Recent Advances in Bio-Based Smart Active Packaging Materials

Abstract

:1. Introduction

2. Types of Bio-Based Materials

2.1. Protein-Based Materials

2.1.1. Whey Protein

2.1.2. Collagen

2.1.3. Zein

2.1.4. Soy Protein Isolate

2.2. Polysaccharide-Based Materials

2.2.1. Starch

2.2.2. Chitosan

2.2.3. Sodium Alginate

2.2.4. Pullulan

2.3. Composite Materials

3. Methods for Preparing Reactive Packaging Materials

3.1. Casting Method

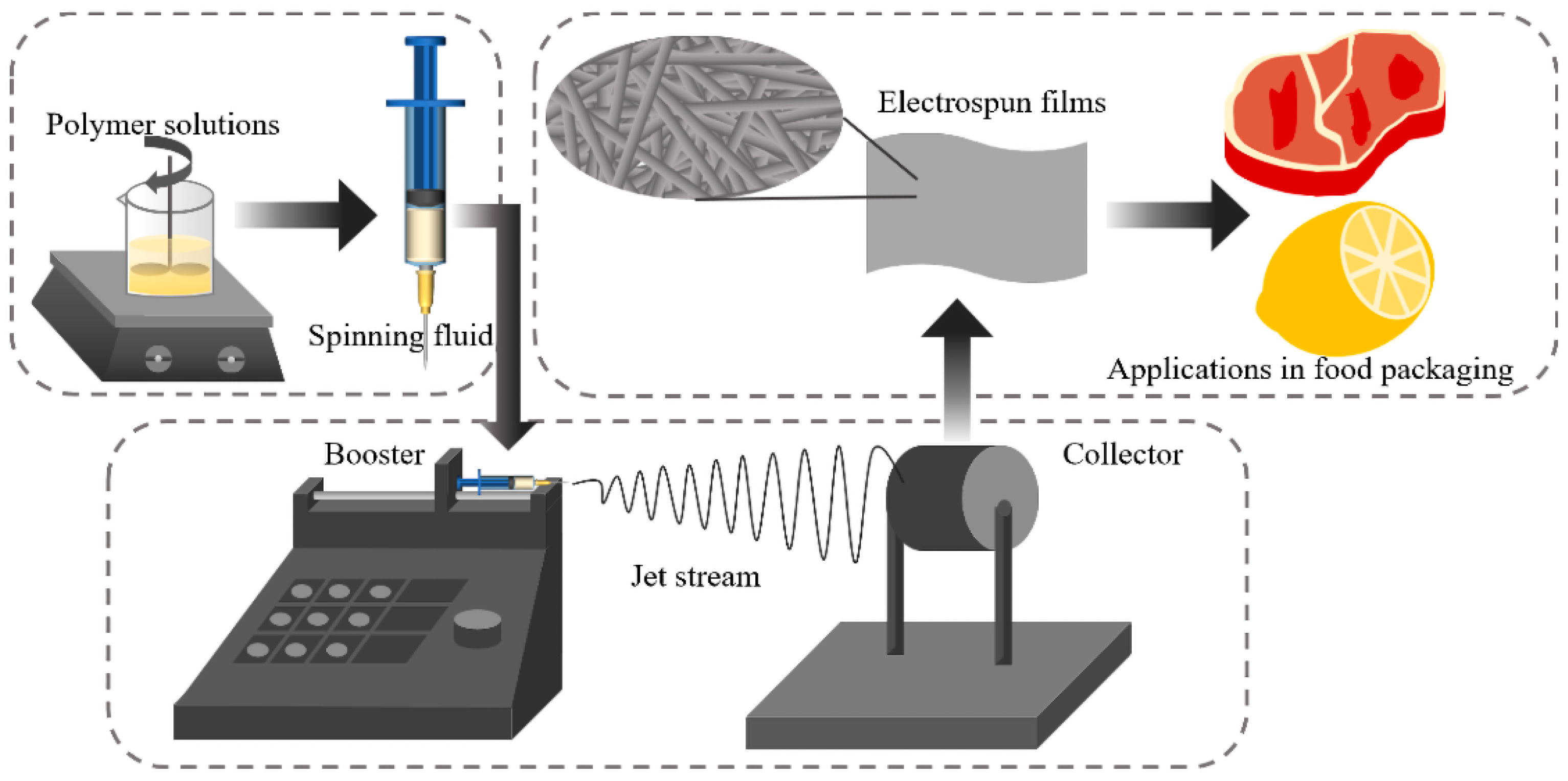

3.2. Electrostatic Spinning Technology

3.3. Three-Dimensional Printing Technology

4. Bio-Based Smart Active Packaging Materials for Food Applications

4.1. Application in Food Preservation

4.2. Application in Indicating Food Freshness

5. Conclusions

- ①

- The raw materials used in the preparation of smart packaging are both naturally derived and synthetic. It is difficult to guarantee the safety of synthetic substances, and therefore, there is a lack of toxicological testing on synthetic colourants. Smart packaging materials exist to improve food safety, and a poor choice of raw materials can lead to counterproductive test results.

- ②

- The choice of indicator also determines the effectiveness of the application of the product. The majority of studies have been carried out using pH changes to change the colour of the indicator, but in practice, environmental conditions can easily affect the colour development of the indicator, and changes in the external factors can have an impact on the accuracy of the indicator. Moreover, the colour development effect of some indicators is not obvious, and it is difficult to judge subtle colour changes by the naked eye, and even the colour change of some indicators can be reversed, which further increases the impact on the accuracy of smart packaging.

- ③

- Further research is needed into the kinetics of active substance diffusion. The rate of diffusion of the active substance affects the quality of the food, and a model for the slow release of the active substance needs to be developed.

- ④

- The technology used in the preparation of packaging materials still needs to be improved. Due to the diversity of the preparation methods, there are also gaps in the performances of the packaging materials they produce. In an analysis of the current state of research at home and abroad, it was found that the performances of packaging materials largely determine their applications and that poor mechanical properties due to imperfect preparation techniques can seriously undermine the functionality of a product.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dörnyei, K.R.; Bauer, A.-S.; Krauter, V.; Herbes, C. (Not) Communicating the Environmental Friendliness of Food Packaging to Consumers—An Attribute- and Cue-Based Concept and Its Application. Foods 2022, 11, 1371. [Google Scholar] [CrossRef]

- Shlush, E.; Davidovich-Pinhas, M. Bioplastics for food packaging. Trends Food Sci. Technol. 2022, 125, 66–80. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A. The application of natural food colorants as indicator substances in intelligent biodegradable packaging materials. Food Chem. Toxicol. 2020, 135, 110975. [Google Scholar] [CrossRef] [PubMed]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [Green Version]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Karim, A.A.; Norizan, M.N.; Sarifuddin, N.; Desa, M.S.Z.M.; Basri, M.S.M.; et al. A Review on Antimicrobial Packaging from Biodegradable Polymer Composites. Polymers 2022, 14, 174. [Google Scholar] [CrossRef]

- Yan, M.R.; Hsieh, S.; Ricacho, N. Innovative Food Packaging, Food Quality and Safety, and Consumer Perspectives. Processes 2022, 10, 747. [Google Scholar] [CrossRef]

- Pirsa, S.; Sani, I.K.; Mirtalebi, S.S. Nano-biocomposite based color sensors: Investigation of structure, function, and applications in intelligent food packaging. Food Packag. Shelf Life 2022, 31, 100789. [Google Scholar] [CrossRef]

- Prabhakar, P.; Sen, R.K.; Mayandi, V.; Patel, M.; Swathi, B.; Vishwakarma, J.; Gowri, V.S.; Lakshminarayanan, R.; Mondal, D.P.; Srivastava, A.K.; et al. Mussel-inspired chemistry to design biodegradable food packaging films with antimicrobial properties. Process Saf. Environ. Prot. 2022, 162, 17–29. [Google Scholar] [CrossRef]

- Zhen, N.; Wang, X.; Li, X.; Xue, J.; Zhao, Y.; Wu, M.; Zhou, D.; Liu, J.; Guo, J.; Zhang, H. Protein-based natural antibacterial materials and their applications in food preservation. Microb. Biotechnol. 2022, 15, 1324–1338. [Google Scholar] [CrossRef]

- Zhao, Y.; An, J.; Su, H.; Li, B.; Liang, D.; Huang, C. Antimicrobial food packaging integrating polysaccharide-based substrates with green antimicrobial agents: A sustainable path. Food Res. Int. 2022, 155, 111096. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Yang, W.; Xia, Y.; Xue, W.; Wu, H.; Li, Z.; Zhang, F.; Qiu, B.; Fu, C. Properties and Applications of Intelligent Packaging Indicators for Food Spoilage. Membranes 2022, 12, 477. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.; Bangar, S.P.; Thakur, N.; Trif, M. Recent Advancements in Smart Biogenic Packaging: Reshaping the Future of the Food Packaging Industry. Polymers 2022, 14, 829. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, D.; Regenstein, J.M.; Xia, W.; Dong, J. A comprehensive review on natural bioactive films with controlled release characteristics and their applications in foods and pharmaceuticals. Trends Food Sci. Technol. 2021, 112, 690–707. [Google Scholar] [CrossRef]

- Pereira, R.C.; de Deus Souza Carneiro, J.; Borges, S.V.; Assis, O.B.G.; Alvarenga, G.L. Preparation and Characterization of Nanocomposites from Whey Protein Concentrate Activated with Lycopene. J. Food Sci. 2016, 81, E637–E642. [Google Scholar] [CrossRef]

- Song, H.-G.; Choi, I.; Lee, J.-S.; Chang, Y.; Yoon, C.S.; Han, J. Whey protein isolate coating material for high oxygen barrier properties: A scale-up study from laboratory to industrial scale and its application to food packaging. Food Packag. Shelf Life 2022, 31, 100765. [Google Scholar] [CrossRef]

- Fitriani, F.; Aprilia, S.; Arahman, N.; Bilad, M.R.; Suhaimi, H.; Huda, N. Properties of Biocomposite Film Based on Whey Protein Isolate Filled with Nanocrystalline Cellulose from Pineapple Crown Leaf. Polymers 2021, 13, 4278. [Google Scholar] [CrossRef]

- Pino, P.; Ronchetti, S.; Mollea, C.; Sangermano, M.; Onida, B.; Bosco, F. Whey Proteins–Zinc Oxide Bionanocomposite as Antibacterial Films. Pharmaceutics 2021, 13, 1426. [Google Scholar] [CrossRef]

- Timorshina, S.; Popova, E.; Osmolovskiy, A. Sustainable Applications of Animal Waste Proteins. Polymers 2022, 14, 1601. [Google Scholar] [CrossRef] [PubMed]

- Mihalca, V.; Kerezsi, A.; Weber, A.; Gruber-Traub, C.; Schmucker, J.; Vodnar, D.C.; Dulf, F.V.; Socaci, S.A.; Fărcaș, A.; Mureșan, C.; et al. Protein-Based Films and Coatings for Food Industry Applications. Polymers 2021, 13, 769. [Google Scholar] [CrossRef]

- Lionetto, F.; Corcione, C.E. Recent Applications of Biopolymers Derived from Fish Industry Waste in Food Packaging. Polymers 2021, 13, 2337. [Google Scholar] [CrossRef]

- Ahmad, M.; Nirmal, N.P.; Chuprom, J. Molecular characteristics of collagen extracted from the starry triggerfish skin and its potential in the development of biodegradable packaging film. RSC Adv. 2016, 6, 33868–33879. [Google Scholar] [CrossRef]

- Xie, Z.; Yu, S.; He, M.; Yu, S.; Zhao, H.; Xiao, H.; Song, Y. Preparation of Antimicrobial Collagen Casings with High Mechanical Properties. Am. J. Biochem. Biotechnol. 2020, 16, 407–416. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Liu, A.; Wang, W. Improved thermal-stability and mechanical properties of type I collagen by crosslinking with casein, keratin and soy protein isolate using transglutaminase. Int. J. Biol. Macromol. 2017, 98, 292–301. [Google Scholar] [CrossRef]

- Xue, J.; Li, X.; Jin, X.; Wang, X.; Zhen, N.; Song, T.; Lan, T.; Qian, S.; Zhang, H.; Liu, J. Electrocatalytic oxidation of formaldehyde using electrospinning porous zein-based polyimide fibers. Mater. Lett. 2022, 320, 132318. [Google Scholar] [CrossRef]

- Huang, X.; Ge, X.; Zhou, L.; Wang, Y. Eugenol embedded zein and poly(lactic acid) film as active food packaging: Formation, characterization, and antimicrobial effects. Food Chem. 2022, 384, 132482. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Xi, S.; Han, Y.; Zhang, H.; Liu, J.; Li, Y. Structure, rheology and electrospinning of zein and poly(ethylene oxide) in aqueous ethanol solutions. Chin. Chem. Lett. 2019, 30, 305–310. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, X.; Tang, X.; Zhen, N.; Wang, Y.; Luo, Z.; Zhang, H.; Liu, J.; Zhou, D.; Huang, K. In vitro antioxidant and antitumor study of zein/SHA nanoparticles loaded with resveratrol. Food Sci. Nutr. 2021, 9, 3530–3537. [Google Scholar] [CrossRef]

- Zhang, L.; Li, K.; Yu, D.; Regenstein, J.M.; Dong, J.; Chen, W.; Xia, W. Chitosan/zein bilayer films with one-way water barrier characteristic: Physical, structural and thermal properties. Int. J. Biol. Macromol. 2022, 200, 378–387. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Sun, J.; Sun, Z.; Liu, F.; Du, L.; Wang, D. Fabrication and Characterization of Gelatin/Zein Nanofiber Films Loading Perillaldehyde for the Preservation of Chilled Chicken. Foods 2021, 10, 1277. [Google Scholar] [CrossRef] [PubMed]

- Ashfaq, J.; Channa, I.A.; Shaikh, A.A.; Chandio, A.D.; Shah, A.A.; Bughio, B.; Birmahani, A.; Alshehri, S.; Ghoneim, M.M. Gelatin- and Papaya-Based Biodegradable and Edible Packaging Films to Counter Plastic Waste Generation. Materials 2022, 15, 1046. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Wu, G.; Li, P.; Zhang, H.; Qi, X.; Wang, L.; Qian, H. The characterization and stability of the soy protein isolate/1-Octacosanol nanocomplex. Food Chem. 2019, 297, 124766. [Google Scholar] [CrossRef]

- Niu, C.; Jiang, X. The Preparation and Preservation of Soybean Protein Isolate Were Studied Based on the Internet of Things. J. Sens. 2022, 2022, 4941243. [Google Scholar] [CrossRef]

- Tao, R.; Sedman, J.; Ismail, A. Characterization and in vitro antimicrobial study of soy protein isolate films incorporating carvacrol. Food Hydrocoll. 2022, 122, 107091. [Google Scholar] [CrossRef]

- García-Guzmán, L.; Cabrera-Barjas, G.; Soria-Hernández, C.G.; Castaño, J.; Guadarrama-Lezama, A.Y.; Llamazares, S.R. Progress in Starch-Based Materials for Food Packaging Applications. Polysaccharides 2022, 3, 136–177. [Google Scholar] [CrossRef]

- Romainor, A.N.; Chin, S.F.; Lihan, S. Antimicrobial Starch-Based Film for Food Packaging Application. Starch 2021, 74, 2100207. [Google Scholar] [CrossRef]

- Maliki, S.; Sharma, G.; Kumar, A.; Moral-Zamorano, M.; Moradi, O.; Baselga, J.; Stadler, F.J.; García-Peñas, A. Chitosan as a Tool for Sustainable Development: A Mini Review. Polymers 2022, 14, 1475. [Google Scholar] [CrossRef]

- Herrera-Vázquez, S.E.; Dublán-García, O.; Arizmendi-Cotero, D.; Gómez-Oliván, L.M.; Islas-Flores, H.; Hernández-Navarro, M.D.; Ramírez-Durán, N. Optimization of the Physical, Optical and Mechanical Properties of Composite Edible Films of Gelatin, Whey Protein and Chitosan. Molecules 2022, 27, 869. [Google Scholar] [CrossRef]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Ahmed, S.; Ikram, S. Chitosan and gelatin based biodegradable packaging films with UV-light protection. J. Photochem. Photobiol. B 2016, 163, 115–124. [Google Scholar] [CrossRef]

- Subramanian, K.; Logaraj, H.; Ramesh, V.; Mani, M.; Balakrishnan, K.; Selvaraj, H.; Pugazhvendan, S.R.; Velmurugan, S.; Aruni, W. Intelligent pH Indicative Film from Plant-Based Extract for Active Biodegradable Smart Food Packing. J. Nanomater. 2022, 2022, 4482114. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Rodrigues, P.F.; Lopes, A.; Silva, R.J.; Caldeira, J.; Duarte, M.P.; Fernandes, F.B.; Coelhoso, I.M.; et al. Physical and Morphological Characterization of Chitosan/Montmorillonite Films Incorporated with Ginger Essential Oil. Coatings 2019, 9, 700. [Google Scholar] [CrossRef] [Green Version]

- Perera, K.Y.; Sharma, S.; Pradhan, D.; Jaiswal, A.K.; Jaiswal, S. Seaweed Polysaccharide in Food Contact Materials (Active Packaging, Intelligent Packaging, Edible Films, and Coatings). Foods 2021, 10, 2088. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Z.; Li, P.; Li, W.; Li, C.; Wang, Y.; Chu, P.K. Degradable and Photocatalytic Antibacterial Au-TiO2/Sodium Alginate Nanocomposite Films for Active Food Packaging. Nanomaterials 2018, 8, 930. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Cao, J.; Liu, W.; Mei, J.; Xie, J. Characterization of Sodium Alginate—Locust Bean Gum Films Reinforced with Daphnetin Emulsions for the Development of Active Packaging. Polymers 2022, 14, 731. [Google Scholar] [CrossRef]

- Alghamdi, H.M.; Abutalib, M.M.; Mannaa, M.A.; Nur, O.; Abdelrazek, E.M.; Rajeh, A. Modification and development of high bioactivities and environmentally safe polymer nanocomposites doped by Ni/ZnO nanohybrid for food packaging applications. J. Mater. Res. Technol. 2022, 19, 3421–3432. [Google Scholar] [CrossRef]

- Amjadi, S.; Gholizadeh, S.; Ebrahimi, A.; Almasi, H.; Hamishehkar, H.; Taheri, R.A. Development and characterization of the carvone-loaded zein/pullulan hybrid electrospun nanofibers for food and medical applications. Ind. Crops Prod. 2022, 183, 114964. [Google Scholar] [CrossRef]

- Han, K.; Liu, Y.; Liu, Y.; Huang, X.; Sheng, L. Characterization and film-forming mechanism of egg white/pullulan blend film. Food Chem. 2020, 315, 126201. [Google Scholar] [CrossRef] [PubMed]

- Rai, M.; Wypij, M.; Ingle, A.P.; Trzcińska-Wencel, J.; Golińska, P. Emerging Trends in Pullulan-Based Antimicrobial Systems for Various Applications. Int. J. Mol. Sci. 2021, 22, 13596. [Google Scholar] [CrossRef]

- Silva, N.H.C.S.; Vilela, C.; Almeida, A.; Marrucho, I.M.; Freire, C.S.R. Pullulan-based nanocomposite films for functional food packaging: Exploiting lysozyme nanofibers as antibacterial and antioxidant reinforcing additives. Food Hydrocoll. 2018, 77, 921–930. [Google Scholar] [CrossRef]

- Khanzadi, M.; Jafari, S.M.; Mirzaei, H.; Chegini, F.K.; Maghsoudlou, Y.; Dehnad, D. Physical and mechanical properties in biodegradable films of whey protein concentrate–pullulan by application of beeswax. Carbohydr. Polym. 2015, 118, 24–29. [Google Scholar] [CrossRef]

- Castro, J.I.; Navia-Porras, D.P.; Cortés, J.A.A.; Hernández, J.H.M.; Grande-Tovar, C.D. Synthesis, Characterization, and Optimization Studies of Starch/Chicken Gelatin Composites for Food-Packaging Applications. Molecules 2022, 27, 2264. [Google Scholar] [CrossRef]

- Domínguez, R.; Barba, F.J.; Gómez, B.; Putnik, P.; Kovačević, D.B.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef]

- Tracey, C.T.; Predeina, A.L.; Krivoshapkina, E.F.; Kumacheva, E. A 3D printing approach to intelligent food packaging. Trends Food Sci. Technol. 2022, 127, 87–98. [Google Scholar] [CrossRef]

- Tomasula, P.M.; Sousa, A.M.M.; Liou, S.-C.; Li, R.; Bonnaillie, L.M.; Liu, L.S. Short communication: Electrospinning of casein/pullulan blends for food-grade applications. J. Dairy Sci. 2016, 99, 1837–1845. [Google Scholar] [CrossRef]

- Leidy, R.; Ximena, Q.-C.M. Use of electrospinning technique to produce nanofibres for food industries: A perspective from regulations to characterisations. Trends Food Sci. Technol. 2019, 85, 92–106. [Google Scholar] [CrossRef]

- Gagaoua, M.; Pinto, V.Z.; Göksen, G.; Alessandroni, L.; Lamri, M.; Dib, A.L.; Boukid, F. Electrospinning as a Promising Process to Preserve the Quality and Safety of Meat and Meat Products. Coatings 2022, 12, 644. [Google Scholar] [CrossRef]

- Zhang, W.; Rhim, J.-W. Recent progress in konjac glucomannan-based active food packaging films and property enhancement strategies. Food Hydrocoll. 2022, 128, 107572. [Google Scholar] [CrossRef]

- Li, S.; Jiang, Y.; Zhou, Y.; Li, R.; Jiang, Y.; Hossen, M.A.; Dai, J.; Qin, W.; Liu, Y. Facile fabrication of sandwich-like anthocyanin/chitosan/lemongrass essential oil films via 3D printing for intelligent evaluation of pork freshness. Food Chem. 2022, 370, 131082. [Google Scholar] [CrossRef]

- Song, Z.; Liu, H.; Huang, A.; Zhou, C.; Hong, P.; Deng, C. Collagen/zein electrospun films incorporated with gallic acid for tilapia (Oreochromis niloticus) muscle preservation. J. Food Eng. 2022, 317, 110860. [Google Scholar] [CrossRef]

- Wang, D.; Sun, J.; Li, J.; Sun, Z.; Liu, F.; Du, L.; Wang, D. Preparation and characterization of gelatin/zein nanofiber films loaded with perillaldehyde, thymol, or ε-polylysine and evaluation of their effects on the preservation of chilled chicken breast. Food Chem. 2022, 373, 131439. [Google Scholar] [CrossRef]

- Yilmaz, P.; Demirhan, E.; Ozbek, B. Development of Ficus carica Linn leaves extract incorporated chitosan films for active food packaging materials and investigation of their properties. Food Biosci. 2022, 46, 101542. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Ezati, P.; Rhim, J.-W. Curcumin and its uses in active and smart food packaging applications—A comprehensive review. Food Chem. 2022, 375, 131885. [Google Scholar] [CrossRef]

- Tsironi, M.; Kosma, I.S.; Badeka, A.V. The Effect of Whey Protein Films with Ginger and Rosemary Essential Oils on Microbiological Quality and Physicochemical Properties of Minced Lamb Meat. Sustainability 2022, 14, 3434. [Google Scholar] [CrossRef]

- Kontogianni, V.G.; Kasapidou, E.; Mitlianga, P.; Mataragas, M.; Pappa, E.; Kondyli, E.; Bosnea, L. Production, characteristics and application of whey protein films activated with rosemary and sage extract in preserving soft cheese. LWT 2022, 155, 112996. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Liu, Y.; Zhang, J.; Hossen, M.A.; Sameen, D.E.; Dai, J.; Li, S.; Qin, W. Fabrication and characterization of pH-responsive intelligent films based on carboxymethyl cellulose and gelatin/curcumin/chitosan hybrid microcapsules for pork quality monitoring. Food Hydrocoll. 2022, 124, 107224. [Google Scholar] [CrossRef]

- Ezati, P.; Tajik, H.; Moradi, M. Fabrication and characterization of alizarin colorimetric indicator based on cellulose-chitosan to monitor the freshness of minced beef. Sens. Actuators B 2019, 285, 519–528. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, L.; Yu, J.; Shao, P. Novel trends and applications of natural pH-responsive indicator film in food packaging for improved quality monitoring. Food Control 2022, 134, 108769. [Google Scholar] [CrossRef]

- Erna, K.H.; Felicia, W.X.L.; Vonnie, J.M.; Rovina, K.; Yin, K.W.; Nur’Aqilah, N.M. Synthesis and Physicochemical Characterization of Polymer Film-Based Anthocyanin and Starch. Biosensors 2022, 12, 211. [Google Scholar] [CrossRef]

- Boonsiriwit, A.; Itkor, P.; Sirieawphikul, C.; Lee, Y.S. Characterization of Natural Anthocyanin Indicator Based on Cellulose Bio-Composite Film for Monitoring the Freshness of Chicken Tenderloin. Molecules 2022, 27, 2752. [Google Scholar] [CrossRef]

- Huang, J.; Hu, Z.; Li, G.; Hu, L.; Chen, J.; Hu, Y. Make your packaging colorful and multifunctional: The molecular interaction and properties characterization of natural colorant-based films and their applications in food industry. Trends Food Sci. Technol. 2022, 124, 259–277. [Google Scholar] [CrossRef]

- Aghaei, Z.; Ghorani, B.; Emadzadeh, B.; Kadkhodaee, R.; Tucker, N. Protein-based halochromic electrospun nanosensor for monitoring trout fish freshness. Food Control 2020, 111, 107065. [Google Scholar] [CrossRef]

- Gao, R.; Hu, H.; Shi, T.; Bao, Y.; Sun, Q.; Wang, L.; Ren, Y.; Jin, W.; Yuan, L. Incorporation of gelatin and Fe2+ increases the pH-sensitivity of zein-anthocyanin complex films used for milk spoilage detection. Curr. Res. Food Sci. 2022, 5, 677–686. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, J.; Zhou, H.; Zhou, S.; Lv, Y.; Cheng, Y.; Tao, Y.; Lu, J.; Wang, H. Biodegradable intelligent film for food preservation and real-time visual detection of food freshness. Food Hydrocoll. 2022, 129, 107665. [Google Scholar] [CrossRef]

| CATEGORY | ADVANTAGES | DISADVANTAGES | |

|---|---|---|---|

| PROTEIN | Whey protein | The protein has been deformed by acids, alkaline solvents and heat to create the additional extension system required for proteins with a more cohesive structure. | Packaging materials prepared from a single protein have poor mechanical strength and resistance to water and become brittle after drying. |

| Collagen | |||

| Zein | |||

| Soy protein isolate | |||

| POLYSACCHARIDES | Starch | The ordered hydrogen bonding network of polysaccharides facilitates close bonding between adjacent chains and good oxygen barrier properties. | The presence of the hydrophilic structural domain of the polysaccharide leads to its poor water barrier properties. |

| Chitosan | |||

| Sodium alginate | |||

| Pullulan | |||

| COMPOSITE MATERIALS | The use of two or more polymers and a number of actives allows better control of release properties and enhances the functionality of the packaging material. | The preparation process is more complex than for a single material, and it is important to ensure that the substances added act synergistically rather than antagonistically. | |

| PREPARATION METHODS | ADVANTAGES | DISADVANTAGES |

|---|---|---|

| CASTING METHOD | simple, fast and cost-effective operation | uneven thickness of the product, poor tensile strength and modulus of elasticity of the product |

| ELECTROSTATIC SPINNING TECHNOLOGY | fast, low cost, high specific surface area, high porosity and homogeneous fibres | the equipment parameters are not easily adjustable, and the preparation process is prone to failure |

| 3D PRINTING TECHNOLOGY | complex structures in multiple materials can be printed simultaneously using multiple nozzles at low cost | time-consuming preparation process and more complex than other preparation methods |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, T.; Qian, S.; Lan, T.; Wu, Y.; Liu, J.; Zhang, H. Recent Advances in Bio-Based Smart Active Packaging Materials. Foods 2022, 11, 2228. https://doi.org/10.3390/foods11152228

Song T, Qian S, Lan T, Wu Y, Liu J, Zhang H. Recent Advances in Bio-Based Smart Active Packaging Materials. Foods. 2022; 11(15):2228. https://doi.org/10.3390/foods11152228

Chicago/Turabian StyleSong, Tingyu, Sheng Qian, Tiantong Lan, Yuzhu Wu, Jingsheng Liu, and Hao Zhang. 2022. "Recent Advances in Bio-Based Smart Active Packaging Materials" Foods 11, no. 15: 2228. https://doi.org/10.3390/foods11152228

APA StyleSong, T., Qian, S., Lan, T., Wu, Y., Liu, J., & Zhang, H. (2022). Recent Advances in Bio-Based Smart Active Packaging Materials. Foods, 11(15), 2228. https://doi.org/10.3390/foods11152228