Fabrication and Validation of an Economical, Programmable, Dual-Channel, Electronic Cigarette Aerosol Generator

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Supplies

2.2. E-Liquid and Ecig Atomizer

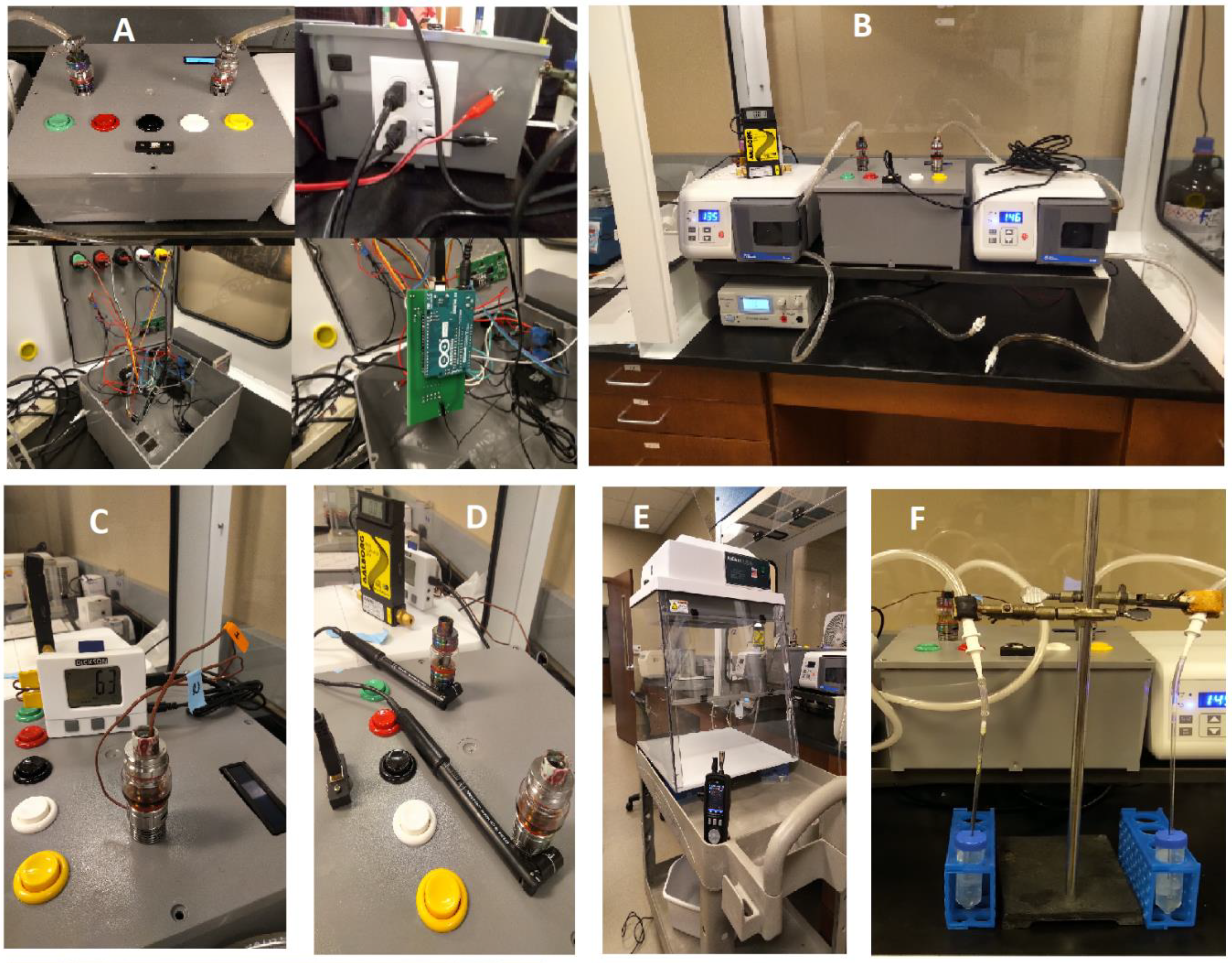

2.3. Fabrication of the Ecig Aerosol Generator

2.4. Puff Topography

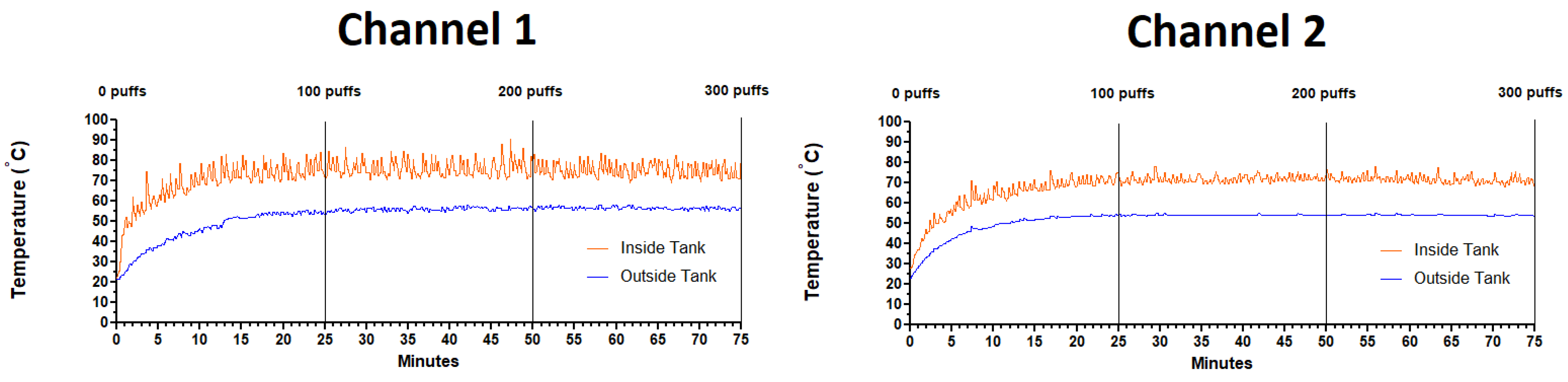

2.5. Measurement of Atomizer Temperatures

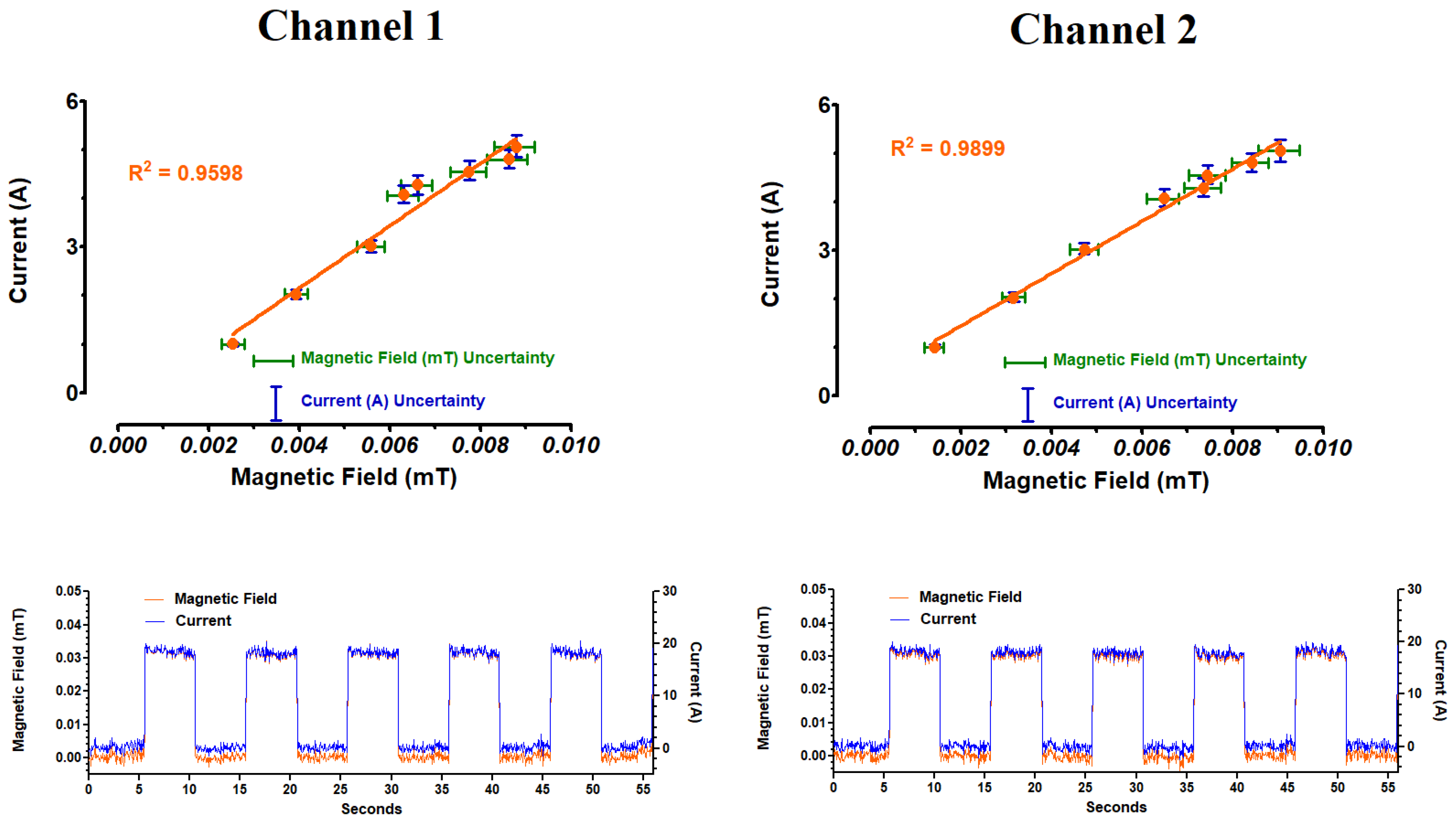

2.6. Measurement of Atomizer Magnetic Fields and Currents

2.7. Measurement of Particle Size Distributions and Mass Concentrations Produced by the Ecig Aerosol Generator

2.8. Aerosol Trapping in Growth Media

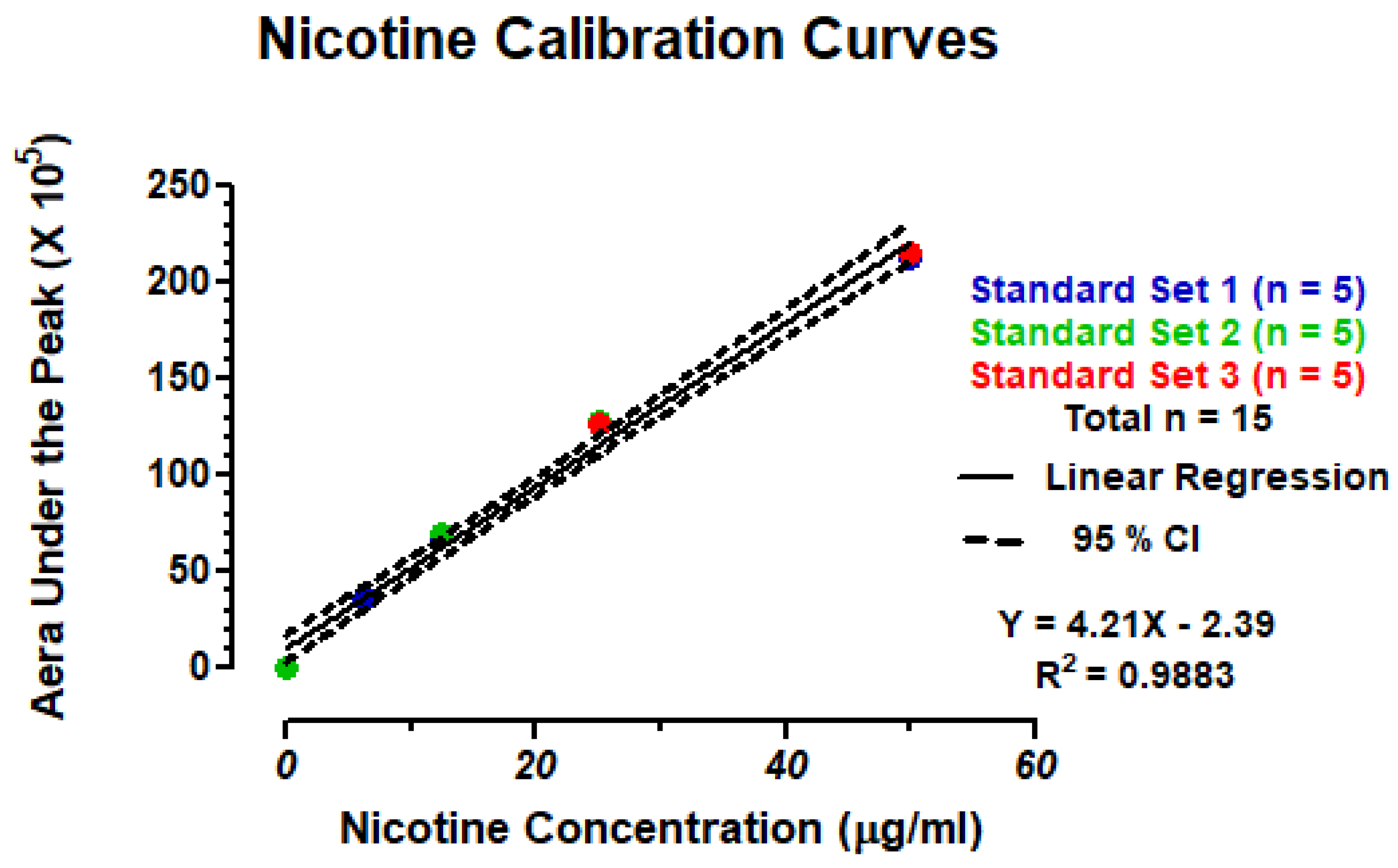

2.9. High Performance Liquid Chromatography (HPLC) of Nicotine

2.10. Statistical Analysis

3. Results

3.1. Temperature Profiles

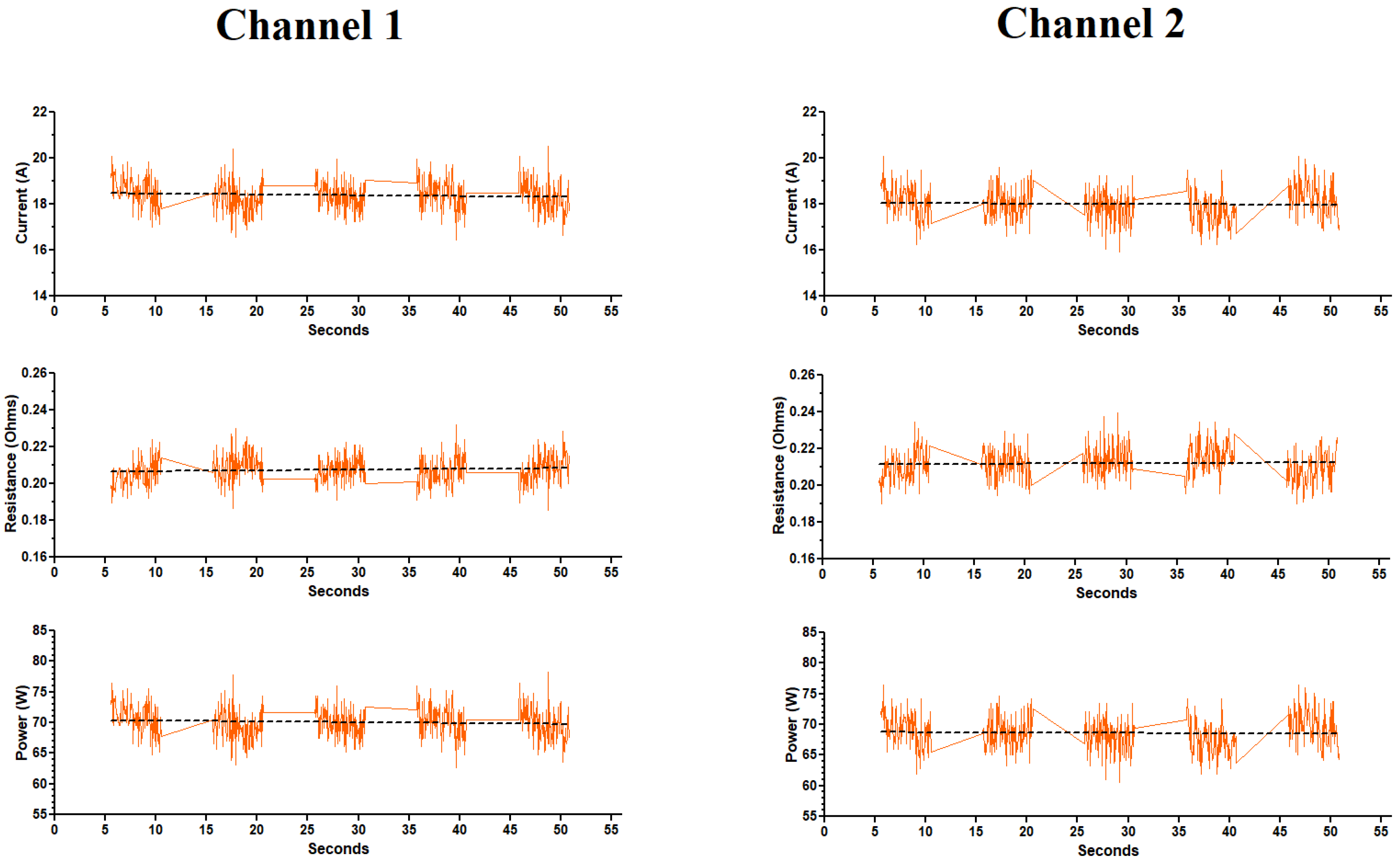

3.2. Electrical Parameters (the First Five Puffs)

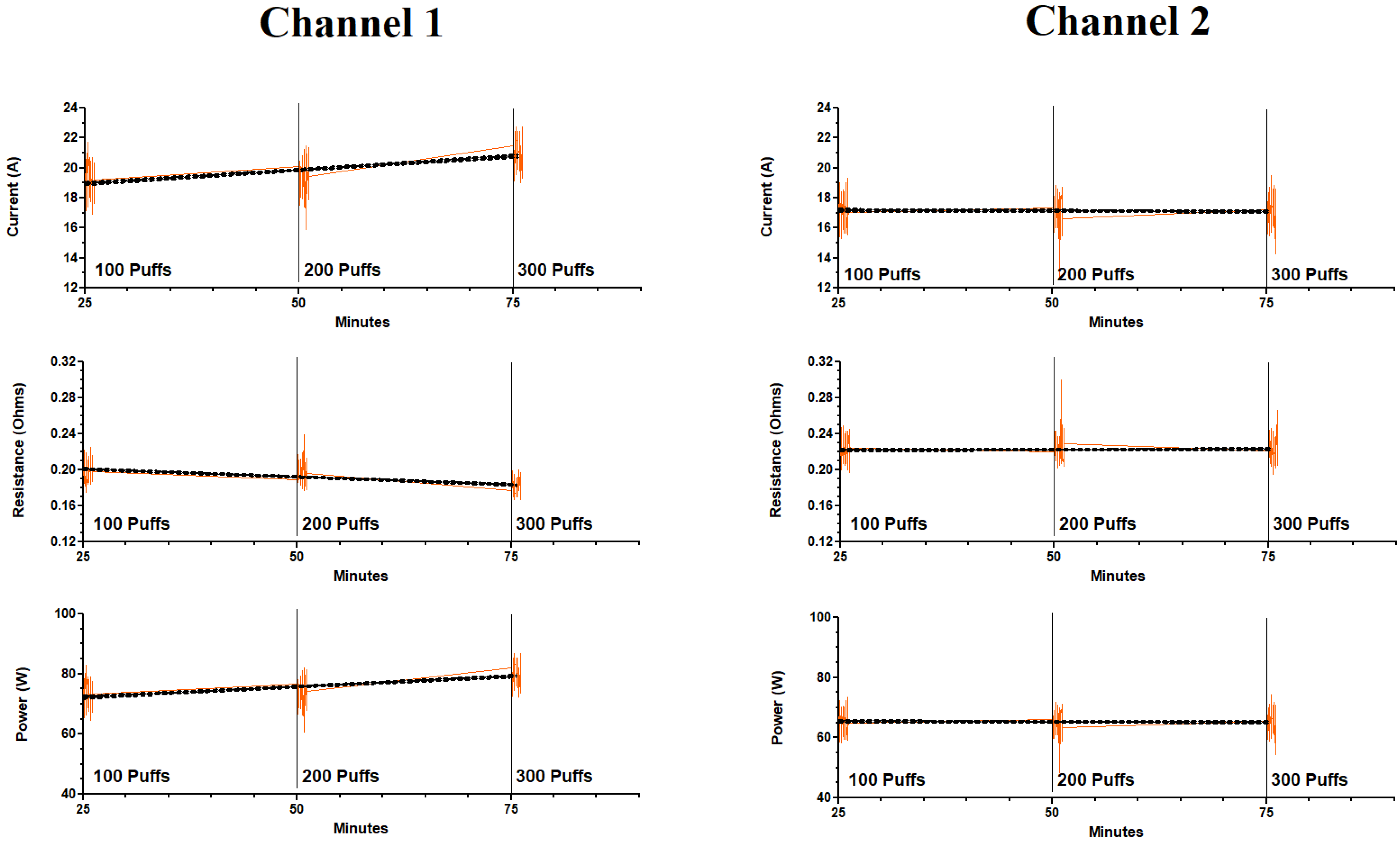

3.3. Electrical Parameters (300 Continous Puffs)

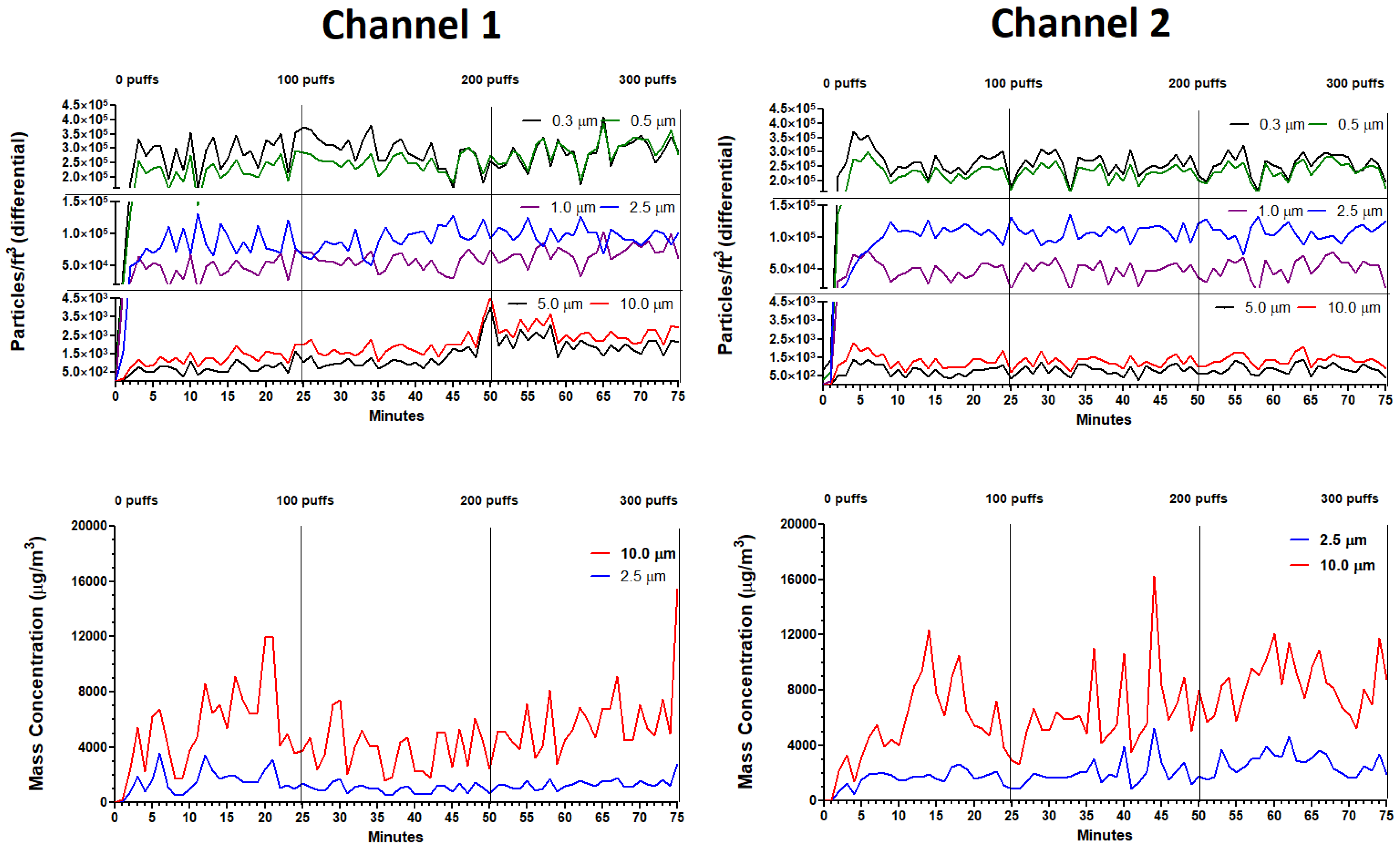

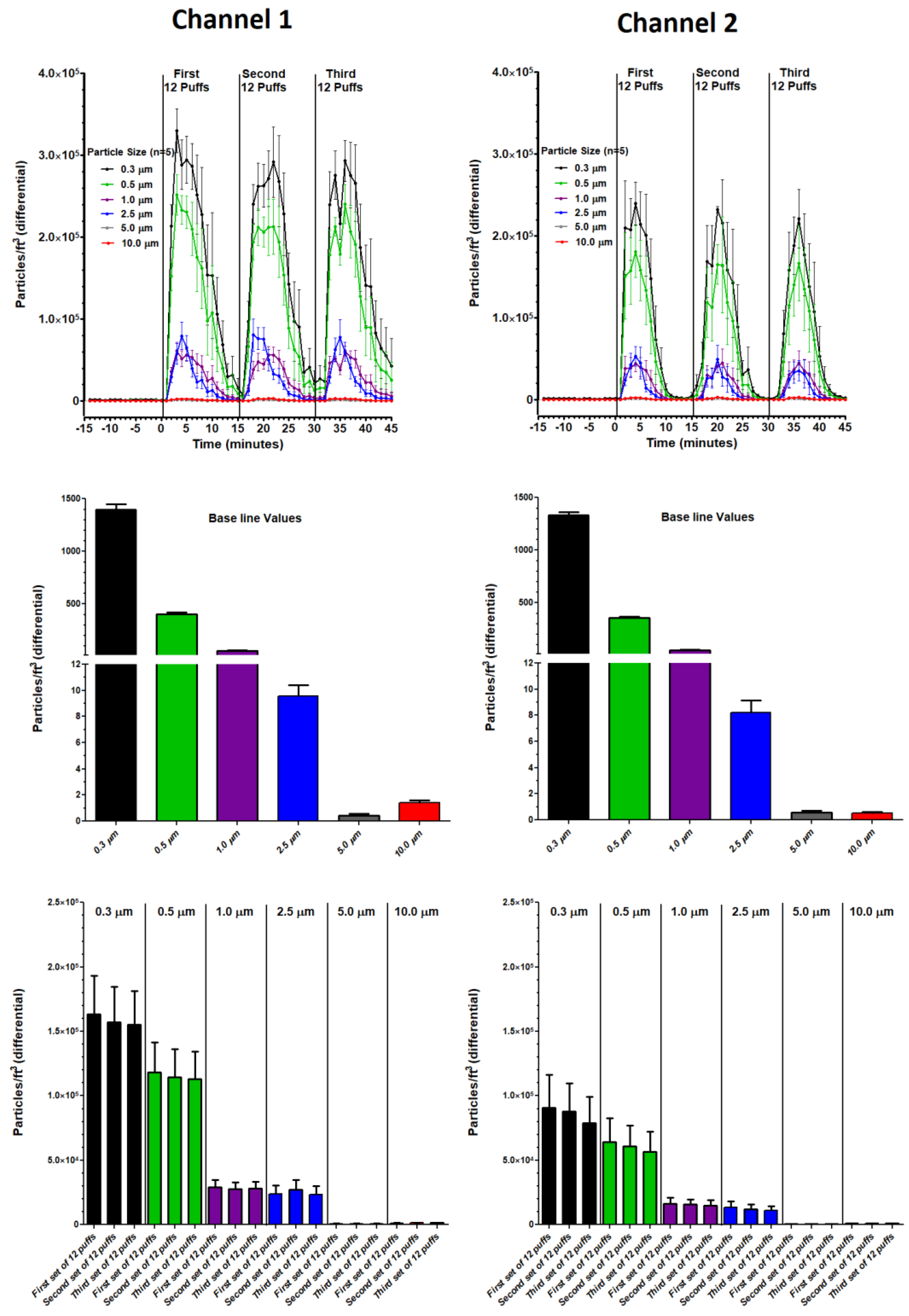

3.4. Particle Size Distributions and Mass Concentrations

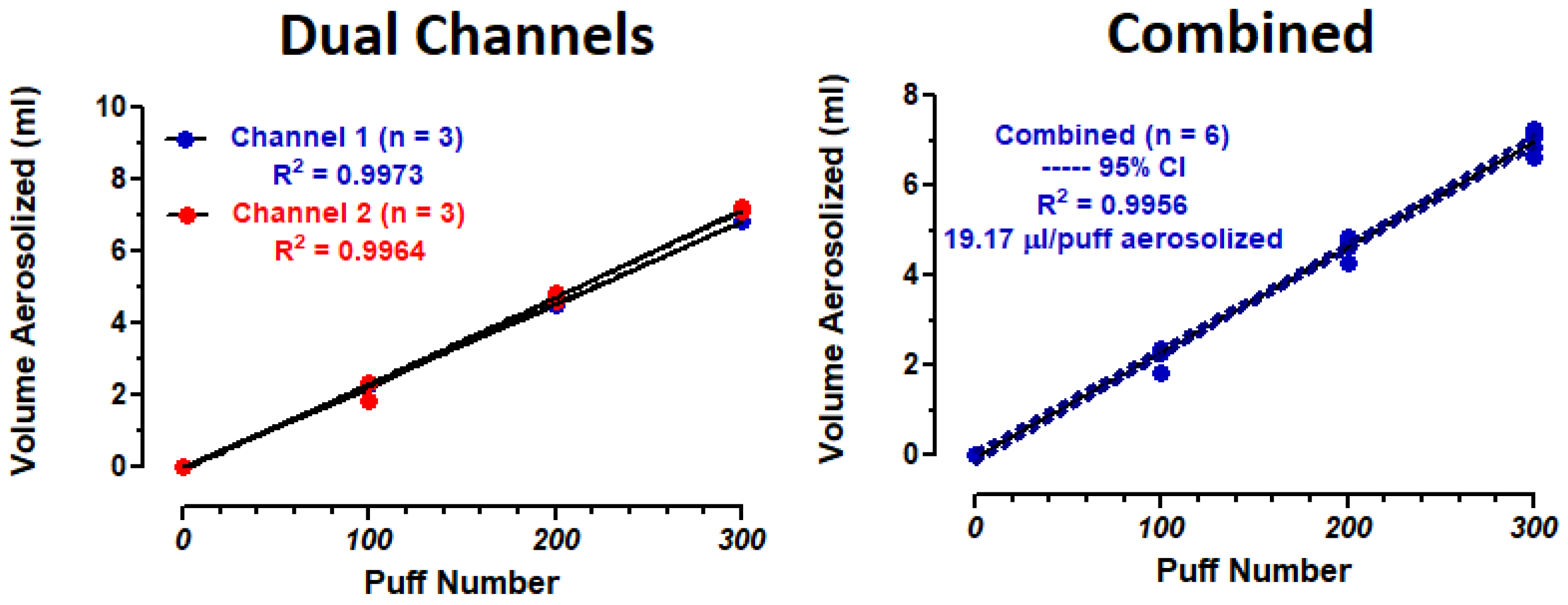

3.5. E-Liquid Vaporization

3.6. Aerosol Delivery Based on Nicotine Recovery

4. Discussion

4.1. Temperature Profiles

4.2. Electrical Parameters

4.3. Particle Distributions

4.4. E-Liquid Vaporization and Aerosol Delivery

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Palazzolo, D.L. Electronic cigarettes and vaping: A new challenge in clinical medicine and public health. A literature review. Front. Public Health 2013, 1, 56. [Google Scholar] [CrossRef] [Green Version]

- Agaku, I.T.; King, B.A.; Husten, C.G.; Bunnell, R.; Ambrose, B.K.; Hu, S.S.; Holder-Hayes, E.; Day, H.R. Tobacco Product Use Among Adults—United States, 2012–2013. MMWR Morb. Mortal. Wkly. Rep. 2014, 63, 542–547. [Google Scholar] [PubMed]

- Kalininskiy, A.; Bach, C.T.; Nacca, N.E.; Ginsberg, G.; Marraffa, J.; Navarette, K.A.; McGraw, M.D.; Croft, D.P. E-cigarette, or vaping, product use associated lung injury (EVALI): Case series and diagnostic approach. Lancet Respir. Med. 2019, 7, 1017–1026. [Google Scholar] [CrossRef]

- Conuel, E.J.; Chieng, H.C.; Fantauzzi, J.; Pokhrel, K.; Goldman, C.; Smith, T.C.; Tiwari, A.; Chopra, A.; Judson, M.A. Cannabinoid oil vaping-associated lung injury and its radiographic appearance. Am. J. Med. 2020, 133, 865–867. [Google Scholar] [CrossRef]

- Duffy, B.; Li, L.; Lu, S.; Durocher, L.; Dittmar, M.; Delaney-Baldwin, E.; Panawennage, D.; LeMaster, D.; Navarette, K.; Spink, D. Analysis of cannabinoid-containing fluids in illicit vaping cartridges recovered from pulmonary injury patients: Identification of vitamin E acetate as a major diluent. Toxics 2020, 8, 8. [Google Scholar] [CrossRef] [Green Version]

- Chand, H.S.; Muthumalage, T.; Maziak, W.; Rahman, I. Pulmonary toxicity and the pathophysiology of electronic cigarette, or vaping product, use associated lung injury. Front. Pharmacol. 2019, 10, 1619. [Google Scholar] [CrossRef] [Green Version]

- Coresta Recommended Method N° 81. Available online: https://www.coresta.org/sites/default/files/technical_documents/main/CRM_81.pdf (accessed on 29 September 2021).

- Adamson, J.; Jaunky, T.; Thorne, D.; Gaça, M.D. Characterisation of the borgwaldt LM4E system for in vitro exposures to undiluted aerosols from next generation tobacco and nicotine products (NGPs). Food Chem. Toxicol. 2018, 113, 337–344. [Google Scholar] [CrossRef] [PubMed]

- Gillman, I.G.; Kistler, K.A.; Stewart, E.W.; Paolantonio, A.R. Determining the impact of flavored e-liquids on aldehyde production during Vaping. Regul. Toxicol. Pharmacol. 2020, 112, 104588. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Nelson, J.; Dada, O.; Pyrgiotakis, G.; Kavouras, I.G.; Demokritou, P. Assessing electronic cigarette emissions: Linking physico-chemical properties to product brand, e-liquid flavoring additives, operational voltage and user puffing patterns. Inhal. Toxicol. 2018, 30, 78–88. [Google Scholar] [CrossRef] [PubMed]

- Olmedo, P.; Navas-Acien, A.; Hess, C.; Jarmul, S.; Rule, A. A direct method for e-cigarette aerosol sample collection. Environ. Res. 2016, 149, 151–156. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palazzolo, D.L.; Crow, A.P.; Nelson, J.M.; Johnson, R.A. Trace Metals Derived from Electronic Cigarette (ECIG) Generated Aerosol: Potential Problem of ECIG Devices That Contain Nickel. Front. Physiol. 2017, 7, 663. [Google Scholar] [CrossRef] [Green Version]

- Alanazi, H.; Semlali, A.; Chmielewski, W.; Rouabhia, M. E-Cigarettes Increase Candida albicans Growth and Modulate its Interaction with Gingival Epithelial Cells. Int. J. Environ. Res. Public Health 2019, 16, 294. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lynch, J.; Lorenz, L.; Brueggemeyer, J.L.; Lanzarotta, A.; Falconer, T.M.; Wilson, R.A. Simultaneous Temperature Measurements and Aerosol Collection During Vaping for the Analysis of Δ9-Tetrahydrocannabinol and Vitamin E Acetate Mixtures in Ceramic Coil Style Cartridges. Front. Chem. 2021, 9, 734793. [Google Scholar] [CrossRef] [PubMed]

- Floyd, E.L.; Queimado, L.; Wang, J.; Regens, J.L.; Johnson, D.L. Electronic cigarette power affects count concentration and particle size distribution of vaping aerosol. PLoS ONE 2018, 13, e0210147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gillman, I.G.; Kistler, K.A.; Stewart, E.W.; Paolantonio, A.R. Effect of variable power levels on the yield of total aerosol mass and formation of aldehydes in e-cigarette aerosols. Regul. Toxicol. Pharmacol. 2016, 75, 58–65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zelinkova, Z.; Wenzl, T. Influence of battery power setting on carbonyl emissions from electronic cigarettes. Tob. Induc. Dis. 2020, 18, 77. [Google Scholar] [CrossRef] [PubMed]

- Kosmider, L.; Sobczak, A.; Fik, M.; Knysak, J.; Zaciera, M.; Kurek, J.; Goniewicz, M.L. Carbonyl compounds in electronic cigarette vapors: Effects of nicotine solvent and battery output voltage. Nicotine Tob. Res. 2014, 16, 1319–1326. [Google Scholar] [CrossRef]

- Sun, Y.; Kong, L.; Abbas Khan, H.; Pecht, M.G. Li-ion Battery Reliability—A Case Study of the Apple iPhone®. IEEE Access 2019, 7, 71131–71141. [Google Scholar] [CrossRef]

- King, R. What the Vape! What Are Coil Ohms & Watts? Available online: https://rockygreenking.com/blogs/knowledge-base/what-the-vape-what-are-coil-ohms (accessed on 29 September 2021).

- Palazzolo, D.L.; Nelson, J.M.; Hudson, Z. The Use of HPLC-PDA in Determining Nicotine and Nicotine-Related Alkaloids from E-Liquids: A Comparison of Five E-Liquid Brands Purchased Locally. Int. J. Environ. Res. Public Health 2019, 16, 3015. [Google Scholar] [CrossRef] [Green Version]

- Nelson, J.M.; Cuadra, G.A.; Palazzolo, D.L. A Comparison of Flavorless Electronic Cigarette-Generated Aerosol and Conventional Cigarette Smoke on the Planktonic Growth of Common Oral Commensal Streptococci. Int. J. Environ. Res. Public Health 2019, 16, 5004. [Google Scholar] [CrossRef] [Green Version]

- Cuadra, G.A.; Smith, M.T.; Nelson, J.M.; Loh, E.K.; Palazzolo, D.L. A Comparison of Flavorless Electronic Cigarette-Generated Aerosol and Conventional Cigarette Smoke on the Survival and Growth of Common Oral Commensal Streptococci. Int. J. Environ. Res. Public Health 2019, 16, 1669. [Google Scholar] [CrossRef] [Green Version]

- Borgwaldt. Available online: https://www.borgwaldt.com/en/products/smoking-vaping-machines/modular-smoking-vaping-machines/modular-vaping-machine-lm4e.html (accessed on 29 September 2021).

- Cerulean. Available online: https://www.cerulean.com/en/solutions/product/sm450e (accessed on 29 September 2021).

- Eaerosols. Available online: http://www.eaerosols.com/our-products/1-port-and-3-port-electronic-cigarette-aerosol-generator-ecag/ (accessed on 29 September 2021).

- Soulet, S.; Pairaud, C.; Lalo, H. A Novel Vaping Machine Dedicated to Fully Controlling the Generation of E-Cigarette Emissions. Int. J. Environ. Res. Public Health 2017, 14, 1225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamill, S. SMOK TFV16 Tank Review: SMOK Goes Bigger but Is It Better? Available online: https://www.ecigclick.co.uk/smok-tfv16-review/ (accessed on 29 September 2021).

- Saleh, Q.M.; Hensel, E.C.; Eddingsaas, N.C.; Robinson, R.J. Effects of Manufacturing Variation in Electronic Cigarette Coil Resistance and Initial Pod Mass on Coil Lifetime and Aerosol Generation. Int. J. Environ. Res. Public Health 2021, 18, 4380. [Google Scholar] [CrossRef]

- Saleh, Q.M.; Hensel, E.C.; Robinson, R.J. Method for Quantifying Variation in the Resistance of Electronic Cigarette Coils. Int. J. Environ. Res. Public Health 2020, 17, 7779. [Google Scholar] [CrossRef] [PubMed]

- Sleiman, M.; Logue, J.M.; Montesinos, V.N.; Russell, M.L.; Litter, M.I.; Gundel, L.A.; Destaillats, H. Emissions from electronic cigarettes: Key parameters affecting the release of harmful chemicals. Environ. Sci. Technol. 2016, 50, 9644–9651. [Google Scholar] [CrossRef] [Green Version]

- Geiss, O.; Bianchi, I.; Barrero-Moreno, J. Correlation of volatile carbonyl yields emitted by e-cigarettes with the temperature of the heating coil and the perceived sensorial quality of the generated vapours. Int. J. Hyg. Environ. Health 2016, 219, 268–277. [Google Scholar] [CrossRef]

- Beauval, N.; Verrièle, M.; Garat, A.; Fronval, I.; Dusautoir, R.; Anthérieu, S.; Garçon, G.; Lo-Guidice, J.-M.; Allorge, D.; Locoge, N. Influence of puffing conditions on the carbonyl composition of e-cigarette aerosols. Int. J. Hyg. Environ. Health 2019, 222, 136–146. [Google Scholar] [CrossRef]

- Chen, W.; Wang, P.; Ito, K.; Fowles, J.; Shusterman, D.; Jaques, P.A.; Kumagai, K. Measurement of heating coil temperature for e-cigarettes with a “top-coil” clearomizer. PLoS ONE 2018, 13, e0195925. [Google Scholar] [CrossRef] [Green Version]

- Dewi, S.D.T.; Panatarani, C.; Joni, I.M. Design and development of DC high current sensor using Hall-Effect method. AIP Conf. Proc. 2016, 1712, 030006. [Google Scholar] [CrossRef] [Green Version]

- Khalaf, H.N.; Mostafa, M.Y.A.; Zhukovsky, M. Effect of electronic cigarette (EC) aerosols on particle size distribution in indoor air and in a radon chamber. Nukleonika 2019, 64, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Belka, M.; Lizal, F.; Jedelsky, J.; Jicha, M.; Pospisil, J. Measurement of an electronic cigarette aerosol size distribution during a puff. EPJ Web Conf. 2017, 143, 02006. [Google Scholar] [CrossRef] [Green Version]

- Manigrasso, M.; Buonanno, G.; Fuoco, F.C.; Stabile, L.; Avino, P. Aerosol deposition doses in the human respiratory tree of electronic cigarette smokers. Environ. Pollut. 2015, 196, 257–267. [Google Scholar] [CrossRef]

- Fuoco, F.C.; Buonanno, G.; Stabile, L.; Vigo, P. Influential parameters on particle concentration and size distribution in the mainstream of e-cigarettes. Environ. Pollut. 2014, 184, 523–529. [Google Scholar] [CrossRef] [PubMed]

- Ingebrethsen, B.J.; Cole, S.K.; Alderman, S.L. Electronic cigarette aerosol particle size distribution measurements. Inhal. Toxicol. 2012, 24, 976–984. [Google Scholar] [CrossRef]

- Lechasseur, A.; Altmejd, S.; Turgeon, N.; Buonanno, G.; Morawska, L.; Brunet, D.; Duchaine, C.; Morissette, M.C. Variations in coil temperature/power and e-liquid constituents change size and lung deposition of particles emitted by an electronic cigarette. Physiol. Rep. 2019, 7, e14093. [Google Scholar] [CrossRef] [PubMed]

- National Academies of Sciences, Engineering, and Medicine; Health and Medicine Division; Board on Population Health and Public Health Practice; Committee on the Review of the Health Effects of Electronic Nicotine Delivery Systems. Public Health Consequences of E-Cigarettes; Eaton, D.L., Kwan, L.Y., Stratton, K., Eds.; Toxicology of E-Cigarette Constituents; National Academies Press (US): Washington, DC, USA, 2018. Available online: https://www.ncbi.nlm.nih.gov/books/NBK507184/ (accessed on 29 September 2021).

- Borgini, A.; Veronese, C.; DeMarco, C.; Boffi, R.; Tittarelli, A.; Bertoldi, M.; Fernandez, E.; Tigova, O.; Gallus, S.; Lugo, A.; et al. Particulate matter in aerosols produced by two last generation electronic cigarettes: A comparison in areal-world environment. Pulmonology 2021. [Google Scholar] [CrossRef]

- Li, Y.; Burns, A.E.; Tran, L.N.; Abellar, K.A.; Poindexter, M.; Li, X.; Madl, A.K.; Pinkerton, K.E.; Nguyen, T.B. Impact of e-Liquid Composition, Coil Temperature, and Puff Topography on the Aerosol Chemistry of Electronic Cigarettes. Chem. Res. Toxicol. 2021, 34, 1640–1654. [Google Scholar] [CrossRef]

- Talih, S.; Balhas, Z.; Salman, R.; El-Hage, R.; Karaoghlanian, N.; El-Hellani, A.; Baassiri, M.; Jaroudi, E.; Eissenberg, T.; Saliba, N.; et al. Transport phenomena governing nicotine emissions from electronic cigarettes: Model formulation and experimental investigation. Aerosol. Sci. Technol. 2017, 51, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soulet, S.; Duquesne, M.; Toutain, J.; Pairaud, C.; Lalo, H. Influence of Coil Power Ranges on the E-Liquid Consumption in Vaping Devices. Int. J. Environ. Res. Public Health 2018, 15, 1853. [Google Scholar] [CrossRef] [Green Version]

- Taylor, M.; Carr, T.; Oke, O.; Jaunky, T.; Breheny, D.; Lowe, F.; Gaça, M. E-cigarette aerosols induce lower oxidative stress in vitro when compared to tobacco smoke. Toxicol. Mech. Methods 2016, 26, 465–476. [Google Scholar] [CrossRef]

- Smart, D.J.; Phillips, G. Collecting e-cigarette aerosols for in vitro applications: A survey of the biomedical literature and opportunities to increase the value of submerged cell culture-based assessments. J. Appl. Toxicol. 2021, 41, 161–174. [Google Scholar] [CrossRef]

- Taylor, M.; Jaunky, T.; Hewitt, K.; Breheny, D.; Lowe, F.; Fearon, I.M.; Gaca, M. A comparative assessment of e-cigarette aerosols and cigarette smoke on in vitro endothelial cell migration. Toxicol. Lett. 2017, 277, 123–128. [Google Scholar] [CrossRef] [PubMed]

- Breheny, D.; Oke, O.; Pant, K.; Gaça, M. Comparative tumor promotion assessment of e-cigarette and cigarettes using the in vitro Bhas 42 cell transformation assay. Environ. Mol. Mutagen. 2017, 58, 190–198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Health Canada. Official Method T115. Determination of “Tar”, Nicotine and Carbon Monoxide in Mainstream Tobacco Smoke—Health Canada, Ottawa. 1999. Available online: https://healthycanadians.gc.ca/en/open-information/tobacco/t100/nicotine: (accessed on 10 December 2021).

- Munakata, S.; Ishimori, K.; Kitamura, N.; Ishikawa, S.; Takanami, Y.; Ito, S. Oxidative stress responses in human bronchial epithelial cells exposed to cigarette smoke and vapor from tobacco- and nicotine-containing products. Regul. Toxicol. Pharmacol. 2018, 99, 122–128. [Google Scholar] [CrossRef]

- Noël, A.; Hossain, E.; Perveen, Z.; Zaman, H.; Penn, A.L. Sub-ohm vaping increases the levels of carbonyls, is cytotoxic, and alters gene expression in human bronchial epithelial cells exposed at the air–liquid interface. Respir. Res. 2020, 21, 305. [Google Scholar] [CrossRef]

- Floyd, E.; Greenlee, S.; Oni, T.; Sadhasivam, B.; Queimado, L. The Effect of Flow Rate on a Third-Generation Sub-Ohm Tank Electronic Nicotine Delivery System—Comparison of CORESTA Flow Rates to More Realistic Flow Rates. Int. J. Environ. Res. Public Health 2021, 18, 7535. [Google Scholar] [CrossRef] [PubMed]

| Temperatures | Channel 1 | Channel 2 | Channel 1 vs. Channel 2 (p Values) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 to 100 Puffs (n = 300) | 100 to 200 Puffs (n = 299) | 200 to 300 Puffs (n = 299) | 0 to 100 Puffs (n = 300) | 100 to 200 Puffs (n = 299) | 200 to 300 Puffs (n = 299) | 0 tor 100 Puffs | 100 to 200 Puffs | 200 to 300 Puffs | |

| Inside Temp. (°C) | 68.3 ± 0.6 *,@,# | 76.2 ± 0.2 | 75.4 ± 0.2 | 62.7 ± 0.6 @,# | 72.0 ± 0.1 | 71.6 ± 0.1 | p < 0.001 | p < 0.001 | p < 0.001 |

| Outside Temp. (°C) | 45.9 ± 0.5 @,# | 56.0 ± 0.1 | 56.6 ± 0.0 | 47.6 ± 0.4 @,# | 54.1 ± 0.0 | 54.1 ± 0.0 | p < 0.001 | p < 0.001 | p < 0.001 |

| Magnetic Field (mT) | Currents (A) @ | Resistance (Ω) # | Power (W) ^ | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Channel 1 | Channel 2 | Channel 1 | Channel 2 | Channel 1 | Channel 2 | Stated on Coil ! | Channel 1 | Channel 2 | Stated on Coil | |

| Mean (n = 503) | 0.0316 * | 0.0305 | 18.4 * | 18.0 | 0.208 * | 0.212 | 0.17 Ω | 70.1 * | 68.6 | Best at |

| Standard Deviation | 0.0012 | 0.0013 | 0.7 | 0.7 | 0.008 | 0.009 | 2.6 | 2.8 | 120 W | |

| Standard Error | 0.0001 | 0.0001 | 0.0 | 0.0 | 0.000 | 0.000 | Direct Measure $ | 0.1 | 0.1 | Rated between 80 to 160 W |

| 0.24 Ω | ||||||||||

| Electrical Parameters (A) | Channel 1 | Channel 2 | Channel 1 vs. Channel 2 (p Values) | ||||||

| 0 to 100 Puffs (n = 303) | 100 to 200 Puffs (n = 305) | 200 to 300 Puffs (n = 304) | 0 to 100 Puffs (n = 303) | 100 to 200 Puffs (n = 305) | 200 to 300 Puffs (n = 304) | 0 tor 100 Puffs | 100 to 200 Puffs | 200 to 300 Puffs | |

| Magnetic Field (mT) | 0.0331 ± 0.0001 *,# | 0.0333 ± 0.0001 # | 0.0362 ± 0.0001 | 0.0292 ± 0.0001 | 0.0289 ± 0.0001 | 0.0290 ± 0.0001 | p < 0.001 | p < 0.001 | p < 0.001 |

| Current (A) | 19.2 ± 0.0 # | 19.4 ± 0.0 # | 21.1 ± 0.0 | 17.2 ± 0.0 | 17.1 ± 0.0 | 17.2 ± 0.0 | p < 0.001 | p < 0.001 | p < 0.001 |

| Resistance (Ω) | 0.198 ± 0.000 # | 0.197 ± 0.000 # | 0.181 ± 0.000 | 0.221 ± 0.001 | 0.224 ± 0.001 | 0.221 ± 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| Power (W) | 73.3 ± 0.2 # | 73.9 ± 0.2 # | 80.3 ± 0.2 | 65.7 ± 0.2 | 65.0 ± 0.2 | 65.4 ± 0.2 | p < 0.001 | p < 0.001 | p < 0.001 |

| Electrical Parameters (B) | Channel 1 | Channel 2 | |||||||

| First 5 Puffs from Table 2 (n = 503) | After 100 Puffs from above (n = 303) | First 5 Puffs (n = 503) | After 100 Puffs from above (n = 303) | First 5 Puffs | After 100 Puffs | ||||

| Magnetic Field (mT) | 0.0316 ± 0.0001 ^ | 0.0331 ± 0.0001 | 0.0305 ± 0.0001 ^ | 0.0292 ± 0.0001 | p < 0.001 | p < 0.001 | |||

| Current (A) | 18.4 ± 0.0 ^ | 19.2 ± 0.0 | 18.0 ± 0.0 ^ | 17.2 ± 0.0 | p < 0.001 | p < 0.001 | |||

| Resistance (Ω) | 0.208 ± 0.000 ^ | 0.198 ± 0.000 | 0.212 ± 0.000 ^ | 0.221 ± 0.001 | p < 0.001 | p < 0.001 | |||

| Power (W) | 70.1 ± 0.1^ | 73.3 ± 0.2 | 68.6 ± 0.1 ^ | 65.7 ± 0.2 | p < 0.001 | p < 0.001 | |||

| Experiment 1 300 Consecutive Puffs | Channel 1 | Channel 2 | Channel 1 vs. Channel 2 (p Values) | ||||||

| 0 to 100 Puffs (n = 26) | 100 to 200 Puffs (n = 25) | 200 to 300 Puffs (n = 25) | 0 to 100 Puffs (n = 26) | 100 to 200 Puffs (n = 25) | 200 to 300 Puffs (n = 25) | 0 to 100 Puffs | 100 to 200 Puffs | 200 to 300 Puffs | |

| Particle Count | |||||||||

| 0.3 µm (particles/ft 3) | 264,415 ± 18,162 * | 245,322 ± 16,755 | 284,808 ± 10,319 | 258,144 ± 7063 | 286,950 ± 10,115 | 256,517 ± 7872 | NS | NS | NS |

| 0.5 µm (particles/ft 3) | 206,922 ± 13,836 @,# | 248,815 ± 6038 # | 293,491 ± 9031 | 206,613 ± 13,860 | 228,549 ± 5446 | 235,091 ± 6789 | NS | NS | p < 0.001 |

| 1.0 µm (particles/ft 3) | 43,202 ± 4054 # | 56,159 ± 2585 # | 70,512 ± 3150 | 44,561 ± 3859 | 49,352 ± 2562 | 51,448 ± 3428 | NS | NS | p < 0.01 |

| 2.5 µm (particles/ft 3) | 77,581 ± 6082 # | 92,067 ± 3838 | 98,047 ± 2607 | 89,687 ± 7612 | 107,573 ± 2440 | 108,615 ± 2694 | NS | NS | NS |

| 5.0 µm (particles/ft 3) | 679.2 ± 70 @,# | 1317 ± 151 # | 2046 ± 89 | 724 ± 73 @,# | 818 ± 52# | 859 ± 56 | NS | p < 0.01 | p < 0.001 |

| 10.0 µm (particles/ft 3) | 1209 ± 104 | 1271 ± 54 | 1369 ± 60 | 1199 ± 97 | 1955 ± 148 | 2622 ± 89 | NS | p < 0.001 | p < 0.001 |

| Mass Concentration | |||||||||

| 2.5 µm (µg/m3) | 1526 ± 180 | 1018 ± 64 | 1372 ± 80 | 1531 ± 133 | 2029 ± 190 | 2746 ± 159 | NS | p < 0.001 | p < 0.001 |

| 10.0 µm (µg/m3) | 5249 ± 606 | 3885 ± 331 | 5922 ± 504 | 5281 ± 596 # | 6521 ± 570 | 8446 ± 386 | NS | p < 0.01 | p < 0.01 |

| Experiment 2 3 sets of 12 puffs | Channel 1 | Channel 2 | Channel 1 vs. Channel 2 (p values) | ||||||

| First 12 Puffs (n = 15) | Second 12 Puffs (n = 15) | Third 12 Puffs (n = 15) | First 12 Puffs (n = 15) | Second 12 Puffs (n = 15) | Third 12 Puffs (n = 15) | First 12 Puffs | Second 12 Puffs | Third 12 Puffs | |

| Particle Count | |||||||||

| 0.3 µm (particles/ft 3) | 163,494 ± 29,738 | 157,120 ± 27,515 | 155,424 ± 26,053 | 90,806 ± 25,485 | 87,848 ± 21,593 | 78,751 ± 20,548 | NS | NS | NS |

| 0.5 µm (particles/ft 3) | 117,984 ± 23,286 | 114,452 ± 21,869 | 113,120 ± 21,082 | 63,994 ± 18,744 | 60,827 ± 16,020 | 56,611 ± 15,654 | NS | NS | NS |

| 1.0 µm (particles/ft 3) | 28,946 ± 5632 | 27,612 ± 5323 | 28,154 ± 5349 | 16,183 ± 4729 | 15,570 ± 4186 | 15,009 ± 4216 | NS | NS | NS |

| 2.5 µm (particles/ft 3) | 23,791 ± 6676 | 26,958 ± 7659 | 23,195 ± 6603 | 13,130 ± 4878 | 11,866 ± 3959 | 10,904 ± 3563 | NS | NS | NS |

| 5.0 µm (particles/ft 3) | 690 ± 163 | 731 ± 182 | 723 ± 183 | 521 ± 185 | 526 ± 178 | 548 ± 187 | NS | NS | NS |

| 10.0 µm (particles/ft 3) | 1167 ± 245 | 1276 ± 280 | 1315 ± 288 | 797 ± 256 | 860 ± 270 | 867 ± 277 | NS | NS | NS |

| Mass Concentration | |||||||||

| 2.5 µm (µg/m3) | 307 ± 90 | 305 ± 79 | 439 ± 155 | 527 ± 165 | 767 ± 298 | 708 ± 253 | NS | NS | NS |

| 10.0 µm (µg/m3) | 845 ± 247 | 1023 ± 294 | 1328 ± 439 | 1425 ± 427 | 1897 ± 596 | 1724 ± 551 | NS | NS | NS |

| Channel 1 | Channel 2 | Combined Channels | |

|---|---|---|---|

| Weight of 1 mL E-liquid (g/mL) | * 1.18 ± 0.01 (n = 3) | 1.18 ± 0.01 (n = 3) | 1.18 ± 0.01 (n = 6) |

| Tank weight difference (g) before and after 100 puffs | 2.26 ± 0.00 (n = 3) | 2.18 ± 0.18 (n = 3) | 2.22 ± 0.08 (n = 6) |

| Tank weight difference (g) before and after 200 puffs | 4.51 ± 0.12 (n = 3) | 4.76 ± 0.06 (n = 3) | 4.63 ± 0.08 (n = 6) |

| Tank weight difference (g) before and after 300 puffs | 6.85 ± 0.14 (n = 3) | 7.15 ± 0.05 (n = 3) | 7.00 ± 0.09 (n = 6) |

| Volume (mL) aerosolized after 100 puffs | 1.92 ± 0.00 (n = 3) | 1.84 ± 0.15 (n = 3) | 1.88 ± 0.07 (n = 6) |

| Volume (mL) aerosolized after 200 puffs | 3.82 ± 0.10 (n = 3) | 4.03 ± 0.05 (n = 3) | 3.93 ± 0.07 (n = 6) |

| Volume (mL) aerosolized after 300 puffs | 5.80 ± 0.12 (n = 3) | 6.06 ± 0.04 (n = 3) | 5.93 ± 0.8 (n = 6) |

| Volume (µL) aerosolized per puff | 19.00 ± 0.00 (n = 3) | 19.33 ± 0.67 (n = 3) | 19.17 ± 0.31 (n = 6) |

| Study | Culture Media | Puff Topography | Culture Media Volume (mL) for Aerosol Trapping | E-liquid Nicotine Concentration (mg/mL) | Number | Theoretical Maximum Nicotine Concentration (mg/mL) @, + | Nicotine Recovered in Media (mg/mL) ^ | Percent Recovery (%) |

|---|---|---|---|---|---|---|---|---|

| Brain Heart Infusion | CORESTA [7] Sub-Ohm # Atomizer Tank (open) | 10 | 20 | 10 100 200 300 | 0.378 3.426 5.543 7.302 | 0.081 0.673 1.331 1.989 | 22 20 24 27 | |

| Taylor et al. (2016) [47] | Dulbecco’s Modified Eagle Medium | CORESTA [7] Vype ePen (Cigilike) Modular Devise (Closed Tank) | 20 20 | 36 18 | 10 10 | 0.342 0.171 | 0.005 0.005 | 1 3 |

| Taylor et al. (2017) [49] | VascuLifeTM | CORESTA [7] Vype ePen (Cigilike) Modular Devise (Closed Tank) | 20 20 | 36 18 | 10 10 | 0.342 0.171 | 0.004 0.005 | 1 3 |

| Breheny et al. (2017) [50] | Dulbecco’s Modified Eagle Medium | CORESTA [7] Vype ePen (Cigilike) | 20 | 18 | 10 | 0.171 | 0.005 | 3 |

| Munakata et al. (2018) [52] | Dulbecco’s Modified Eagle Medium | Health Canada Smoking Regimen [51] (55 mL per 2 s puff every 30 s) Unspecified Cigilike devise | 15 | Unknown Assume between 18 and 36 mg/mL | 300 | 2.823–5.65 | 0.31 | 5 to 11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palazzolo, D.L.; Caudill, J.; Baron, J.; Cooper, K. Fabrication and Validation of an Economical, Programmable, Dual-Channel, Electronic Cigarette Aerosol Generator. Int. J. Environ. Res. Public Health 2021, 18, 13190. https://doi.org/10.3390/ijerph182413190

Palazzolo DL, Caudill J, Baron J, Cooper K. Fabrication and Validation of an Economical, Programmable, Dual-Channel, Electronic Cigarette Aerosol Generator. International Journal of Environmental Research and Public Health. 2021; 18(24):13190. https://doi.org/10.3390/ijerph182413190

Chicago/Turabian StylePalazzolo, Dominic L., Jordan Caudill, James Baron, and Kevin Cooper. 2021. "Fabrication and Validation of an Economical, Programmable, Dual-Channel, Electronic Cigarette Aerosol Generator" International Journal of Environmental Research and Public Health 18, no. 24: 13190. https://doi.org/10.3390/ijerph182413190