Determination of Key Technical Parameters in the Study of New Pressure Sealing Technology for Coal Seam Gas Extraction

Abstract

:1. Introduction

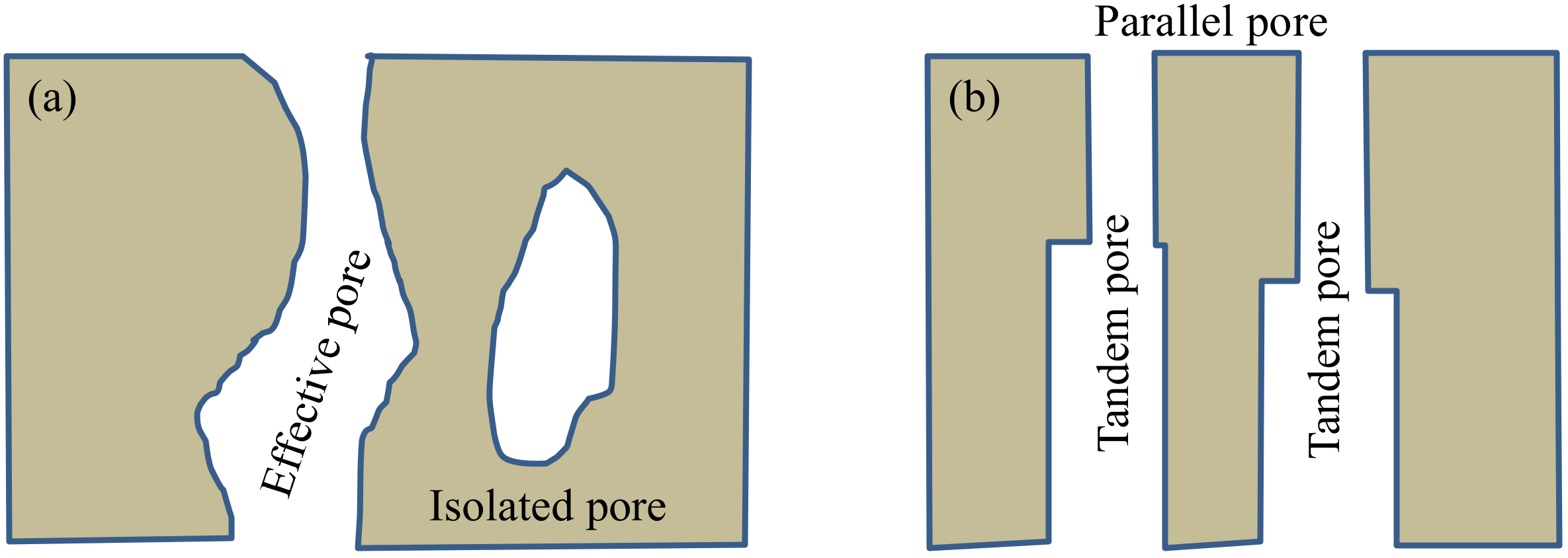

2. Current Problems with Sealing Technology

3. Experimental Study on Pressure Sealing Borehole in Coal Seam

3.1. Principle and Procedure

3.2. Parameter Determination

3.2.1. Grouting Slurry

3.2.2. Sealing Length

3.2.3. Grouting Radius

3.2.4. Grouting Pressure

4. Field Application

4.1. Experimental Parameter

- (1)

- Sealing length

- (2)

- Sealing radius

- (3)

- Sealing grouting pressure

4.2. Experimental Results

5. Discussion

5.1. Influence of Coal Properties on Process

5.2. The Effect of Grouting on the Process

5.3. Practical Significance of Grouting and Sealing for Gas Drainage

- (1)

- Minimizing the possibility of mine gas disasters and improving coal mine production safety. In this study, a large amount of gas stored in the coal seam can be pumped out through the extraction drilling borehole to reduce the residual gas content in the coal seam and prevent the occurrence of gas disasters. At the same time, reduce the pressure on the ventilation system caused by the gas emission from the working face, and save ventilation costs. This plays an important role in guiding gas extraction work, reducing coal mine gas emission, and highlighting dangers.

- (2)

- Conducive to the development and utilization of coalbed methane resources, energy saving, and emission reduction. In order to comprehensively utilize gas resources and advocate sustainable development strategies, most high-gas mines have built gas-fired power generation facilities to meet the needs of daily life, and use the extracted coal seam gas to develop and create added value. This study can provide sufficient and secure sources of coalbed methane for gas power stations, and therefore has important social and economic benefits.

6. Conclusions

- (1)

- The principle of pressure sealing the coal seam gas drainage belt is proposed—that is, the pressure grouting is used to realize the coal gas release crack in the sealing borehole wall. The technology is based on the objective existence of concentrated stress disturbance cracks in the coal roadway of the working face. The pressure grouting is used to block the gas leakage micropores and crack channels. After the slurry solidifies, the organic plastomer with high adhesion to the coal is formed and improved. The coal wall fissure environment of the borehole wall improves the integrity and uniformity of the coal.

- (2)

- Through on-site inspection, the gas drainage effect is significantly improved. The theoretical sealing length L1 = 9.69 m of the Wu 9-20180 mining face is calculated; the sealing length L2 = 13.98 m is verified, and the final sealing length is determined to be 15 m; the sealing radius is determined to be 0.6 m; The cement slurry was prepared on site with a water:cement ratio of 2:1; PG = 0.43 MPa was calculated; the range of the slurry diffusion radius R was 93.4–176.6 cm; the grouting pressure was determined to be 0.516 MPa. The on-site sealing experiment of the gas drainage hole shows that the pressure sealing process can increase the gas drainage concentration by 30% to 55%, and prolong the drainage time by about 40 days. The effect of sealing the hole with pressure is 2.3 times higher than that of the hole without pressure.

- (3)

- The process meets the technical requirements of the gas drainage and drilling engineering of coal seams, and provides a new scientific and effective sealing method for the direct extraction and utilization of coal seam gas. It is worth promoting.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Cheng, Y.; Dong, J.; Jiang, J.; Wang, L.; Li, W. Master role conversion between diffusion and seepage on coalbed methane production: Implications for adjusting suction pressure on extraction borehole. Fuel 2018, 223, 373–384. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Zhang, Y.; Qin, X.; Khan, M. Comparative study on fracture characteristics of coal and rock samples based on acoustic emission technology. Theor. Appl. Fract. Mech. 2021, 111, 102851. [Google Scholar] [CrossRef]

- Hu, J.; Zhuang, Z.; Pan, M.; Han, T.; Li, Y.; Liu, W. A method of the determination nitrate nitrogen (NO3−-N) in high-salinity water samples. Chem. Pap. 2022, 76, 1739–1744. [Google Scholar] [CrossRef]

- Cruickshank, K. Creating pathways for internationally educated teachers into the teaching profession: Practices, policies and problems in the Australian context. Eur. Educ. Res. J. 2022, 21, 230–246. [Google Scholar] [CrossRef]

- Anna, G.; Marzena, I.; Marcin, P.; Mateusz, K.; Katarzyna, S.; JodOwski, P.J.; Joanna, L.; Andrzej, K. Catalytic combustion of low-concentration methane on structured catalyst supports. Ind. Eng. Chem. Res. 2018, 57, 10281–10291. [Google Scholar] [CrossRef]

- Kostinek, J.; Roiger, A.; Eckl, M.; Fiehn, A.; Luther, A.; Wildmann, N.; Klausner, T.; Fix, A.; Knote, C.; Stohl, A.; et al. Estimating Upper Silesian coal mine methane emissions from airborne in situ observations and dispersion modeling. Atmos. Chem. Phys. 2021, 21, 8791–8807. [Google Scholar] [CrossRef]

- Pant, L.M.; Huang, H.; Secanell, M.; Larter, S.; Mitra, S.K. Multi scale characterization of coal structure for mass transport. Fuel 2015, 159, 315–323. [Google Scholar] [CrossRef]

- Meng, Y.; Li, Z. Experimental comparisons of gas adsorption, sorption induced strain, diffusivity and permeability for low and high rank coals. Fuel 2018, 234, 914–923. [Google Scholar] [CrossRef]

- Szott, W.; Gołąbek, A. Numerical modelling of stimulated methane drainage from coal seams. Artykuł-Szczegóły 2016, 209, 829–836. [Google Scholar]

- Zhang, C.; Wang, E.; Xu, J.; Peng, S. A new method for coal and gas outburst prediction and prevention based on the fragmentation of ejected coal. Fuel 2021, 287, 119493. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D.; Camilleri, M.; Connelly, L. Effects of matrix moisture on gas diffusion and flow in coal. Fuel 2010, 89, 3207–3217. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.; Wang, S.; Zhao, M.; Liu, H. Study on In Situ Stress Distribution Law of the Deep Mine: Taking Linyi Mining Area as an Example. Adv. Mater. Sci. Eng. 2021, 2021, 5594181. [Google Scholar] [CrossRef]

- Kirk, M.F.; Wilson, B.H.; Marquart, K.A.; Zeglin, L.H.; Vinson, D.S.; Flynn, T.M. Solute Concentrations Influence Microbial Methanogenesis in Coal-bearing Strata of the Cherokee Basin, USA. Front. Microbiol. 2015, 6, 1287. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Zhang, L.W.; Wang, L.; Chen, X.J. Negative pressure distribution of variable mass flow in coal mine drainage boreholes. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 2020, 1832162. [Google Scholar] [CrossRef]

- Wang, C.; Song, D.; Zhang, C.; Liu, L.; Zhou, Z.; Huang, X. Research on the classification model of coal’s bursting liability based on database with large samples. Arab. J. Geosci. 2019, 12, 411. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, E.; Liu, X.; Zhang, Y.; Li, S.; Khan, M.; Gao, Y. Anisotropic characteristics of ultrasonic transmission velocities and stress inversion during uniaxial compression process. J. Appl. Geophys. 2021, 186, 104274. [Google Scholar] [CrossRef]

- Li, X.-L.; Chen, S.-J.; Liu, S.-M.; Li, Z.-H. AE waveform characteristics of rock mass under uniaxial loading based on Hilbert-Huang transform. J. Cent. South Univ. 2021, 28, 1843–1856. [Google Scholar] [CrossRef]

- Liu, S.; Li, X.; Wang, D.; Zhang, D. Investigations on the mechanism of the microstructural evolution of different coal ranks under liquid nitrogen cold soaking. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 2020, 1841856. [Google Scholar] [CrossRef]

- Feng, J.; Wang, E.; Huang, Q.; Ding, H.; Ma, Y. Study on coal fractography under dynamic impact loading based on multifractal method. Fractals 2020, 28, 2050006. [Google Scholar] [CrossRef]

- Jia, L.; Peng, S.; Xu, J.; Yan, F.; Chen, J.; Wu, B. Investigation on gas drainage effect under different borehole layout via 3D monitoring of gas pressure. J. Nat. Gas Sci. Eng. 2022, 101, 104522. [Google Scholar] [CrossRef]

- Huang, W.; Duan, J.; Chang, H.; Luo, Q.; Zhou, L.; Sun, Q. Construction of natural gas energy-measuring system in China: A discussion. Nat. Gas Ind. B 2022, 9, 33–40. [Google Scholar] [CrossRef]

- Glasmeier, A.K.; Williams, D.A. Toward a theory of high reliability for natural gas distribution utilities. Util. Policy 2022, 75, 101353. [Google Scholar] [CrossRef]

- Szott, W.; Słota-Valim, M.; Gołąbek, A.; Sowiżdżał, K.; Łętkowski, P. Numerical studies of improved methane drainage technologies by stimulating coal seams in multi-seam mining layouts. Int. J. Rock Mech. Min. Sci. 2018, 108, 157–168. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Pan, Y.; Hao, Z.; Chen, S.; Cheng, F. Experimental study on the mechanical behavior and deformation characteristics of lining structure of super-large section tunnels with a small clearance. Eng. Fail. Anal. 2022, 136, 106186. [Google Scholar] [CrossRef]

- Tanabe, T.; Suzuki, H.; Hasegawa, Y.; Ushijima, T. Study on the relationship between decay characteristics and pressure drop in grid turbulence. In Proceedings of the 2017 Annual Meeting, Saitama, Japan, 3–6 September 2017. [Google Scholar] [CrossRef]

- Qiu, P.; Zhang, L.; Li, Y.; Li, B.; Zhu, J.; Ma, C.; Bi, X.; Yu, Y. Permeability evolution model of coarse porous concrete under sulphuric acid corrosion. Constr. Build. Mater. 2022, 326, 126475. [Google Scholar] [CrossRef]

- Roman, A.; Ahmadi, G.; Issen, K.A.; Smith, D.H. Permeability of Fractured Media under Confining Pressure: A Simplified Model. Open Pet. Eng. J. 2012, 5, 1153–1185. [Google Scholar] [CrossRef] [Green Version]

- Zareifard, M.R. Ground response curve of deep circular tunnel in rock mass exhibiting Hoek–Brown strain-softening behaviour considering the dead weight loading. Eur. J. Environ. Civ. Eng. 2019, 25, 2509–2539. [Google Scholar] [CrossRef]

- Tan, B.T.; Wu, P.; Anariba, F. Modeling stress-strain nonlinear mechanics via entropy changes on surface wetting using the Born-Oppenheimer approximation. Results Eng. 2022, 13, 100349. [Google Scholar] [CrossRef]

- Terumoto, K.; Tsuchiya, Y.; Otagiri, R.; Nakabayashi, H.; Nakabayashi, I. Trends and relationships in victims’ recovery perceptions: A case study of the recovery process following the Great East Japan Earthquake. Nat. Hazards 2021, 59, 254–269. [Google Scholar] [CrossRef]

- Azadpour, M.; Javaherian, A.; Saberi, M.R.; Shabani, M.; Shojaei, H. Rock physics model-based investigation on the relationship between static and dynamic Biot’s coefficients in carbonate rocks. J. Pet. Sci. Eng. 2022, 211, 110243. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Yuan, L.; Wang, S.; Yu, G.; Liu, Z. Analysis of precursor information for coal and gas outbursts induced by roadway tunneling: A simulation test study for the whole process. Tunn. Undergr. Space Technol. 2022, 122, 104349. [Google Scholar] [CrossRef]

- Maitlo, H.A.; Maitlo, G.; Song, X.; Zhou, M.; Kim, K.-H. A figure of merits-based performance comparison of various advanced functional nanomaterials for adsorptive removal of gaseous ammonia. Sci. Total Environ. 2022, 822, 153428. [Google Scholar] [CrossRef] [PubMed]

- Romanova, Z.; Hrivikova, K.; Riecansky, I.; Jezova, D. Salivary testosterone, testosterone/cortisol ratio and non-verbal behavior in stress. Steroids 2022, 182, 108999. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.; Zhang, Q.; Gao, X.; Feng, F. Research on theory, simulation and measurement of stress behavior under regenerated roof condition. Geomech. Eng. 2021, 26, 49–61. [Google Scholar] [CrossRef]

- Yue, G.; Li, M.; Wang, L.; Liang, W. Optimal layout of blasting holes in structural anisotropic coal seam. PLoS ONE 2019, 14, e0218105. [Google Scholar] [CrossRef] [PubMed]

- Aghabarari, A.; Ghaedi, M. Evaluation of the effects of homogenizing matrix block sizes on the simulation of naturally fractured reservoirs. J. Pet. Sci. Eng. 2022, 213, 110373. [Google Scholar] [CrossRef]

- Laing, Y.; Wang, F.; Luo, Y.; Wang, H.; Hu, Q. Experimental study on principles of isothermal dehydration of anthracite. Dry. Technol. 2018, 37, 38–46. [Google Scholar] [CrossRef]

- Li, X.; Cao, Z.; Xu, Y. Characteristics and trends of coal mine safety development. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 2020, 1852339. [Google Scholar] [CrossRef]

- Sjölander, A.; Hellgren, R.; Malm, R.; Ansell, A. Verification of failure mechanisms and design philosophy for a bolt-anchored and fibre-reinforced shotcrete lining. Eng. Fail. Anal. 2020, 116, 104741. [Google Scholar] [CrossRef]

- Wang, F.; Luo, Y.; Liang, Y.; Peng, J.; Li, B. Sampling Methane-Bearing Coal Seams by Freezing Method: Coalbed Methane Desorption and Inhibition Characteristics Under Freezing Temperature. Nonrenew. Resour. 2020, 29, 1351–1360. [Google Scholar] [CrossRef]

- Shrivastava, N.; Zen, K. An Experimental Study of Compaction Grouting on Its Densification and Confining Effects. Geotech. Geol. Eng. 2017, 36, 983–993. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.; Zhang, S.; Liu, Q.; Chu, Z. Real-time characterization of the grouting diffusion process in fractured sandstone based on the low-field nuclear magnetic resonance technique. Int. J. Rock Mech. Min. Sci. 2022, 152, 105060. [Google Scholar] [CrossRef]

- Zullo, R.; Verdolotti, L.; Liguori, B.; Lirer, S.; de Luna, M.S.; Malara, P.; Filippone, G. Effect of rheology evolution of a sustainable chemical grout, sodium-silicate based, for low pressure grouting in sensitive areas: Urbanized or historical sites. Constr. Build. Mater. 2020, 230, 117055. [Google Scholar] [CrossRef]

- Wang, F.; Liang, Y.; Zou, Q. Correlation between coal and gas outburst risk and adsorption properties of coal seams. Energy Sci. Eng. 2019, 7, 974–985. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Du, Y.; Li, Z.; Zhao, F.; Zuo, W.; Wei, J.; Mitri, H. A rapid and accurate direct measurement method of underground coal seam gas content based on dynamic diffusion theory. Int. J. Min. Sci. Technol. 2020, 30, 799–810. [Google Scholar] [CrossRef]

- Xiao, P.; Mao, H.; Qian, B.; Li, B.; Yang, X.; Xu, N. Stability analysis of surrounding rock mass in underground powerhouse considering damage effect of microfractures. J. Rock Mech. Geotech. Eng. 2022. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Liang, Y.; Li, X.; Chen, Y. Calculation Model and Rapid Estimation Method for Coal Seam Gas Content. Processes 2018, 6, 223. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Tang, J.; Cheng, Y.; Huang, L.; Guo, F.; Yin, X.; Li, N. Prediction of landslide displacement with dynamic features using intelligent approaches. Int. J. Min. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Chen, L.; Ou, Q.; Peng, Z.; Wang, Y.; Chen, Y.; Tian, Y. Numerical simulation of abnormal roof water-inrush mechanism in mining under unconsolidated aquifer based on overburden dynamic damage. Eng. Fail. Anal. 2022, 133, 106005. [Google Scholar] [CrossRef]

- Zhai, J.; Ren, S.; Wang, F.; Bi, C.; Niu, T.; Li, Z. Response of ground pressure behavior and gas migration in fully mechanized top-coal caving mining. J. Min. Strat. Control Eng. 2022, 4, 51–59. [Google Scholar] [CrossRef]

| Density | Viscosity | Mixing Ratio | Shelf Time | Casting Multiple | Dimensional Stability | Bond Strength | Compressive Strength | Curing Time | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | Β | A | Β | A:Β | A | Β | 4–10 times | 70 °C 48 h ≤ 2 | ΜPa 3–5 | ΜPa ≥12 | 360 s–600 s |

| 1.17 | 1.42 | 120 | 60 | 1:1 | 6 months | 6 months | |||||

| Water:Cement Ratio | Viscosity (s) | Specific Gravity (g/cm) | Condensation Time | Stone Body (%) | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 | 7 | 14 | 28 | ||||

| 0.5:1 | 139 | 1.86 | 7–41 | 12–36 | 99 | 4.14 | 6.46 | 15.30 | 22.00 |

| 0.75:1 | 33 | 1.62 | 10–47 | 20–33 | 97 | 2.43 | 2.6 | 5.54 | 11.27 |

| 1:1 | 18 | 1.49 | 14–56 | 24–27 | 85 | 2.00 | 2.4 | 2.42 | 8.90 |

| 1.5:1 | 17 | 1.37 | 16–52 | 34–47 | 67 | 2.04 | 2.33 | 1.78 | 2.22 |

| 2:1 | 16 | 1.30 | 17–7 | 48–15 | 56 | 1.66 | 2.56 | 2.10 | 2.80 |

| Coal Seam | Type | Vr (%) | H (mm) | Ag (%) | S (%) | Q (kcal/kg) |

|---|---|---|---|---|---|---|

| 8 | Bituminous | 31.84–35 | 24–39 28–34 | 18.19–33.86 24.83–29.13 | <0.4 | 7112–8742 |

| 9–10 | Bituminous | 32.63–34.97 | 30–34 | 15.83–22.55 | 0.31–0.63 | 7600–8600 |

| 11 | Bituminous | 31.24–32.73 | 22 | 21–37 22.79–25.92 | <0.4 | 8562–8542 |

| P0 (MPa) | δ (cm) | μ (s) | r0 (mm) | R (cm) | K (cm/s) | M |

|---|---|---|---|---|---|---|

| 0 | 0.04 | 13.5 | 72 | 60 | 0.005–0.08 | 1.28–20.44 |

| Time | 0 (d) | 6 (d) | 12 (d) | 18 (d) | 24 (d) | 30 (d) | 36 (d) | 42 (d) | 48 (d) | 54 (d) | 60 (d) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number | ||||||||||||

| 1# | 82.5 | 43.2 | 32.1 | 12.3 | 8.6 | 5.2 | 3.8 | 3.0 | 2.8 | 1.6 | 1.5 | |

| 2# | 85.4 | 60.8 | 53.4 | 32.4 | 22.8 | 14.6 | 10.4 | 9.3 | 5.1 | 3.8 | 3.4 | |

| 3# | 92.5 | 86.4 | 80.4 | 75.6 | 70.2 | 64.6 | 56.3 | 50.0 | 42.4 | 34.2 | 24.0 | |

| 4# | 93.0 | 85.6 | 82.3 | 74.8 | 71.2 | 67.2 | 60.4 | 53.2 | 44.3 | 34.3 | 26.6 | |

| 5# | 93.4 | 87.2 | 82.0 | 76.9 | 75.6 | 67.8 | 59.2 | 54.4 | 45.6 | 37.6 | 28.2 | |

| 6# | 94.0 | 86.7 | 87.2 | 80.3 | 75.4 | 69.2 | 62.3 | 56.2 | 47.4 | 38.2 | 31.0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Li, X.; Wang, K.; Wang, F.; Chen, D.; Li, Z. Determination of Key Technical Parameters in the Study of New Pressure Sealing Technology for Coal Seam Gas Extraction. Int. J. Environ. Res. Public Health 2022, 19, 4968. https://doi.org/10.3390/ijerph19094968

Sun Z, Li X, Wang K, Wang F, Chen D, Li Z. Determination of Key Technical Parameters in the Study of New Pressure Sealing Technology for Coal Seam Gas Extraction. International Journal of Environmental Research and Public Health. 2022; 19(9):4968. https://doi.org/10.3390/ijerph19094968

Chicago/Turabian StyleSun, Zhongguang, Xuelong Li, Kequan Wang, Fakai Wang, Deyou Chen, and Zhen Li. 2022. "Determination of Key Technical Parameters in the Study of New Pressure Sealing Technology for Coal Seam Gas Extraction" International Journal of Environmental Research and Public Health 19, no. 9: 4968. https://doi.org/10.3390/ijerph19094968

APA StyleSun, Z., Li, X., Wang, K., Wang, F., Chen, D., & Li, Z. (2022). Determination of Key Technical Parameters in the Study of New Pressure Sealing Technology for Coal Seam Gas Extraction. International Journal of Environmental Research and Public Health, 19(9), 4968. https://doi.org/10.3390/ijerph19094968