Mitigating the Toxic Effects of Chromium on Wheat (Triticum aestivum L.) Seed Germination and Seedling Growth by Using Biochar and Polymer-Modified Biochar in Contaminated Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biochar Production, Polymerization and Characterization

2.2. Soil Collection and Characterization

2.3. Germination Experiment

2.4. Statistical Analysis

3. Results and Discussion

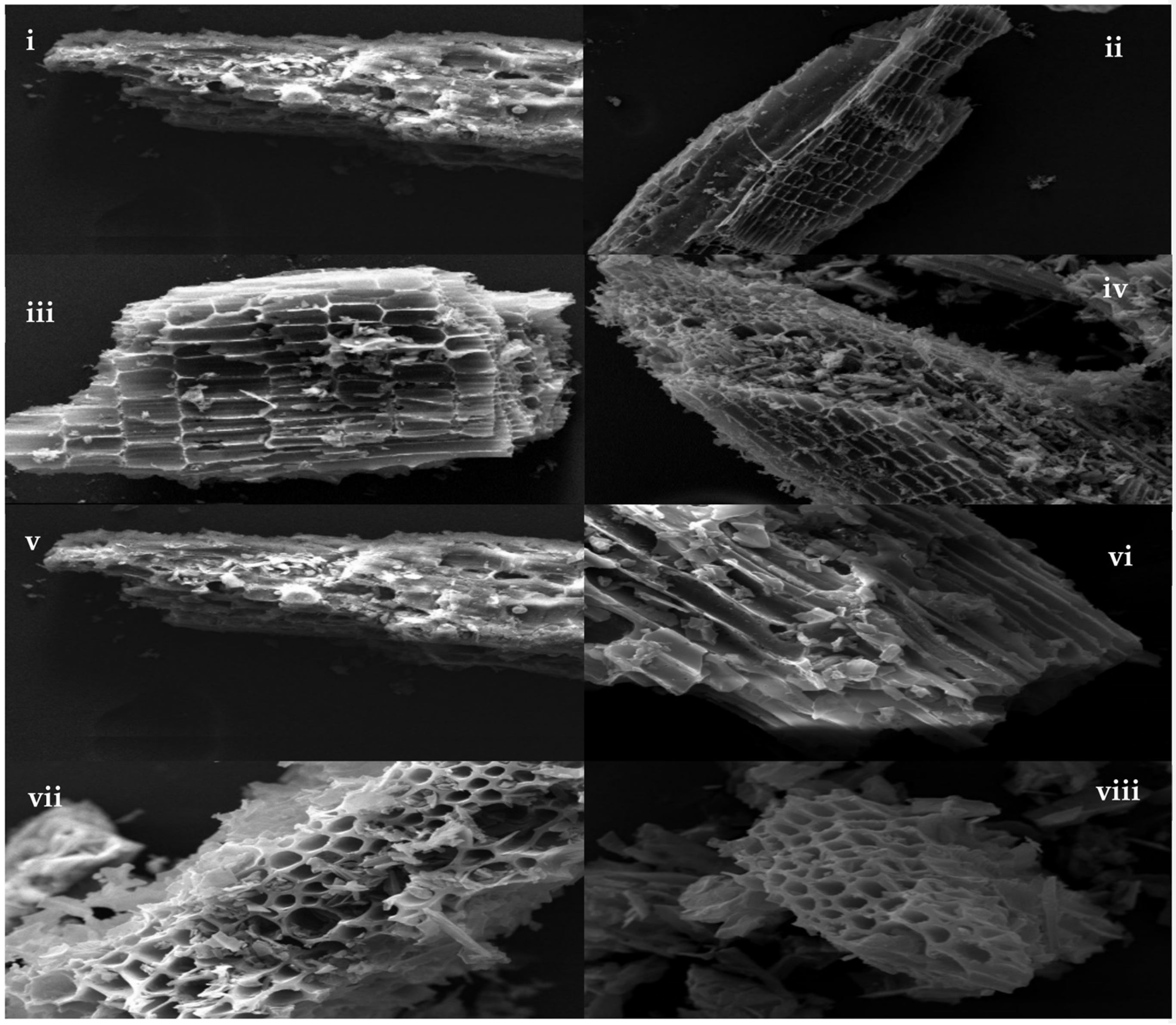

3.1. Biochar and Polymer MODIFIED Biochar Characteristics

3.2. Germination Experiment

3.2.1. Soil Characterization

3.2.2. Effect of CrVI Concentration on Germination Percentage

3.2.3. Effect of CrVI Concentration on Fresh and Dry Weight of Seedlings (g)

3.2.4. Effect of CrVI Concentration on Root and Shoot Lengths (cm)

3.2.5. Effect of Charred Materials on Germination (%)

3.2.6. Effect of Charred Materials on Fresh and Dry Weight of Seedlings (g)

3.2.7. Effect of Charred Materials on Root and Shoot Lengths (cm)

3.2.8. Effect of Charred Materials on Cr Uptake (µg/Seedling)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karimi, H.; Mahdavi, S.; Asgari Lajayer, B.; Moghiseh, E.; Rajput, V.D.; Minkina, T.; Astatkie, T. Insights on the bioremediation technologies for pesticide-contaminated soils. Environ. Geochem. Health 2022, 44, 1329–1354. [Google Scholar] [CrossRef] [PubMed]

- McBride, M.B.; Richards, B.K.; Steenhuis, T. Bioavailability and crop uptake of trace elements in soil columns amended with sewage sludge products. Plant Soil 2004, 262, 71–84. [Google Scholar] [CrossRef]

- Surita, C.A.; Gloaguen, T.; Montes, C.R.; Dias, C.T.S. Assessment of soil solution chemicals after tannery effluents disposal. Am. J. Appl. Sci. 2007, 4, 1063–1070. [Google Scholar] [CrossRef]

- Famielec, S.; Wieczorek-Ciurowa, K. Waste from leather industry. Threats to the environment. Czasopismo. Techniczne. Chemia. 2011, 108, 43–48. [Google Scholar]

- Akter, F.; Tinni, H.H.; Banarjee, P.; Hossain, M.Z. Effects Of heavy metals (Cd, Zn And Cu) on carbon, nitrogen and iron mineralization in soil. Malays. J. Sustain. Agric. 2019, 3, 33–38. [Google Scholar] [CrossRef]

- Du, Y.; He, J.H.; Chen, J.J. Effects of heavy metals of Pb, Cd and Cr on the growth of vegetables and their uptake. Acta Hortic. Sin. 2003, 30, 51–55. [Google Scholar]

- Gunatilake, S.K. Removal of Cr (III) Ions from Wastewater using Sawdust and Rice Husk Biochar Pyrolyzed at Low Temperature. Int. J. Innov. Educ. Res. 2016, 4, 44–54. [Google Scholar] [CrossRef]

- Choppala, G.; Bolan, N.; Kunhikrishnan, A.; Skinner, W.; Seshadri, B. Concomitant reduction and immobilization of chromium in relation to its bioavailability in soils. Environ. Sci. Pollut. 2015, 22, 8969–8978. [Google Scholar] [CrossRef]

- Rafique, M.I.; Usman, A.R.; Ahmad, M.; Sallam, A.; Al-Wabel, M.I. In situ immobilization of Cr and its availability to maize plants in tannery waste contaminated soil: Effects of biochar feedstock and pyrolysis temperature. J. Soils. Sediments 2020, 20, 330–339. [Google Scholar] [CrossRef]

- Rafique, M.I.; Usman, A.R.; Ahmad, M.; Al-Wabel, M.I. Immobilization and mitigation of chromium toxicity in aqueous solutions and tannery waste-contaminated soil using biochar and polymer-modified biochar. Chemosphere 2021, 266, 129198. [Google Scholar] [CrossRef]

- Lehmann, J. Bio-energy in the black. Front. Ecol. Environ. 2007, 5, 381–387. [Google Scholar] [CrossRef] [Green Version]

- Al-Wabel, M.I.; Usman, A.R.A.; Al-Farraj, A.S.; Ok, Y.S.; Abduljabbar, A.; Al-Faraj, A.I.; Sallam, A.S. Date palm waste biochars alter a soil respiration, microbial biomass carbon, and heavy metal mobility in contaminated mined soil. Environ. Geochem. Health 2017, 41, 1705–1722. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar effects on soil biota. A review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Lu, H.; Fu, S.; Mendez, A.; Gasco, G. Use of phytoremediation and biochar to remediate heavy metal polluted soils. Solid Earth 2014, 5, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Luo, L.; Xu, C.; Chen, Z.; Zhang, S. Properties of biomass-derived biochars: Combined effects of operating conditions and biomass types. Bioresour. Technol. 2015, 192, 83–89. [Google Scholar] [CrossRef]

- Nobaharan, K.; Bagheri Novair, S.; Asgari Lajayer, B.; van Hullebusch, E.D. Phosphorus removal from wastewater: The potential use of biochar and the key controlling factors. Water 2021, 13, 517. [Google Scholar] [CrossRef]

- Ahmad, M.; Lee, S.S.; Lim, J.E.; Lee, S.E.; Cho, J.S.; Moon, D.H.; Hashimoto, Y.; Ok, Y.S. Speciation and phytoavailability of lead and antimony in a small arms range soil amended with mussel shell, cow bone and biochar: EXAF spectroscopy and chemical extractions. Chemosphere 2014, 95, 433–441. [Google Scholar] [CrossRef]

- Uchimiya, M.; Chang, S.; Klasson, K.T. Screening biochars for heavy metal retention in soil: Role of oxygen functional groups. J. Hazard. Mater. 2011, 190, 432–441. [Google Scholar] [CrossRef]

- Islam, S.N.; Rahman, M.L.; Tareq, M.Z.; Mostofa, B.; Karim, M.M.; Sultana, A.; Sadat, M.A. Nutrient Combination with Biochar: Improving Yield and Quality of Jute Seed. Malays. J. Sustain. Agric. 2021, 5, 43–50. [Google Scholar] [CrossRef]

- Novak, J.M.; Lima, I.; Xing, B.; Gaskin, J.W.; Steiner, C.; Das, K.C.; Ahmedna, M.; Rehrah, D.; Watts, D.W.; Busscher, W.J.; et al. Characterization of designer biochar produced at different temperatures and their effects on a loamy sand. Ann. Environ. Sci. 2009, 3, 195–206. [Google Scholar]

- Herath, I.; Kumarathilaka, P.; Navaratne, A.; Rajakaruna, N.; Vithanage, M. Immobilization and phytotoxicity reduction of heavy metals in serpentine soil using biochar. J. Soils Sediments 2015, 15, 126–138. [Google Scholar] [CrossRef] [Green Version]

- Nigussie, A.; Kissi, E.; Misganaw, M.; Ambaw, G. Effect of biochar application on soil properties and nutrient uptake of lettuces (Lactuca sativa) grown in chromium polluted soils. Am-Eurasian. J. Sustain. Agric. 2012, 12, 369–376. [Google Scholar]

- Ok, Y.S.; Chang, S.X.; Gao, B.; Chung, H.J. SMART biochar technology e a shifting paradigm towards advanced materials and healthcare research. Environ. Technol. Innovation. 2015, 4, 206–209. [Google Scholar] [CrossRef]

- Ekebafe, L.O.; Ogbeifun, D.E.; Okieimen, F.E. Effect of cassava starch hydrogel on the water requirement of maize (Zea may) seedlings and selected properties of sandy loam soil. Int. J. Basic. Appl. Sci. 2012, 1, 132–139. [Google Scholar]

- Wang, K.; Qiu, G.; Cao, H.; Jin, R. Removal of chromium (VI) from aqueous solutions using Fe3O4 magnetic polymer microspheres functionalized with amino groups. Materials 2015, 8, 8378–8391. [Google Scholar] [CrossRef] [PubMed]

- Bai, W.; Zhang, H.; Liu, B.; Wu, Y.; Song, J. Effects of superabsorbent polymers on the physical and chemical properties of soil following different wetting and drying cycles. Soil Use Manag. 2010, 26, 253–260. [Google Scholar] [CrossRef]

- Ballav, N.; Maity, A.; Mishra, S.B. High efficient removal of chromium (VI) using glycine doped polypyrrole adsorbent from aqueous solution. Chem. Eng. J. 2012, 198, 536–546. [Google Scholar] [CrossRef]

- de-Bashan, L.E.; Bashan, Y. Immobilized microalgae for removing pollutants: Review of practical aspects. Bioresour. Technol. 2010, 101, 1611–1627. [Google Scholar] [CrossRef]

- Shigetomi, Y.; Hori, Y.O.I.; Kojima, T. The removal of arsenate in waste water with an adsorbent prepared by binding hydrous iron (III) oxide with polyacrylamide. Bull. Chem. Soc. Jpn. 1980, 53, 1475–1476. [Google Scholar] [CrossRef] [Green Version]

- Richard, L.A. Diagnosis and Improvement of Saline and Alkali Soils. U.S. Department of Agriculture Handbook: Washington, DC, USA, 1954; Volume 60, p. 160. [Google Scholar]

- ASTM D1762-84; Standard Method for Chemical Analysis of Wood Charcoal. American Society for Testing and Materials (ASTM): Philadelphia, PA, USA, 1989.

- Bouyoucos, G.J. Hydrometer method improved for making particle size analysis of soils. Agron. J. 1962, 54, 464–465. [Google Scholar] [CrossRef]

- Walkley, A.; Black, I.A. An examination of Degtjareff method for determining soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–37. [Google Scholar] [CrossRef]

- Hossner, L.R. Dissolution for total elemental analysis. In Methods of Soil Analysis: Part 3e Chemical Methods; Sparks, Bigham, J.M., Eds.; SSSA and ASA: Madison, WI, USA, 1996; pp. 49–64. [Google Scholar]

- Campbell, C.R.; Plank, C.O. Preparation of plant tissue for laboratory analysis. In Handbook of Reference Methods for Plant Analysis; Kalra, Y.P., Ed.; CRC Press: Boca Raton, FL, USA, 1998; pp. 37–49. [Google Scholar]

- Steel, R.G.D.; Torrie, J.H.; Deekey, D.A. Principles and Procedures of Statistics: A Biometrical Approach, 3rd ed.; McGraw Hill Book Co.: New York, NY, USA, 1997. [Google Scholar]

- Usman, A.R.A.; Abduljabbar, A.; Vithanage, M.; Ok, Y.S.; Ahmad, M.; Ahmad, M.; Elfaki, J.; Abdulazeem, S.S.; Al-Wabel, M.I. Biochar production from date palm waste: Charring temperature induced changes in composition and surface chemistry. J. Anal. Appl. Pyrolysis 2015, 115, 392–400. [Google Scholar] [CrossRef]

- Fan, R.; Luo, J.; Yan, S.; Zhou, Y.; Zhang, Z. Effects of biochar and super absorbent polymer on substrate properties and water spinach growth. Pedosphere 2015, 25, 737–748. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Kim, J.Y.; Cho, T.S.; Choi, J.W. Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresour. Technol. 2012, 118, 158–162. [Google Scholar] [CrossRef]

- Mohamed, R.M.; Mkhalid, I.A.; Barakat, M.A. Rice husk ash as a renewable source for the production of zeolite NaY and its characterization. Arab. J. Chem. 2015, 8, 48–53. [Google Scholar] [CrossRef] [Green Version]

- Al-Wabel, M.I.; Al-Omran, A.; El-Naggar, A.H.; Nadeem, M.; Usman, A.R.A. Pyrolysis temperature in- duced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 2013, 131, 374–379. [Google Scholar] [CrossRef]

- Chen, T.; Liu, R.; Scott, N.R. Characterization of energy carriers obtained from the pyrolysis of white ash, switchgrass and corn stover—Biochar, syngas and bio-oil. Fuel Process. Technol. 2016, 142, 124–134. [Google Scholar] [CrossRef]

- Ma, X.; Yuan, S.; Yang, L.; Li, L.; Zhang, X.; Su, C.; Wang, K. Fabrication and potential applications of CaCO3–lentinan hybrid materials with hierarchical composite pore structure obtained by self-assembly of nanoparticles. Cryst. Eng. Comm. 2013, 15, 8288–8299. [Google Scholar] [CrossRef]

- Xu, X.; Hu, X.; Ding, Z.; Chen, Y. Effects of copyrolysis of sludge with calcium carbonate and calcium hydrogen phosphate on chemical stability of carbon and release of toxic elements in the resultant biochars. Chemosphere 2017, 189, 76–85. [Google Scholar] [CrossRef]

- Meri, N.H.; Alias, A.B.; Talib, N.; Rashid, Z.A.; Wan, W.A.; Ghani, A.K. Effect of Chemical Washing Pre-treatment of Empty Fruit Bunch (EFB) biochar on Characterization of Hydrogel Biochar composite as Bioadsorbent. Mater. Sci. Eng. 2018, 358, 012018. [Google Scholar] [CrossRef] [Green Version]

- Amin, H.; Arain, B.A.; Amin, F.; Surhio, M.A. Phytotoxicity of Chromium on Germination, Growth and Biochemical Attributes of Hibiscus esculentus L. Am. J. Plant. Sci. 2013, 4, 2431. [Google Scholar] [CrossRef] [Green Version]

- Peralta, J.R.; Gardea-Torresdey, J.L.; Tiemann, K.J.; Gomez, E.; Arteaga, S.; Rascon, E.; Parsons, J.G. Uptake and effects of five heavy metals on seed germination and plant growth in alfalfa (Medicago sativa L.). Bull. Environ. Contam. Toxicol. 2001, 66, 727–734. [Google Scholar] [CrossRef] [PubMed]

- Panda, S.K. Heavy metal phytotoxicity induces oxidative stress in Taxithalium sp. Curr. Sci. 2003, 84, 631–633. [Google Scholar]

- Barcelo, j.; Poschenrieder, C. Chromium in plants. In Chromium Environmental Issue; Carati, S., Tottareli, F., Seqmi, P., Eds.; Francotangati Press: Milan, Italy, 1997; pp. 101–129. [Google Scholar]

- Rout, G.R.; Samantaray, S.; Das, P. Differential chromium tolerance among eight mungbean cultivars grown in nutrient culture. J. Plant Nutr. 1997, 20, 473–483. [Google Scholar] [CrossRef]

- Zeid, I.M. Responses of Phaseolus vulgaris chromium and cobalt treatments. Biologia. Plantarum. 2001, 44, 111–115. [Google Scholar] [CrossRef]

- Fozia, A.; Muhammad, A.Z.; Muhammad, A.; Zafar, M.K. Effect of chromium on growth attributes in sunflower (Helianthus annuus L.). J. Environ. Sci. 2008, 20, 1475–1480. [Google Scholar] [CrossRef]

- Chandra, R.; Bharagava, R.N.; Yadav, S.; Mohan, D. Accumulation and distribution of toxic metals in wheat (Triticum aestivum L.) and Indian mustard (Brassica campestris L.) irrigated with distillery and tannery effluents. J. Hazard. Mater. 2009, 15, 1514–1521. [Google Scholar] [CrossRef]

- Gill, S.S.; Tuteja, N. Reactive oxygen species and antioxidant machinery in abiotic stress tolerance in crop plants. Plant Physiol. Biochem. 2010, 48, 909–930. [Google Scholar] [CrossRef]

- Sangwan, P.; Kumar, V.; Joshi, U.N. Chromium (VI) affected nutritive value of forage clusterbean (Cyamopsis tetragonoloba L.). Int. J. Agric. Environ. Biotechnol. 2014, 7, 17. [Google Scholar] [CrossRef]

- Kumar, P. Evaluation of toxic effects of hexavalent chromium on the yield and quality of Sorghum. Preprints 2020, 2020110564. [Google Scholar]

- Jiang, W.; Liu, D.; Liu, X. Effects of copper on root growth, cell division, and nucleolus of Zea mays. Biol. Plant. 2001, 44, 105–109. [Google Scholar] [CrossRef]

- Liu, D.; Jiang, W.; Gao, X. Effects of cadmium on root growth, cell division and nucleoli in root tip cells of garlic. Biol. Plant. 2003, 47, 79–83. [Google Scholar] [CrossRef]

- Samantaray, S.; Rout, G.R.; Das, P. Studies on differential tolerance of mungbean cultivars to metalliferous minewastes. Agribiol. Res. 1999, 52, 193–201. [Google Scholar]

- Wyszkowski, M.; Radziemska, M. Effects of chromium (III and VI) on spring barley and maize biomass yield and content of nitrogenous compounds. J. Toxicol. Environ. Health Part A 2010, 30, 1274–1282. [Google Scholar] [CrossRef]

- Ali, B.; Wang, B.; Ali, S.; Ghani, M.A.; Hayat, M.T.; Yang, C.; Xu, L.; Zhou, W.J. Aminolevulinic acid ameliorates the growth, photosynthetic gas exchange capacity, and ultrastructural changes under cadmium stress in Brassica napus L. J. Plant Growth Regul. 2013, 32, 604–614. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Z. The effects of biochar on germination and growth of wheat in different saline-alkali soil. Asian Agric. Res. 2013, 5, 116. [Google Scholar]

- Bashir, M.A.; Wang, X.; Naveed, M.; Mustafa, A.; Ashraf, S.; Samreen, T.; Nadeem, S.M.; Jamil, M. Biochar mediated-alleviation of chromium stress and growth improvement of different maize cultivars in tannery polluted soils. Int. J. Environ. Res. Public Health 2021, 18, 4461. [Google Scholar] [CrossRef]

- Rajkovich, S.; Enders, A.; Hanley, K.; Hyland, C.; Zimmerman, A.R.; Lehmann, J. Corn growth and nitrogen nutrition after additions of biochars with varying properties to a temperate soil. Biol. Fertil. Soils 2012, 48, 271–284. [Google Scholar] [CrossRef]

- Inyang, M.; Gao, B.; Pullammanappallil, P.; Ding, W.; Zimmerman, A.R. Biochar from anaerobically digested sugarcane bagasse. Bioresour. Technol. 2010, 101, 8868–8872. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2013, 99, 19–33. [Google Scholar] [CrossRef]

- Cao, X.; Ma, L.; Gao, B.; Harris, W. Dairy-manure derived biochar effectively sorbs lead and atrazine. Environ. Sci. Technol. 2009, 43, 3285–3291. [Google Scholar] [CrossRef] [PubMed]

- Beesley, L.; Inneh, O.S.; Norton, G.J.; Moreno-Jimenez, E.; Pardo, T.; Clemente, R.; Dawson, J.J.C. Assessing the influence of compost and biochar amendments of the mobility and toxicity of metals and arsenic in a naturally contaminated mine soil. Environ. Pollut. 2014, 186, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Shahid, M.; Shamshad, S.; Rafiq, M.; Khalid, S.; Bibi, I.; Niazi, N.K.; Dumat, C.; Rashid, M.I. Chromium speciation, bioavailability, uptake, toxicity and detoxification in soil-plant system: A review. Chemosphere 2017, 178, 513–533. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Fan, J.; Xing, Y.; Xu, G.; Wang, H.; Deng, J.; Wang, Y.; Zhang, F.; Li, P.; Li, Z. The effects of mulch and nitrogen fertilizer on the soil environment of crop plants. Adv. Agron. 2019, 153, 121–173. [Google Scholar]

| Electrical Conductivity (dSm−1) | pH (1:2.5) | CEC (cmol kg−1) | Organic Matter (%) | Total Metal Concentration (mg kg−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Cr | Fe | Mn | Zn | Cu | ||||

| 1.05 ± 0.03 | 7.41 ± 1.1 | 9.95 ± 1.3 | 2.5.0 ± 0.15 | 160 ± 16 | 270 ± 14 | 129 ± 30 | 119 ± 13 | 94 ± 11 |

| CrVI Concentration (mg L−1) | Germination % | Fresh Weight (g) | Dry Weight (g) | Shoot Length (cm) | Root Length (cm) | Cr Uptake (μg/Seedling) |

|---|---|---|---|---|---|---|

| 0 | 100 ± 1.5 A | 0.18 ± 0.08 A | 0.13 ± 0.05 A | 7.39 ± 1.5 A | 7.29 ± 1.2 A | 0.5 ± 0.02 C |

| 5 | 80 ± 2.8 AB | 0.14 ± 0.07 B | 0.09 ± 0.02 B | 6.15 ± 1.4 B | 5.67 ± 0.9 B | 7.66 ± 1.1 B |

| 10 | 65 ± 2.2 BC | 0.11 ± 0.02 B | 0.08 ± 0.01 B | 4.90 ± 0.9 C | 3.94 ± 0.6 C | 8.26 ± 1.8 B |

| 20 | 50 ± 3.8 C | 0.07 ± 0.01 C | 0.04 ± 0.01 C | 2.66 ± 0.4 D | 1.54 ± 0.8 D | 9.98 ± 1.5 B |

| 40 | 40 ± 4.2 C | 0.03 ± 0.01 D | 0.02 ± 0.01 C | 1.37 ± 0.6 E | 0.84 ± 0.2 D | 13.24 ± 1.3 A |

| Tuckey HCD | 28.377 | 0.0311 | 0.0347 | 0.8238 | 0.8979 | 2.6961 |

| CrVI Concentration | Germination (%) | Fresh Weight (g) | Dry Weight (g) | Shoot Length (cm) | Root Length (cm) | Cr Uptake (µg/Seedling) |

|---|---|---|---|---|---|---|

| Control | 67 ± 3.3 B | 0.18 ± 0.04 E | 0.075 ± 0.01 C | 4.492 ± 0.5 E | 3.854 ± 0.3 E | 7.928 ± 1.1 A |

| JBC-300 | 79 ± 5.9 AB | 0.164 ± 0.05 B | 0.123 ± 0.01 AB | 5.722 ± 0.3 B | 5.107 ± 0.4 AB | 4.275 ± 0.8 B |

| JBC-500 | 76 ± 5.1 AB | 0.134 ± 0.02 D | 0.108 ± 0.01 B | 4.922 ± 0.3 D | 4.266 ± 0.4 DE | 5.184 ± 1.1 B |

| JBC-700 | 74 ± 2.8 AB | 0.145 ± 0.01 CD | 0.111 ± 0.01 B | 5.044 ± 0.4 CD | 4.502 ± 0.5 CD | 4.923 ± 0.9 B |

| JPBC-300 | 83 ± 3.4 A | 0.179 ± 0.03 A | 0.139 ± 0.01 A | 6.226 ± 0.6 A | 5.442 ± 0.9 A | 0.226 ± 0.03 C |

| JPBC-500 | 79 ± 3.6 AB | 0.148 ± 0.04 CD | 0.106 ± 0.02 B | 5.087 ± 0.7 CD | 4.490 ± 0.7 CD | 0.396 ± 0.03 C |

| JPBC-700 | 77 ± 7.8 AB | 0.152 ± 0.01 BC | 0.111 ± 0.01 B | 5.376 ± 0.7 BC | 4.853 ± 0.8 BC | 0.328 ± 0.01 C |

| Tuckey HCD | 13.235 | 0.0148 | 0.0187 | 0.3650 | 0.5649 | 2.4014 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rafique, M.I.; Ahmad, M.; Al-Wabel, M.I.; Ahmad, J.; Al-Farraj, A.S. Mitigating the Toxic Effects of Chromium on Wheat (Triticum aestivum L.) Seed Germination and Seedling Growth by Using Biochar and Polymer-Modified Biochar in Contaminated Soil. Sustainability 2022, 14, 16093. https://doi.org/10.3390/su142316093

Rafique MI, Ahmad M, Al-Wabel MI, Ahmad J, Al-Farraj AS. Mitigating the Toxic Effects of Chromium on Wheat (Triticum aestivum L.) Seed Germination and Seedling Growth by Using Biochar and Polymer-Modified Biochar in Contaminated Soil. Sustainability. 2022; 14(23):16093. https://doi.org/10.3390/su142316093

Chicago/Turabian StyleRafique, Muhammad I., Munir Ahmad, Mohammad I. Al-Wabel, Jahangir Ahmad, and Abdullah S. Al-Farraj. 2022. "Mitigating the Toxic Effects of Chromium on Wheat (Triticum aestivum L.) Seed Germination and Seedling Growth by Using Biochar and Polymer-Modified Biochar in Contaminated Soil" Sustainability 14, no. 23: 16093. https://doi.org/10.3390/su142316093