Enhancing Methane Recovery with Cryogenic Liquid CO2 Cyclic Injection: Determination of Cyclic Injection Parameters

Abstract

:1. Introduction

2. Experimental Section

2.1. Specimen Preparation

2.2. Experimental System and Equipment

2.3. Experimental Procedures

3. Evaluation of the Experimental Data

3.1. Porosity Calculated from the T2 Spectra

3.2. NMR Permeability

4. Results and Discussion

4.1. Variation in the Temperature and Pressure of the Freeze–Thaw Container

4.2. T2 Spectrum Analysis of Coal Samples before and after L-CO2 Treatment

4.3. Porosity Change in Coal Samples before and after L-CO2 Treatment

4.4. NMR Permeability Change Analysis

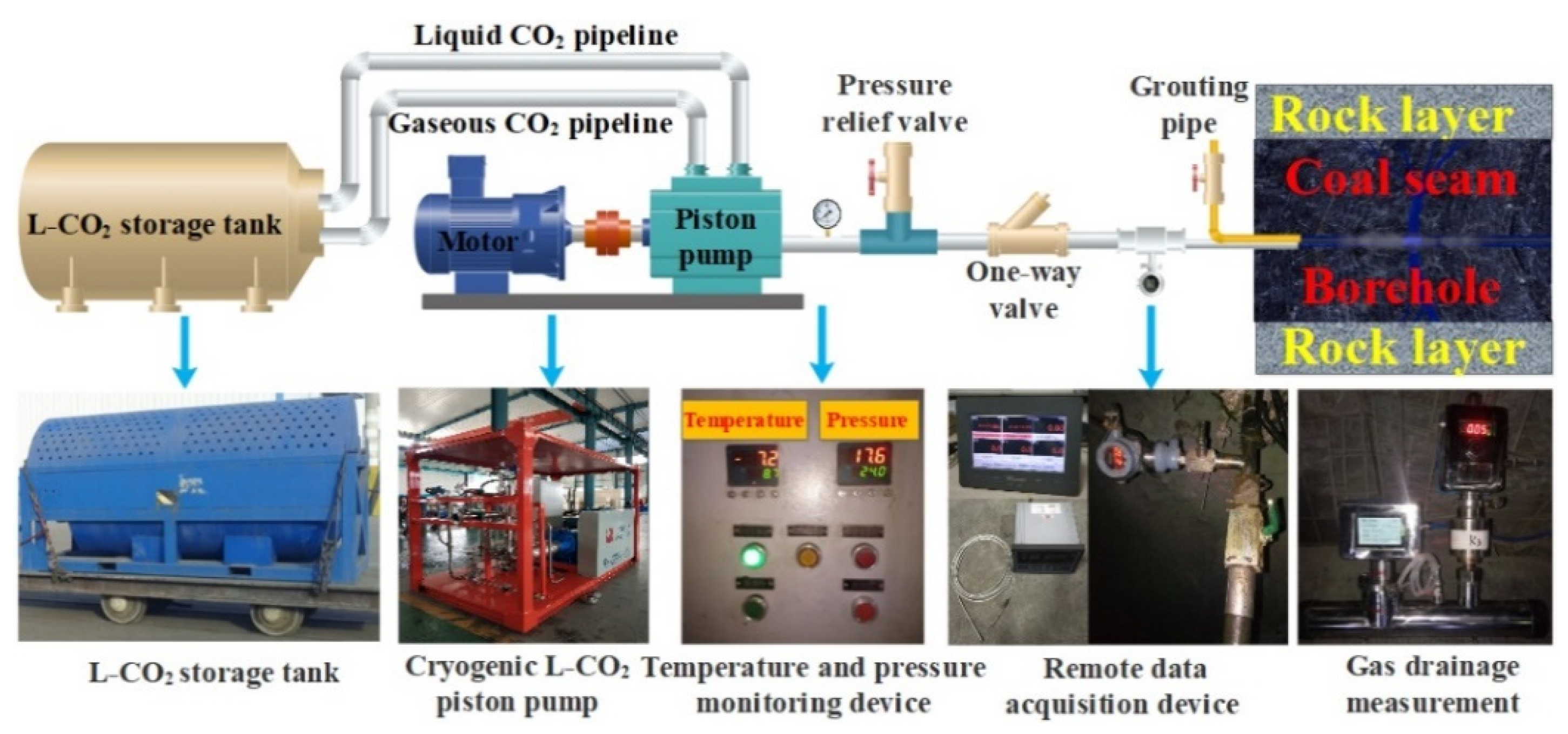

5. Field

5.1. Field Situation

5.2. Borehole Layout

5.3. Test Results and Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wen, H.; Wang, H.; Fan, S.; Li, Z.; Chen, J.; Cheng, X.; Cheng, B.; Yu, Z. Improving coal seam permeability and displacing methane by injecting liquid CO2: An experimental study. Fuel 2020, 281, 118747. [Google Scholar] [CrossRef]

- Li, Z.; Wei, G.; Liang, R.; Shi, P.; Wen, H.; Zhou, W. LCO2-ECBM technology for preventing coal and gas outburst: Integrated effect of permeability improvement and gas displacement. Fuel 2021, 285, 119219. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, D.; Zeng, S.; Zhang, S.; Wang, D.; Wang, F. An enhanced coalbed methane recovery technique based on CO2 phase transition jet coal-breaking behavior. Fuel 2020, 265, 116912. [Google Scholar] [CrossRef]

- Li, Z.; Wang, F.; Shu, C.-M.; Wen, H.; Wei, G.; Liang, R. Damage effects on coal mechanical properties and micro-scale structures during liquid CO2-ECBM process. J. Nat. Gas Sci. Eng. 2020, 83, 103579. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Bai, G.; Zeng, X.; Li, X.; Zhou, X.; Cheng, Y.; Linghu, J. Influence of Carbon Dioxide on the Adsorption of Methane by Coal Using Low-Field Nuclear Magnetic Resonance. Energy Fuels 2020, 34, 6113–6123. [Google Scholar] [CrossRef]

- Song, X.; Guo, Y.; Zhang, J.; Sun, N.; Shen, G.; Chang, X.; Yu, W.; Tang, Z.; Chen, W.; Wei, W.; et al. Fracturing with Carbon Dioxide: From Microscopic Mechanism to Reservoir Application. Joule 2019, 3, 1913–1926. [Google Scholar] [CrossRef]

- Wen, H.; Cheng, X.; Chen, J.; Zhang, C.; Yu, Z.; Li, Z.; Fan, S.; Wei, G.; Cheng, B. Micro-pilot test for optimized pre-extraction boreholes and enhanced coalbed methane recovery by injection of liquid carbon dioxide in the Sangshuping coal mine. Process Saf. Environ. Prot. 2020, 136, 39–48. [Google Scholar] [CrossRef]

- Wei, G.; Wen, H.; Deng, J.; Ma, L.; Li, Z.; Lei, C.; Fan, S.; Liu, Y. Liquid CO2 injection to enhance coalbed methane recovery: An experiment and in-situ application test. Fuel 2021, 284, 119043. [Google Scholar] [CrossRef]

- Lin, B.; Yan, F.; Zhu, C.; Zhou, Y.; Zou, Q.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Yang, W.; Hong, Y.; Wang, Z. A fully coupled electromagnetic-thermal-mechanical model for coalbed methane extraction with microwave heating. J. Nat. Gas Sci. Eng. 2017, 46, 830–844. [Google Scholar] [CrossRef]

- Zhai, C.; Yu, X.; Xiang, X.; Li, Q.; Wu, S.; Xu, J. Experimental study of pulsating water pressure propagation in CBM reservoirs during pulse hydraulic fracturing. J. Nat. Gas Sci. Eng. 2015, 25, 15–22. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Qin, L.; Wu, S.; Sun, Y.; Dong, R. Characteristics of Pores under the Influence of Cyclic Cryogenic Liquid Carbon Dioxide Using Low-Field Nuclear Magnetic Resonance. Geofluids 2018, 2018, 1682125. [Google Scholar] [CrossRef]

- Mosleh, M.H.; Turner, M.; Sedighi, M.; Vardon, P.J. Carbon dioxide flow and interactions in a high rank coal: Permeability evolution and reversibility of reactive processes. Int. J. Greenh. Gas Control 2018, 70, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Yin, G.; Deng, B.; Li, M.; Zhang, D.; Wang, W.; Li, W.; Shang, D. Impact of injection pressure on CO2–enhanced coalbed methane recovery considering mass transfer between coal fracture and matrix. Fuel 2017, 196, 288–297. [Google Scholar] [CrossRef]

- Vishal, V.; Singh, T.; Ranjith, P. Influence of sorption time in CO2-ECBM process in Indian coals using coupled numerical simulation. Fuel 2015, 139, 51–58. [Google Scholar] [CrossRef]

- Du, X.; Cheng, Y.; Liu, Z.; Yin, H.; Wu, T.; Huo, L.; Shu, C. CO2 and CH4 adsorption on different rank coals: A thermodynamics study of surface potential, Gibbs free energy change and entropy loss. Fuel 2021, 283, 118886. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Y.; Wang, Y.; Wang, L.; Li, W. Experimental investigation of CO2 injection into coal seam reservoir at in-situ stress conditions for enhanced coalbed methane recovery. Fuel 2019, 236, 709–716. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Wang, K.; Wang, G.; Ren, T.; Cheng, Y. Methane and CO2 sorption hysteresis on coal: A critical review. Int. J. Coal Geol. 2014, 132, 60–80. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Z.; Chen, X.; Chen, X.; Wang, L. Increasing permeability of coal seams using the phase energy of liquid carbon dioxide. J. CO2 Util. 2017, 19, 112–119. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, J.; Zhai, H.; Fu, G.; Tian, L.; Liu, S. CO2 gas fracturing: A novel reservoir stimulation technology in low permeability gassy coal seams. Fuel 2017, 203, 197–207. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Tang, J.; Zhou, Z.; Liao, Y. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- Jiang, Y.; Qin, C.; Kang, Z.; Zhou, J.; Li, Y.; Liu, H.; Song, X. Experimental study of supercritical CO2 fracturing on initiation pressure and fracture propagation in shale under different triaxial stress conditions. J. Nat. Gas Sci. Eng. 2018, 55, 382–394. [Google Scholar] [CrossRef]

- Deng, B.; Yin, G.; Zhang, D.; Li, M.; Liu, Y.; Lu, J. Experimental investigation of fracture propagation induced by carbon dioxide and water in coal seam reservoirs. Powder Technol. 2018, 338, 847–856. [Google Scholar] [CrossRef]

- Wen, H.; Li, Z.; Wang, Z.; Ma, L.; Guo, Y.; Wang, X. Experiment on the liquid CO2 fracturing process for increasing permeability and the characteristics of crack propagation in coal seam. J. China Coal Soc. 2016, 41, 1793–2799. [Google Scholar]

- Su, E.; Liang, Y.; Chang, X.; Zou, Q.; Xu, M.; Sasmito, A.P. Effects of cyclic saturation of supercritical CO2 on the pore structures and mechanical properties of bituminous coal: An experimental study. J. CO2 Util. 2020, 40, 101208. [Google Scholar] [CrossRef]

- Song, Y.; Zou, Q.; Su, E.; Zhang, Y.; Sun, Y. Changes in the microstructure of low-rank coal after supercritical CO2 and water treatment. Fuel 2020, 279, 118493. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, J.; Liu, D.; Chen, J.; Pan, Z. A new application of NMR in characterization of multiphase methane and adsorption capacity of shale. Int. J. Coal Geol. 2019, 201, 76–85. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J.; Yu, G.; Sun, Y. Changes in the petrophysical properties of coal subjected to liquid nitrogen freeze-thaw—A nuclear magnetic resonance investigation. Fuel 2017, 194, 102–114. [Google Scholar] [CrossRef]

- Qin, L.; Li, S.; Zhai, C.; Lin, H.; Zhao, P.; Shi, Y.; Bai, Y. Changes in the pore structure of lignite after repeated cycles of liquid nitrogen freezing as determined by nitrogen adsorption and mercury intrusion. Fuel 2020, 267, 117214. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Ranjith, P.G.; Sun, Y.; Qin, L. Petrological and ultrasonic velocity changes of coals caused by thermal cycling of liquid carbon dioxide in coalbed methane recovery. Fuel 2019, 249, 15–26. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z.; Zhou, Y. Application of nuclear magnetic resonance (NMR) in coalbed methane and shale reservoirs: A review. Int. J. Coal Geol. 2020, 218, 103261. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Petrophysical characterization of Chinese coal cores with heat treatment by nuclear magnetic resonance. Fuel 2013, 108, 292–302. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Sun, X.; Yao, Y.; Liu, D.; Zhou, Y. Investigations of CO2-water wettability of coal: NMR relaxation method. Int. J. Coal Geol. 2018, 188, 38–50. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Liu, J.; Xie, S. Assessing the water migration and permeability of large intact bituminous and anthracite coals using NMR relaxation spectrometry. Transp. Porous Med. 2015, 107, 527–542. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Liu, S.; Qin, L.; Dong, R. Investigation of temperature effects from LCO2 with different cycle parameters on the coal pore variation based on infrared thermal imagery and low-field nuclear magnetic resonance. Fuel 2018, 215, 528–540. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J.; Wu, S.; Dong, R. Fractal dimensions of low rank coal subjected to liquid nitrogen freeze-thaw based on nuclear magnetic resonance applied for coalbed methane recovery. Powder Technol. 2018, 325, 11–20. [Google Scholar] [CrossRef]

- Zhai, C.; Qin, L.; Liu, S.; Xu, J.; Tang, Z.; Wu, S. Pore Structure in Coal: Pore Evolution after Cryogenic Freezing with Cyclic Liquid Nitrogen Injection and Its Implication on Coalbed Methane Extraction. Energy Fuels 2016, 30, 6009–6020. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, D.; Wen, H.; Cheng, X.; Liu, X.; Yu, Z.; Hu, B. Enhancing coalbed methane recovery with liquid CO2 fracturing in underground coal mine: From experiment to field application. Fuel 2021, 290, 119793. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, X.; Guo, J.; Zhang, D.; Wang, B. Experimental Study on CH4 Displacement from Coal Seam Fractured by Liquid CO2. Int. J. Heat Technol. 2019, 37, 212–218. [Google Scholar] [CrossRef]

| Core | Coal Type | Diameter (mm) | Length (mm) | Density (kg/m3) | Proximate Analysis (wt%) | Water-Saturated Porosity (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vad | FCad | ||||||

| DNH | Lignite | 9.9 | 19.8 | 1.23 | 8.80 | 36.62 | 24.68 | 29.90 | 11.3 |

| ZL | Gas coal | 10.0 | 20.1 | 1.36 | 2.06 | 8.75 | 32.28 | 56.91 | 9.45 |

| ZJ | 1/3 Coking coal | 9.9 | 19.9 | 1.41 | 1.64 | 11.35 | 32.70 | 54.31 | 7.38 |

| Core | Coal Type | Relationship between φt and Nc Fitting Functions | a | b | R2 |

|---|---|---|---|---|---|

| DNH | Lignite | φt = a·Nc + b | 0.83 | 12.95 | 0.96 |

| ZL | Gas coal | 0.52 | 0.88 | 0.88 | |

| ZJ | 1/3 Coking coal | 0.24 | 0.96 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Fan, S. Enhancing Methane Recovery with Cryogenic Liquid CO2 Cyclic Injection: Determination of Cyclic Injection Parameters. Int. J. Environ. Res. Public Health 2022, 19, 13155. https://doi.org/10.3390/ijerph192013155

Zhang D, Fan S. Enhancing Methane Recovery with Cryogenic Liquid CO2 Cyclic Injection: Determination of Cyclic Injection Parameters. International Journal of Environmental Research and Public Health. 2022; 19(20):13155. https://doi.org/10.3390/ijerph192013155

Chicago/Turabian StyleZhang, Duo, and Shixing Fan. 2022. "Enhancing Methane Recovery with Cryogenic Liquid CO2 Cyclic Injection: Determination of Cyclic Injection Parameters" International Journal of Environmental Research and Public Health 19, no. 20: 13155. https://doi.org/10.3390/ijerph192013155