Optimization of Work Environment and Community Labor Health Based on Digital Model—Empirical Evidence from Developing Countries

Abstract

:1. Introduction

2. Materials and Methods

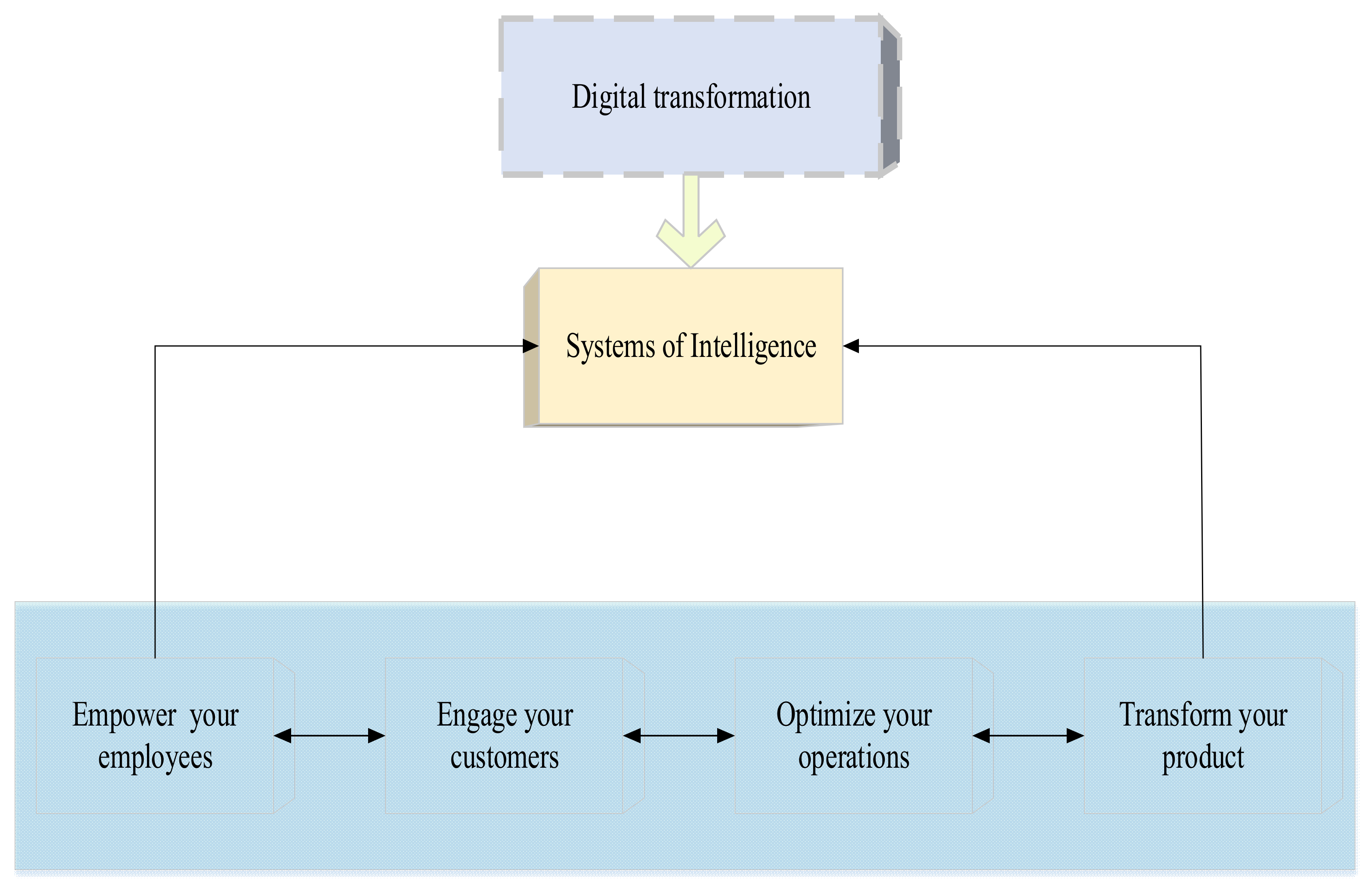

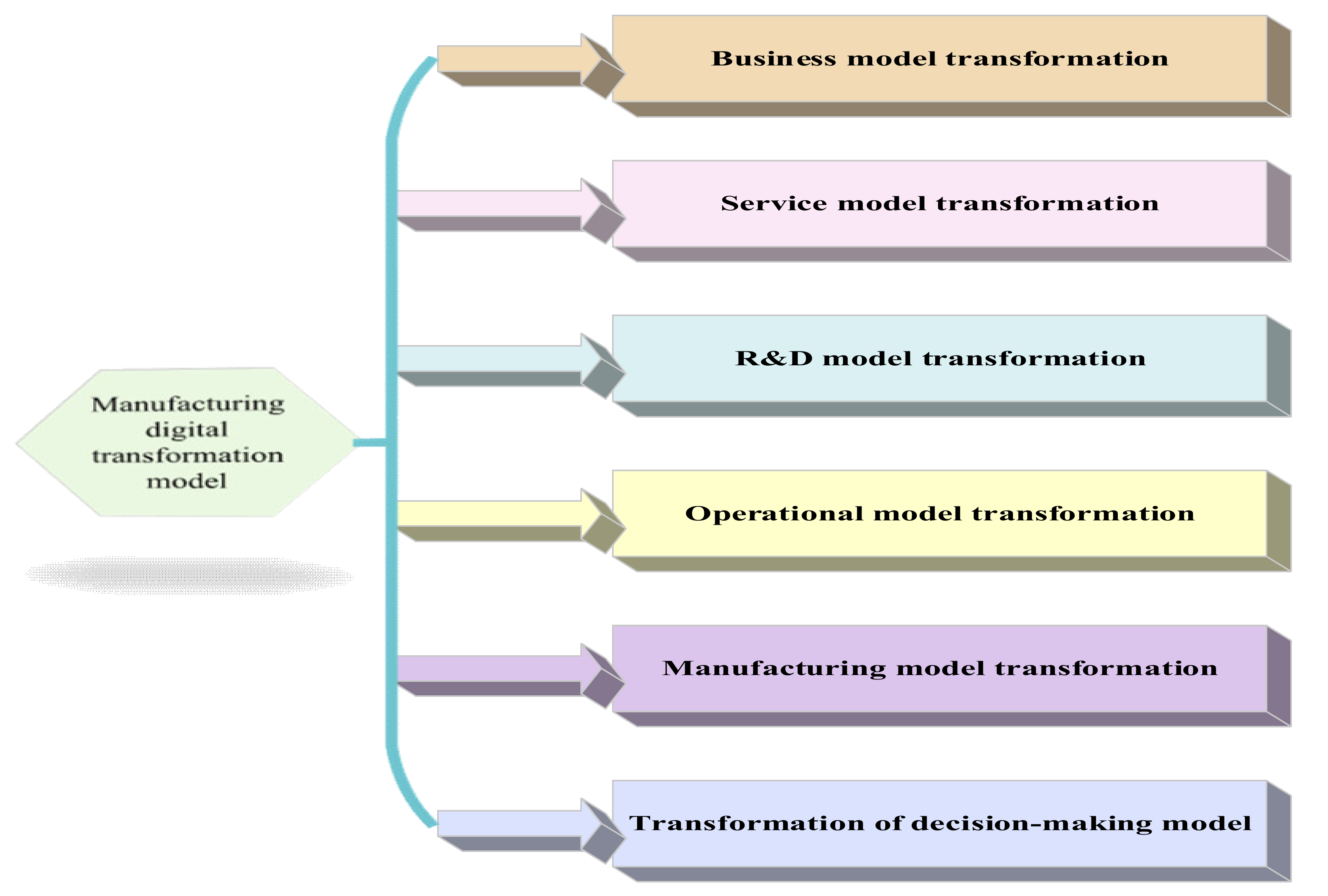

2.1. Significance of EDT

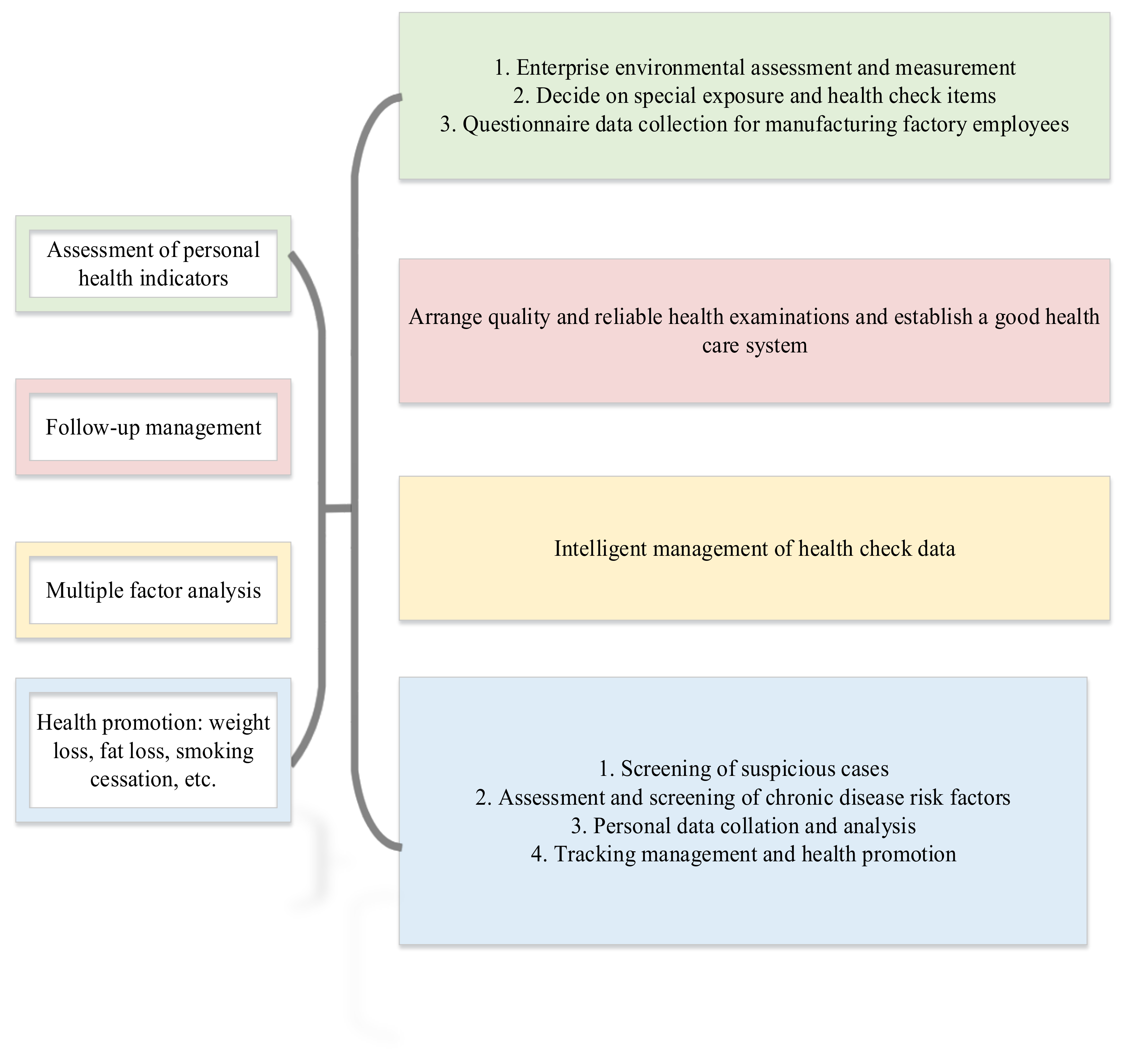

2.2. CME and WHSM

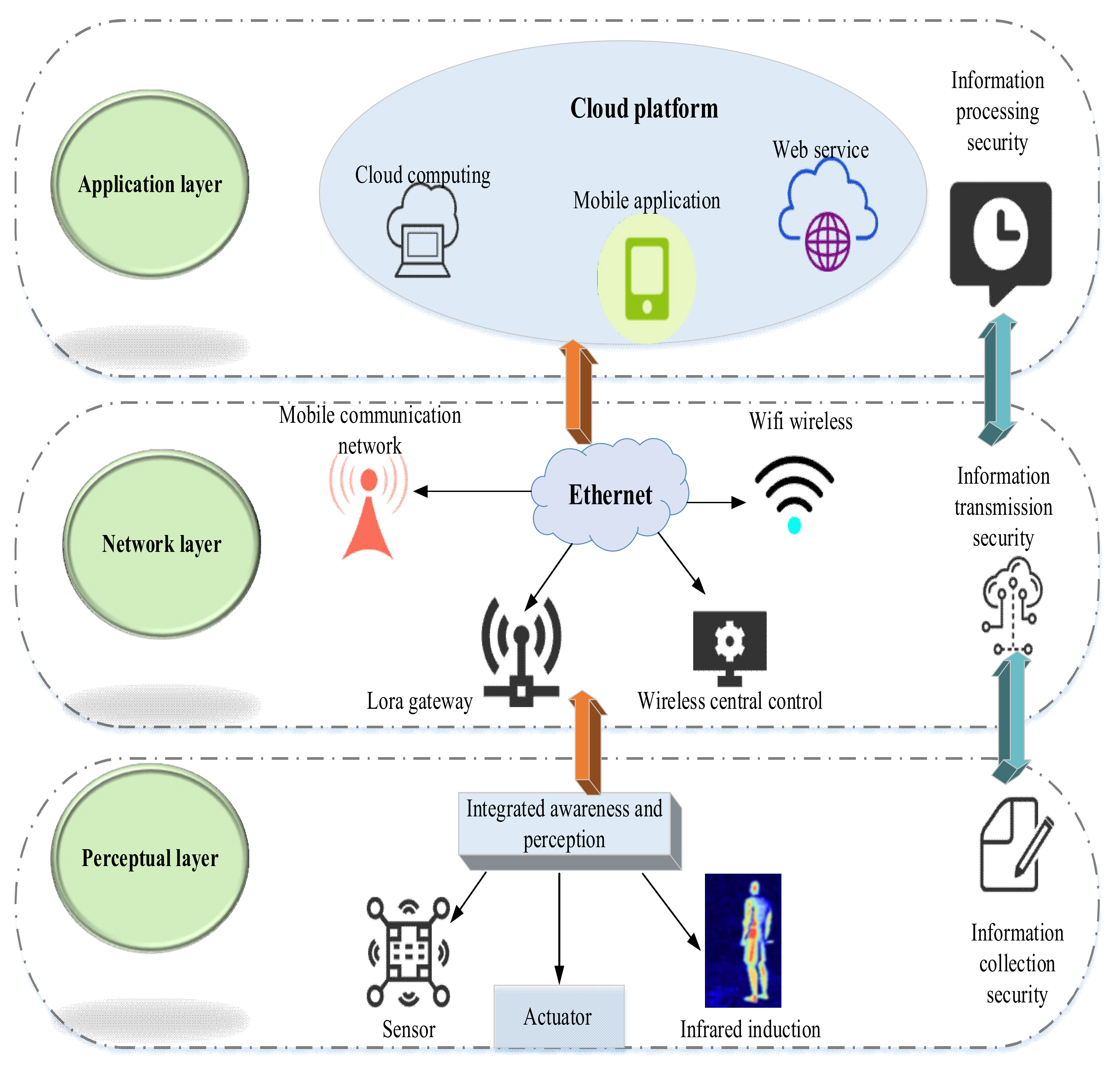

2.3. IoT Technology

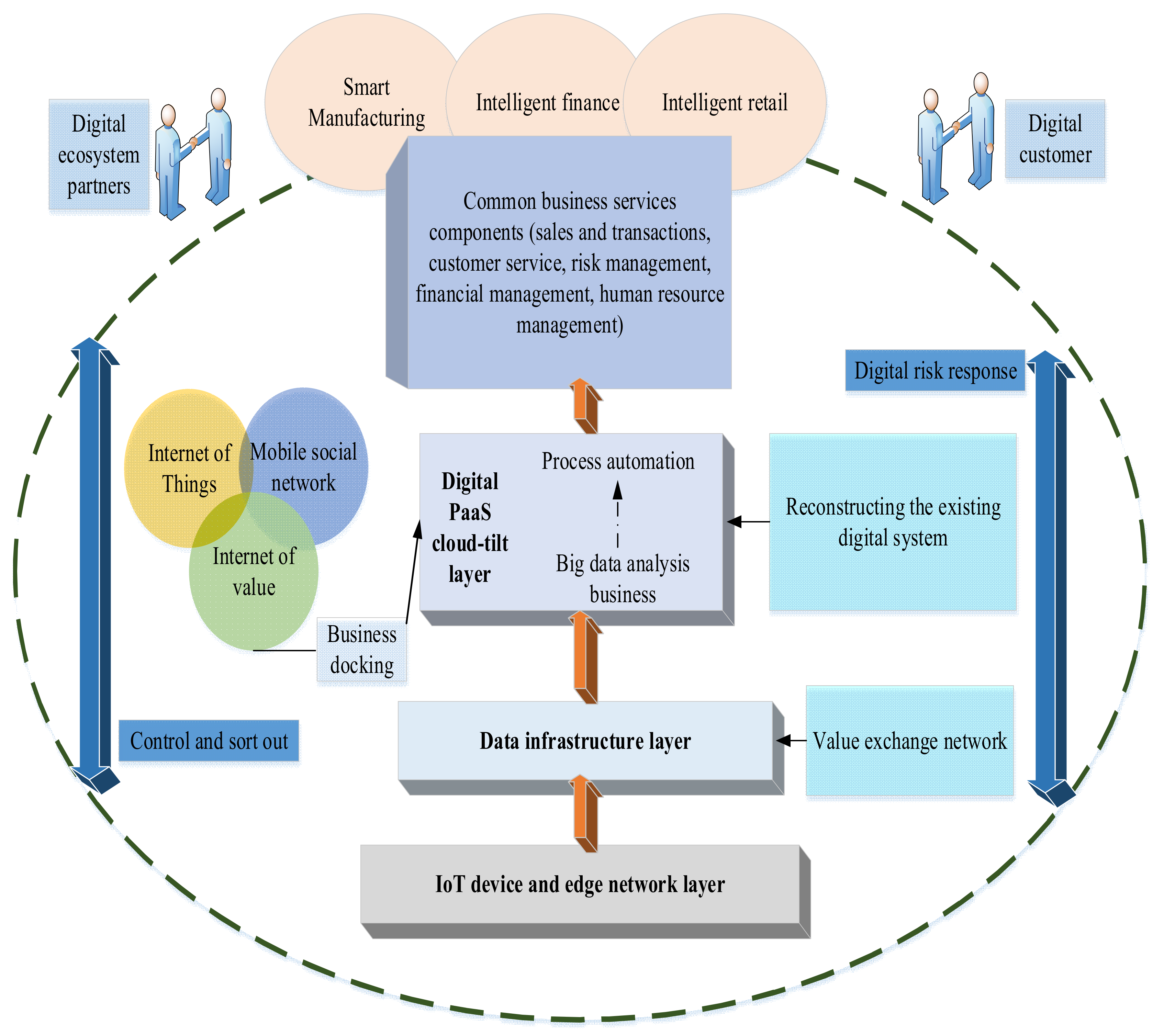

2.3.1. Modeling CMEs-Oriented EDT Based on IoT

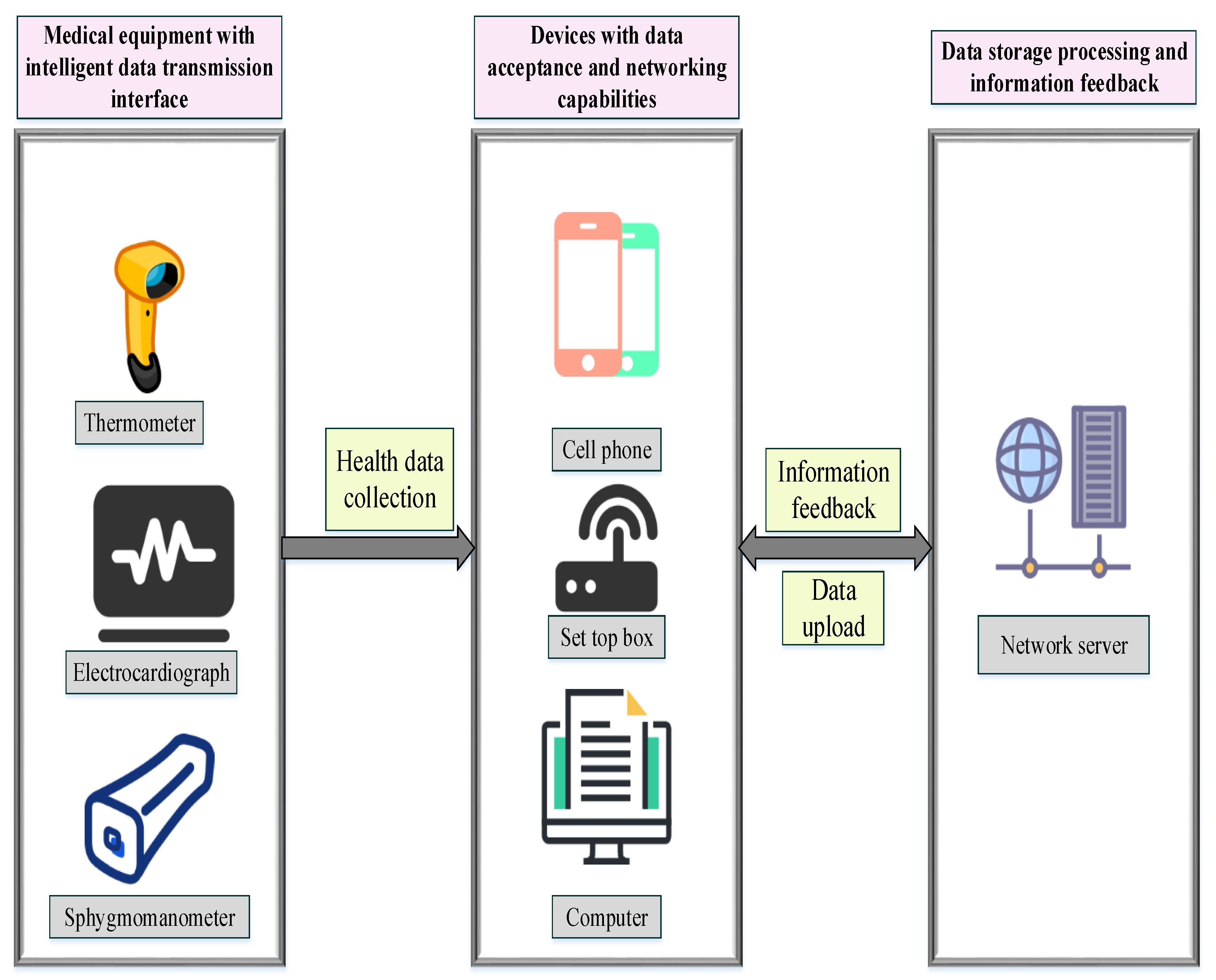

2.3.2. WHSM System Based on IoT

2.4. Data Source and Processing Method

3. Results

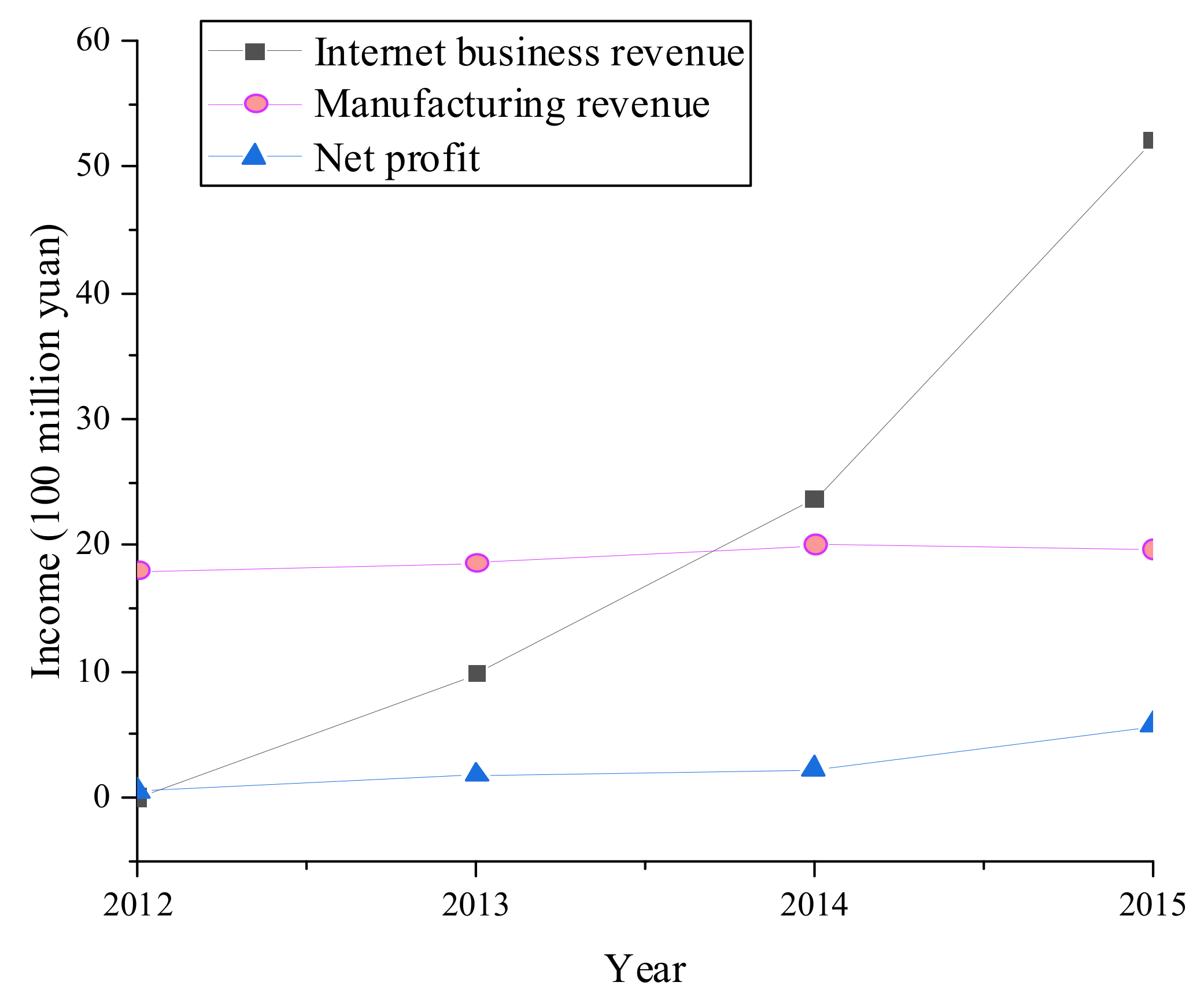

3.1. Adaptability and Performance Analysis of CMEs-Oriented EDT Model

3.2. Analysis of Worker Health Status under the Proposed WHSM System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giraldo, S.; la Rotta, D.; Nieto-Londoño, C.; Vásquez, R.E.; Escudero-Atehortúa, A. Digital transformation of energy companies: A colombian case study. Energies 2021, 14, 2523. [Google Scholar] [CrossRef]

- Wrede, M.; Velamuri, V.K.; Dauth, T. Top managers in the digital age: Exploring the role and practices of top managers in firms’ digital transformation. Manag. Decis. Econ. 2020, 41, 1549–1567. [Google Scholar] [CrossRef]

- Kääriäinen, J.; Pussinen, P.; Saari, L.; Kuusisto, O.; Saarela, M.; Hänninen, K. Applying the positioning phase of the digital transformation model in practice for SMEs: Toward systematic development of digitalization. Int. J. Inf. Syst. Proj. Manag. 2021, 8, 24–43. [Google Scholar] [CrossRef]

- García-Peñalvo, F.J. Avoiding the dark side of digital transformation in teaching. An institutional reference framework for eLearning in higher education. Sustainability 2021, 13, 2023. [Google Scholar] [CrossRef]

- Radionova, N.; Skrypnyk, M.; Voronkova, T. Dual nature of industrial enterprise cost management system. Balt. J. Econ. Stud. 2019, 5, 184–190. [Google Scholar] [CrossRef]

- Mugge, P.; Abbu, H.; Michaelis, T.L.; Kwiatkowski, A.; Gudergan, G. Patterns of digitization: A practical guide to digital transformation. Res. Technol. Manag. 2020, 63, 27–35. [Google Scholar] [CrossRef]

- Schuh, G.; Kozielski, S.; Weber, W.; Gützlaff, A.; Sauermann, F.; Wlecke, S.; Maetschke, J. Digital Lean Lighthouse Factory—Nachhaltig effiziente Produktion. Z. Für Wirtsch. Fabr. 2020, 115, 175–177. [Google Scholar] [CrossRef]

- Wessel, L.; Baiyere, A.; Ologeanu-Taddei, R.; Cha, J.; Blegind-Jensen, T. Unpacking the difference between digital transformation and IT-enabled organizational transformation. J. Assoc. Inf. Syst. 2021, 22, 102–129. [Google Scholar] [CrossRef]

- Holmström, J. From AI to digital transformation: The AI readiness framework. Bus. Horiz. 2022, 65, 329–339. [Google Scholar] [CrossRef]

- Szalavetz, A. Digitalisation, automation and upgrading in global value chains–factory economy actors versus lead companies. Post-Communist Econ. 2019, 31, 646–670. [Google Scholar] [CrossRef]

- Zimmerman, P.; Gilbert, T.; Salvatore, F. Digital engineering transformation across the Department of Defense. J. Def. Modeling Simul. 2019, 16, 325–338. [Google Scholar] [CrossRef]

- Kaletnik, G.; Lutkovska, S. Innovative Environmental Strategy for Sustainable Development. Eur. J. Sustain. Dev. 2020, 9, 89. [Google Scholar] [CrossRef]

- Correani, A.; De Massis, A.; Frattini, F.; Petruzzelli, A.M.; Natalicchio, A. Implementing a digital strategy: Learning from the experience of three digital transformation projects. Calif. Manag. Rev. 2020, 62, 37–56. [Google Scholar] [CrossRef]

- Shen, L.; Sun, C.; Ali, M. Role of servitization, digitalization, and innovation performance in manufacturing enterprises. Sustainability 2021, 13, 9878. [Google Scholar] [CrossRef]

- Kane, G. The technology fallacy: People are the real key to digital transformation. Res. Technol. Manag. 2019, 62, 44–49. [Google Scholar] [CrossRef]

- Son, K.J.; Son, H.R.; Park, B.; Kim, H.J.; Kim, C.B. A community-based intervention for improving medication adherence for elderly patients with hypertension in Korea. Int. J. Environ. Res. Public Health 2019, 16, 721. [Google Scholar] [CrossRef] [Green Version]

- Rengasamy, D.; Jafari, M.; Rothwell, B.; Chen, X.; Figueredo, G.P. Deep learning with dynamically weighted loss function for sensor-based prognostics and health management. Sensors 2020, 20, 723. [Google Scholar] [CrossRef] [Green Version]

- Feng, H.; Wang, F.; Song, G.; Liu, L. Digital Transformation on Enterprise Green Innovation: Effect and Transmission Mechanism. Int. J. Environ. Res. Public Health 2022, 19, 10614. [Google Scholar] [CrossRef]

- Shpak, N.; Kuzmin, O.; Dvulit, Z.; Onysenko, T.; Sroka, W. Digitalization of the marketing activities of enterprises: Case study. Information 2020, 11, 109. [Google Scholar] [CrossRef] [Green Version]

- Lin, T.C.; Sheng, M.L.; Jeng Wang, K. Dynamic capabilities for smart manufacturing transformation by manufacturing enterprises. Asian J. Technol. Innov. 2020, 28, 403–426. [Google Scholar] [CrossRef]

- Hanelt, A.; Bohnsack, R.; Marz, D.; Antunes Marante, C. A systematic review of the literature on digital transformation: Insights and implications for strategy and organizational change. J. Manag. Stud. 2021, 58, 1159–1197. [Google Scholar] [CrossRef]

- Maciag, R. Digital Transformation as an Epistemological Event: Predigital Transformation. Dialogue Univers. 2022, 32, 83–102. [Google Scholar] [CrossRef]

- Zhang, T.; Shi, Z.Z.; Shi, Y.R.; Chen, N.J. Enterprise digital transformation and production efficiency: Mechanism analysis and empirical research. Econ. Res. Ekon. Istraživanja 2022, 35, 2781–2792. [Google Scholar] [CrossRef]

- Solberg, E.; Traavik, L.E.; Wong, S.I. Digital mindsets: Recognizing and leveraging individual beliefs for digital transformation. Calif. Manag. Rev. 2020, 62, 105–124. [Google Scholar] [CrossRef]

- Pronchakov, Y.; Prokhorov, O.; Fedorovich, O. Concept of High-Tech Enterprise Development Management in the Context of Digital Transformation. Computation 2022, 10, 118. [Google Scholar] [CrossRef]

- Bican, P.M.; Brem, A. Digital business model, digital transformation, digital entrepreneurship: Is there a sustainable “digital”? Sustainability 2020, 12, 5239. [Google Scholar] [CrossRef]

- Giorgi, G.; Lecca, L.I.; Alessio, F.; Finstad, G.L.; Bondanini, G.; Lulli, L.G.; Arcangeli, G.; Mucci, N. COVID-19-related mental health effects in the workplace: A narrative review. Int. J. Environ. Res. Public Health 2020, 17, 7857. [Google Scholar] [CrossRef]

- Priyono, A.; Moin, A.; Putri, V.N.A.O. Identifying digital transformation paths in the business model of SMEs during the COVID-19 pandemic. J. Open Innov. Technol. Mark. Complex. 2020, 6, 104. [Google Scholar] [CrossRef]

- Lv, Z.; Singh, A.K. Big data analysis of internet of things system. ACM Trans. Internet Technol. 2021, 21, 1–15. [Google Scholar] [CrossRef]

- Mehmood, I.; Ullah, A.; Muhammad, K.; Deng, D.J.; Meng, W.; Al-Turjman, F.; Sajjad, M.; de Albuquerque, V.H.C. Efficient image recognition and retrieval on IoT-assisted energy-constrained platforms from big data repositories. IEEE Internet Things J. 2019, 6, 9246–9255. [Google Scholar] [CrossRef]

- Sanchis, R.; García-Perales, Ó.; Fraile, F.; Poler, R. Low-code as enabler of digital transformation in manufacturing industry. Appl. Sci. 2019, 10, 12. [Google Scholar] [CrossRef] [Green Version]

- Lutfi, A.; Alsyouf, A.; Almaiah, M.A.; Alrawad, M.; Abdo, A.A.K.; Al-Khasawneh, A.L.; Ibrahim, N.; Saad, M. Factors Influencing the Adoption of Big Data Analytics in the Digital Transformation Era: Case Study of Jordanian SMEs. Sustainability 2022, 14, 1802. [Google Scholar] [CrossRef]

- Dall’Ora, N.; Alamin, K.; Fraccaroli, E.; Poncino, M.; Quaglia, D.; Vinco, S. Digital transformation of a production line: Network design, online data collection and energy monitoring. IEEE Trans. Emerg. Top. Comput. 2021, 10, 46–59. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Z. Application of big data technology in agricultural Internet of Things. Int. J. Distrib. Sens. Netw. 2019, 15, 1550147719881610. [Google Scholar] [CrossRef]

- Li, W.; Zhu, J.; Zhang, Y.; Zhang, S. Design and implementation of intelligent traffic and big data mining system based on internet of things. J. Intell. Fuzzy Syst. 2020, 38, 1967–1975. [Google Scholar] [CrossRef]

- Willner, A.; Gowtham, V. Toward a reference architecture model for industrial edge computing. IEEE Commun. Stand. Mag. 2020, 4, 42–48. [Google Scholar] [CrossRef]

- Dayan, V.; Chileshe, N.; Hassanli, R. A scoping review of information-modeling development in bridge management systems. J. Constr. Eng. Manag. 2022, 148, 03122006. [Google Scholar] [CrossRef]

- Gu, H.; Fu, X.; Zhu, Y.; Chen, Y.; Huang, L. Analysis of social and environmental impact of earth-rock dam breaks based on a fuzzy comprehensive evaluation method. Sustainability 2020, 12, 6239. [Google Scholar] [CrossRef]

- Peizhi, R.; Wei, L.; Ran, B.; Ping, M. A Simulation Credibility Assessment Method Based on Improved Fuzzy Comprehensive Evaluation. J. Syst. Simul. 2020, 32, 2469. [Google Scholar] [CrossRef]

- Wang, Z.; Li, M.; Lu, J.; Cheng, X. Business Innovation based on artificial intelligence and Blockchain technology. Inf. Process. Manag. 2022, 59, 102759. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Wang, Z.; Jiang, S.; Ding, W.; Wang, Y.; Dong, X. Optimization of Work Environment and Community Labor Health Based on Digital Model—Empirical Evidence from Developing Countries. Int. J. Environ. Res. Public Health 2022, 19, 13114. https://doi.org/10.3390/ijerph192013114

Gao S, Wang Z, Jiang S, Ding W, Wang Y, Dong X. Optimization of Work Environment and Community Labor Health Based on Digital Model—Empirical Evidence from Developing Countries. International Journal of Environmental Research and Public Health. 2022; 19(20):13114. https://doi.org/10.3390/ijerph192013114

Chicago/Turabian StyleGao, Shiya, Zeyu Wang, Shaoxiang Jiang, Wen Ding, Yuchen Wang, and Xiufang Dong. 2022. "Optimization of Work Environment and Community Labor Health Based on Digital Model—Empirical Evidence from Developing Countries" International Journal of Environmental Research and Public Health 19, no. 20: 13114. https://doi.org/10.3390/ijerph192013114

APA StyleGao, S., Wang, Z., Jiang, S., Ding, W., Wang, Y., & Dong, X. (2022). Optimization of Work Environment and Community Labor Health Based on Digital Model—Empirical Evidence from Developing Countries. International Journal of Environmental Research and Public Health, 19(20), 13114. https://doi.org/10.3390/ijerph192013114