Rational Distributed Bragg Reflector Design for Improving Performance of Flip-Chip Micro-LEDs

Abstract

:1. Introduction

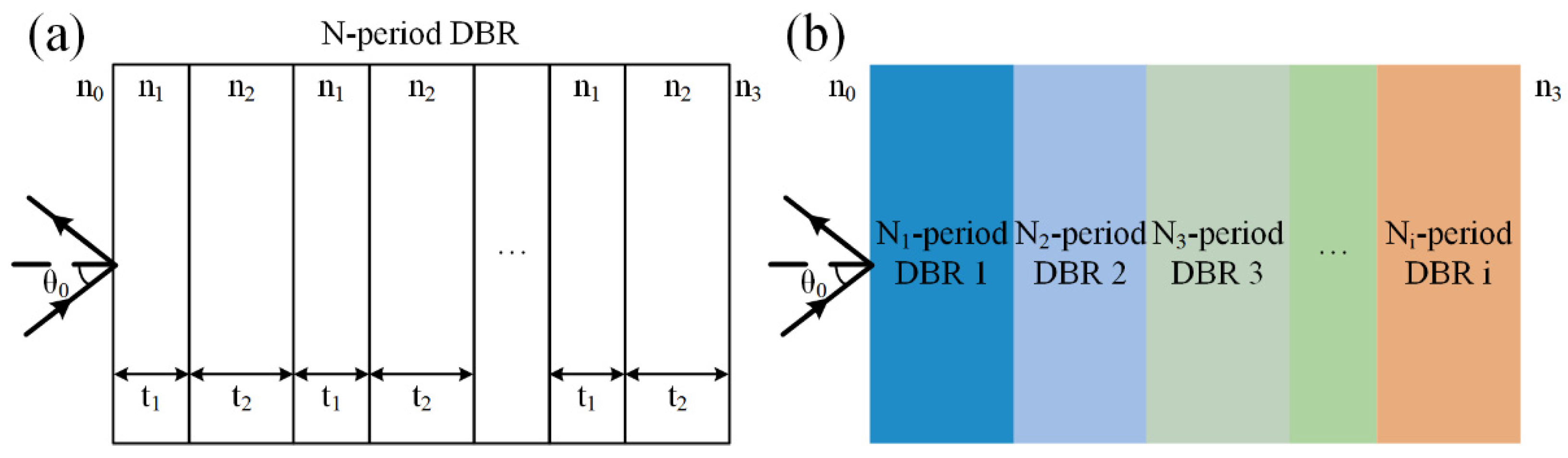

2. Model and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Y.M.; Chen, J.H.; Liou, Y.H.; Singh, K.J.; Tsai, W.C.; Han, J.; Lin, C.J.; Kao, T.S.; Lin, C.C.; Chen, S.C.; et al. High-Uniform and High-Efficient Color Conversion Nanoporous GaN-Based Micro-LED Display with Embedded Quantum Dots. Nanomaterials 2021, 11, 2696. [Google Scholar] [CrossRef] [PubMed]

- Hsiang, E.L.; He, Z.; Huang, Y.; Gou, F.; Lan, Y.F.; Wu, S.T. Improving the Power Efficiency of Micro-LED Displays with Optimized LED Chip Sizes. Crystals 2020, 10, 494. [Google Scholar] [CrossRef]

- Kishino, K.; Sakakibara, N.; Narita, K.; Oto, T. Two-dimensional multicolor (RGBY) integrated nanocolumn micro-LEDs as a fundamental technology of micro-LED display. Appl. Phys. Express 2019, 13, 014003. [Google Scholar] [CrossRef]

- Gou, F.; Hsiang, E.L.; Tan, G.; Chou, P.T.; Li, Y.L.; Lan, Y.F.; Wu, S.T. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746–A757. [Google Scholar] [CrossRef]

- Horng, R.H.; Chien, H.Y.; Tarntair, F.G.; Wuu, D.S. Fabrication and Study on Red Light Micro-LED Displays. IEEE J. Electron Devices Soc. 2018, 6, 1064–1069. [Google Scholar] [CrossRef]

- Chang, K.P.; Tsai, Y.T.; Yen, C.C.; Horng, R.H.; Wuu, D.S. Structural design and performance improvement of flip-chip AlGaInP mini light-emitting diodes. Semicond. Sci. Technol. 2021, 36, 095008. [Google Scholar] [CrossRef]

- Kim, T.K.; Islam, A.; Cha, Y.J.; Kwak, J.S. 32 × 32 Pixelated High-Power Flip-Chip Blue Micro-LED-on-HFET Arrays for Submarine Optical Communication. Nanomaterials 2021, 11, 3045. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.L.; Deng, M.Y.; Wu, S.T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef]

- Xiong, J.; Hsiang, E.L.; He, Z.; Zhan, T.; Wu, S.T. Augmented reality and virtual reality displays: Emerging technologies and future perspectives. Light Sci. Appl. 2021, 10, 216. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, J.; Su, P.; Zhang, L.; Xia, B. Full-Color Realization of Micro-LED Displays. Nanomaterials 2020, 10, 2482. [Google Scholar] [CrossRef]

- Peng, D.; Zhang, K.; Chao, V.S.D.; Mo, W.; Lau, K.M.; Liu, Z. Full-Color Pixelated-Addressable Light Emitting Diode on Transparent Substrate (LEDoTS) Micro-Displays by CoB. J. Display Technol. 2016, 12, 742–746. [Google Scholar] [CrossRef]

- Zhou, X.; Tian, P.; Sher, C.W.; Wu, J.; Liu, H.; Liu, R.; Kuo, H.C. Growth, transfer printing and colour conversion techniques towards full-colour micro-LED display. Prog. Quantum Electron. 2020, 71, 100263. [Google Scholar] [CrossRef]

- Ding, K.; Avrutin, V.; Izyumskaya, N.; Özgür, Ü.; Morkoç, H. Micro-LEDs, a Manufacturability Perspective. Appl. Sci. 2019, 9, 1206. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Chen, Z.; Liu, Y.; Liu, S. Highly efficient GaN-based high-power flip-chip light-emitting diodes. Opt. Express 2019, 27, A669–A692. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Zhao, H. Analysis of light extraction efficiency enhancement for thin-film-flip-chip InGaN quantum wells light-emitting diodes with GaN micro-domes. Opt. Express 2012, 20, A765–A776. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Peng, Y.; Mou, Y.; Cheng, H.; Chen, M.; Liu, S. Thermally stable multi-color phosphor-in-glass bonded on flip-chip UV-LEDs for chromaticity-tunable WLEDs. Appl. Opt. 2017, 56, 7921–7926. [Google Scholar] [CrossRef]

- Konoplev, S.S.; Bulashevich, K.A.; Karpov, S.Y. From Large-Size to Micro-LEDs: Scaling Trends Revealed by Modeling. Phys. Status Solidi Appl. Mater. Sci. 2018, 215, 1700508. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, S.; Gao, Y.; Hu, H.; Liu, Y.; Gui, C.; Liu, S. Numerical simulation and experimental investigation of GaN-based flip-chip LEDs and top-emitting LEDs. Appl. Opt. 2017, 56, 9502–9509. [Google Scholar] [CrossRef]

- Shchekin, O.B.; Epler, J.E.; Trottier, T.A.; Margalith, T.; Steigerwald, D.A.; Holcomb, M.O.; Martin, P.S.; Krames, M.R. High performance thin-film flip-chip InGaN–GaN light-emitting diodes. Appl. Phys. Lett. 2006, 89, 071109. [Google Scholar] [CrossRef]

- Hu, H.; Tang, B.; Wan, H.; Sun, H.; Zhou, S.; Dai, J.; Chen, C.; Liu, S.; Guo, L.J. Boosted ultraviolet electroluminescence of InGaN/AlGaN quantum structures grown on high-index contrast patterned sapphire with silica array. Nano Energy 2020, 69, 104427. [Google Scholar] [CrossRef]

- Tang, B.; Miao, J.; Liu, Y.; Zhou, S.; Xu, H.; Wan, H. Insights into the Influence of Sidewall Morphology on the Light Extraction Efficiency of Mini-LEDs. IEEE Photon. J. 2019, 11, 8200907. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Y.; Yan, J.; Xie, H.; Liu, L.; Chen, X.; Hou, M.; Qin, Z.; Wang, J.; Li, J. Light extraction enhancement of AlGaN-based ultraviolet light-emitting diodes by substrate sidewall roughening. Appl. Phys. Lett. 2017, 111, 011102. [Google Scholar] [CrossRef]

- Zhuang, Z.; Iida, D.; Ohkawa, K. Effects of size on the electrical and optical properties of InGaN-based red light-emitting diodes. Appl. Phys. Lett. 2020, 116, 173501. [Google Scholar] [CrossRef]

- Smith, J.M.; Ley, R.; Wong, M.S.; Baek, Y.H.; Kang, J.H.; Kim, C.H.; Gordon, M.J.; Nakamura, S.; Speck, J.S.; DenBaars, S.P. Comparison of size-dependent characteristics of blue and green InGaN microLEDs down to 1 μm in diameter. Appl. Phys. Lett. 2020, 116, 071102. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, Y.; Zhang, Z.H.; Zhu, B.; Zheng, H.; Tan, S.T.; Demir, H.V. High-Performance Triangular Miniaturized-LEDs for High Current and Power Density Applications. ACS Photon. 2021, 8, 2304–2310. [Google Scholar] [CrossRef]

- Chao, S.H.; Yeh, L.H.; Wu, R.T.; Kawagishi, K.; Hsu, S.C. Novel patterned sapphire substrates for enhancing the efficiency of GaN-based light-emitting diodes. RSC Adv. 2020, 10, 16284–16290. [Google Scholar] [CrossRef]

- Manley, P.; Walde, S.; Hagedorn, S.; Hammerschmidt, M.; Burger, S.; Becker, C. Nanopatterned sapphire substrates in deep-UV LEDs: Is there an optical benefit? Opt. Express 2020, 28, 3619–3635. [Google Scholar] [CrossRef]

- Ooi, Y.K.; Zhang, J. Light Extraction Efficiency Analysis of Flip-Chip Ultraviolet Light-Emitting Diodes with Patterned Sapphire Substrate. IEEE Photon. J. 2018, 10, 8200913. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, S. III-Nitride LEDs: From UV to Green; Springer Nature: Singapore, 2022; pp. 91–95. [Google Scholar]

- Wang, D.X.; Ferguson, I.T.; Buck, J.A. GaN-based distributed Bragg reflector for high-brightness LED and solid-state lighting. Appl. Opt. 2007, 46, 4763–4767. [Google Scholar] [CrossRef]

- Huang, S.Y.; Horng, R.H.; Wang, W.K.; Wuu, D.S. GaN-Based Green Resonant Cavity Light-Emitting Diodes. Jpn. J. Appl. Phys. 2006, 45, 3433–3435. [Google Scholar] [CrossRef]

- Zhi, T.; Tao, T.; Liu, B.; Yan, Y.; Xie, Z.; Zhao, H.; Chen, D. High Performance Wide Angle DBR Design for Optoelectronic Devices. IEEE Photon. J. 2021, 13, 8200206. [Google Scholar] [CrossRef]

- Ding, X.; Gui, C.; Hu, H.; Liu, M.; Liu, X.; Lv, J.; Zhou, S. Reflectance bandwidth and efficiency improvement of light-emitting diodes with double-distributed Bragg reflector. Appl. Opt. 2017, 56, 4375–4380. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Zhao, X.; Du, P.; Liu, Y.; Lv, Q.; Zhou, S. Enhanced performance of GaN-based visible flip-chip mini-LEDs with highly reflective full-angle distributed Bragg reflectors. Opt. Express 2021, 29, 42276–42286. [Google Scholar] [CrossRef]

- Kats, M.A.; Blanchard, R.; Genevet, P.; Capasso, F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nat. Mater. 2013, 12, 20–24. [Google Scholar] [CrossRef]

- Wu, C.J.; Chu, B.H.; Weng, M.T. Analysis of Optical Reflection in a Chirped Distributed Bragg Reflector. J. Electromagn. Waves Appl. 2009, 23, 129–138. [Google Scholar] [CrossRef]

- Pérez, E.X. Design, Fabrication and Characterization of Porous Silicon Multilayer Optical Devices. Ph.D. Thesis, Universitat Rovira i Virgili, Tarragona, Spain, 2008. [Google Scholar]

- Hu, X.; Cai, J.; Liu, Y.; Zhao, M.; Chen, E.; Sun, J.; Yan, Q.; Guo, T. Design of inclined omni-directional reflector for sidewall-emission-free micro-scale light-emitting diodes. Opt. Laser Technol. 2022, 154, 108335. [Google Scholar] [CrossRef]

| Red Micro-LED | Thickness (μm) | n | k | Green/Blue Micro-LED | Thickness (μm) | n | k |

|---|---|---|---|---|---|---|---|

| Green (Blue) | Green (Blue) | ||||||

| p-GaP | 2 | 3.322 | 0 | p-GaN | 0.5 | 2.38 (2.43) | 5 × 10−3 (6 × 10−3) |

| p-AlInP | 0.42 | 3.014 | 4 × 10−3 | n-GaN | 2.5 | 2.38 (2.43) | 5 × 10−3 (6 × 10−3) |

| n-AlGaInP | 1.3 | 3.223 | 9 × 10−3 | ITO | 0.28 | 1.89 (1.95) | 4 × 10−3 (6 × 10−3) |

| n-GaAs | 0.08 | 3.856 | 0.196 | - | - | - | - |

| ITO | 0.28 | 1.79 | 0 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Shi, L.; Du, P.; Zhao, X.; Zhou, S. Rational Distributed Bragg Reflector Design for Improving Performance of Flip-Chip Micro-LEDs. Electronics 2022, 11, 3030. https://doi.org/10.3390/electronics11193030

Sun Y, Shi L, Du P, Zhao X, Zhou S. Rational Distributed Bragg Reflector Design for Improving Performance of Flip-Chip Micro-LEDs. Electronics. 2022; 11(19):3030. https://doi.org/10.3390/electronics11193030

Chicago/Turabian StyleSun, Yuechang, Lang Shi, Peng Du, Xiaoyu Zhao, and Shengjun Zhou. 2022. "Rational Distributed Bragg Reflector Design for Improving Performance of Flip-Chip Micro-LEDs" Electronics 11, no. 19: 3030. https://doi.org/10.3390/electronics11193030

APA StyleSun, Y., Shi, L., Du, P., Zhao, X., & Zhou, S. (2022). Rational Distributed Bragg Reflector Design for Improving Performance of Flip-Chip Micro-LEDs. Electronics, 11(19), 3030. https://doi.org/10.3390/electronics11193030