Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bernoulli Flow Cell Design Description

2.2. Data Acquisition System

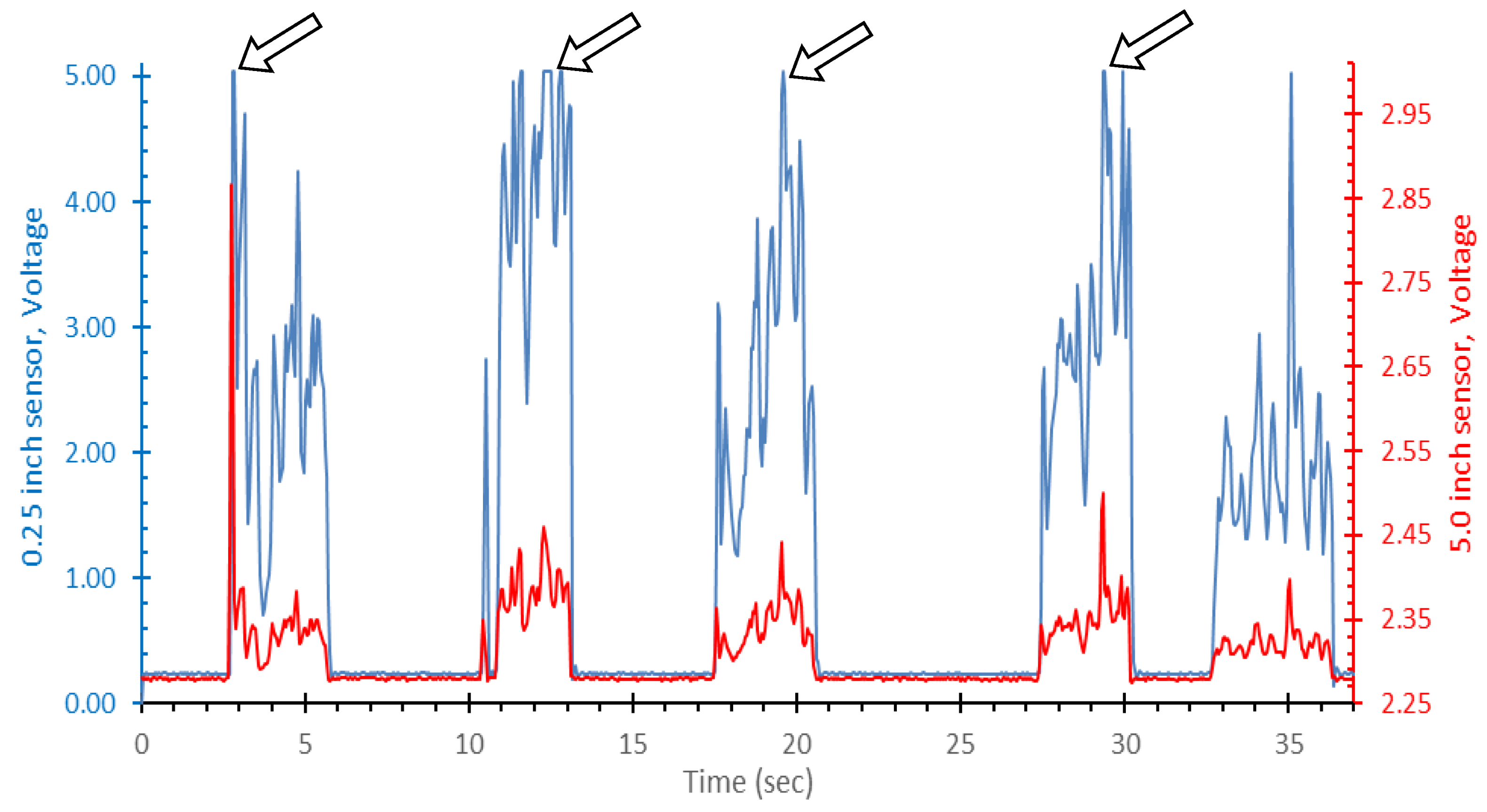

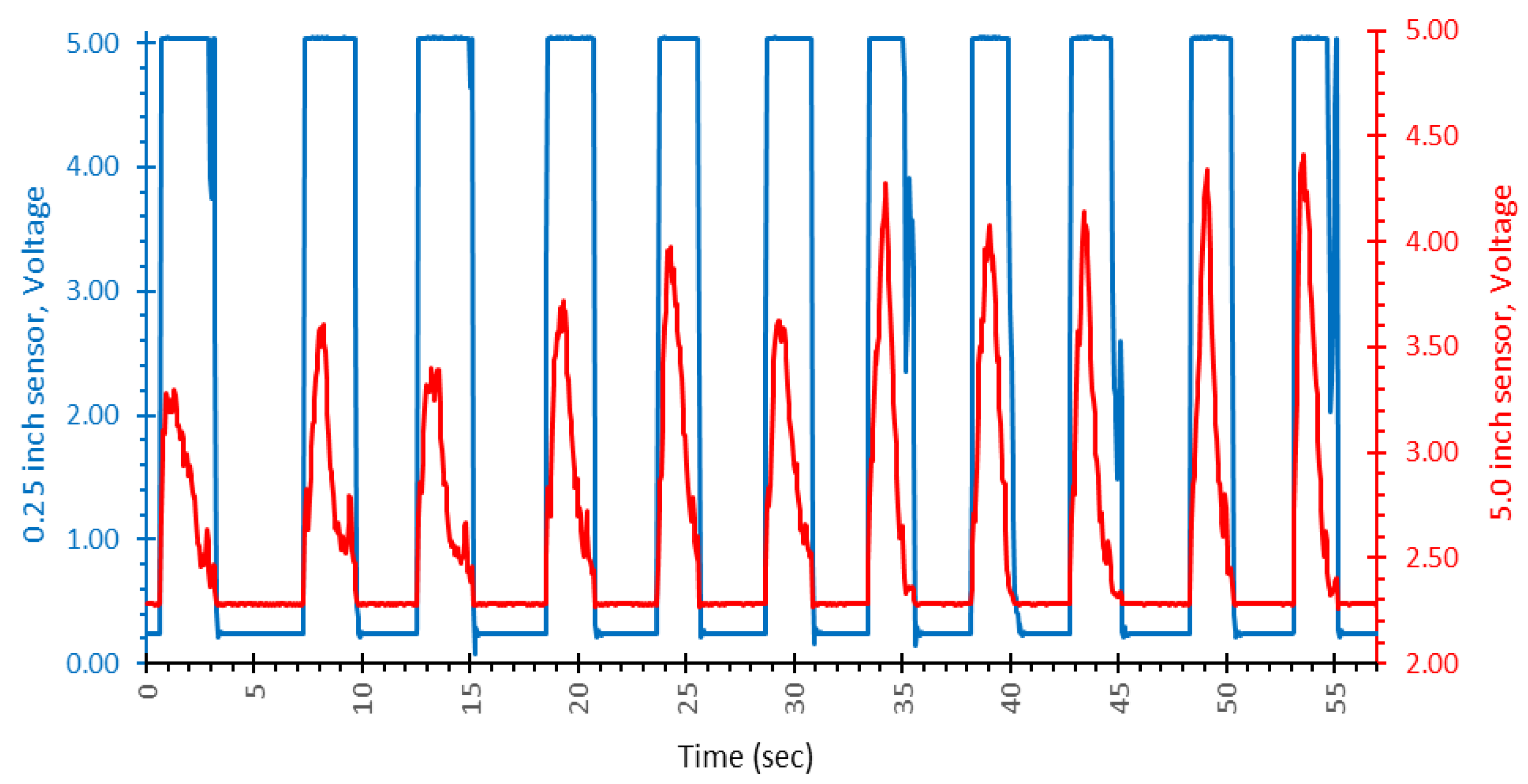

2.3. Flow Cell Evaluation

2.4. Flow Cell Cleaning, Maintenance, and Durability

2.5. Data Analysis

3. Results

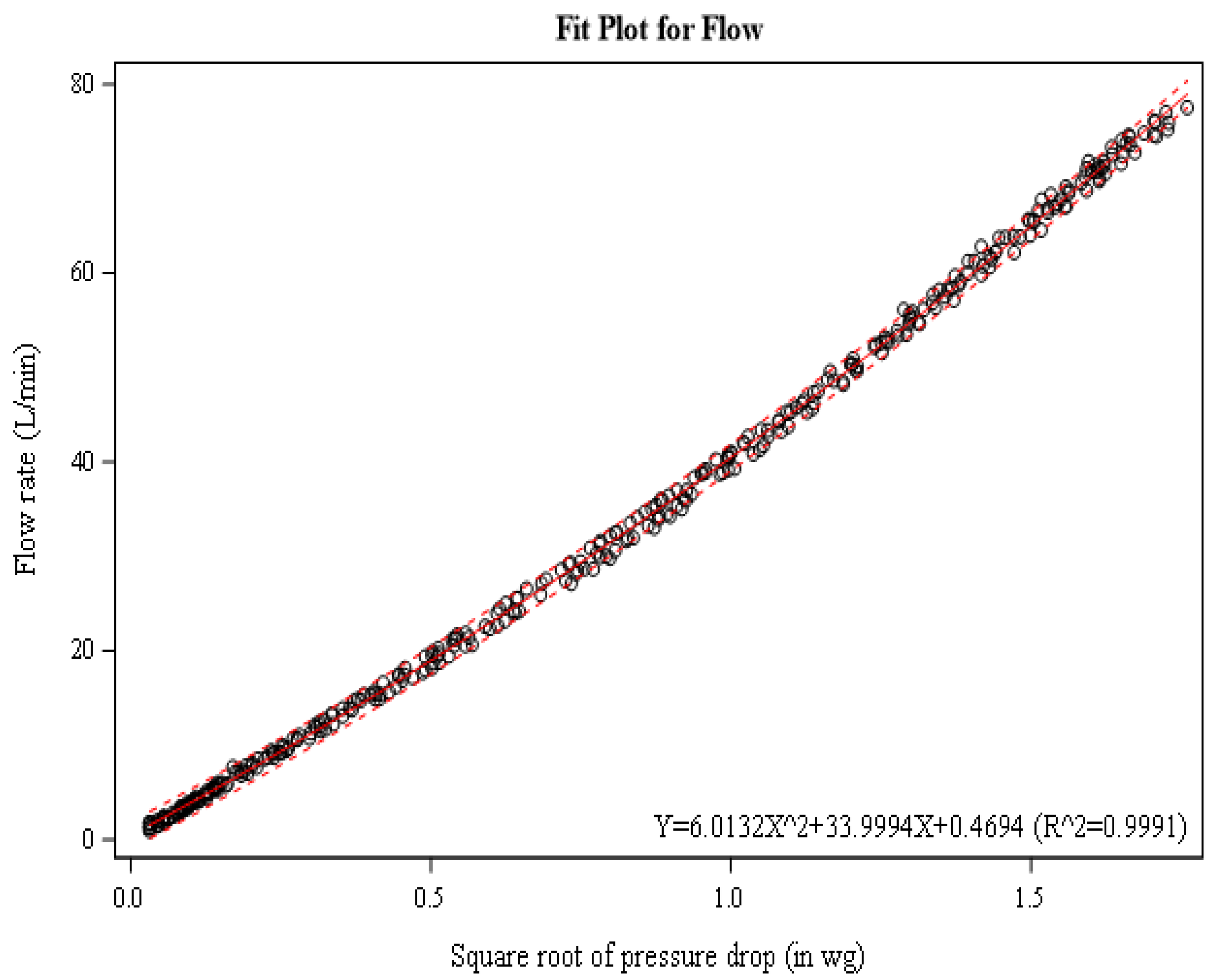

3.1. Flow Rate—Pressure Model

3.2. Volume Estimation

4. Discussion

5. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dawkins, L.; Kimber, C.; Panwanesarasa, Y.; Soar, K. First-versus second-generation electronic cigarettes: Predictors of choice and effects on urge to smoke and withdrawal symptoms. Addiction 2015, 110, 669–677. [Google Scholar] [CrossRef] [PubMed]

- Williams, M.; Talbot, P. Design Features in Multiple Generations of Electronic Cigarette Atomizers. Int. J. Environ. Res. Public Health 2019, 16, 2904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wagener, T.L.; Floyd, E.L.; Stepanov, I.; Driskill, L.M.; Frank, S.G.; Meier, E.; Leavens, E.L.; Tackett, A.P.; Molina, N.; Queimado, L. Have combustible cigarettes met their match? The nicotine delivery profiles and harmful constituent exposures of second-generation and third-generation electronic cigarette users. Tob. Control 2016, 26, e23–e28. [Google Scholar] [CrossRef] [PubMed]

- Walley, S.C.; Wilson, K.M.; Winickoff, J.P.; Groner, J. A Public Health Crisis: Electronic Cigarettes, Vape, and JUUL. Pediatrics 2019, 143, e20182741. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Floyd, E.L.; Queimado, L.; Wang, J.; Regens, J.L.; Johnson, D.L. Electronic cigarette power affects count concentration and particle size distribution of vaping aerosol. PLoS ONE 2018, 13, e0210147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abrams, D.B. Promise and peril of e-cigarettes: Can disruptive technology make cigarettes obsolete? Jama 2014, 311, 135–136. [Google Scholar] [CrossRef]

- Floyd, E.L.; Subedi, S.; Wagener, T.L.; Johnson, D.L.; Oni, T.M. Low powered variable voltage E-Cigarette batteries under perform at higher power settings. Inhal. Toxicol. 2020, 32, 110–114. [Google Scholar] [CrossRef]

- Mikheev, V.B.; Brinkman, M.C.; Granville, C.A.; Gordon, S.M.; Clark, P.I. Real-Time Measurement of Electronic Cigarette Aerosol Size Distribution and Metals Content Analysis. Nicotine Tob. Res. 2016, 18, 1895–1902. [Google Scholar] [CrossRef] [Green Version]

- Saliba, N.A.; El Hellani, A.; Honein, E.; Salman, R.; Talih, S.; Zeaiter, J.; Shihadeh, A. Surface chemistry of electronic cigarette electrical heating coils: Effects of metal type on propylene glycol thermal decomposition. J. Anal. Appl. Pyrolysis 2018, 134, 520–525. [Google Scholar] [CrossRef]

- Strasser, A.A.; Souprountchouk, V.; Kaufmann, A.; Blazekovic, S.; Leone, F.; Benowitz, N.L.; Schnoll, R.A. Nicotine Replacement, Topography, and Smoking Phenotypes of E-cigarettes. Tob. Regul. Sci. 2016, 2, 352–362. [Google Scholar] [CrossRef] [Green Version]

- Farsalinos, K.E.; Romagna, G.; Tsiapras, D.; Kyrzopoulos, S.; Voudris, V. Evaluation of Electronic Cigarette Use (Vaping) Topography and Estimation of Liquid Consumption: Implications for Research Protocol Standards Definition and for Public Health Authorities’ Regulation. Int. J. Environ. Res. Public Health 2013, 10, 2500–2514. [Google Scholar] [CrossRef]

- Robinson, R.J.; Hensel, E.C.; Roundtree, K.A.; DiFrancesco, A.G.; Nonnemaker, J.M.; Lee, Y.O. Week Long Topography Study of Young Adults Using Electronic Cigarettes in Their Natural Environment. PLoS ONE 2016, 11, e0164038. [Google Scholar]

- Lee, Y.O.; Nonnemaker, J.M.; Bradfield, B.B.; Hensel, E.; Robinson, R.J. Examining Daily Electronic Cigarette Puff Topography Among Established and Nonestablished Cigarette Smokers in their Natural Environment. Nicotine Tob. Res. 2018, 20, 1283–1288. [Google Scholar] [CrossRef] [PubMed]

- Grana, R.; Benowitz, N.; Glantz, S.A. E-cigarettes: A scientific review. Circulation 2014, 129, 1972–1986. [Google Scholar] [CrossRef] [PubMed]

- Robinson, R.J.; Hensel, E.C.; Morabito, P.N.; Roundtree, K.A. Electronic Cigarette Topography in the Natural Environment. PLoS ONE 2015, 10, e0129296. [Google Scholar] [CrossRef] [PubMed]

- Behar, R.Z.; Hua, M.; Talbot, P. Puffing Topography and Nicotine Intake of Electronic Cigarette Users. PLoS ONE 2015, 10, e0117222. [Google Scholar] [CrossRef]

- Lopez, A.A.; Hiler, M.M.; Soule, E.K.; Ramôa, C.P.; Karaoghlanian, N.V.; Lipato, T.; Breland, A.B.; Shihadeh, A.L.; Eissenberg, T. Effects of Electronic Cigarette Liquid Nicotine Concentration on Plasma Nicotine and Puff Topography in Tobacco Cigarette Smokers: A Preliminary Report. Nicotine Tob. Res. 2015, 18, 720–723. [Google Scholar] [CrossRef] [Green Version]

- Yingst, J.M.; Veldheer, S.; Hrabovsky, S.; Nichols, T.T.; Wilson, S.J.; Foulds, J. Factors Associated With Electronic Cigarette Users’ Device Preferences and Transition From First Generation to Advanced Generation Devices. Nicotine Tob. Res. 2015, 17, 1242–1246. [Google Scholar] [CrossRef] [Green Version]

- Lechner, W.V.; Meier, E.; Wiener, J.L.; Grant, D.; Gilmore, J.; Judah, M.R.; Mills, A.C.; Wagener, T.L. The comparative efficacy of first- versus second-generation electronic cigarettes in reducing symptoms of nicotine withdrawal. Addiction 2015, 110, 862–867. [Google Scholar] [CrossRef]

- Protano, C.; Avino, P.; Manigrasso, M.; Vivaldi, V.; Perna, F.; Valeriani, F.; Vitali, M. Environmental Electronic Vape Exposure from Four Different Generations of Electronic Cigarettes: Airborne Particulate Matter Levels. Int. J. Environ. Res. Public Health 2018, 15, 2172. [Google Scholar] [CrossRef] [Green Version]

- Rankin, G.D.; Wingfors, H.; Uski, O.; Hedman, L.; Ekstrand-Hammarström, B.; Bosson, J.; Lundbäck, M. The toxic potential of a fourth-generation E-cigarette on human lung cell lines and tissue explants. J. Appl. Toxicol. 2019, 39, 1143–1154. [Google Scholar] [CrossRef] [PubMed]

- Cao, D.J.; Aldy, K.; Hsu, S.; McGetrick, M.; Verbeck, G.; De Silva, I.W.; Feng, S.-Y. Review of Health Consequences of Electronic Cigarettes and the Outbreak of Electronic Cigarette, or Vaping, Product Use-Associated Lung Injury. J. Med Toxicol. 2020, 16, 295–310. [Google Scholar] [CrossRef] [PubMed]

- Boykan, R.; Goniewicz, M.L.; Messina, C.R. Evidence of Nicotine Dependence in Adolescents Who Use Juul and Similar Pod Devices. Int. J. Environ. Res. Public Health 2019, 16, 2135. [Google Scholar] [CrossRef] [Green Version]

- Cunningham, A.; Slayford, S.; Vas, C.; Gee, J.; Costigan, S.; Prasad, K. Development, validation and application of a device to measure e-cigarette users’ puffing topography. Sci. Rep. 2016, 6, 35071. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Shu, S.; Guo, Q.; Zhu, Y. Effects of design parameters and puff topography on heating coil temperature and mainstream aerosols in electronic cigarettes. Atmospheric Environ. 2016, 134, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Fuoco, F.; Buonanno, G.; Stabile, L.; Vigo, P. Influential parameters on particle concentration and size distribution in the mainstream of e-cigarettes. Environ. Pollut. 2014, 184, 523–529. [Google Scholar] [CrossRef]

- Talih, S.; Balhas, Z.; Eissenberg, T.; Salman, R.; Karaoghlanian, N.; El Hellani, A.; Baalbaki, R.; Saliba, N.; Shihadeh, A. Effects of User Puff Topography, Device Voltage, and Liquid Nicotine Concentration on Electronic Cigarette Nicotine Yield: Measurements and Model Predictions. Nicotine Tob. Res. 2015, 17, 150–157. [Google Scholar] [CrossRef]

- Farsalinos, K.; Poulas, K.; Voudris, V. Changes in Puffing Topography and Nicotine Consumption Depending on the Power Setting of Electronic Cigarettes. Nicotine Tob. Res. 2018, 20, 993–997. [Google Scholar] [CrossRef]

- Floyd, E.; Greenlee, S.; Oni, T.; Sadhasivam, B.; Queimado, L. The Effect of Flow Rate on a Third-Generation Sub-Ohm Tank Electronic Nicotine Delivery System—Comparison of CORESTA Flow Rates to More Realistic Flow Rates. Int. J. Environ. Res. Public Health 2021, 18, 7535. [Google Scholar] [CrossRef]

- Ross, K.C.; Juliano, L.M. Smoking Through a Topography Device Diminishes Some of the Acute Rewarding Effects of Smoking. Nicotine Tob. Res. 2016, 18, 564–571. [Google Scholar] [CrossRef]

- Goniewicz, M.L.; Kuma, T.; Gawron, M.; Knysak, J.; Kosmider, L. Nicotine Levels in Electronic Cigarettes. Nicotine Tob. Res. 2013, 15, 158–166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olonoff, M.; Niaura, R.; Hitsman, B. “Electronic Cigarettes” Are Not Cigarettes, and Why That Matters. Nicotine Tob. Res. 2019, 21, 1441–1444. [Google Scholar] [CrossRef] [PubMed]

- Helen, G.S.; Ross, K.C.; Dempsey, D.A.; Havel, C.M.; Jacob, P.; Benowitz, N.L. Nicotine Delivery and Vaping Behavior during ad libitum E-cigarette Access. Tob. Regul. Sci. 2016, 2, 363–376. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Norton, K.J.; June, K.M.; O’Connor, R.J. Initial puffing behaviors and subjective responses differ between an electronic nicotine delivery system and traditional cigarettes. Tob. Induc. Dis. 2014, 12, 17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Jesus, S.; Hsin, A.; Faulkner, G.; Prapavessis, H. A systematic review and analysis of data reduction techniques for the CReSS smoking topography device. J. Smok. Cessat. 2015, 10, 12–28. [Google Scholar] [CrossRef]

- Robinson, R.J.; Eddingsaas, N.C.; DiFrancesco, A.G.; Jayasekera, S.; Hensel, E.C. A framework to investigate the impact of topography and product characteristics on electronic cigarette emissions. PLoS ONE 2018, 13, e0206341. [Google Scholar] [CrossRef]

- Pearson, J.L.; Elmasry, H.; Das, B.; Smiley, S.L.; Rubin, L.F.; DeAtley, T.; Harvey, E.; Zhou, Y.; Niaura, R.; Abrams, D.B.; et al. Comparison of Ecological Momentary Assessment Versus Direct Measurement of E-Cigarette Use With a Bluetooth-Enabled E-Cigarette: A Pilot Study. JMIR Res. Protoc. 2017, 6, e84. [Google Scholar] [CrossRef]

- Soule, E.; Bansal-Travers, M.; Grana, R.; McIntosh, S.; Price, S.; Unger, J.B.; Walton, K. Electronic cigarette use intensity measurement challenges and regulatory implications. Tob. Control 2021, 1–6. [Google Scholar] [CrossRef]

- Spindle, T.R.; Talih, S.; Hiler, M.M.; Karaoghlanian, N.; Halquist, M.S.; Breland, A.B.; Shihadeh, A.; Eissenberg, T. Effects of electronic cigarette liquid solvents propylene glycol and vegetable glycerin on user nicotine delivery, heart rate, subjective effects, and puff topography. Drug Alcohol Depend. 2018, 188, 193–199. [Google Scholar] [CrossRef] [Green Version]

- Benowitz, N.L.; Fraiman, J.B. Cardiovascular effects of electronic cigarettes. Nat. Rev. Cardiol. 2017, 14, 447–456. [Google Scholar] [CrossRef]

- Mikheev, V.B.; Buehler, S.S.; Brinkman, M.C.; Granville, C.A.; Lane, T.E.; Ivanov, A.; Cross, K.M.; Clark, P.I. The Application of Commercially Available Mobile Cigarette Topography Devices for E-cigarette Vaping Behavior Measurements. Nicotine Tob. Res. 2020, 22, 681–688. [Google Scholar] [CrossRef] [PubMed]

- Robinson, R.J.; Jayasekera, S.; DiFrancesco, G.; Hensel, E.C. Characterization and Validation of the Second-generation wPUM Topography Monitors. Nicotine Tob. Res. 2021, 23, 390–396. [Google Scholar] [CrossRef] [PubMed]

- Kong, G.; Lavallee, H.; Rams, A.; Ramamurthi, D.; Krishnan-Sarin, S. Promotion of Vape Tricks on YouTube: Content Analysis. J. Med. Internet Res. 2019, 21, e12709. [Google Scholar] [CrossRef] [PubMed]

- Hewitt, P.G. Bernoulli’s Principle. Sci. Teach. 2004, 71, 51. [Google Scholar]

| Challenge Volume | 0.710 L Slow | 0.710 L Fast | 2 L Slow | 2 L Fast | 3 L Slow | 3 L Fast | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Sensor | Low | High | Low | High | Low | High | Low | High | Low | High | Low | High |

| Predicted Volume (L) | 0.729 | 0.724 | 0.431 | 0.786 | 1.845 | 1.912 | 0.744 | 2.065 | 2.900 | 3.002 | 1.597 | 3.199 |

| RSD (%) | 0.019 | 0.011 | 0.112 | 0.011 | 0.028 | 0.006 | 0.115 | 0.012 | 0.021 | 0.001 | 0.057 | 0.004 |

| Accuracy (%) | 103 | 102 | 61 | 111 | 92 | 96 | 37 | 103 | 96.7 | 100.1 | 53 | 107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Floyd, E.; Oni, T.; Cai, C.; Rehman, B.; Hwang, J.; Watson, T. Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems. Int. J. Environ. Res. Public Health 2022, 19, 7989. https://doi.org/10.3390/ijerph19137989

Floyd E, Oni T, Cai C, Rehman B, Hwang J, Watson T. Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems. International Journal of Environmental Research and Public Health. 2022; 19(13):7989. https://doi.org/10.3390/ijerph19137989

Chicago/Turabian StyleFloyd, Evan, Toluwanimi Oni, Changjie Cai, Bilal Rehman, Jooyeon Hwang, and Tyler Watson. 2022. "Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems" International Journal of Environmental Research and Public Health 19, no. 13: 7989. https://doi.org/10.3390/ijerph19137989

APA StyleFloyd, E., Oni, T., Cai, C., Rehman, B., Hwang, J., & Watson, T. (2022). Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems. International Journal of Environmental Research and Public Health, 19(13), 7989. https://doi.org/10.3390/ijerph19137989