A Gas Pressure Prediction Model of the Excavation Face Based on Gas Emission

Abstract

:1. Introduction

2. Gas Pressure Model Based on Gas Emission

2.1. Gas Emission Model

2.1.1. Intensity of Gas Emission from Collapsed Coal

2.1.2. Intensity of Gas Emission from the Coal Wall

2.1.3. Model for Continuous Gas Emission

2.2. Model for Gas Pressure Prediction

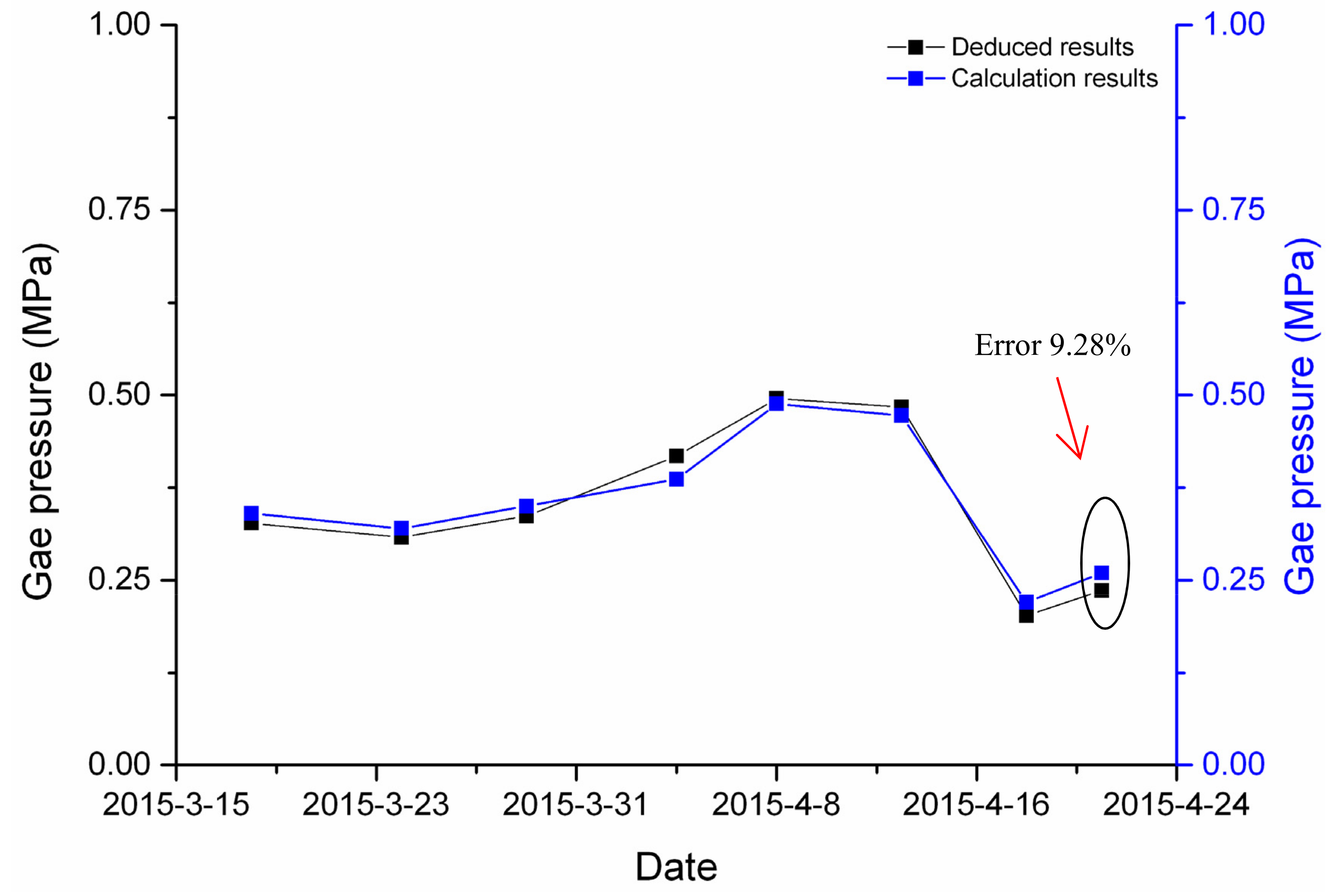

3. Verification of Gas Pressure Model

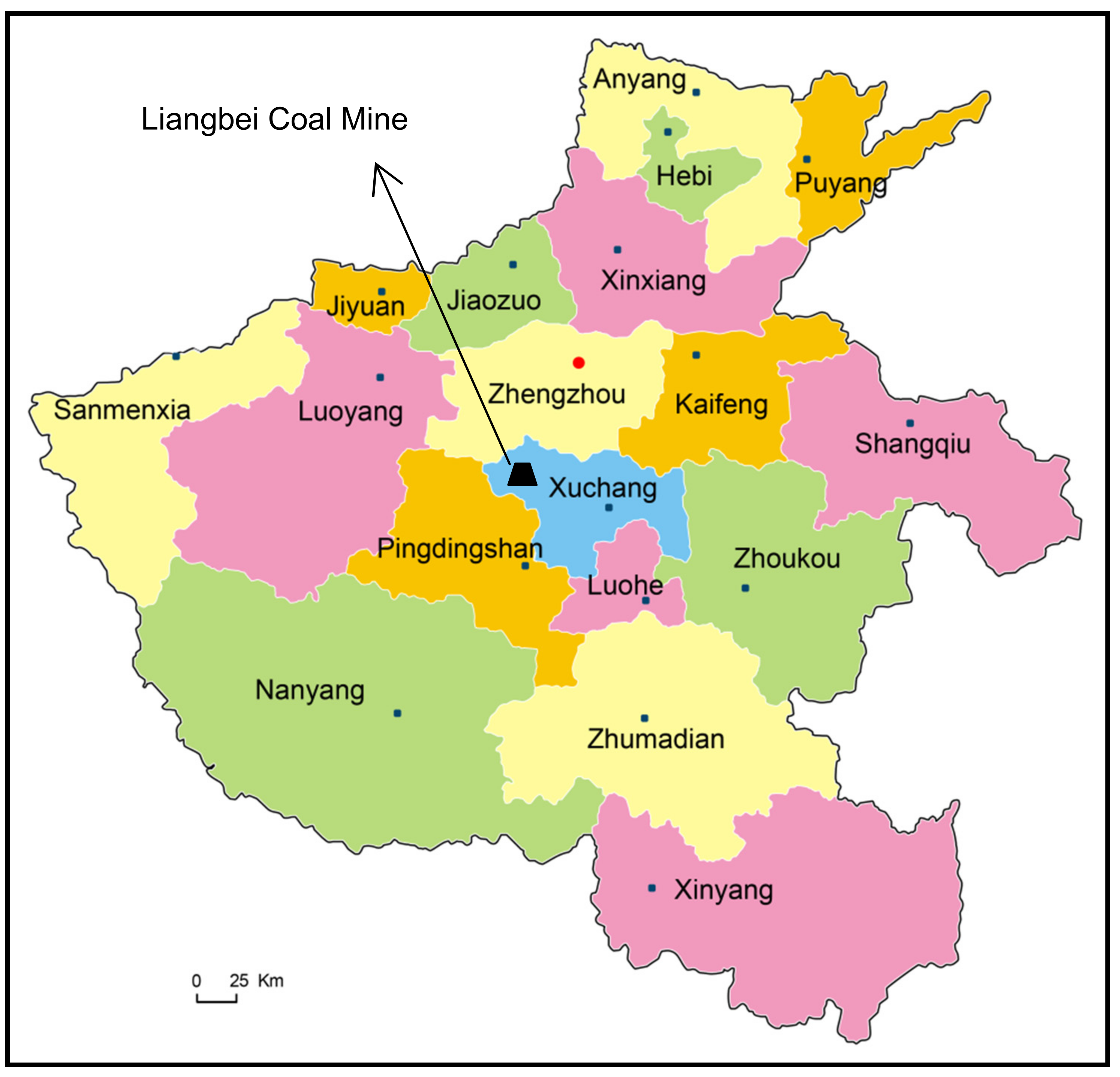

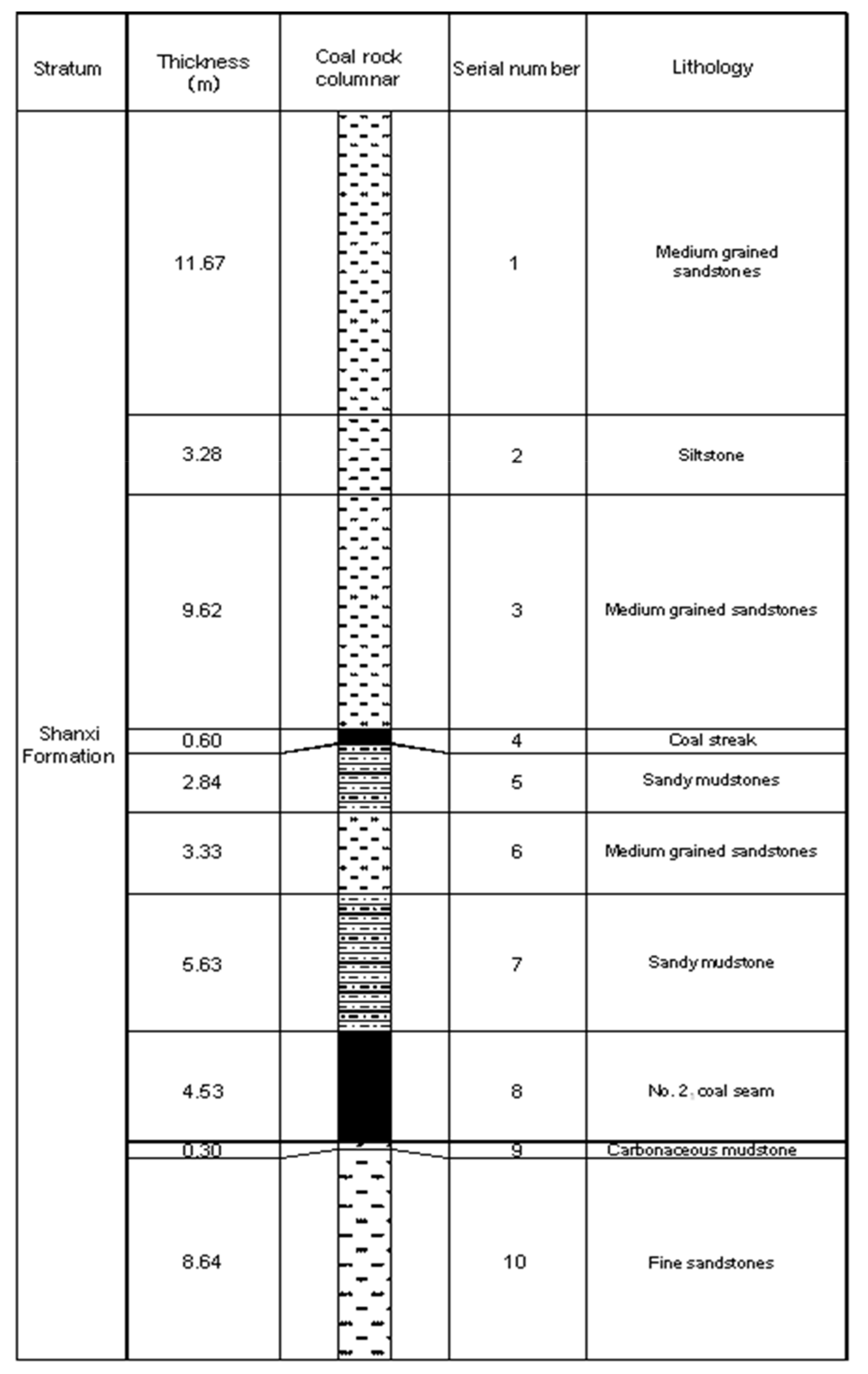

3.1. Geological Background

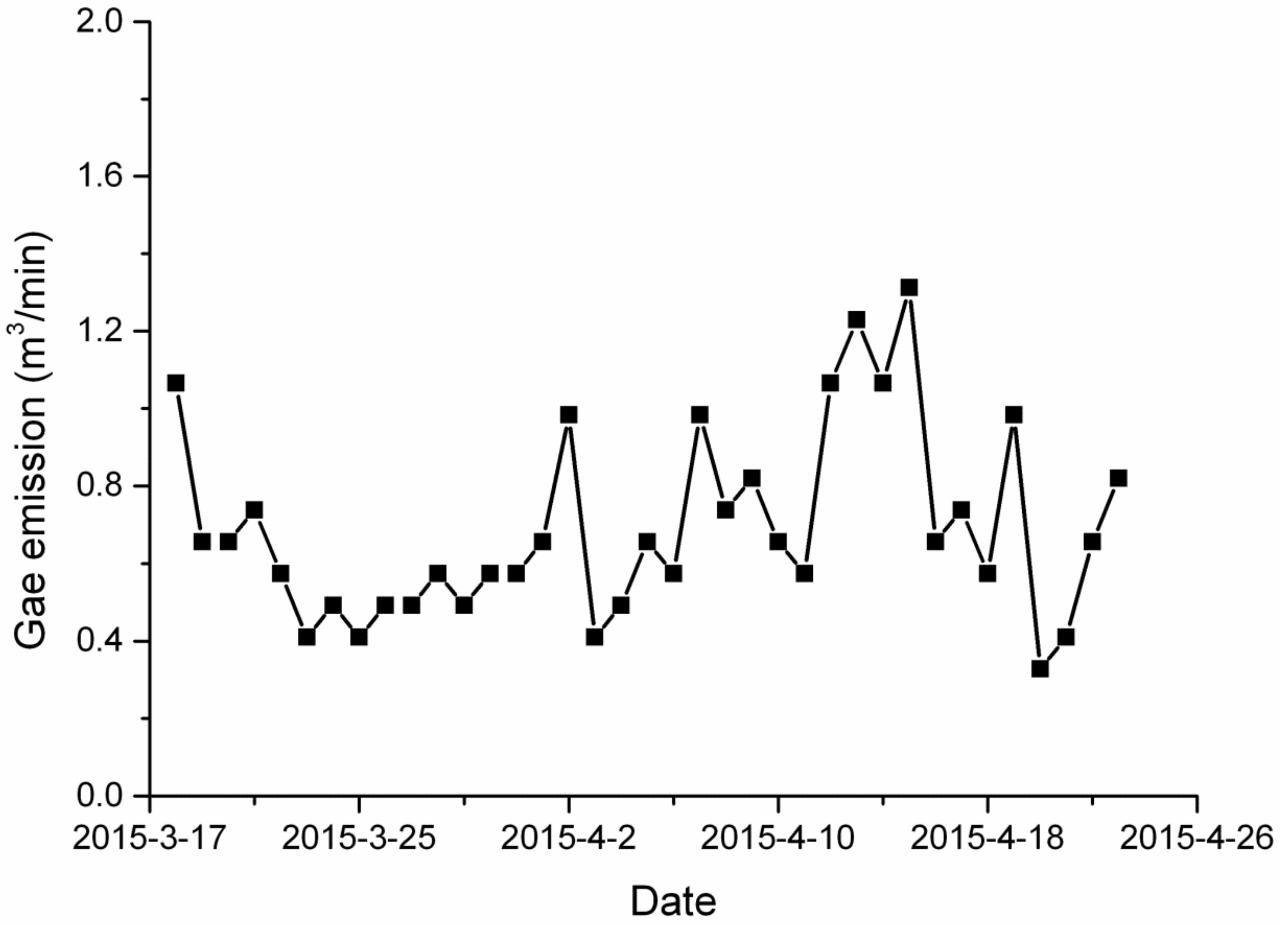

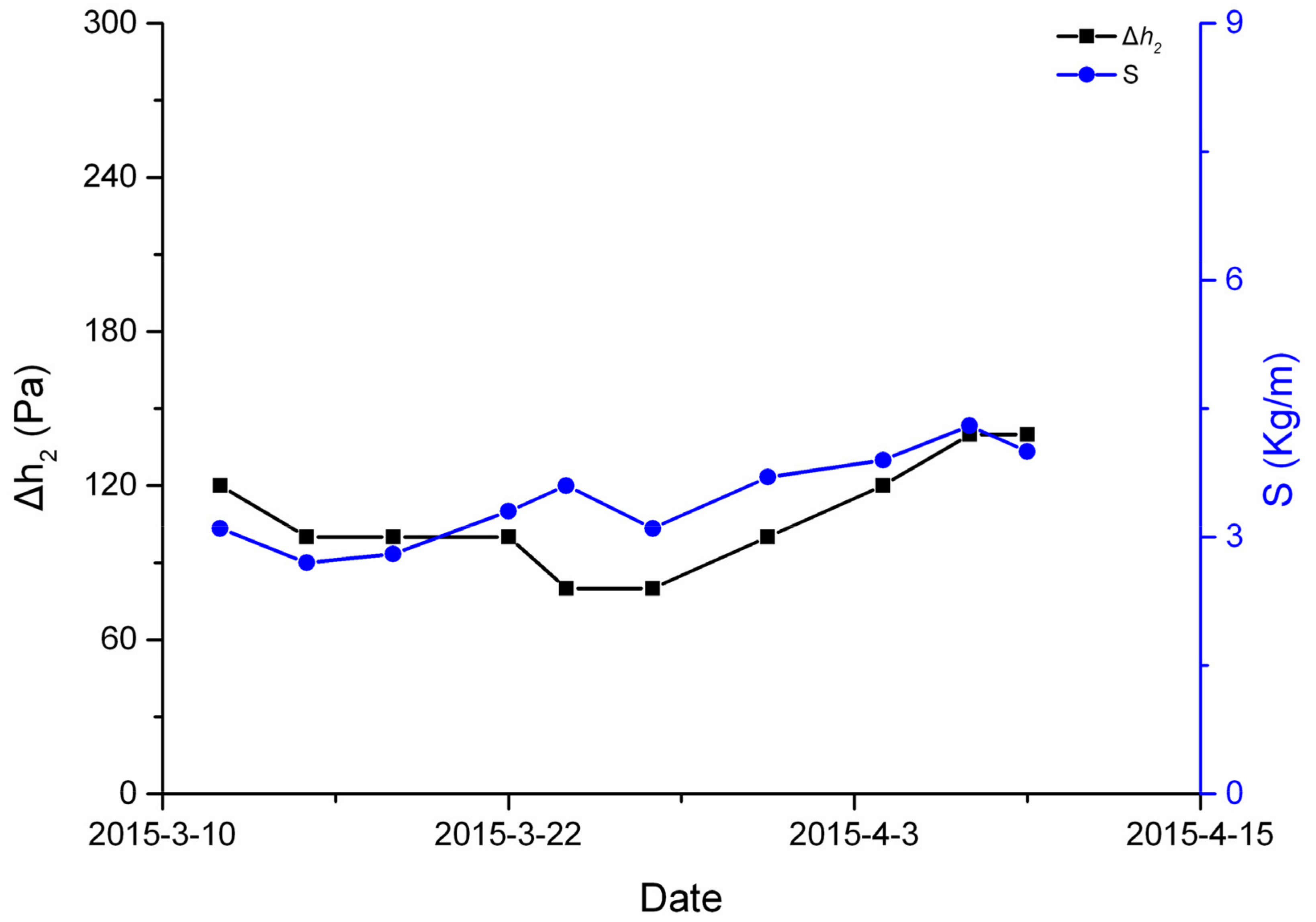

3.2. Verification Result

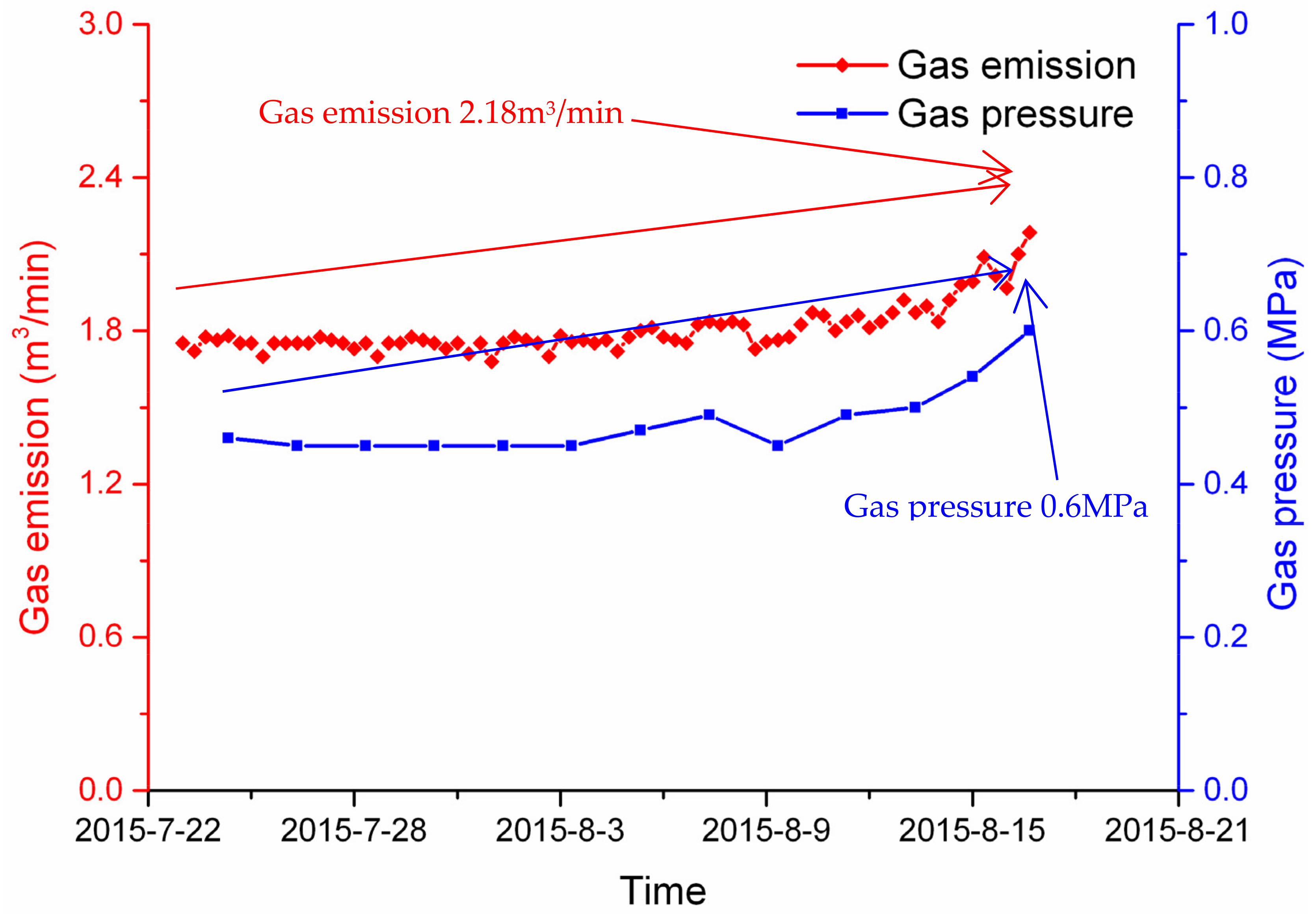

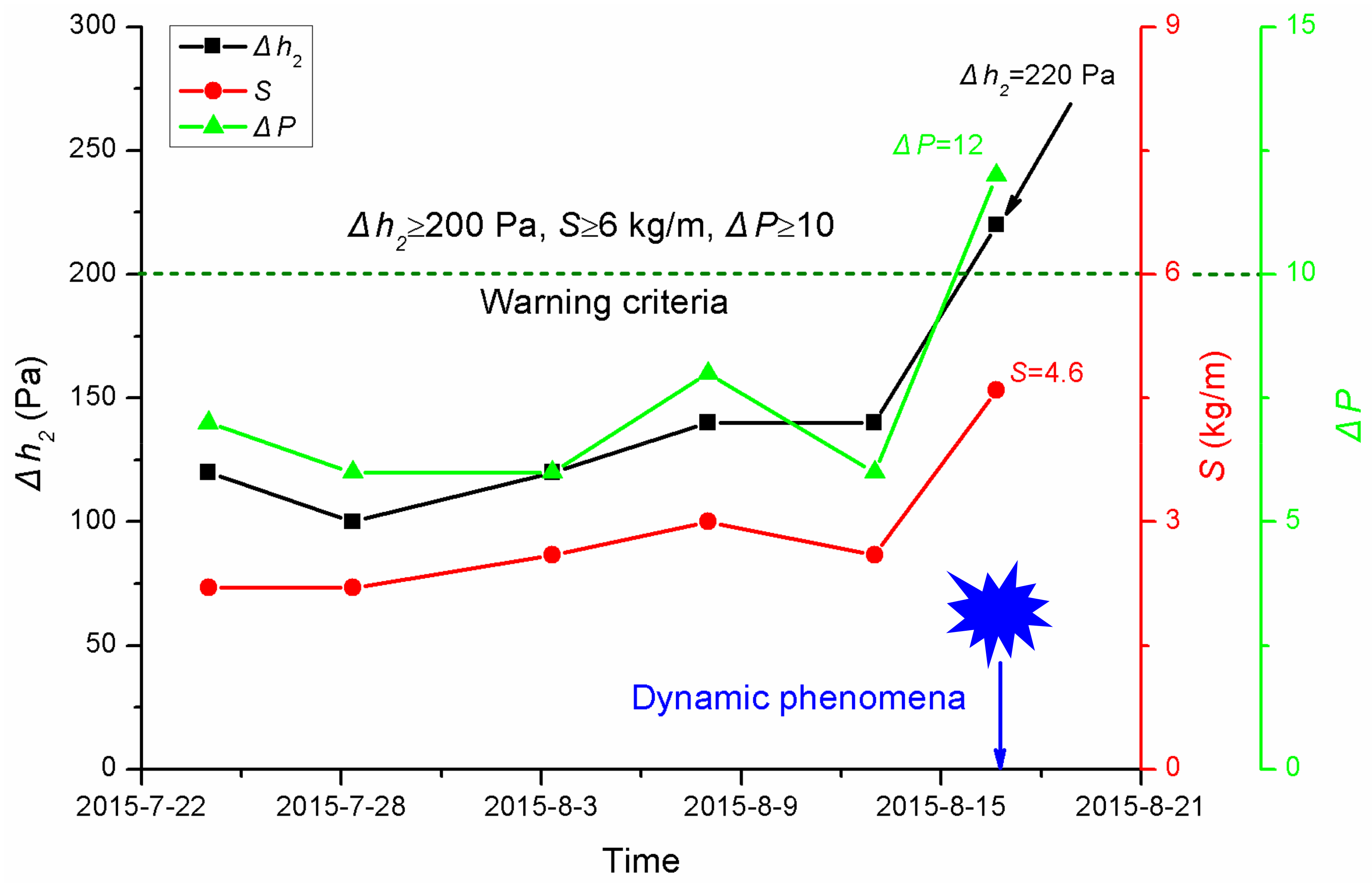

4. Engineering Application

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Toraño, J.; Torno, S.; Alvarez, E.; Riesgo, P. Application of outburst risk indices in the underground coal mines by sublevel caving. Int. J. Rock Mech. Min. Sci. 2012, 50, 94–101. [Google Scholar] [CrossRef]

- Chen, L.; Wang, E.; Ou, J.; Fu, J. Coal and gas outburst hazards and factors of the No. B-1 Coalbed, Henan, China. Geosci. J. 2018, 22, 171–182. [Google Scholar] [CrossRef]

- Chen, L.; Yu, L.; Ou, J.; Zhou, Y.; Fu, J.; Wang, F. Prediction of coal and gas outburst risk at driving working face based on Bayes discriminant analysis model. Earthq. Struct. 2020, 18, 73–82. [Google Scholar]

- Fişne, A.; Esen, O. Coal and gas outburst hazard in Zonguldak Coal Basin of Turkey, and association with geological parameters. Nat. Hazards 2014, 74, 1363–1390. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Jiang, C.; Yang, D.; Zhang, C.; Li, X.; Chen, Y.; Tang, J. A method of rapid determination of gas pressure in a coal seam based on the advantages of gas spherical flow field. J. Nat. Gas Sci. Eng. 2017, 45, 502–510. [Google Scholar] [CrossRef]

- Zeng, J.; Tian, S.; Wu, G.; Zuo, Y.; Xu, S.; Pei, P.; Wang, C. The research of coal seam gas pressure and initial gas emission characteristics of borehole. Energy Sci. Eng. 2019, 7, 1961–1969. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Wang, E.; Ding, H.; Huang, Q.; Chen, X. Deterministic seismic hazard assessment of coal fractures in underground coal mine: A case study. Soil Dyn. Earthq. Eng. 2020, 129, 105921. [Google Scholar] [CrossRef]

- Sa, Z.; Liu, J.; Li, J.; Zhang, Y. Research on effect of gas pressure in the development process of gassy coal extrusion. Saf. Sci. 2019, 115, 28–35. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, E.; Kong, X.; Li, Q.; Hu, S.; Li, D. Numerical simulation on the coupling law of stress and gas pressure in the uncovering tectonic coal by cross-cut. Int. J. Rock Mech. Min. Sci. 2018, 103, 33–42. [Google Scholar] [CrossRef]

- Shu, C.; Wang, H.; Li, X.; Fan, J.; Ye, X. A Thermo–Hydro–Mechanical Model: Capturing the Effects of Initial Permeability and Gas Pressure on Outburst-Prone Indicators. Nonrenewable Resour. 2019, 29, 1897–1914. [Google Scholar] [CrossRef]

- Fernandez-Diaz, J.J.; Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Lopez-Gayarre, F. Analysis of gas-dynamic phenomenon in underground coal mines in the central basin of Asturias (Spain). Eng. Fail. Anal. 2013, 34, 464–477. [Google Scholar] [CrossRef]

- Xue, S.; Yuan, L.; Xie, J.; Wang, Y. Advances in gas content based on outburst control technology in Huainan, China. Int. J. Min. Sci. Technol. 2014, 24, 385–389. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, S. Modeling and prediction of daily gas concentration variation at a mining face based on the elliptic orbit model: A case study. Int. J. Min. Sci. Technol. 2015, 25, 1045–1052. [Google Scholar] [CrossRef]

- Yu, B.; Su, C.; Wang, D. Study of the features of outburst caused by rock cross-cut coal uncovering and the law of gas dilatation energy release. Int. J. Min. Sci. Technol. 2015, 25, 453–458. [Google Scholar] [CrossRef]

- Kong, X.; Wang, E.; Hu, S.; Li, Z.; Liu, X.; Fang, B.; Zhan, T. Critical slowing down on acoustic emission characteristics of coal containing methane. J. Nat. Gas Sci. Eng. 2015, 24, 156–165. [Google Scholar] [CrossRef]

- Lu, C.-P.; Dou, L.-M.; Liu, H.; Liu, H.-S.; Liu, B.; Du, B.-B. Case study on microseismic effect of coal and gas outburst process. Int. J. Rock Mech. Min. Sci. 2012, 53, 101–110. [Google Scholar] [CrossRef]

- Wang, E.; He, X.; Wei, J.; Nie, B.; Song, D. Electromagnetic emission graded warning model and its applications against coal rock dynamic collapses. Int. J. Rock Mech. Min. Sci. 2011, 48, 556–564. [Google Scholar] [CrossRef]

- Aguado, M.B.D.; Nicieza, C.G. Control and prevention of gas outbursts in coal mines, Riosa–Olloniego coalfield, Spain. Int. J. Coal Geol. 2007, 69, 253–266. [Google Scholar] [CrossRef]

- Wold, M.; Connell, L.; Choi, S. The role of spatial variability in coal seam parameters on gas outburst behaviour during coal mining. Int. J. Coal Geol. 2008, 75, 1–14. [Google Scholar] [CrossRef]

- Guo, B.; Li, Y.; Jiao, F.; Luo, T.; Ma, Q. Experimental study on coal and gas outburst and the variation characteristics of gas pressure. Géoméch. Geophys. Geo-Energy Geo-Resour. 2018, 4, 355–368. [Google Scholar] [CrossRef]

- Hu, Z.; Sun, J.; Tang, M. An Experimental Study on the Interaction Law of the Pore Gas Pressure and Stress in Gassy Coals. Teh. Vjesn. Tech. Gaz. 2018, 25, 1154–1161. [Google Scholar] [CrossRef]

- Zhao, B.; Cao, J.; Sun, H.; Wen, G.; Dai, L.; Wang, B. Experimental investigations of stress-gas pressure evolution rules of coal and gas outburst: A case study in Dingji coal mine, China. Energy Sci. Eng. 2019, 8, 61–73. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Yang, S.; Hu, X.; Song, W.; Song, Y.; Xu, Q.; Zhang, S. Risk assessment of dynamic disasters induced by gas injection displacement in coal seams. Process Saf. Environ. Prot. 2019, 128, 41–49. [Google Scholar] [CrossRef]

- An, F.; Yuan, Y.; Chen, X.; Li, Z.; Li, L. Expansion energy of coal gas for the initiation of coal and gas outbursts. Fuel 2019, 235, 551–557. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.-P.; Wang, L.; Guo, P.-K.; Li, W. Safety line method for the prediction of deep coal-seam gas pressure and its application in coal mines. Saf. Sci. 2012, 50, 523–529. [Google Scholar] [CrossRef]

- Gao, J.; Hou, S. Dynamic distribution of gas pressure and emission around a diving roadway. J. China Coal Soc. 2007, 32, 1127–1131. (In Chinese) [Google Scholar]

- Liang, B.; Liu, J.; Sun, W. Numerical simulation of flowing gas on heading face during coal mining. Chin. J. Geol. Hazard Control 2011, 22, 46–51. (In Chinese) [Google Scholar]

- Zhou, S.; Lin, B. The Theory of Gas Flow and Storage in Coal Seams; China Coal Industry Publishing House: Beijing, China, 1999; pp. 12–32. (In Chinese) [Google Scholar]

- State Administration of Work Safety. The Predicted Method of Mine Gas Emission. China’s Saf. Prod. Ind. Stand. 2006, 1018, 1–14. (In Chinese) [Google Scholar]

- Yu, Q.; Wang, K.; Yang, S. Study on Pattern and Control of Gas Emission at Coal Face in China. J. China Univ. Min. Technol. 2000, 29, 9–14. (In Chinese) [Google Scholar]

- Liu, Q.; Cheng, Y.; Zhou, H.; Guo, P.; An, F.; Chen, H. A Mathematical Model of Coupled Gas Flow and Coal Deformation with Gas Diffusion and Klinkenberg Effects. Rock Mech. Rock Eng. 2015, 48, 1163–1180. [Google Scholar] [CrossRef]

- State Administration of Work Safety. Code for Coal Mine Gas Drainag. China’s Saf. Prod. Ind. Stand. 2006, 1027, 1–8. (In Chinese) [Google Scholar]

| Parameter | Value |

|---|---|

| Elastic modulus of roof and floor rocks | 30 GPa |

| Poisson’s ratio of roof and floor rocks | 0.22 |

| Density of roof and floor rocks | 2.5 t/m3 |

| Internal cohesive force of roof and floor rocks | 40 MPa |

| Internal friction angle of roof and floor rocks | 34° |

| Elastic modulus of coal | 2600 MPa |

| Poisson’s ratio of coal | 0.22 |

| Internal cohesive force of coal | 2.1 MPa |

| Internal friction angle of coal | 30° |

| Limiting gas adsorption amount of coal | 22.2 m3/t |

| Adsorption equilibrium constant | 0.68 MPa−1 |

| Temperature Mass of combustible materials per volume of coal | 293 K 1.07 t/m3 |

| Initial porosity of coal | 0.055 |

| Initial permeability of coalbed | 1.8 × 10−15 m2 |

| Kinetic viscosity coefficient of gas | 1.84 × 10−5 Pa.s |

| Density of gas | 0.717 kg/m3 |

| Atmospheric pressure at face | 0.1 MPa |

| Area of roadway cross-section | 14 m2 |

| Bulk density | 1.4 t/m3 |

| Intensity of gas emission from initially collapsed coal | 0.07 m3/t.min |

| Decay coefficient of gas from collapsed coal | 0.079 min−1 |

| Decay coefficient of gas from coal wall | 0.000054 min−1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Liu, Q. A Gas Pressure Prediction Model of the Excavation Face Based on Gas Emission. Int. J. Environ. Res. Public Health 2022, 19, 4891. https://doi.org/10.3390/ijerph19084891

Chen L, Liu Q. A Gas Pressure Prediction Model of the Excavation Face Based on Gas Emission. International Journal of Environmental Research and Public Health. 2022; 19(8):4891. https://doi.org/10.3390/ijerph19084891

Chicago/Turabian StyleChen, Liang, and Qi Liu. 2022. "A Gas Pressure Prediction Model of the Excavation Face Based on Gas Emission" International Journal of Environmental Research and Public Health 19, no. 8: 4891. https://doi.org/10.3390/ijerph19084891

APA StyleChen, L., & Liu, Q. (2022). A Gas Pressure Prediction Model of the Excavation Face Based on Gas Emission. International Journal of Environmental Research and Public Health, 19(8), 4891. https://doi.org/10.3390/ijerph19084891