Application of Olfactometry to Assess the Anti-Odor Properties of Filtering Facepiece Respirators Containing Activated Carbon Nonwovens

Abstract

:1. Introduction

2. Materials

2.1. Filtering Facepiece Respirators

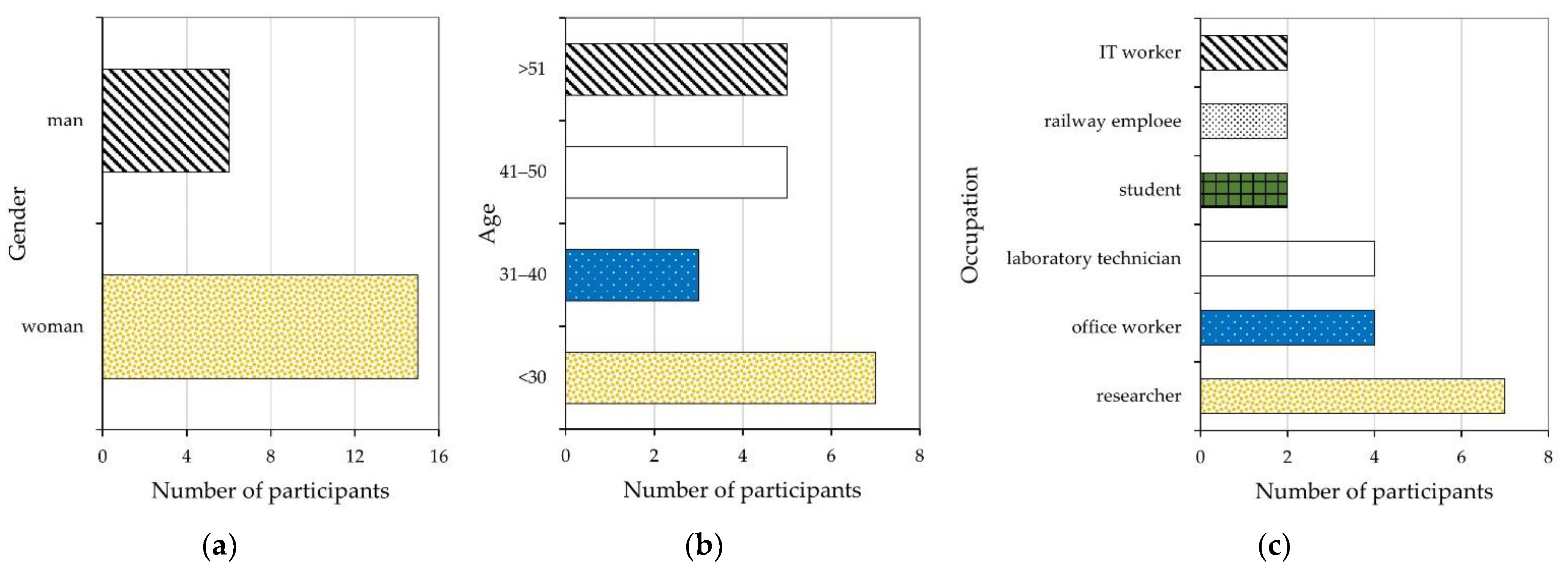

2.2. Study Group Characteristics

3. Methods

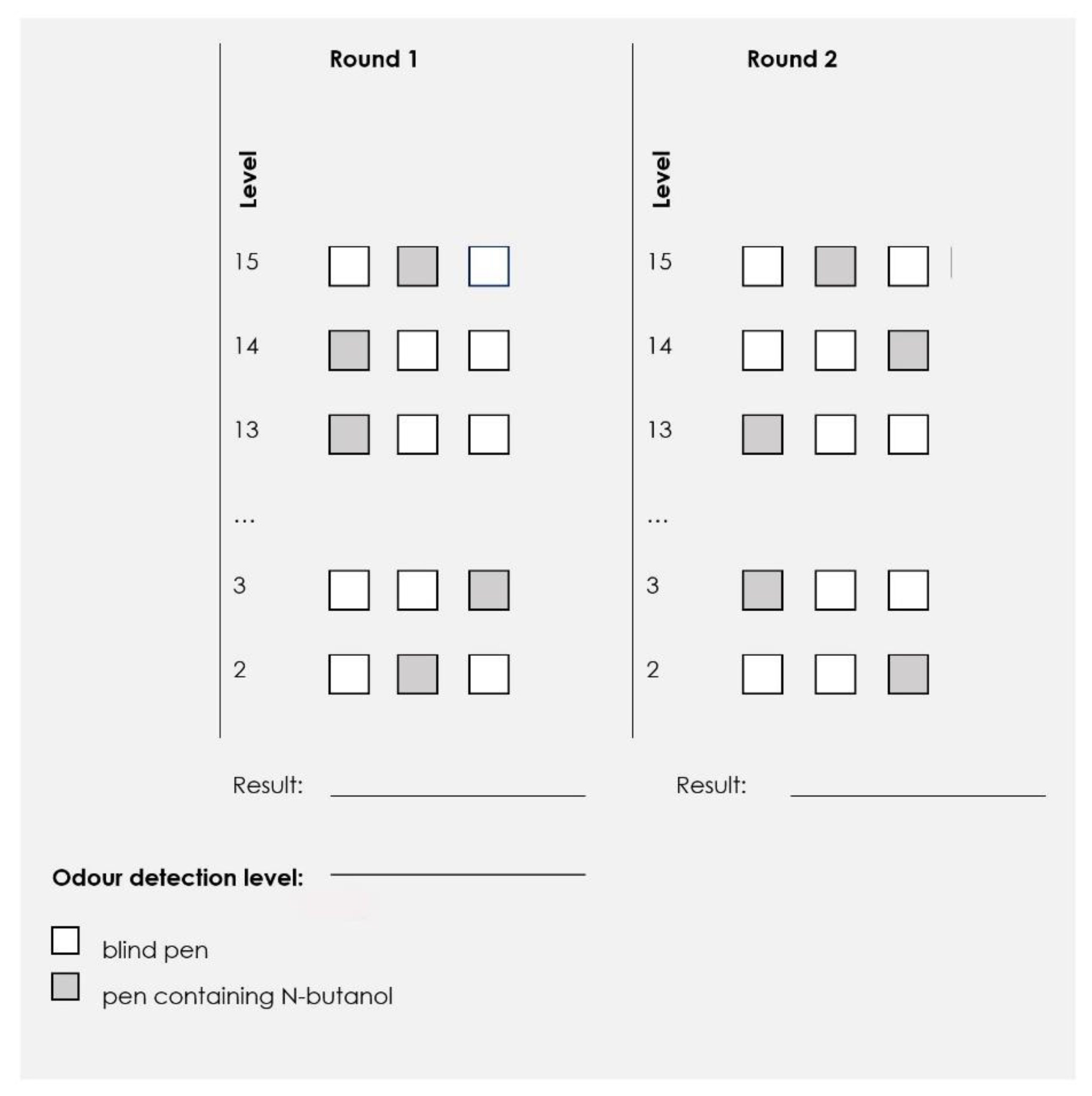

3.1. Determining Individual Odor Sensitivity Levels

3.2. Assessment of FFRs Odor Reduction Efficiency

3.3. Questionnaire

3.4. Statistical Analysis

4. Results and Discussion

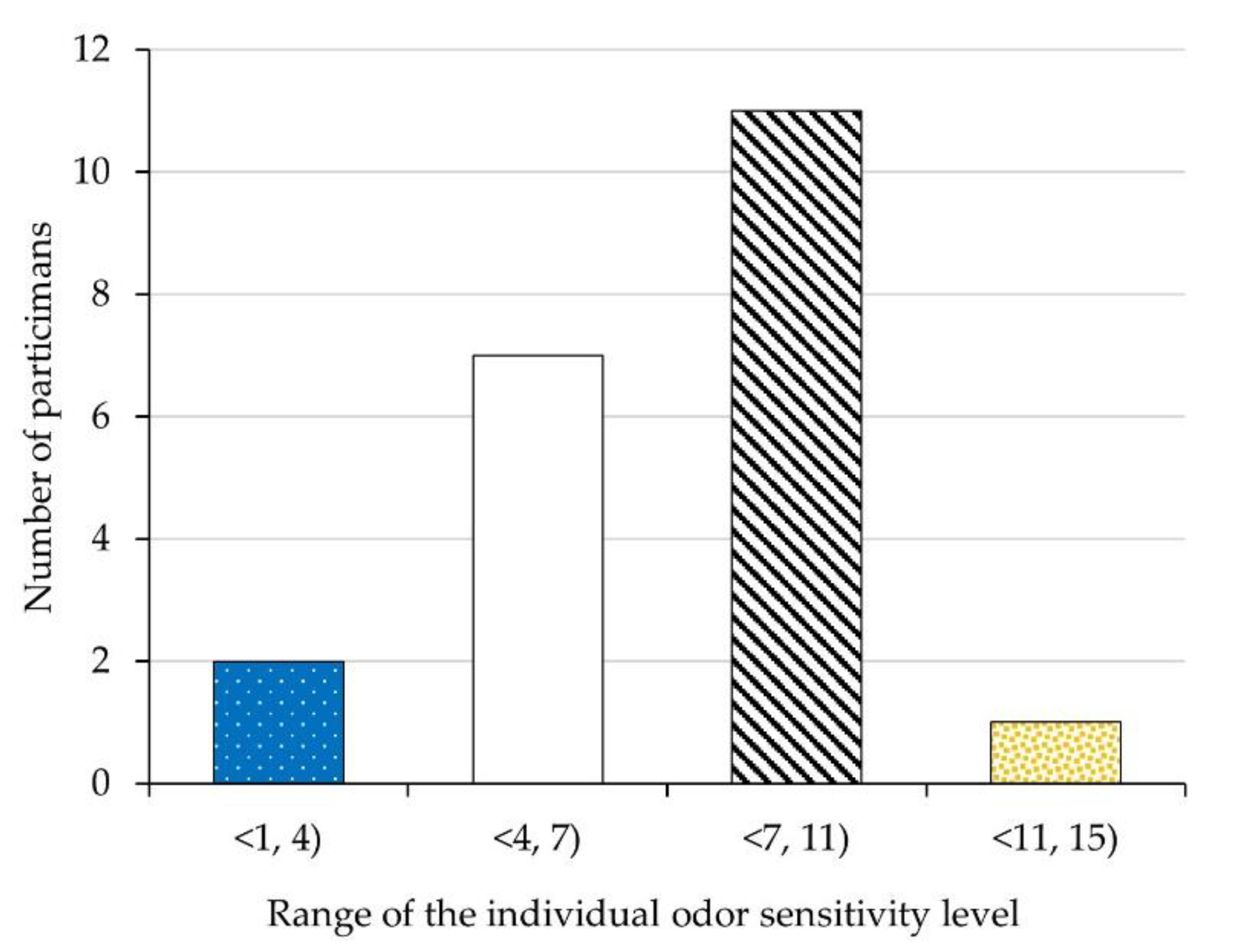

4.1. Individual Odor Sensitivities

4.2. Odor Reduction Efficiency

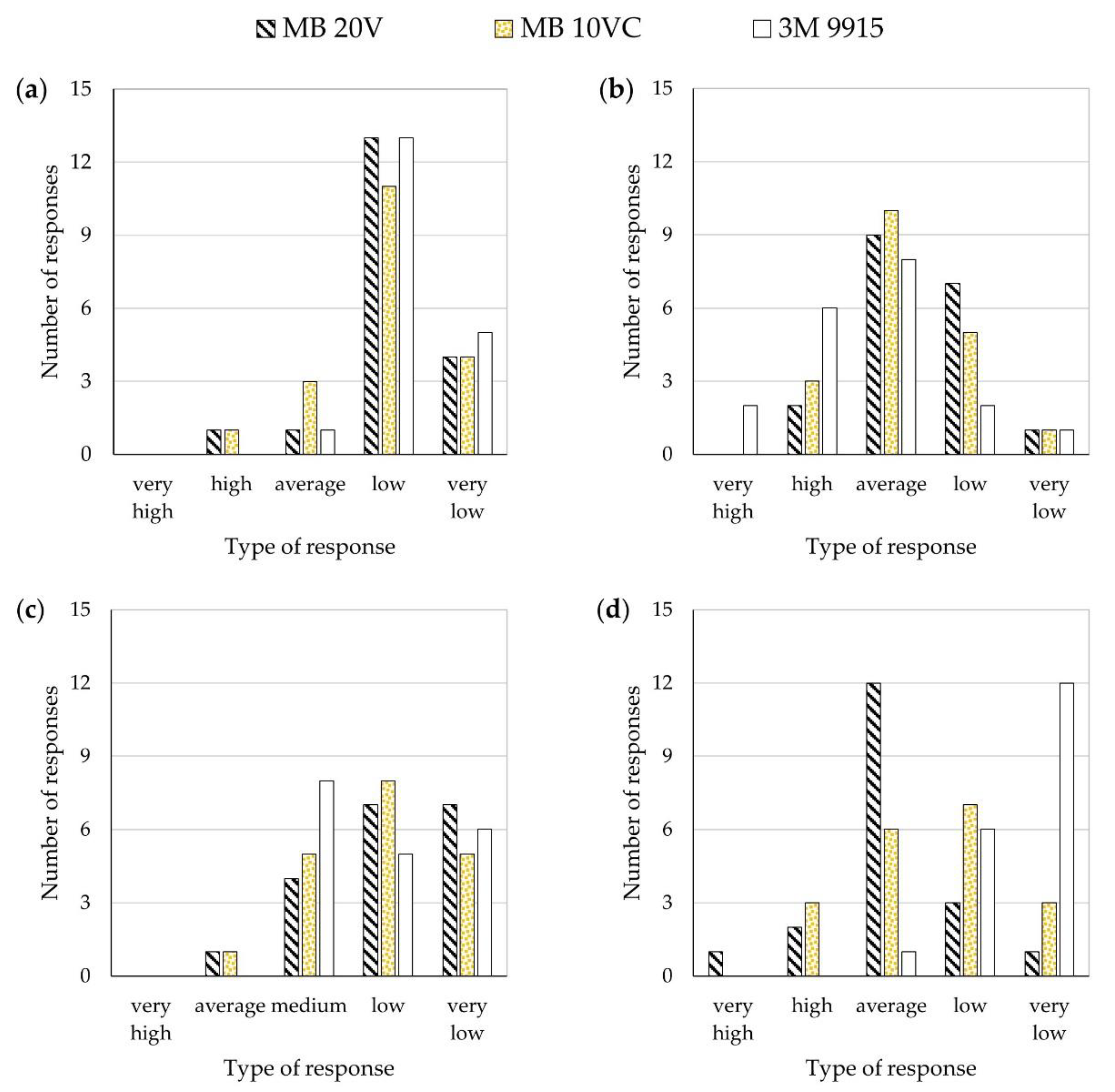

4.3. Subjective Assessment of Odor Reduction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Integrated Pollution Prevention and Control (IPCC) Bureau. Best Available Techniques (BAT) Reference Document for the Refining of Mineral Oil and Gas; European Union: Brussels, Belgium, 2015. [Google Scholar] [CrossRef]

- Besis, A.; Latsios, I.; Papakosta, E.; Simeonidis, T.; Kouras, A.; Voliotis, A.; Samara, C. Spatiotemporal variation of odor-active VOCs in Thessaloniki, Greece: Implications for impacts from industrial activities. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef]

- Chan, Y.J.; Yuan, T.H.; Sun, H.C.; Lin, T.C. Characterization and exposure assessment of odor emissions from laser cutting of plastics in the optical film industry. Aerosol Air Qual. Res. 2016, 16, 2216–2226. [Google Scholar] [CrossRef] [Green Version]

- Yuwono, A.S.; Lammers, P.S. Odor pollution in the environment and the detection instrumentation. Agric. Eng. Int. CIGR J. Sci. Res. Dev. 2004, 6, 1–33. [Google Scholar]

- Han, B.; Liu, Y.T.; Wu, J.H.; Feng, Y.C. Characterization of industrial odor sources in Binhai New Area of Tianjin, China. Environ. Sci. Pollut. Res. 2018, 25, 14006–14017. [Google Scholar] [CrossRef]

- Chang, S.T.; Chou, M.S.; Chang, H.Y. Elimination of odors emitted from Hot-melting of recycle P.S. by oxidative-reductive scrubbing. Aerosol Air Qual. Res. 2014, 14, 293–300. [Google Scholar] [CrossRef] [Green Version]

- Schiffman, S.S. Livestock odors: Implications for human health and wellbeing. J. Anim. Sci. 1998, 76, 1343–1355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schiffman, S.S.; Bennett, J.L.; Raymer, J.H. Quantification of odors and odorants from swine operations in North Carolina. Agric. For. Meteorol. 2001, 108, 213–240. [Google Scholar] [CrossRef]

- Lo, Y.-C.M.; Koziel, J.A.; Cai, L.; Hoff, S.J.; Jenks, W.S.; Xin, H. Simultaneous chemical and sensory characterization of volatile organic compounds and semi-volatile organic compounds emitted from swine manure using solid phase microextraction and multidimensional gas chromatography-mass spectrometry-olfactometry. J. Environ. Qual. 2008, 37, 521–534. [Google Scholar] [CrossRef] [PubMed]

- Skóra, J.; Matusiak, K.; Wojewódzki, P.; Nowak, A.; Sulyok, M.; Ligocka, A.; Okrasa, M.; Hermann, J.; Gutarowska, B. Evaluation of microbiological and chemical contaminants in poultry farms. Int. J. Environ. Res. Public Health 2016, 13, 192. [Google Scholar] [CrossRef] [PubMed]

- Schlegelmilch, M.; Streese, J.; Biedermann, W.; Herold, T.; Stegmann, R. Odour control at biowaste composting facilities. Waste Manag. 2005, 25, 917–927. [Google Scholar] [CrossRef]

- Rincón, C.A.; de Guardia, A.; Couvert, A.; Wolbert, D.; le Roux, S.; Soutrel, I.; Nunes, G. Odor concentration (O.C.) prediction based on odor activity values (OAVs) during composting of solid wastes and digestates. Atmos. Environ. 2019, 201, 1–12. [Google Scholar] [CrossRef]

- Borrás, E.; Tortajada-Genaro, L.A.; Muñoz, A. Determination of reduced sulfur compounds in air samples for the monitoring of malodor caused by landfills. Talanta 2016, 148, 472–477. [Google Scholar] [CrossRef] [Green Version]

- Gostelow, P.; Parsons, S.A.; Stuetz, R.M. Odour measurements for sewage treatment. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef]

- Fisher, R.M.; Barczak, R.J.; Suffet, I.H.M.; Hayes, J.E.; Stuetz, R.M. Framework for the use of odour wheels to manage odours throughout wastewater biosolids processing. Sci. Total Environ. 2018, 634, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Talaiekhozani, A.; Bagheri, M.; Goli, A.; Khoozani, M.R.T. An overview of principles of odor production, emission, and control methods in wastewater collection and treatment systems. J. Environ. Manag. 2016, 170, 186–206. [Google Scholar] [CrossRef] [PubMed]

- Dalton, P.; Wysocki, C.J.; Brody, M.J.; Lawley, H.J. Perceived odor, irritation, and health symptoms following short-term exposure to acetone. Am. J. Ind. Med. 1997, 31, 558–569. [Google Scholar] [CrossRef]

- Wing, S.; Horton, R.A.; Marshall, S.W.; Thu, K.; Tajik, M.; Schinasi, L.; Schiffman, S.S. Air pollution and odor in communities near industrial swine operations. Environ. Health Perspect. 2008, 116, 1362–1368. [Google Scholar] [CrossRef] [PubMed]

- Schiffman, S.S.; Williams, C.M. Science of odor as a potential health issue. J. Environ. Qual. 2005, 34, 129–138. [Google Scholar]

- Jaén, C.; Dalton, P. Asthma and odors: The role of risk perception in asthma exacerbation. J. Psychosom. Res. 2014, 77, 302–308. [Google Scholar] [CrossRef] [Green Version]

- Blanes-Vidal, V.; Bælum, J.; Schwartz, J.; Løfstrøm, P.; Christensen, L.P. Respiratory and sensory irritation symptoms among residents exposed to low-to-moderate air pollution from biodegradable wastes. J. Expo. Sci. Environ. Epidemiol. 2014, 24, 388–397. [Google Scholar] [CrossRef]

- Avery, R.C.; Wing, S.; Marshall, S.W.; Schiffman, S.S. Odor from Industrial Hog Farming Operations and Mucosal Immune Function in Neighbors. Arch. Environ. Health An Int. J. 2004, 59, 101–108. [Google Scholar] [CrossRef]

- Claeson, A.-S.; Lidén, E.; Nordin, M.; Nordin, S. The role of perceived pollution and health risk perception in annoyance and health symptoms: A population-based study of odorous air pollution. Int. Arch. Occup. Environ. Health 2013, 86, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Horton, R.A.; Wing, S.; Marshall, S.W.; Brownley, K.A. Malodor as a trigger of stress and negative mood in neighbors of industrial hog operations. Am. J. Public Health 2009, 99 (Suppl. 3), 610–615. [Google Scholar] [CrossRef]

- Eltarkawe, M.A.; Miller, S.L. The impact of industrial odors on the subjective wellbeing of communities in Colorado. Int. J. Environ. Res. Public Health 2018, 15, 1091. [Google Scholar] [CrossRef] [Green Version]

- Pike, W.Y.; Proctor, M.D.; Burgess, D.N. Reliability and Feasibility Considerations in the Assessment of a Malodor Adaptation Technique: A Pilot Study. Mil. Med. 2017, 182, e1521–e1527. [Google Scholar] [CrossRef] [Green Version]

- Millot, J.; Brand, G.; Morand, N. Effects of ambient odors on reaction time in humans. Neurosci. Lett. 2002, 322, 79–82. [Google Scholar] [CrossRef]

- Michael, G.A.; Jacquot, L.; Millot, J. Ambient Odors Influence the Amplitude and Time Course of Visual Distraction. Behav. Neurosci. 2005, 119, 708–715. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dirk, A.; Jay, W.; Shabir, B.; Carla, D.; Ed, T.; Richard, C.; Bob, F.; Chris, Q.; Matthew, W.; Robert, M.; et al. Gas phase odor treatment. In Minimization Odors and Corrosion in Collection Systems; IWA Publishing: London, UK, 2007; Volume 8, pp. 1–17. [Google Scholar]

- Apgar, D.; Bassrai, S.; Dillon, C.; Torres, E.; Corsi, R.; Forbes, B.; Quigley, C.; Ward, M.; Morton, R.; Weiss, J.; et al. Minimization of Odors and Corrosion in Collection Systems. 2007. Available online: www.werf.org%5Cnwww.wef.org (accessed on 30 June 2021).

- Okrasa, M.; Hitz, J.; Nowak, A.; Brochocka, A.; Thelen, C.; Walczak, Z. Adsorption performance of activated-carbon-loaded nonwoven filters used in filtering facepiece respirators. Int. J. Environ. Res. Public Health 2019, 16, 1973. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ligotski, R.; Sager, U.; Schneiderwind, U.; Asbach, C.; Schmidt, F. Prediction of VOC adsorption performance for estimation of service life of activated carbon based filter media for indoor air purification. Build. Environ. 2019, 149, 146–156. [Google Scholar] [CrossRef]

- Vizhemehr, A.K.; Haghighat, F.; Lee, C.S. Predicting gas-phase air-cleaning system efficiency at low concentration using high concentration results: Development of a framework. Build. Environ. 2013, 68, 12–21. [Google Scholar] [CrossRef]

- Clinger, J.C.; O’Shaughnessy, P.T. Breakthrough analysis for filtering facepiece respirators impregnated with activated carbon. J. Occup. Environ. Hyg. 2019, 16, 423–431. [Google Scholar] [CrossRef]

- Nelson, G.O.; Correia, A.N. Respiratory cartridge efficiency studies: VIII. summary and conclusions. Am. Ind. Hyg. Assoc. J. 1976, 37, 514–525. [Google Scholar] [CrossRef]

- Frechen, F. State of the art of odour measurement. Int. Symp. Odor Meas. Tokyo 2003, 3, 149–155. [Google Scholar]

- Capelli, L.; Sironi, S.; del Rosso, R. Odor sampling: Techniques and strategies for the estimation of odor emission rates from different source types. Sensors 2013, 13, 938–955. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brattoli, M.; de Gennaro, G.; de Pinto, V.; Loiotile, A.D.; Lovascio, S.; Penza, M. Odour detection methods: Olfactometry and chemical sensors. Sensors 2011, 11, 5290–5322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barczak, R.J.; Kulig, A. Comparison of different measurement methods of odour and odorants used in the odour impact assessment of wastewater treatment plants in Poland. Water Sci. Technol. 2017, 75, 944–951. [Google Scholar] [CrossRef] [PubMed]

- Aeloor, D.; Patil, N. A survey on odour detection sensors. In Proceedings of the 2017 International Conference on Inventive Systems and Control (ICISC 2017), Coimbatore, India, 19–20 January 2017; pp. 1–5. [Google Scholar]

- McGinley, A.; McGinley, C. The New European Olfactometry Standard: Implementation, Experience and Perspectives; Air and Waste Management Association, 2001 Annual Conference Technical Program Session No: EE-6b; St. Croix Sensory Inc.: Stillwater, MN, USA, 2001; pp. 1–16. [Google Scholar]

- St. Croix Sensory Inc. Odor Sensitivity Test Procedure; St. Croix Sensory Inc.: Stillwater, MN, USA, 2000; pp. 1–12. Available online: http://www.fivesenses.com/equipment/olfactometry-equipment/odor-sensitivity-test-kit/ (accessed on 30 June 2021).

- ASTM E1432-19. Standard Practice for Defining and Calculating Individual and Group Sensory Thresholds from Forced-Choice Data Sets of Intermediate Size; ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 30 June 2021).

- ASTM E679-19. Standard Practice for Determination of Odor and Taste Thresholds by a Forced-Choice Ascending Concentration Series Method of Limits; ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 30 June 2021).

- World Health Organization. How to Perform a Particulate Respirator Seal Check. Available online: https://www.who.int/csr/resources/publications/respiratorsealcheck/en/ (accessed on 30 June 2021).

- Likert, R. A technique for the measurement of attitudes. Arch. Psychol. 1932, 22, 55. [Google Scholar]

- Kobal, G.; Klimek, L.; Wolfensberger, M.; Gudziol, H.; Temmel, A.; Owen, C.M.; Seeber, H.; Pauli, E.; Hummel, T. Multicenter investigation of 1036 subjects using a standardized method for the assessment of olfactory function combining tests of odor identification, odor discrimination, and olfactory thresholds. Eur. Arch. Oto Rhino Laryngol. 2000, 257, 205–211. [Google Scholar] [CrossRef]

- Lay, A.M.; Sensory, S.C.; Mcginley, C.M. A Nasal Chemosensory Performance Test for Odor Inspectors; St. Croix Sensory Inc.: Stillwater, MN, USA, 2004; pp. 18–21. [Google Scholar]

| Manufacturer/ Type/ Protection Class | Construction | Configuration of Filtering Materials | Characteristics of the Activated Carbon Layer |

|---|---|---|---|

| MB Filter type MB 20V FFP2 | Cup-type FFR (cup surface 184 ± 7 cm2), equipped with one exhalation valve, adjustable nose clip, two head harness rubber bands, and a facepiece without seals | Spun-bonded nonwoven High efficiency melt-blown nonwoven Spun-bonded nonwoven Calendered needle-punched nonwoven | Not applicable |

| MB Filter type MB 10VC FFP1 | Spun-bonded nonwoven High efficiency melt-blown nonwoven Spun-bonded nonwoven Polymer nonwoven loaded with activated carbon adsorbent material Calendered needle-punched nonwoven | Surface mass: 214 ± 3 g/m2 Thickness: 1.9 ± 0.2 mm Carbon content: circa 35% Carbon mass: 1.4 ± 0.1 g Carbon BET surface area: 43 m2/g | |

| 3M type 9915 FFP1 | Cup-type FFR (cup surface 187 ± 1 cm2), valveless, equipped with an adjustable nose clip, two head harness textile bands, and a facepiece sealed under the nose clip | Spun-bonded nonwoven High efficiency melt-blown nonwoven Melt-blown nonwoven containing powdered activated carbon adsorbent High efficiency melt-blown nonwoven Needle-punched nonwoven | Surface mass: 216 ± 19 g/m2 Thickness: 1.2 ± 0.1 mm Carbon content: circa 35% Carbon mass: 1.4 ± 0.1 g Carbon BET surface area: 651 m2/g |

| FFR Type | Parameter | Paraffin Oil Mist Penetration, % | Inhalation Resistance, Pa | Exhalation Resistance, Pa | CO2 Content in the Inhaled Air, % | |

|---|---|---|---|---|---|---|

| 30 L/min | 95 L/min | 160 L/min | ||||

| MB 20V | N | 7 | 7 | 7 | 7 | 9 |

| M | 0.45 a | 46.84 a | 151.93 a | 177.51 a | 0.68 a | |

| SD | 0.22 | 6.99 | 19.11 | 9.22 | 0.04 | |

| Max | 0.85 | 57.10 | 173.30 | 190.10 | 0.76 | |

| Min | 0.23 | 40.50 | 132.80 | 165.50 | 0.64 | |

| MB 10VC | N | 10 | 10 | 10 | 10 | 9 |

| M | 1.56 b | 27.60 b | 91.94 b | 122.72 b | 0.77 b | |

| SD | 0.07 | 1.42 | 3.98 | 2.99 | 0.05 | |

| Max | 1.70 | 29.30 | 96.60 | 128.30 | 0.84 | |

| Min | 1.50 | 24.70 | 82.90 | 119.30 | 0.69 | |

| 3M 9915 | N | 10 | 10 | 10 | 10 | 9 |

| M | 4.27 c | 42.08 a | 145.52 a | 227.04 c | 0.79 b | |

| SD | 0.42 | 3.92 | 7.28 | 10.71 | 0.02 | |

| Max | 4.70 | 47.20 | 157.50 | 247.20 | 0.81 | |

| Min | 3.40 | 34.30 | 137.10 | 207.30 | 0.75 | |

| FFR Type | Parameter | N | M | SD | Med | Max | Min | |

|---|---|---|---|---|---|---|---|---|

| MB 20V | Odor detection level | 1st round | 19 | 4.16 | 1.57 | 5.0 | 6.0 | 1.0 |

| 2nd round | 4.63 | 1.67 | 4.0 | 8.0 | 2.0 | |||

| Average level of odor detection | 4.39 | 1.36 | 4.5 | 6.5 | 1.5 | |||

| Odor reduction degree | 2.71 a | 1.55 | 2.5 | 6.0 | 0.5 | |||

| Odor reduction efficiency W, % | 37.21 a | 18.24 | 36.4 | 70.0 | 7.1 | |||

| MB 10VC | Odor detection level | 1st round | 19 | 3.00 | 1.49 | 3.0 | 6.0 | 1.0 |

| 2nd round | 3.26 | 1.45 | 3.0 | 5.0 | 1.0 | |||

| Average level of odor detection | 3.13 | 1.41 | 3.0 | 5.5 | 1.0 | |||

| Odor reduction degree | 3.97 ab | 2.04 | 4.0 | 8.0 | 0.5 | |||

| Odor reduction efficiency W, % | 54.25 b | 22.04 | 57.1 | 88.9 | 12.5 | |||

| 3M 9915 | Odor detection level | 1st round | 19 | 1.63 | 0.90 | 1.0 | 4.0 | 1.0 |

| 2nd round | 1.84 | 1.07 | 1.0 | 4.0 | 1.0 | |||

| Average level of odor detection | 1.74 | 0.93 | 1.5 | 4.0 | 1.0 | |||

| Odor reduction degree | 5.37 b | 2.22 | 5.0 | 10.0 | 1.5 | |||

| Odor reduction efficiency W, % | 73.24 c | 16.92 | 80.0 | 90.9 | 37.5 | |||

| FFR Type | Leak-Tightness | Comfort of Use | The Degree of Donning and Fitting Difficulty | Perception of Odor Reduction |

|---|---|---|---|---|

| MB 20V | 4.1 a ± 0.7 | 3.3 a ± 1.1 | 1.9 a ± 0.9 | 3.1 a ± 0.8 |

| MB 10VC | 4.0 a ± 0.8 | 3.2 ab ± 1.0 | 2.1 a ± 0.9 | 3.5 b ± 1.0 |

| 3M 9915 | 4.3 a ± 0.5 | 2.7 b ± 1.2 | 2.1 a ± 0.9 | 4.6 c ± 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okrasa, M.; Szulc, J.; Brochocka, A.; Gutarowska, B. Application of Olfactometry to Assess the Anti-Odor Properties of Filtering Facepiece Respirators Containing Activated Carbon Nonwovens. Int. J. Environ. Res. Public Health 2021, 18, 8157. https://doi.org/10.3390/ijerph18158157

Okrasa M, Szulc J, Brochocka A, Gutarowska B. Application of Olfactometry to Assess the Anti-Odor Properties of Filtering Facepiece Respirators Containing Activated Carbon Nonwovens. International Journal of Environmental Research and Public Health. 2021; 18(15):8157. https://doi.org/10.3390/ijerph18158157

Chicago/Turabian StyleOkrasa, Małgorzata, Justyna Szulc, Agnieszka Brochocka, and Beata Gutarowska. 2021. "Application of Olfactometry to Assess the Anti-Odor Properties of Filtering Facepiece Respirators Containing Activated Carbon Nonwovens" International Journal of Environmental Research and Public Health 18, no. 15: 8157. https://doi.org/10.3390/ijerph18158157

APA StyleOkrasa, M., Szulc, J., Brochocka, A., & Gutarowska, B. (2021). Application of Olfactometry to Assess the Anti-Odor Properties of Filtering Facepiece Respirators Containing Activated Carbon Nonwovens. International Journal of Environmental Research and Public Health, 18(15), 8157. https://doi.org/10.3390/ijerph18158157