Numerical Simulation of an Improved Updraft Biomass Gasifier Based on Aspen Plus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

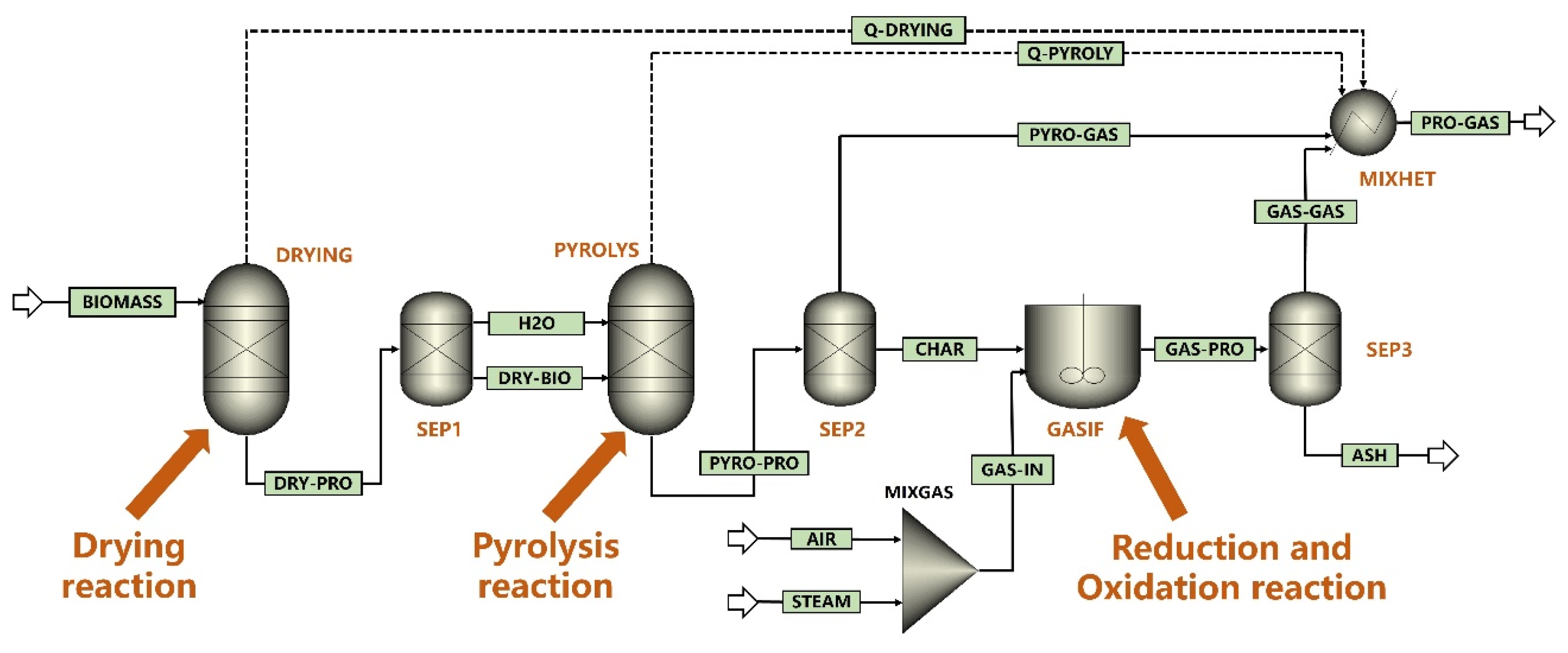

2.2. Model Construction

2.3. Evaluation Indexes

- (1)

- Product yield

- (2)

- Gasification efficiency

- (3)

- Air ratio

3. Results and Discussion

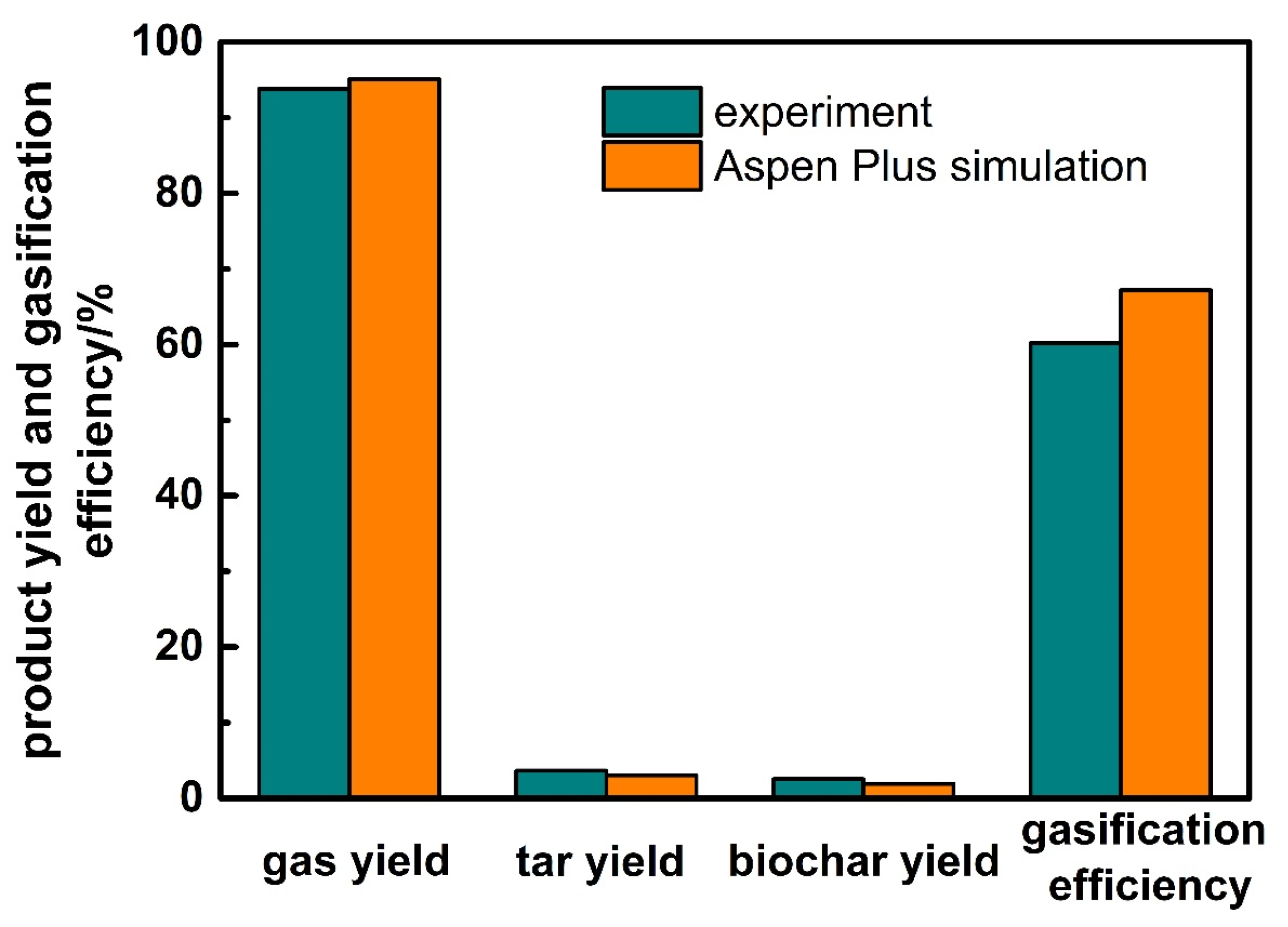

3.1. Model Validation

3.2. Comparison between Conventional and Improved Updraft Gasifier

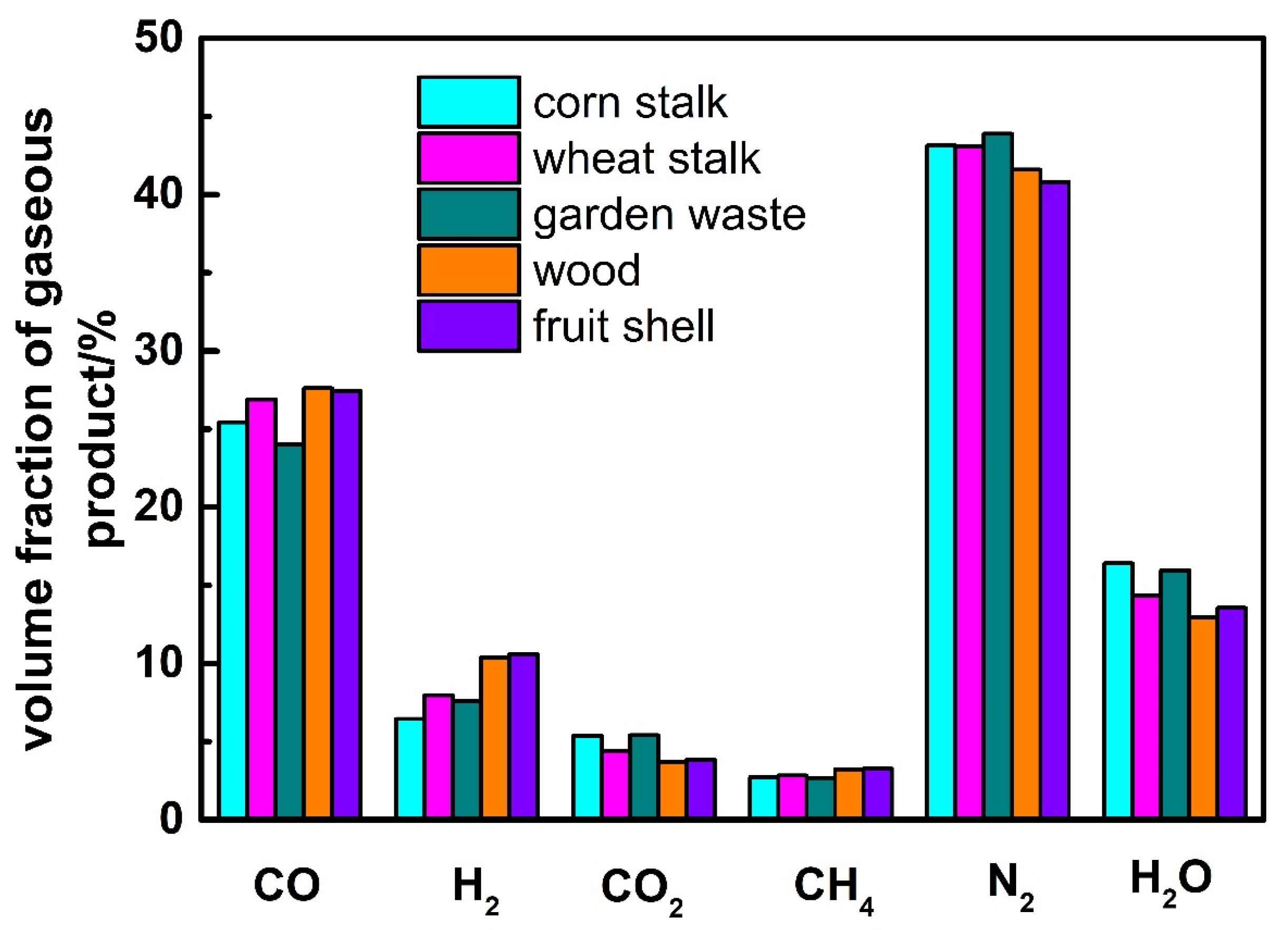

3.3. Effect of Biomass Types

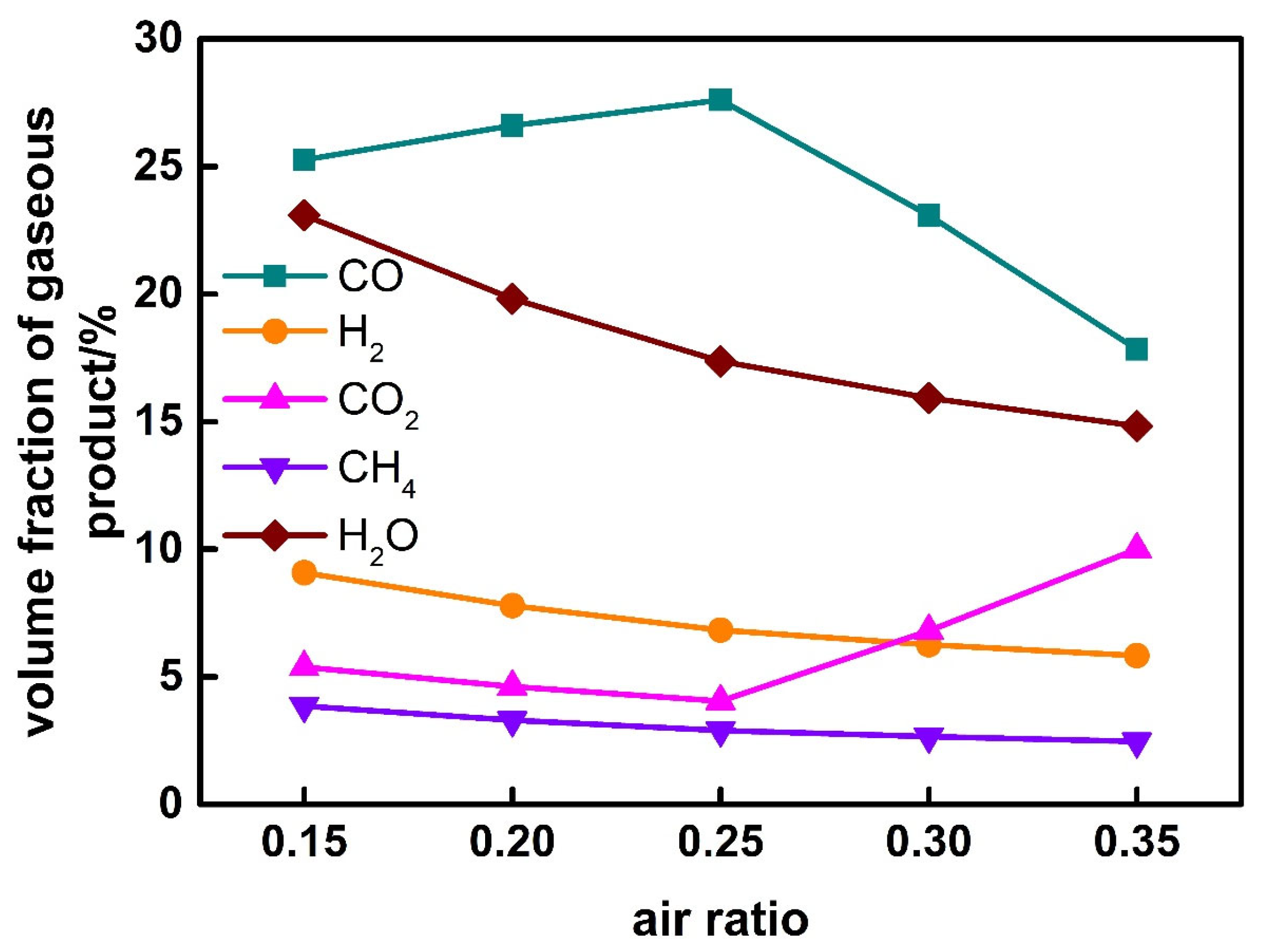

3.4. Effect of Air Ratio

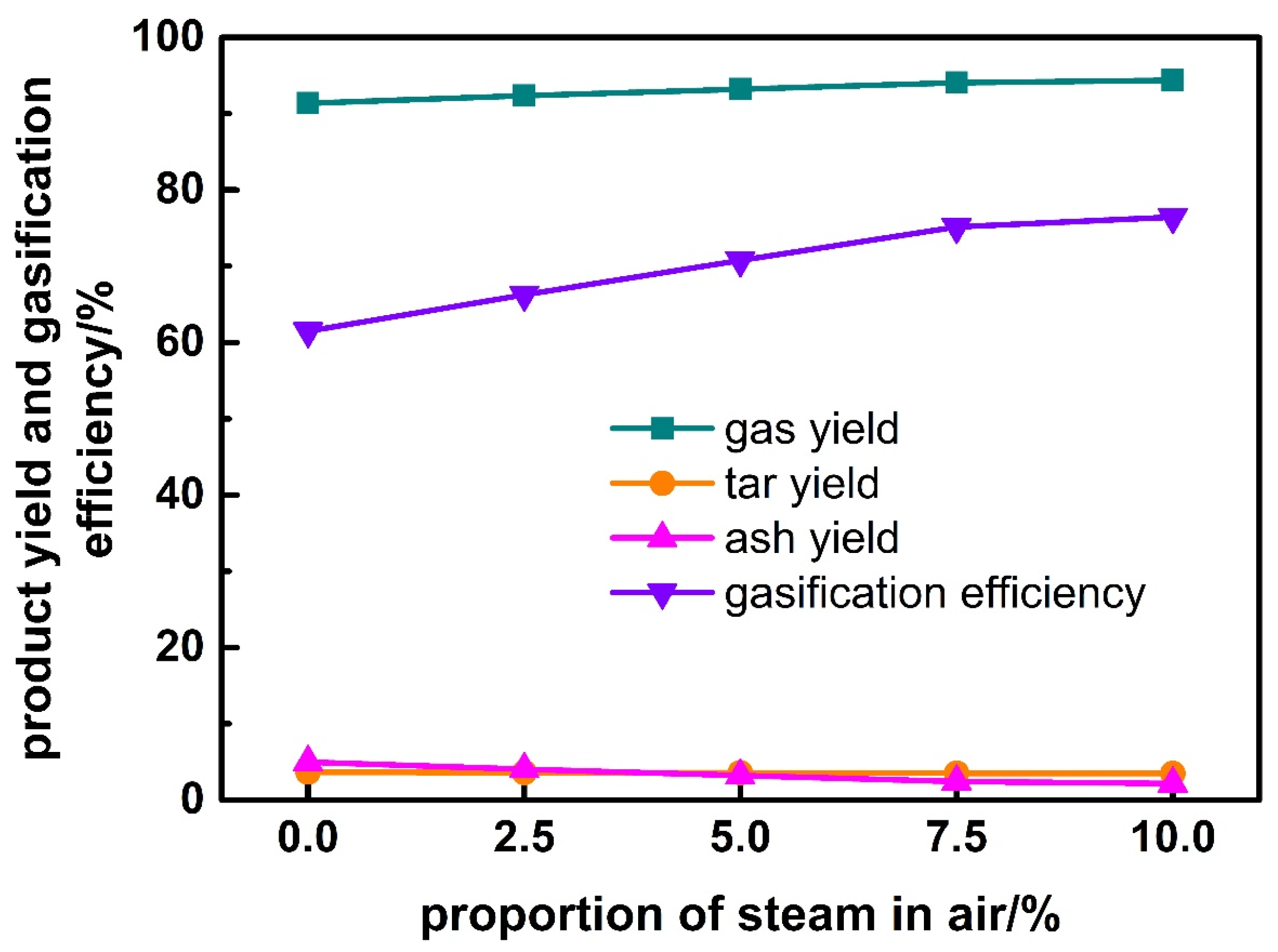

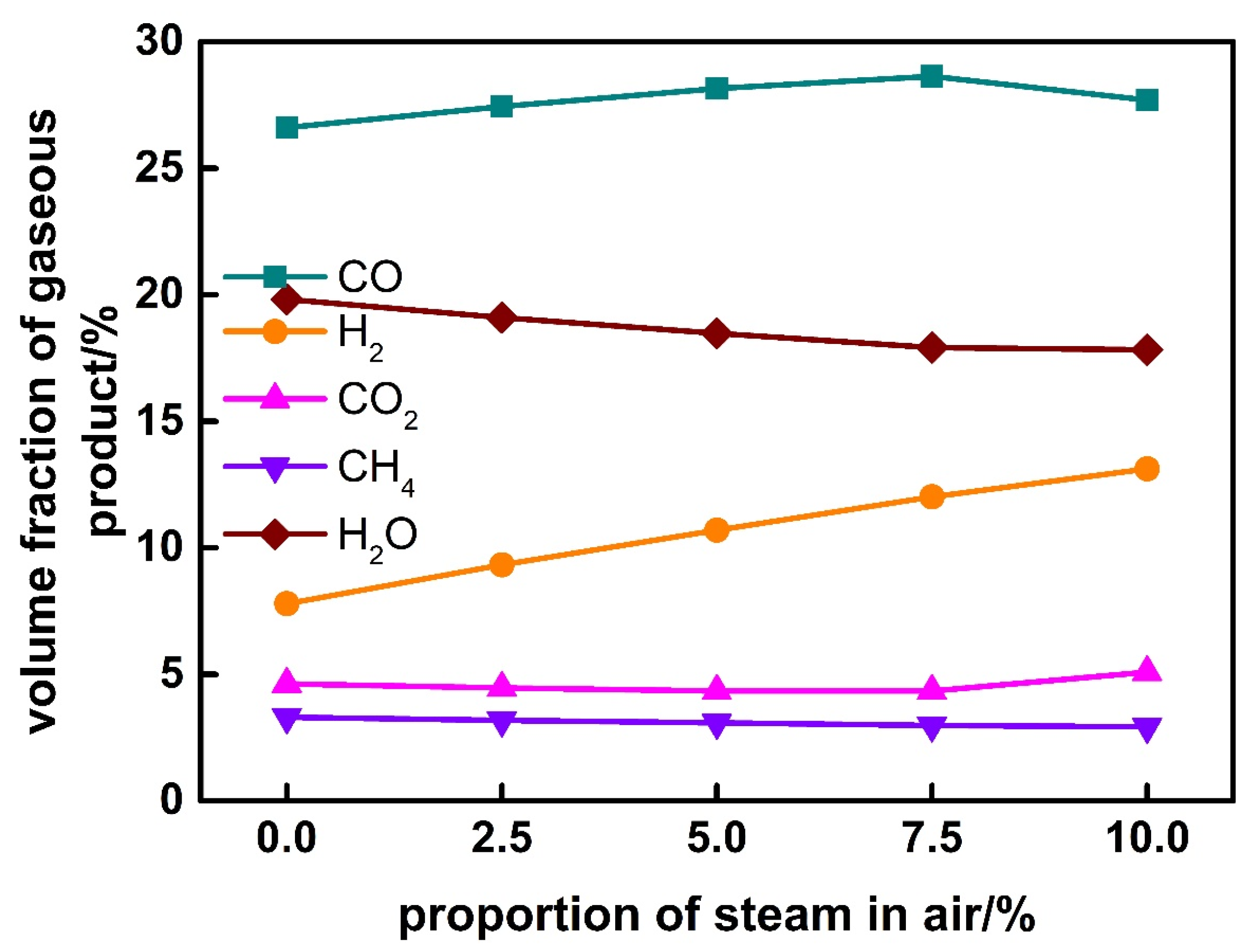

3.5. Effect of Steam Proportion in Air

4. Conclusions

- A comprehensive Aspen Plus model of the improved updraft gasifier is constructed based on the RYield and RCSTR reactor. The tar prediction model is constructed, and the yield of tar is determined by the volatile of biomass and gasification temperature. The Aspen Plus simulation results agree very well with experiment results for the product yields and gasification efficiency, which shows the accuracy of the Aspen Plus model.

- The comparison between the conventional and improved updraft gasifier by this model shows that the tar content in syngas of the improved gasifier is much lower than that of the conventional one, which shows the novelty and superiority of the improved updraft gasifier.

- For the five different kinds of biomass, the gas yield is: fruit shell > corn stalk > wood > wheat stalk > garden waste, and biochar yield is the opposite. Wheat stalk has the highest efficiency of 70.2%, while wood has the lowest of 65.3%.

- With the increase of air ratio, the gas yield increases while the tar and biochar yield decrease. Gasification efficiency increases firstly and then decreases, and the inflection point occurs when air ratio is about 0.25, and the optimum steam proportion in the air is 7.5%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; Chang, J.; Guan, Y.; Chen, H.; Yang, Y.; Jiang, J. Lignocellulosic biomass gasification technology in China. Renew. Energy 2013, 49, 175–184. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Alam, M.T.; Krishna, B.B.; Bhaskar, T.; Perkins, G. A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Eden, M.R. Recent advances in optimal design of thermochemical conversion of biomass to chemicals and liquid fuels. Curr. Opin. Chem. Eng. 2015, 10, 70–76. [Google Scholar] [CrossRef]

- Samiran, N.A.; Jaafar, M.N.M.; Ng, J.; Lam, S.S.; Chong, C.T. Progress in biomass gasification technique—With focus on Malaysian palm biomass for syngas production. Renew. Sustain. Energy Rev. 2016, 62, 1047–1062. [Google Scholar] [CrossRef]

- Goodman, B.A. Utilization of waste straw and husks from rice production: A review. J. Bioresour. Bioprod. 2020, 5, 143–162. [Google Scholar] [CrossRef]

- Narnaware, S.L.; Panwar, N.L. Biomass gasification for climate change mitigation and policy framework in India: A review. Bioresour. Technol. Rep. 2022, 17, 100892. [Google Scholar] [CrossRef]

- Saxena, R.C.; Seal, D.; Kumar, S.; Goyal, H.B. Thermo-chemical routes for hydrogen rich gas from biomass: A review. Renew. Sustain. Energy Rev. 2008, 12, 1909–1927. [Google Scholar] [CrossRef]

- Kong, S.; Loh, S.; Bachmann, R.T.; Rahim, S.A.; Salimon, J. Biochar from oil palm biomass: A review of its potential and challenges. Renew. Sustain. Energy Rev. 2014, 39, 729–739. [Google Scholar] [CrossRef]

- Pandey, B.; Prajapati, Y.K.; Sheth, P.N. Recent progress in thermochemical techniques to produce hydrogen gas from biomass: A state of the art review. Int. J. Hydrog. Energy 2019, 44, 25384–25415. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of biomass lignin to high-value polyurethane: A review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and Application of Granular Activated Carbon from Biomass Waste Materials for Water Treatment: A Review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Ke, C.; Shi, C.; Zhang, Y.; Guang, M.; Li, B. Energy conversion performances during biomass air gasification process under microwave irradiation. Int. J. Hydrogen Energy 2022, 47, 31833–31842. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Narayanan, K.S. Hydrogen production from steam gasification of biomass: Influence of process parameters on hydrogen yield—A review. Renew. Energy 2014, 66, 570–579. [Google Scholar] [CrossRef]

- Shamsul, N.S.; Kamarudin, S.K.; Rahman, N.A.; Kofli, N.T. An overview on the production of bio-methanol as potential renewable energy. Renew. Sustain. Energy Rev. 2014, 33, 578–588. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Q.; Bai, Z.; Xie, G.; Zheng, J. A distributed cogeneration system with a two-stage solar-driven biomass gasifier for heating, power and hydrogen in Northern China. Energy Procedia 2018, 152, 1057–1062. [Google Scholar] [CrossRef]

- Gabbrielli, R.; Barontini, F.; Frigo, S.; Bressan, L. Numerical analysis of bio-methane production from biomass-sewage sludge oxy-steam gasification and methanation process. Appl. Energy 2022, 307, 118292. [Google Scholar] [CrossRef]

- Quintero-Coronel, D.A.; Lenis-Rodas, Y.A.; Corredor, L.; Perreault, P.; Bula, A.; Gonzalez-Quiroga, A. Co-gasification of biomass and coal in a top-lit updraft fixed bed gasifier: Syngas composition and its interchangeability with natural gas for combustion applications. Fuel 2022, 316, 123394. [Google Scholar] [CrossRef]

- Tezer, Ö.; Karabağ, N.; Öngen, A.; Çolpan, C.Ö.; Ayol, A. Biomass gasification for sustainable energy production: A review. Int. J. Hydrog. Energy 2022, 47, 15419–15433. [Google Scholar] [CrossRef]

- Ghorbani, S.; Atashkari, K.; Borji, M. Three-stage model-based evaluation of a downdraft biomass gasifier. Renew. Energy 2022, 194, 734–745. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, L.; Zhang, M.; Han, Z.; Jia, X.; Bai, D.; Duo, W.; Bi, X.; Abudula, A.; Guan, G.; et al. A two-stage circulated fluidized bed process to minimize tar generation of biomass gasification for fuel gas production. Renew. Energy 2022, 323, 119639. [Google Scholar] [CrossRef]

- Hejazi, B. Heat integration and waste minimization of biomass steam gasification in a bubbling fluidized bed reactor. Biomass Bioenergy 2022, 159, 106409. [Google Scholar] [CrossRef]

- Sharma, P.; Gupta, B.; Pandey, M.; Singh Bisen, K.; Baredar, P. Downdraft biomass gasification: A review on concepts, designs analysis, modelling and recent advances. Mater. Today Proc. 2021, 46, 5333–5341. [Google Scholar] [CrossRef]

- Fazil, A.; Kumar, S.; Mahajani, S.M. Downdraft co-gasification of high ash biomass and plastics. Energy 2022, 243, 123055. [Google Scholar] [CrossRef]

- Song, H.; Yang, G.; Xue, P.; Li, Y.; Zou, J.; Wang, S.; Yang, H.; Chen, H. Recent development of biomass gasification for H2 rich gas production. Appl. Energy Combust. Sci. 2022, 10, 100059. [Google Scholar] [CrossRef]

- Nunes, L.J.R. Biomass gasification as an industrial process with effective proof-of-concept: A comprehensive review on technologies, processes and future developments. Results Eng. 2022, 14, 100408. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on biomass gasification: Gasifiers, gasifying mediums, and operational parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Patuzzi, F.; Basso, D.; Vakalis, S.; Antolini, D.; Piazzi, S.; Benedetti, V.; Cordioli, E.; Baratieri, M. State-of-the-art of small-scale biomass gasification systems: An extensive and unique monitoring review. Energy 2021, 223, 120039. [Google Scholar] [CrossRef]

- Kangas, P.; Hannula, I.; Koukkari, P.; Hupa, M. Modelling super-equilibrium in biomass gasification with the constrained Gibbs energy method. Fuel 2014, 129, 86–94. [Google Scholar] [CrossRef]

- Ayub, H.M.U.; Qyyum, M.A.; Qadeer, K.; Binns, M.; Tawfik, A.; Lee, M. Robustness enhancement of biomass steam gasification thermodynamic models for biohydrogen production: Introducing new correction factors. J. Clean. Prod. 2021, 321, 128954. [Google Scholar] [CrossRef]

- Li, H.; Zhou, N.; Dai, L.; Cheng, Y.; Cobb, K.; Chen, P.; Ruan, R. Effect of lime mud on the reaction kinetics and thermodynamics of biomass pyrolysis. Bioresour. Technol. 2020, 310, 123475. [Google Scholar] [CrossRef]

- Felix, C.B.; Chen, W.; Ubando, A.T.; Park, Y.; Lin, K.A.; Pugazhendhi, A.; Nguyen, T.; Dong, C. A comprehensive review of thermogravimetric analysis in lignocellulosic and algal biomass gasification. Chem. Eng. J. 2022, 445, 136730. [Google Scholar] [CrossRef]

- Ajorloo, M.; Ghodrat, M.; Scott, J.; Strezov, V. Recent advances in thermodynamic analysis of biomass gasification: A review on numerical modelling and simulation. J. Energy Inst. 2022, 102, 395–419. [Google Scholar] [CrossRef]

- Naaz, Z.; Ravi, M.R.; Kohli, S. Modelling and simulation of downdraft biomass gasifier: Issues and challenges. Biomass Bioenergy 2022, 162, 106483. [Google Scholar] [CrossRef]

- Ismail, T.M.; El-Salam, M.A. Numerical and experimental studies on updraft gasifier HTAG. Renew. Energy 2015, 78, 484–497. [Google Scholar] [CrossRef]

- Cerinski, D.; Ferreiro, A.I.; Baleta, J.; Costa, M.; Zimbardi, F.; Cerone, N.; Wang, J. Modelling the biomass updraft gasification process using the combination of a pyrolysis kinetic model and a thermodynamic equilibrium model. Energy Rep. 2021, 7, 8051–8061. [Google Scholar] [CrossRef]

- Umeki, K.; Namioka, T.; Yoshikawa, K. Analysis of an updraft biomass gasifier with high temperature steam using a numerical model. Appl. Energy 2012, 90, 38–45. [Google Scholar] [CrossRef]

- Yu, J.; Smith, J.D. Validation and application of a kinetic model for biomass gasification simulation and optimization in updraft gasifiers. Chem. Eng. Processing-Process Intensif. 2018, 125, 214–226. [Google Scholar] [CrossRef]

- Rosha, P.; Kumar, S.; Ibrahim, H. Sensitivity analysis of biomass pyrolysis for renewable fuel production using Aspen Plus. Energy 2022, 247, 123545. [Google Scholar] [CrossRef]

| Components | Proximate Analysis (wt%) | Ultimate Analysis (wt%) | LHV (MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vad | FCad | Cad | Had | Oad | Nad | Sad | ||

| Corn stalk | 8.20 | 4.57 | 73.51 | 13.72 | 43.69 | 5.04 | 37.43 | 0.92 | 0.15 | 15.73 |

| Wheat stalk | 5.47 | 8.69 | 66.54 | 19.30 | 43.81 | 5.23 | 36.00 | 0.67 | 0.13 | 16.19 |

| Garden waste | 9.54 | 10.07 | 65.12 | 15.27 | 41.03 | 4.87 | 32.69 | 1.59 | 0.21 | 15.15 |

| Wood | 3.16 | 1.24 | 80.48 | 15.12 | 51.72 | 6.13 | 37.42 | 0.25 | 0.08 | 19.70 |

| Fruit shell | 3.63 | 0.82 | 76.95 | 18.60 | 49.43 | 6.34 | 39.42 | 0.29 | 0.07 | 18.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Shen, L.; Xu, P.; Yuan, H.; Hu, M.; Qi, J.; Chen, Y. Numerical Simulation of an Improved Updraft Biomass Gasifier Based on Aspen Plus. Int. J. Environ. Res. Public Health 2022, 19, 17089. https://doi.org/10.3390/ijerph192417089

Zhu F, Shen L, Xu P, Yuan H, Hu M, Qi J, Chen Y. Numerical Simulation of an Improved Updraft Biomass Gasifier Based on Aspen Plus. International Journal of Environmental Research and Public Health. 2022; 19(24):17089. https://doi.org/10.3390/ijerph192417089

Chicago/Turabian StyleZhu, Fugang, Laihong Shen, Pengcheng Xu, Haoran Yuan, Ming Hu, Jingwei Qi, and Yong Chen. 2022. "Numerical Simulation of an Improved Updraft Biomass Gasifier Based on Aspen Plus" International Journal of Environmental Research and Public Health 19, no. 24: 17089. https://doi.org/10.3390/ijerph192417089

APA StyleZhu, F., Shen, L., Xu, P., Yuan, H., Hu, M., Qi, J., & Chen, Y. (2022). Numerical Simulation of an Improved Updraft Biomass Gasifier Based on Aspen Plus. International Journal of Environmental Research and Public Health, 19(24), 17089. https://doi.org/10.3390/ijerph192417089