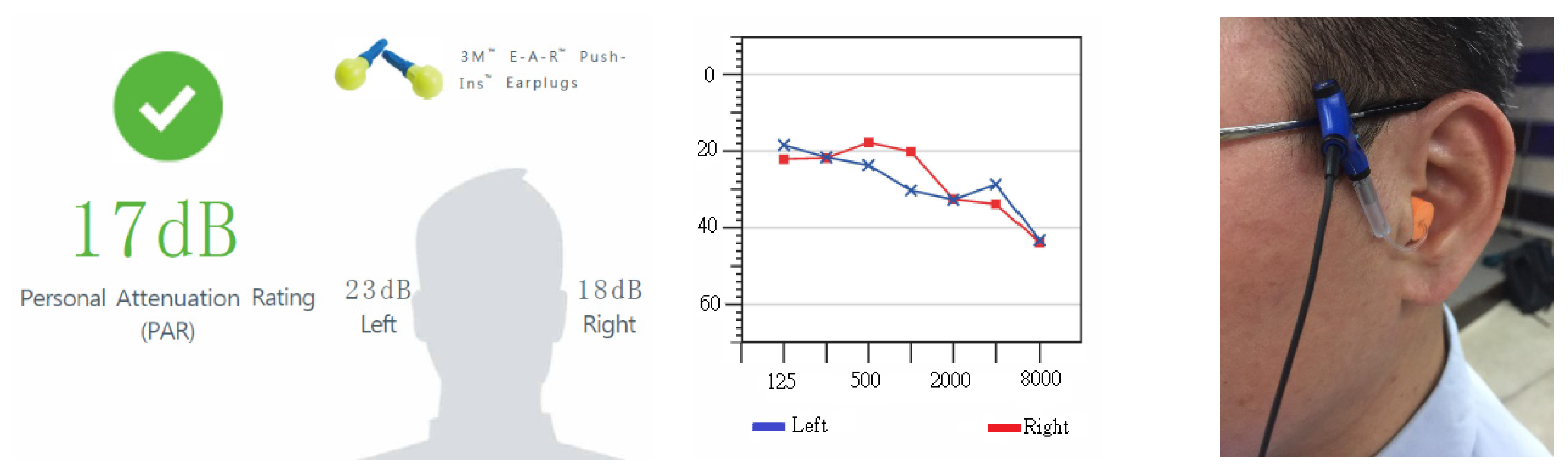

2.2. Types of HPDs

2.3. Experimental Procedure

- After each testee entered the test site, the engineers first explained the PAR test procedure;

- The testee wore the earplugs with probes (Classic™ roll-down foam earplugs);

- The researchers connected the two-element miniature microphone to the left and right probes in the testee’s HPD;

- The testee faced the loudspeaker at the designated position, keeping the ear and loudspeaker at the same height, and the distance from the nose to the clip on the loudspeaker was 40 cm (Figure 6);

- The testee’s PAR value was obtained using the F-MIRE test method;

- The binaural PAR dB was the difference between the binaural PAR dB and the binaural variability; and

- If the sum of the binaural PAR dB and the statutory noise value in the workplace exceeded the setting standard for participating research factories, the result was a pass; otherwise, the result was a fail.

3. Results

4. Discussion

- The highest usage rate of the earplug-type HPDs was the Classic ™ roll-down foam earplugs. For employers, this was because of their relatively low price and convenience for workers to wear.

- The F-MIRE test method could separately measure the sound pressure inside and outside the ear after HPDs were worn, which is intuitive and convenient. However, the test result was easily affected by incorrect posture and contact with the inner wall of the ear canal during wear. For the same type of HPD at different work sites, the measured average PAR value would also be different (Table 4).

- The test result under professional instructions and re-wear of HPD for the testees could indeed show improved protective efficiency of HPD for the wearers (excluding those with different ear canals, which could increase by ca. 35%). This confirmed the effectiveness of education and training.

- At present, the commercially available HPD adaptability test and evaluation system is mainly based on the individual test applications of earplugs and earmuffs. Herein, the F-MIRE test method, among the systems adopted in this study, was convenient to implement at noisy work sites, and the evaluation results could be quickly obtained.

- This study was limited by the fact that it could only be performed during the production period of each plant, and the experimental sampling needed to be completed within a limited time. This study is the first to use the commercially available hearing protectors with the highest usage rate in the current industry. During this period, 105 samples were taken.

5. Conclusions

- The F-MIRE test method could be utilized as an educational training tool to help workers to wear and select HPDs, as it can directly evaluate the protective efficiency of HPDs for wearers. However, attention should be paid to the ambient background noise when the test is conducted.

- The current F-MIRE test method uses a miniature microphone and its extended ear canal probe to measure the sound pressure inside the ear in the external ear canal after earmuffs are worn. This method can directly evaluate the protective efficiency as individuals wear the HPD, but its ear canal probe tube easily touches the inner wall of the ear canal which affects the measurement results. Relevant improvements in measurement methods could be further explored in the future.

- The sound attenuation value, or NRR value, which is marked on the HPD, did not truly reflect the effects of workers wearing HPDs at noisy work sites, and its value was not higher. The best HPD was suitable for the wearers; they could communicate without any obstacles when worn and it could be used effectively for a long time, i.e., it could effectively perform its function and be used continuously.

- This study found that some test subjects had smaller ear canals and the polymeric partially compressible foam earplugs were not easy to insert, making the workers’ earplugs likely to fall off when worn for a long time. Thus, these workers should consider replacing their earbuds with different styles.

- In future work, we will assign different forms of hearing protection to the same tester to verify the best type and performance of personal hearing protection.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martínez, L.F. Can You Hear Me Now: Occupational Hearing Loss, 2004-2010, U.S. Bureau of Labor Statistics (BLS). Monthly Lab. Rev. 2012, 135, 48. [Google Scholar]

- Occupational Safety and Health administration OSHA (OSHA). Overview of the Reporting Statistics in 2008 about Occupational Diseases from the National Diagnosis and Treatment Network for Occupational Diseases and Injuries; OSHA, Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2018. [Google Scholar]

- Institute of Labor, Occupational Safety and Health (ILOSH). Developing an In-situ Measuring and Evaluation Model for Noise Control in Domestic Industries, Annual Research Project (ILOSH104-H312); ILOSH Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2016. [Google Scholar]

- Institute of Labor, Occupational Safety and Health (ILOSH). Study on Implementation Status and Development Strategy for Hearing Conservation Program, 2015 Annual Research Project (ILOSH104-H313); ILOSH, Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2016. [Google Scholar]

- Ministry of Labor (Taiwan). Occupational Safety and Health Act; Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2020.

- Ministry of Labor (Taiwan). Enforcement Rules of the Occupational Safety and Health Act; Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2020.

- Ministry of Labor (Taiwan). Occupational Safety and Health Facilities Regulation; Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2020.

- Daniell, W.E.; Swan, S.S.; McDaniel, M.M.; Stebbins, J.G.; Seixas, N.S.; Morgan, M.S. Noise exposure and hearing conservation practices in an industry with high incidence of workers’ compensation claims for hearing loss. Am. J. Ind. Med. 2002, 42, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Daniell, W.E.; Swan, S.S.; McDaniel, M.M.; Camp, J.E.; Cohen, M.A.; Stebbins, J.G. Noise exposure and hearing loss prevention programmes after 20 years of regulations in the United States. Occup. Environ. Med. 2006, 63, 343–351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miyauchi, H.; Imamiya, S.; Tanaka, S. A study on the effect of training about fitting earplug using the Earphone-Support Device. J. Jpn. Safety Appl. Assoc. (Saf. Health Dig.) 2000, 46, 2–6. (In Japanese) [Google Scholar]

- Heyer, N.; Morata, T.C.; Pinkerton, L.E.; Brueck, S.E.; Stancescu, D.; Panaccio, M.P.; Kim, H.; Sinclair, J.S.; Waters, M.A.; Estill, C.F.; et al. Use of historical data and a novel metric in the evaluation of the effectiveness of hearing conservation program components. Occup. Environ. Med. 2011, 68, 510–517. [Google Scholar] [CrossRef] [PubMed]

- Royster, L.H.; Royster, J.D. An Overview of Hearing Conservation Practices in the U.S.A. J. Acoust. Soc. Am. 1999, 105, 1009. [Google Scholar] [CrossRef]

- Institute of Occupational Safety and Health, (IOSH). A Technical Manual and Guideline to the Selection and Use of Protective Equipment–Hearing Protection Devices, 2nd ed.; IOSH, Council of Labor Affairs, Executive Yuan Republic of China (Taiwan): Taipei, Taiwan, 1998. [Google Scholar]

- U.S. Environmental Protection Agency (EPA). 40CFR, Ch.1: Environmental Protection Agency (7-1-91 Edition), Part 211: Product Noise Labeling; U.S. EPA: Washington, DC, USA, 2012.

- Gauger, D.; Berger, E.H. A New Hearing Protector Rating: The Noise Reduction Statistic for Use with A Weighting (NRSA); A report prepared at the request of the U.S. EPA, reviewed and approved by ANSI S12/WG11, E A R 04 01/HP; U.S. EPA: Indianapolis, IN, USA, 2004.

- Berger, E.H.; Franks, J.R.; Behar, A.; Casali, J.G.; Dixon-Ernst, C.; Kieper, R.W.; Merry, C.J.; Mozo, B.T.; Nixon, C.W.; Ohlin, D.; et al. Development of a new standard laboratory protocol for estimating the field attenuation of hearing protection devices. Part III. The validity of using subject-fit data. J. Acoust. Soc. Am. 1998, 102, 665–672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murphy, W.J.; Themann, C.L.; Murata, T.K. Field-Testing NIOSH HPD Well-Fit: Off-Shore Oil Rig Inspectors in Louisiana and Texas; EPHB Report 360-11a, DHHS-CDC-NIOSH; U.S. National Institute for Occupational Safety and Health (NIOSH): Washington, DC, USA, 2015.

- Hager, L.D.; Voix, J. Individual Field Fit Testing of Hearing Protectors—An Field-MIRE Approach. Presented at Conference American Society of Safety Engineers (ASSE), Seattle, WA, USA, 2006. [Google Scholar]

- Voix, J.; Laville, F. Expandable earplug with smart custom fitting capabilities. In Proceedings of the 2002 International Congress and Exposition on Noise Control Engineering (InterNoise 2002), Dearborn, MI, USA, 19–21 August 2002; pp. 833–841. [Google Scholar]

- Voix, J.; Laville, F. New Method and Device for Customizing in Situ a Hearing Protector. Can. Acoust. 2004, 32, 86–87. [Google Scholar]

- Voix, J. Mise au Point d’un Bouchon D’oreille ‘Intelligent’ (Development of a “Smart” Earplug). Ph. D. Thesis, École de Technologie Supérieure, Montreal, QC, Canada, 2006. [Google Scholar]

- Berger, E.H. Preferred methods for measuring hearing protector attenuation. In Proceedings of the 2005 International Congress and Exposition on Noise Control Engineering (InterNoise 2005), Rio de Janeiro, Brazil, 7–10 August 2005. [Google Scholar]

- Institute of Labor, Occupational Safety and Health (ILOSH). Development of Fit Test Technology for Personal Hearing Protection Device, Annual Research Project (ILOSH107-H301); ILOSH, Ministry of Labor Republic of China (Taiwan): Taipei, Taiwan, 2019. [Google Scholar]

| Regulations | Regulatory Requirements |

|---|---|

| Occupational Safety and Health Act | Employers shall have the necessary safety and health equipment and measures that comply with regulations to “prevent the risks of injuries posed by radiation, high temperature, low temperature, ultrasonic waves, noise, vibration, and abnormal atmospheric pressure” [5]. |

| Enforcement Rules of the Occupational Safety and Health Act | States expressly that job site monitoring plans shall be formulated with the implementation of monitoring whether the job sites are emitting extreme noise [6]. |

| Occupational Safety and Health Facilities Regulation |

|

| Method | Illustration/Formula |

|---|---|

| high, medium, low (HML) | Referring to ISO 4869-2 (1992), three values are provided to calculate the sound attenuation values of high frequency (H), intermediate frequency (M), and low frequency (L). |

| |

| single-number rating (SNR) | Referring to ISO 4869-2 (1992) for a single index of sound attenuation value. It is the value measured under the pink background noise of 100 dB (C). |

| noise-reduction rating (NRR) | Referring to ANSI S12.6 (1984) for a single index of sound attenuation value. It is the value obtained by testing under the pink background noise (total energy 107.9 dBC), in which the energy of each frequency band in the eight band noise is 100 dB (C). |

| octave band (OB) | Referring to ISO 4869-2 (1992), after calculating the sound attenuation value of the eight note frequency band separately, the sound attenuation values of the HPDs can be obtained. |

| Type. | Classic™ Roll-Down Foam Earplugs | Push-Ins™ Stemmed-Style Pod Plugs | UltraFit™ Pre-Molded Earplugs | PELTOR X4A Earmuff |

|---|---|---|---|---|

| Appearance |  |  |  |  |

| Classic™ Roll-Down Foam Earplugs | Push-Ins™ Stemmed-Style Pod Plugs | UltraFit™ Pre-Molded Earplugs | PELTOR X4A Earmuff | Total | ||

|---|---|---|---|---|---|---|

| Factory | A | 36 (69%) | 12 (23%) | 2 (4%) | 2 (4%) | 52 |

| B | 18 (78%) | 4 (17%) | 1 (5%) | 0 (0%) | 23 | |

| C | 57 (78%) | 7 (10%) | 4 (5%) | 5 (7%) | 73 | |

| Total | 111 | 23 | 7 | 7 | 148 | |

| Factory | A | B | C | F value | Significance (p value) | Scheffe’s Method | |

|---|---|---|---|---|---|---|---|

| Left PAR dB | Mean (M) | 25.5 | 24.7 | 27.4 | 4.192 | 0.018 * | C > A |

| Standard deviation (SD) | 8.3 | 8.8 | 8.4 | ||||

| Right PAR dB | Mean (M) | 25.9 | 22.2 | 25.2 | 4.120 | 0.019 * | C > B |

| Standard deviation (SD) | 6.9 | 10.6 | 9.3 | ||||

| Binaural PAR dB | Mean (M) | 22.7 | 19.6 | 22.7 | 3.625 | 0.030 * | C > B |

| Standard deviation (SD) | 7.3 | 9.9 | 9.3 | ||||

| Classic™ Roll-Down Foam Earplugs | Push-Ins™ Stemmed-Style Pod Plugs | UltraFit™ Pre-Molded Earplugs | PELTOR X4A Earmuff | ||

|---|---|---|---|---|---|

| 1st test | 2nd test | ||||

| Caution | 10 (4%) | 4 (14%) | - | 4 (57%) | - |

| Fail | 19 (18%) | 19 (66%) | 7 (30%) | 3 (43%) | - |

| Pass | 82 (78%) | 6 (20%) | 16 (70%) | - | 7 (100%) |

| Total | 111 (100%) | 29 (100%) | 23 (100%) | 7 (100%) | 7 (100%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, C.-C.; Wan, T.-J. Individual Fit Testing of Hearing-Protection Devices Based on Microphones in Real Ears among Workers in Industries with High-Noise-Level Manufacturing. Int. J. Environ. Res. Public Health 2020, 17, 3242. https://doi.org/10.3390/ijerph17093242

Chiu C-C, Wan T-J. Individual Fit Testing of Hearing-Protection Devices Based on Microphones in Real Ears among Workers in Industries with High-Noise-Level Manufacturing. International Journal of Environmental Research and Public Health. 2020; 17(9):3242. https://doi.org/10.3390/ijerph17093242

Chicago/Turabian StyleChiu, Chien-Chen, and Terng-Jou Wan. 2020. "Individual Fit Testing of Hearing-Protection Devices Based on Microphones in Real Ears among Workers in Industries with High-Noise-Level Manufacturing" International Journal of Environmental Research and Public Health 17, no. 9: 3242. https://doi.org/10.3390/ijerph17093242

APA StyleChiu, C.-C., & Wan, T.-J. (2020). Individual Fit Testing of Hearing-Protection Devices Based on Microphones in Real Ears among Workers in Industries with High-Noise-Level Manufacturing. International Journal of Environmental Research and Public Health, 17(9), 3242. https://doi.org/10.3390/ijerph17093242