Influence of Coal Mining on Historical Buildings: Case Study in Shanxi

Abstract

1. Introduction

2. Historic Buildings and Surface Subsidence Due to Coal Mining in Shanxi

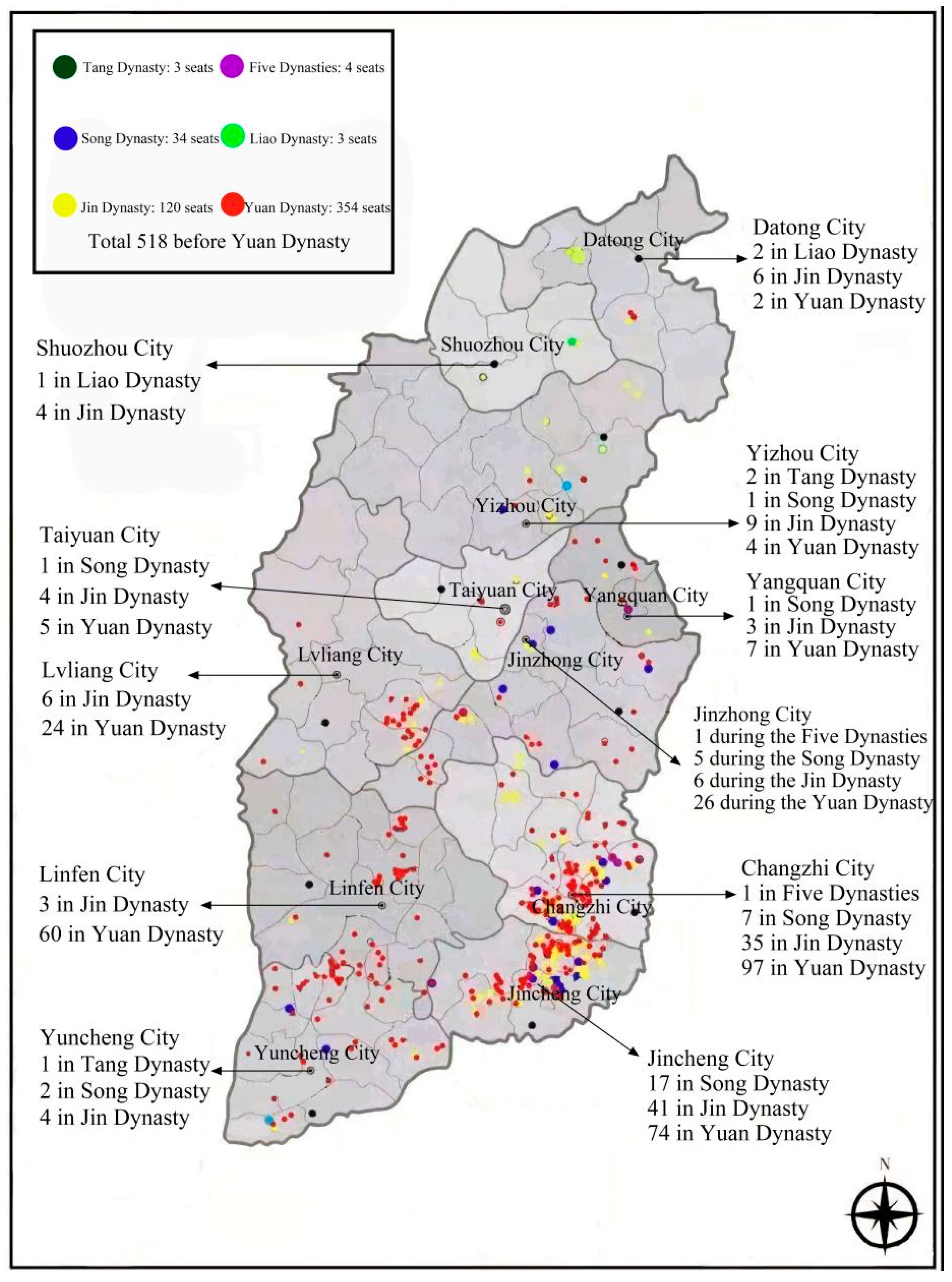

2.1. The Number and Distribution of Ancient Wooden Buildings in Shanxi Province

- (1)

- Northern region: Yizhou, Datong, Shuozhou.

- (2)

- Central region: Taiyuan, Lyuliang, Jinzhong and Yangquan.

- (3)

- Southeastern region: Changzhi, Jincheng.

- (4)

- Southern region: Linfen, Yuncheng.

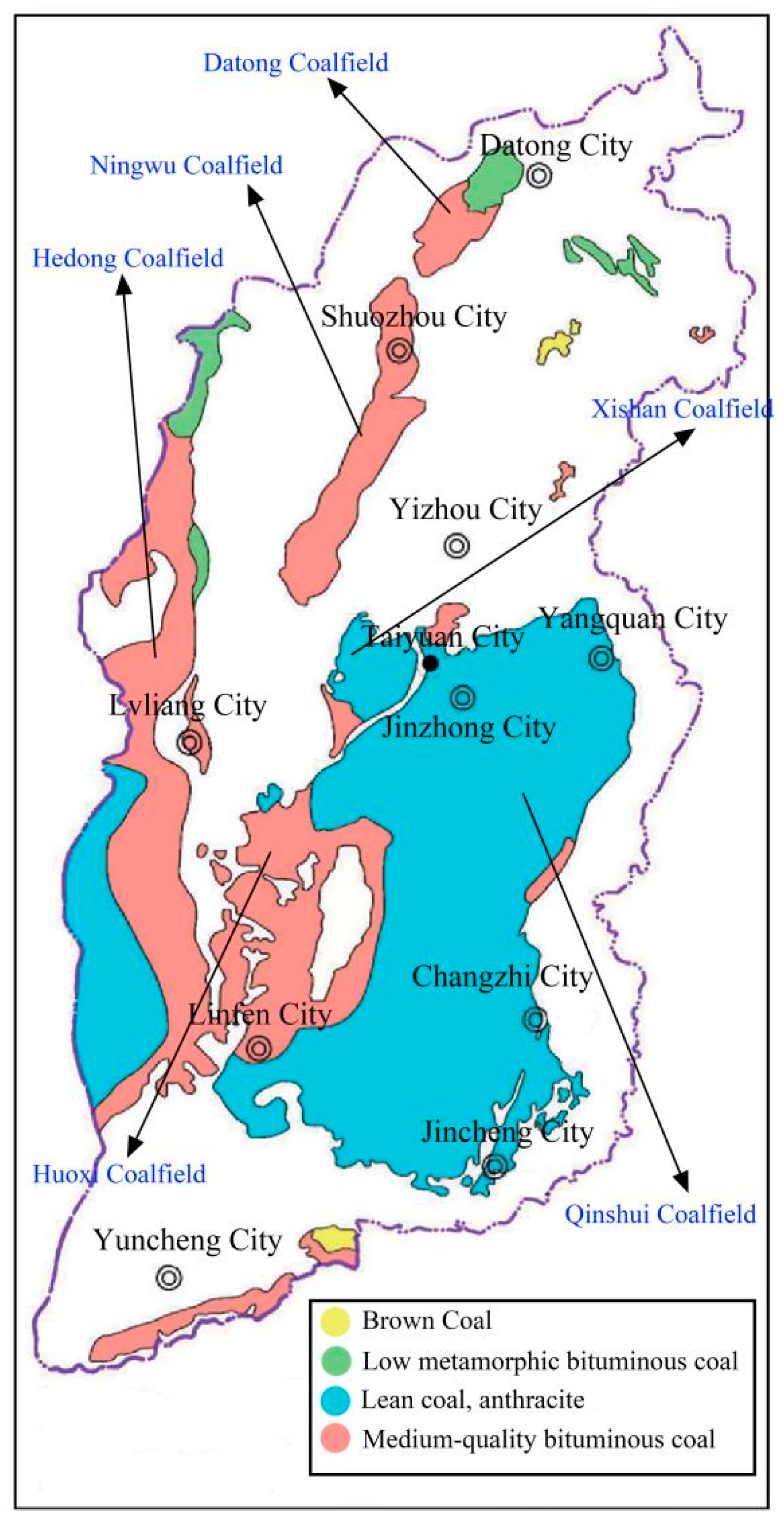

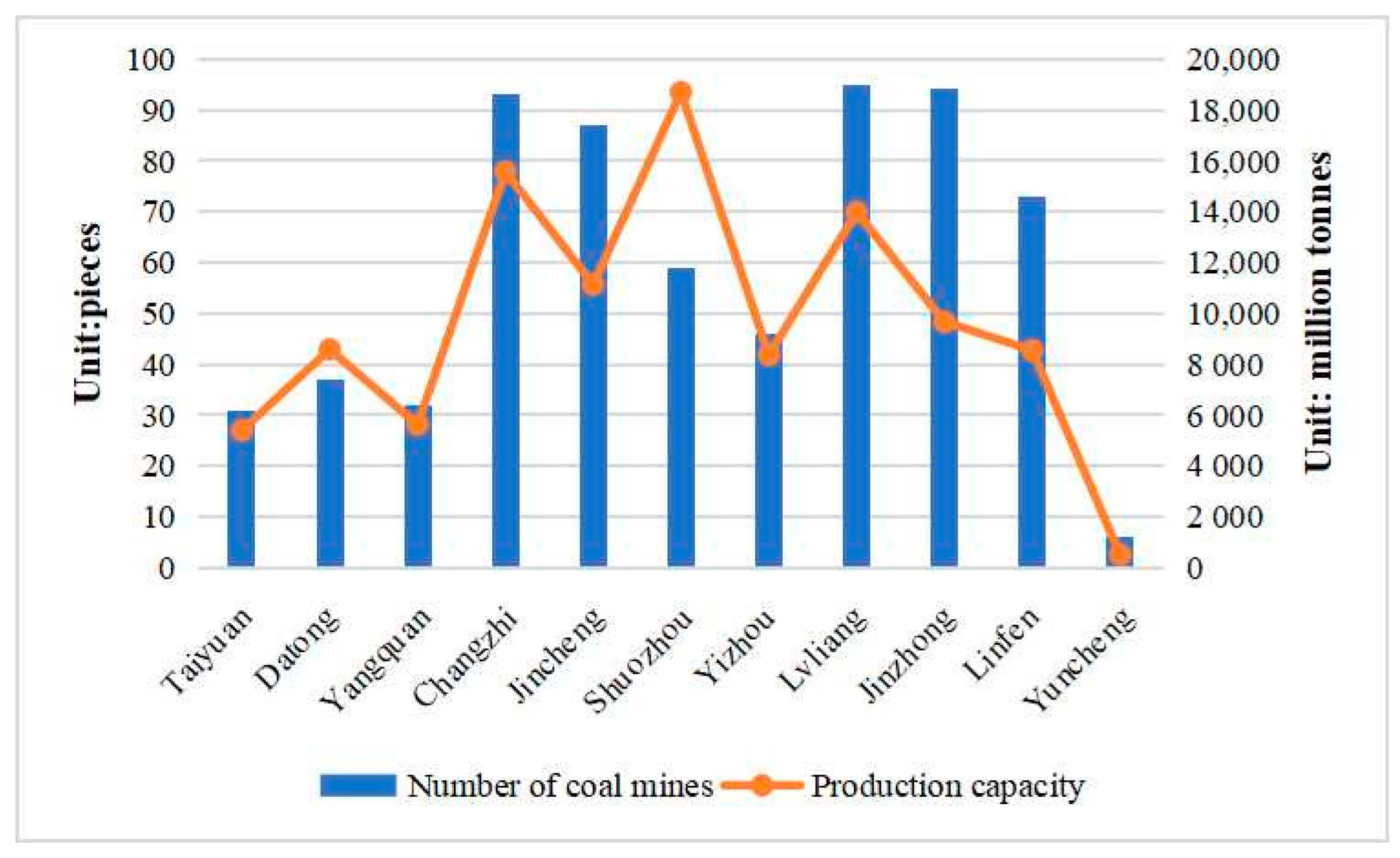

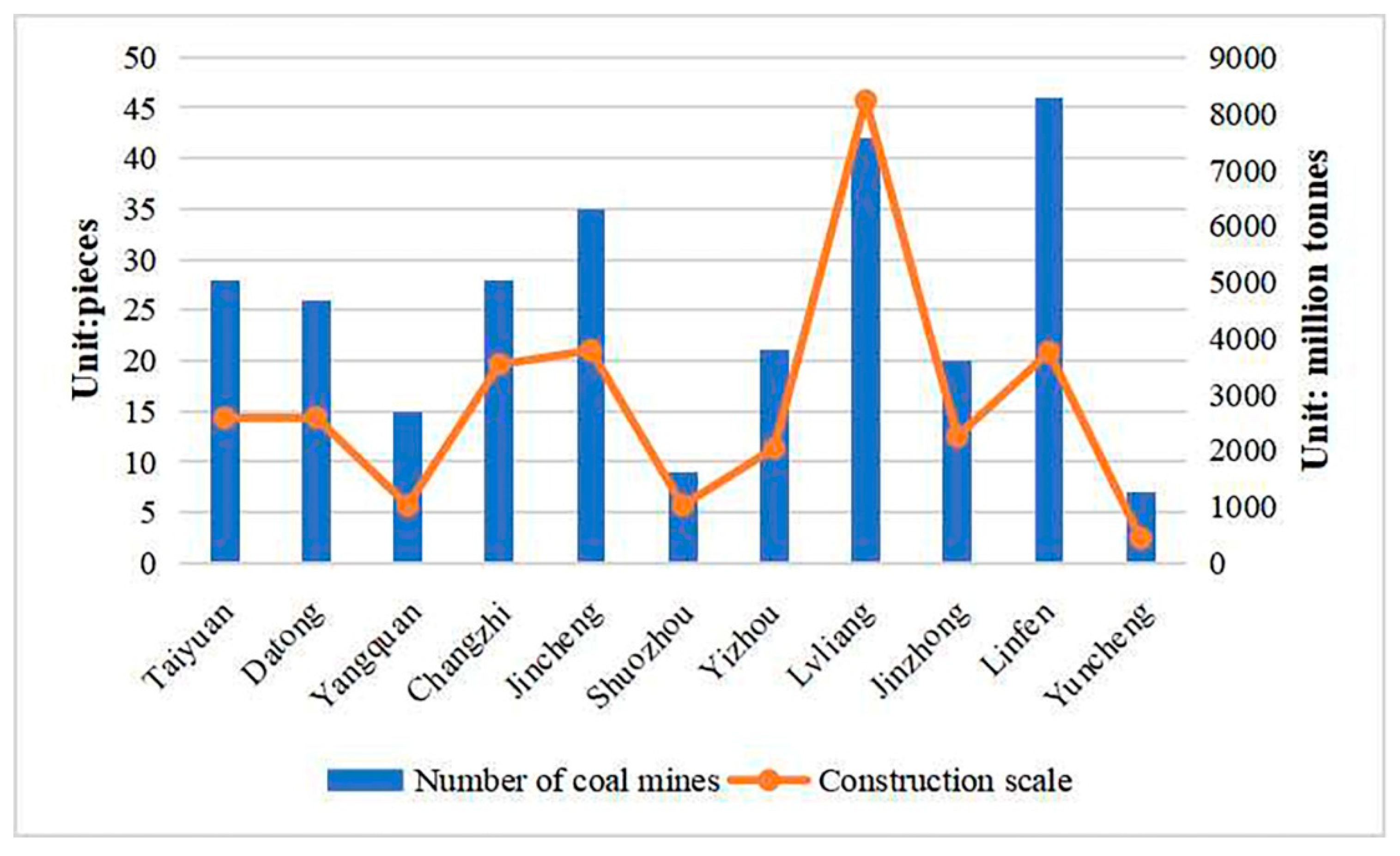

2.2. Distribution and Mining of Coal Resources in Shanxi Province

2.3. Surface Subsidence in Lu’an Mining Area

- (1)

- Due to long-term coal mining in the mining area, the surface subsidence area reaches 79.01 km2, accounting for 2.15% of the total mining area, of which the stable subsidence area is 57.5 km2, the unstable subsidence area is 21.51 km2, and the maximum subsidence of the subsidence area reaches 4.99 m [34].

- (2)

- The areas with significant surface subsidence in the Lu’an mining area are mainly located in the eastern and northern areas of Changzhi County, the southern part of Xiangqi County and the eastern part of Tunliu County.

- (3)

- During 2006.04–2010.05, the southern part of Xiangqi County sinks at an average rate of 0.43 cm per year, Xia Dian at an average rate of 0.16 cm per year, the eastern part of Changzhi County and the northern part of Changzhi County sinks at an average rate of 2.53 cm per year and the eastern part of Tunliu County sinks at an average rate of 3.2 cm.

- (4)

- The distribution of these subsidence areas in the Lu’an mining area is more concentrated. Since 2007, the subsidence rate in the southern part of Xiangqi County has increased slowly, but the subsidence area tends to expand significantly. The subsidence area in the eastern part of Tunliu County does not expand significantly, but the subsidence magnitude increases significantly. The subsidence rate in the eastern part of Changzhi County and the northern part of Changzhi County not only increases in speed, but also the area of the subsidence area continues to expand; in contrast, the subsidence rate and the subsidence area in the Xia Dian area are more stable.

- (5)

- Although the area and scale of subsidence zones formed by other small and medium-sized coal mines in the Lu’an mining area from 2007 onward are smaller, they are almost connected, and their subsidence rates and subsidence areas tend to decrease gradually.

2.4. Mechanism of Surface Subsidence Formation in Lu’an Mining Area

- (1)

- Significant local subsidence caused by the change of rock stress field in the mining area

- (2)

- Large-scale ground subsidence caused by groundwater extraction

- (3)

- Regional faults aggravate surface subsidence

3. Methods

- Wcm—the maximum subsidence value under full mining conditions, mm;

- Wfm—the maximum subsidence value under non-sufficient mining conditions, mm;

- M—mining thickness, mm;

- D2—thickness of Loose Strata, m;

- D1—thickness of bedrock, m;

- H0—average mining depth of the working face, m;

- D0—working face slope length, length of the projection to the surface by angle, m;

- α—dip angle of coal seam, degrees.

4. Results and Discussion

4.1. Analysis of Results

4.2. Impacts of Coal Mining on Historic Buildings in Overlapping Areas

4.3. Technical Measures to Reduce the Impact of Surface Subsidence on Historic Buildings in Overlapping Areas

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; YLei, L.; Wu, S.M.; He, C.Y.; Yan, D. Study on the Coordinated Development of Economy, Environment and Re-source in Coal-Based Areas in Shanxi Province in China: Based on the Multi-Objective Optimization Model. Resour. Policy 2018, 55, 80–86. [Google Scholar] [CrossRef]

- Xue, J.J. Ground Surface Subsidence and Ecological Disturbance in the Mining Area of Loess Plateau with Complex Environments: A Case Study from Xuangang Coal Mining Subsidence Area. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. (In Chinese with an English abstract). [Google Scholar]

- Chen, F.; Lin, H.; Zhang, Y.; Lu, Z. Ground subsidence geo-hazards induced by rapid urbanization: Implications from InSAR observation and geological analysis. Nat. Hazards Earth Syst. Sci. 2012, 12, 935–942. [Google Scholar] [CrossRef]

- Dong, S.; Samsonov, S.; Yin, H.; Ye, S.; Cao, Y. Time-series analysis of subsidence associated with rapid urbanization in Shanghai, China measured with SBAS InSAR method. Environ. Earth Sci. 2014, 72, 677–691. [Google Scholar] [CrossRef]

- Saleh, M.; Becker, M. New estimation of Nile Delta subsidence rates from InSAR and GPS analysis. Environ. Earth Sci. 2019, 78, 6. [Google Scholar] [CrossRef]

- Zebker, H.A.; Goldstein, R.M. Topographic mapping from interferometric synthetic aperture radar observations. J. Geophys. Res. Solid Earth 1986, 91, 4993–4999. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, X.; Lu, Z.; Jung, H.; Hu, J.; Feng, G. A novel multitemporal InSAR model for joint estimation of defor-mation rates and orbital errors. IEEE Trans. Geosci. Remote Sens. 2013, 52, 3529–3540. [Google Scholar] [CrossRef]

- Tang, L.; Hou, H.; Zhang, S.; Guo, S.; Mi, J. Monitoring of short revisited SAR data in rapid deformation field of mining area. Sci. Surv. Mapp. 2021, 46, 95. [Google Scholar]

- Giardina, G.; Hendriks, M.; Rots, J.G. Numerical Analysis of Tunnelling Effects on Masonry Buildings: The Influence of Tunnel Location on Damage Assessment. In Proceedings of the 7th International Conference on Structural Analysis of Historic Constructions, Shanghai, China, 6–8 October 2010; pp. 289–294. [Google Scholar]

- Johnson, K.S. Subsidence hazards due to evaporite dissolution in the United States. Environ. Geol. 2004, 48, 395–409. [Google Scholar] [CrossRef]

- Lee, D.-K.; Mojtabai, N.; Lee, H.-B.; Song, W.-K. Assessment of the influencing factors on subsidence at abandoned coal mines in South Korea. Environ. Earth Sci. 2013, 68, 647–654. [Google Scholar] [CrossRef]

- Solarski, M.; Machowski, R.; Rzetala, M.; Rzetala, M.A. Hypsometric changes in urban areas resulting from multiple years of mining activity. Sci. Rep. 2022, 12, 2982. [Google Scholar] [CrossRef]

- Marschalko, M.; Yilmaz, I.; Křístková, V.; Fuka, M.; Kubečka, K.; Bouchal, T. An indicative method for determination of the most hazardous changes in slopes of the subsidence basins in underground coal mining area in Ostrava (Czech Republic). Environ. Monit. Assess. 2013, 185, 509–522. [Google Scholar] [CrossRef] [PubMed]

- Dang, V.K.; Nguyen, T.D.; Dao, N.H.; Duong, T.L.; Dinh, X.V.; Weber, C. Land subsidence induced by underground coal mining at Quang Ninh, Vietnam: Persistent scatterer inter-ferometric synthetic aperture radar observation using Sentinel-1 data. Int. J. Remote Sens. 2021, 42, 3563–3582. [Google Scholar] [CrossRef]

- Can, E.; Kuscu, S.; Kartal, M.E. Effects of mining subsidence on masonry buildings in Zonguldak hard coal region in Turkey. Environ. Earth Sci. 2012, 66, 2503–2518. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, H.; Gui, Y.; Cao, J. Foundation Pit Excavation on Surrounding Buildings Effect Analysis. In Proceedings of the 2nd International Conference on Mechatronics and Applied Mechanics (ICMAM2012), Hong Kong, China, 6–7 December 2012; pp. 950–954. [Google Scholar]

- Unlu, T.; Akcin, H.; Yilmaz, O. An integrated approach for the prediction of subsidence for coal mining basins. Eng. Geol. 2013, 166, 186–203. [Google Scholar] [CrossRef]

- Ma, X.T.; Bao, C.; Shang, H.; Wang, H.; Doh, S.; Hu, J.; Shu, H. Structural response of RC frame under surface curvature and differential settlement in mining areas. Phys. Chem. Earth 2022, 128, 103239. [Google Scholar] [CrossRef]

- Zhou, J.J. Study on Surface Subsidence Caused by Rail Transit Construction and Its Influence on Ancient Buildings. Master’s Thesis, Soochow University, Suzhou, China, 2017. (In Chinese with an English abstract). [Google Scholar]

- Song, S.J.X.; Zhao, G.; Xie, J.; Guan, Y.Y. Grey Correlation Analysis and Regression Estimation of Mining Subsidence in Yu-Shen-Fu Mining Area. In Proceedings of the 3rd International Conference on Environmental Science and Information Application Technology (ESIAT), Xi’an, China, 18–19 June 2011; pp. 1747–1752. [Google Scholar]

- Zhang, M.; He, H.; Jin, X.; Qu, Y.; Guo, H. Research on Key Factors Influencing Surface Subsidence of Paste Backfilling Mining in Thick Coal Seam of Deep Mine. Adv. Civ. Eng. 2021, 2021, 6634331. [Google Scholar] [CrossRef]

- Luan, Y.; Ji, Z.; Cui, Z.; Liang, Y. Prediction and analysis of surface subsidence coefficient based on combined weight. Coal Sci. Technol. 2022, 50, 223–228. [Google Scholar]

- Zhu, X.X.; Zhang, W.; Wang, Z.; Wang, C.; Li, W.; Wang, C.H. Simulation Analysis of Influencing Factors of Subsidence Based on Mining under Huge Loose Strata: A Case Study of Heze Mining Area, China. Geofluids 2020, 2020, 6357683. [Google Scholar] [CrossRef]

- Huang, C.L. Study of Impacts to Geological Environments by Coal Mining Activites in Lu’an Mining Area. Ph.D. Thesis, China University of Mining and Technology (Beijing), Beijing, China, 2013. (In Chinese with an English abstract). [Google Scholar]

- Gang, C.; Qiong, W.; Ming, L.X. Prediction of Surface Subsidence Due to Mining. Integr. Ferroelectr. 2020, 209, 76–85. [Google Scholar] [CrossRef]

- Du, Y.H.; Yang, W.F. Construction of investigation and monitoring system of coal mining subsidence area based on multi-source data in Shanxi province. Surv. Mapp. Bull. 2022, 8, 133–138, (In Chinese with an English abstract). [Google Scholar]

- Chai, L.; Zhu, X.D.; Wang, C.E. Analysis of Temple Form and Sculpture Value of Song Dynasty in Southeast Shanxi—The Case of Zhangzi Chongqing Temple. In Proceedings of the 2nd International Conference on Civil Engineering and Transportation (ICCET 2012), Guilin, China, 27–28 October 2012; pp. 67–70. [Google Scholar]

- Li, H.Z. Distribution and Regional Characteristics of Wooden-Frame Buildings Before Yuan Dynasty in Shanxi Province. Nat. Cult. Herit. Stud. 2021, 6, 1–28, (In Chinese with an English abstract). [Google Scholar]

- Guo, Y.J.; Zhao, X.; Chu, K.J. Thought on Development of Clean and Efficient Utilization of Coal Resources in Shanxi. Energy Energy Effic. 2018, 5, 63–65+160, (In Chinese with an English abstract). [Google Scholar]

- Huo, C. Study on Coal Resources Distribution Features and Exploration, Exploitation Layout in Shanxi Province. Coal Geol. China 2020, 32, 159–162, (In Chinese with an English abstract). [Google Scholar]

- Tian, L.; Cao, Y.; Chai, X.; Liu, T.; Feng, P.; Feng, H.; Zhou, D.; Shi, B.; Oestreich, R.; Rodvelt, G. Best practices for the determination of low-pressure/permeability coalbed methane reservoirs, Yuwu Coal Mine, Luan mining area, China. Fuel 2015, 160, 100–107. [Google Scholar] [CrossRef]

- Pan, J.E.A.; Sun, T.; Hou, Q.; Cao, Y.; Deng, X.W. Examination of the formation phases of coalbed methane reservoirs in the Lu’an mining area (China) based on a fluid inclusion analysis and Ro method. J. Nat. Gas Sci. Eng. 2015, 22, 73–82. [Google Scholar] [CrossRef]

- Zhang, M.; He, H.; Zhang, Y.; Jin, X.; Liang, X.; Zhang, Y.; Guo, H. Research on the Deformation and Control Technology of Surrounding Rock in Entry Retaining along the Gob Side. Adv. Civ. Eng. 2020, 2020, 8885439. [Google Scholar] [CrossRef]

- Tang, X.H. Current Situation, Hazards and Management of Coal Mining Subsidence Area in Shanxi. Ecol. Econ. 2016, 32, 6–9, (In Chinese with an English abstract). [Google Scholar]

- Gong, X.; Geng, J.; Sun, Q.; Gu, C.; Zhang, W. Experimental study on pumping-induced land subsidence and earth fissures: A case study in the Su-Xi-Chang region, China. Bull. Eng. Geol. Environ. 2020, 79, 4515–4525. [Google Scholar] [CrossRef]

- Yang, C.-S.; Zhang, Q.; Zhao, C.-Y.; Wang, Q.-L.; Ji, L.-Y. Monitoring land subsidence and fault deformation using the small baseline subset InSAR technique: A case study in the Datong Basin, China. J. Geodyn. 2014, 75, 34–40. [Google Scholar] [CrossRef]

- Choi, J.K.; Kim, K.; Lee, S.; Won, J.S. Application of a fuzzy operator to susceptibility estimations of coal mine subsidence in Taebaek City, Korea. Environ. Earth Sci. 2010, 59, 1009–1022. [Google Scholar]

- Oh, H.-J.; Ahn, S.-C.; Choi, J.-K.; Lee, S. Sensitivity analysis for the GIS-based mapping of the ground subsidence hazard near abandoned underground coal mines. Environ. Earth Sci. 2011, 64, 347–358. [Google Scholar] [CrossRef]

- Saro, L.; Hyun-Joo, O.; Ki-Dong, K. Statistical Spatial Modeling of Ground Subsidence Hazard near an Abandoned Underground Coal Mine. Disaster Adv. 2010, 3, 11–23. [Google Scholar]

- Hu, H.F. Research on Surface Subsidence Regularity and Prediction under Composite Mediums with Different Thickness Rations of Loose and Bedrock. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2012. (In Chinese with an English abstract). [Google Scholar]

- Liu, D.H.; Deng, N.; Yao, T. Analysis of main controlling factors of coal mining subsidence in Lu’an Mining Area. Min. Saf. Environ. Prot. 2020, 47, 103–107, (In Chinese with an English abstract). [Google Scholar]

- Zhu, X.; Guo, G.; Liu, H.; Yang, X. Surface subsidence prediction method of backfill-strip mining in coal mining. Bull. Eng. Geol. Environ. 2019, 78, 6235–6248. [Google Scholar] [CrossRef]

- Zhai, M.; Bai, H.; Wu, L.; Wu, G.; Yan, X.; Ma, D. A reinforcement method of floor grouting in high-water pressure working face of coal mines: A case study in Luxi coal mine, North China. Environ. Earth Sci. 2022, 81, 28. [Google Scholar] [CrossRef]

| Macro Factors | Number | Influencing Factors |

|---|---|---|

| Geological factors | A1 | Dip angle of coal seam α/° |

| A2 | Bedrock thickness D1/m | |

| A3 | Loose Strata thickness D2/m | |

| Mining Factors | A4 | Mining height H/m |

| A5 | Average mining depth H0/m | |

| A6 | Workface strike length L1/m | |

| A7 | Working surface inclination length L2/m |

| Number | A0 | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.72 | 8 | 187 | 25 | 3 | 212 | 770 | 180 |

| 2 | 0.72 | 7 | 144 | 20 | 3 | 164 | 500 | 160 |

| 3 | 0.80 | 8 | 510 | 40 | 6.5 | 540 | 1514 | 190 |

| 4 | 0.82 | 7 | 300 | 29 | 5.4 | 329 | 1450 | 200 |

| 5 | 0.82 | 2 | 288 | 62 | 6.2 | 350 | 223 | 1560 |

| 6 | 0.86 | 4 | 288 | 30 | 6.2 | 318 | 716 | 188 |

| 7 | 0.94 | 5 | 56 | 186 | 6.7 | 242 | 690 | 174 |

| Number | A0 | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.8873 | 1.3659 | 0.7383 | 0.4464 | 0.5676 | 0.6886 | 0.9193 | 0.4751 |

| 2 | 0.8873 | 1.1951 | 0.5685 | 0.3571 | 0.5676 | 0.5327 | 0.5970 | 0.4223 |

| 3 | 0.9859 | 1.3659 | 2.0135 | 0.7143 | 1.2297 | 1.7541 | 1.8076 | 0.5015 |

| 4 | 1.0106 | 1.1951 | 1.1844 | 0.5179 | 1.0216 | 1.0687 | 1.7312 | 0.5279 |

| 5 | 1.0106 | 0.3415 | 1.1371 | 1.1607 | 1.1730 | 1.1369 | 0.2662 | 4.1176 |

| 6 | 1.0599 | 0.6829 | 1.1371 | 0.5357 | 1.1730 | 1.0329 | 0.8549 | 0.49621 |

| 7 | 1.1585 | 0.8537 | 0.2211 | 3.3214 | 1.2676 | 0.7861 | 0.8238 | 0.4592 |

| |A0-A1| | |A0-A2| | |A0-A3| | |A0-A4| | |A0-A5| | |A0-A6| | |A0-A7| |

|---|---|---|---|---|---|---|

| 0.4786 | 0.1490 | 0.4409 | 0.3197 | 0.1987 | 0.0320 | 0.4122 |

| 0.3078 | 0.3188 | 0.5302 | 0.3197 | 0.3546 | 0.2903 | 0.4650 |

| 0.3800 | 1.0276 | 0.2716 | 0.2438 | 0.7682 | 0.8217 | 0.4844 |

| 0.1845 | 0.1738 | 0.4927 | 0.0110 | 0.0581 | 0.7206 | 0.4827 |

| 0.6691 | 0.1265 | 0.1501 | 0.1624 | 0.1263 | 0.7444 | 3.1070 |

| 03770 | 0.0772 | 0.5242 | 0.1131 | 0.0270 | 0.2050 | 0.5637 |

| 0.3048 | 0.9374 | 2.1629 | 0.1091 | 0.3724 | 0.3347 | 0.6993 |

| Number | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|

| Number of grey contacts | 0.7699 | 0.9189 | 0.7844 | 0.8352 | 0.8928 | 0.9868 | 0.7959 |

| 0.8405 | 0.8356 | 0.7508 | 0.8352 | 0.8199 | 0.8485 | 0.7751 | |

| 0.8092 | 0.6061 | 0.8572 | 0.8705 | 0.6739 | 0.6587 | 0.7677 | |

| 0.9002 | 0.9057 | 0.7646 | 1.0000 | 0.9708 | 0.6880 | 0.7683 | |

| 0.7039 | 0.9313 | 0.9183 | 0.9118 | 0.9314 | 0.6808 | 0.3357 | |

| 0.8104 | 0.9594 | 0.7530 | 0.9387 | 0.9899 | 0.8897 | 0.7389 | |

| 0.8419 | 0.6281 | 0.4210 | 0.9410 | 0.8123 | 0.8286 | 0.6945 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhu, S.; Peng, Z.; Yang, C.; Zhou, B.; Wang, X.; Zhao, Y. Influence of Coal Mining on Historical Buildings: Case Study in Shanxi. Int. J. Environ. Res. Public Health 2023, 20, 1543. https://doi.org/10.3390/ijerph20021543

Sun Y, Zhu S, Peng Z, Yang C, Zhou B, Wang X, Zhao Y. Influence of Coal Mining on Historical Buildings: Case Study in Shanxi. International Journal of Environmental Research and Public Health. 2023; 20(2):1543. https://doi.org/10.3390/ijerph20021543

Chicago/Turabian StyleSun, Yingfeng, Shuaipeng Zhu, Zhiqian Peng, Chunran Yang, Biao Zhou, Xiaoliang Wang, and Yixin Zhao. 2023. "Influence of Coal Mining on Historical Buildings: Case Study in Shanxi" International Journal of Environmental Research and Public Health 20, no. 2: 1543. https://doi.org/10.3390/ijerph20021543

APA StyleSun, Y., Zhu, S., Peng, Z., Yang, C., Zhou, B., Wang, X., & Zhao, Y. (2023). Influence of Coal Mining on Historical Buildings: Case Study in Shanxi. International Journal of Environmental Research and Public Health, 20(2), 1543. https://doi.org/10.3390/ijerph20021543