Shale Gas Content Calculation of the Triassic Yanchang Formation in the Southeastern Ordos Basin, China

Abstract

:1. Introduction

2. Experimental Methods

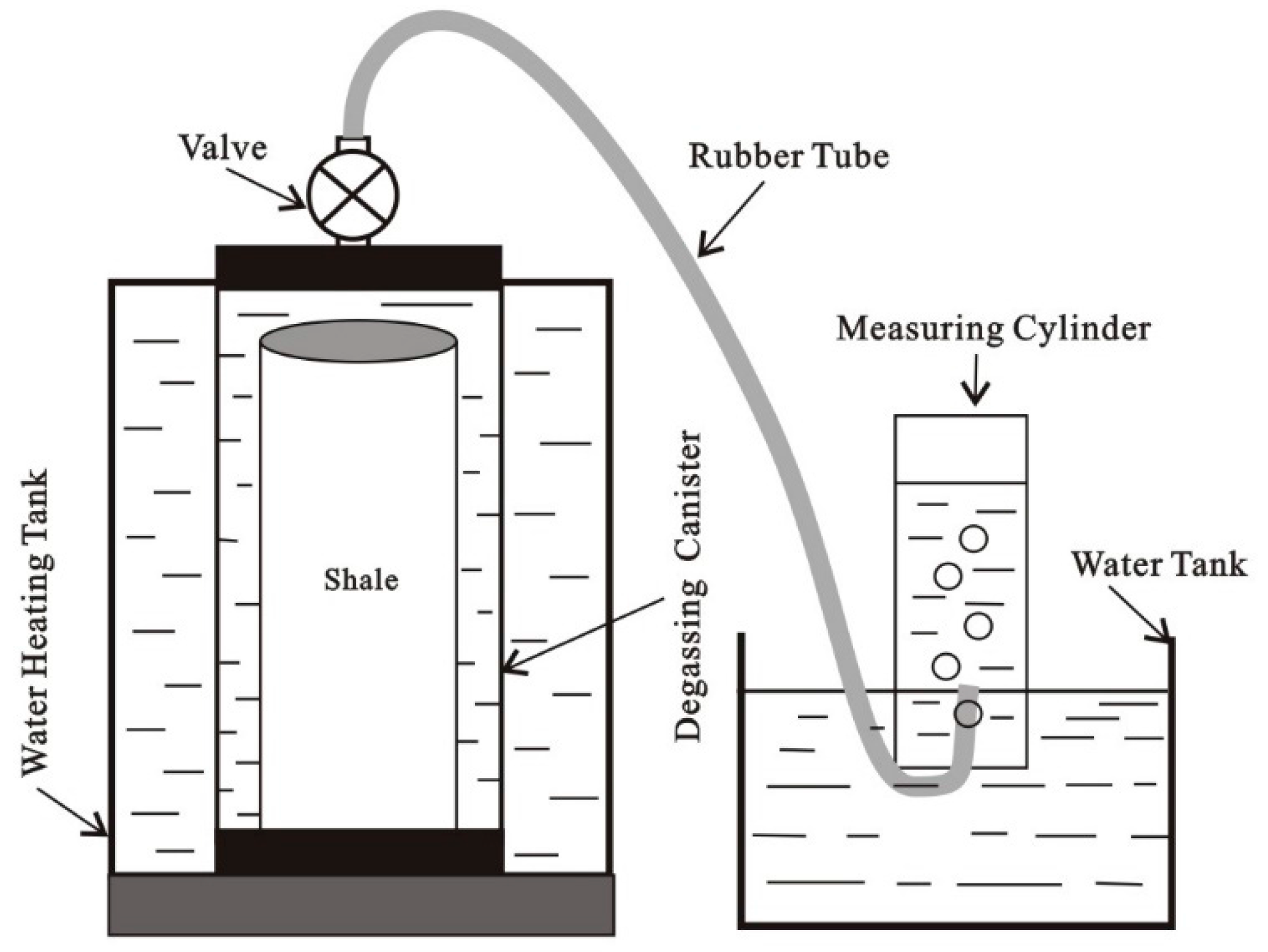

2.1. On-Site Shale Degassing Experiments

2.2. Methane Isothermal Sorption Measurements

3. Calculating Methods

3.1. Direct Method

3.1.1. Degassing Shale Gas Content and Residual Shale Gas Content

3.1.2. Lost Shale Gas Content

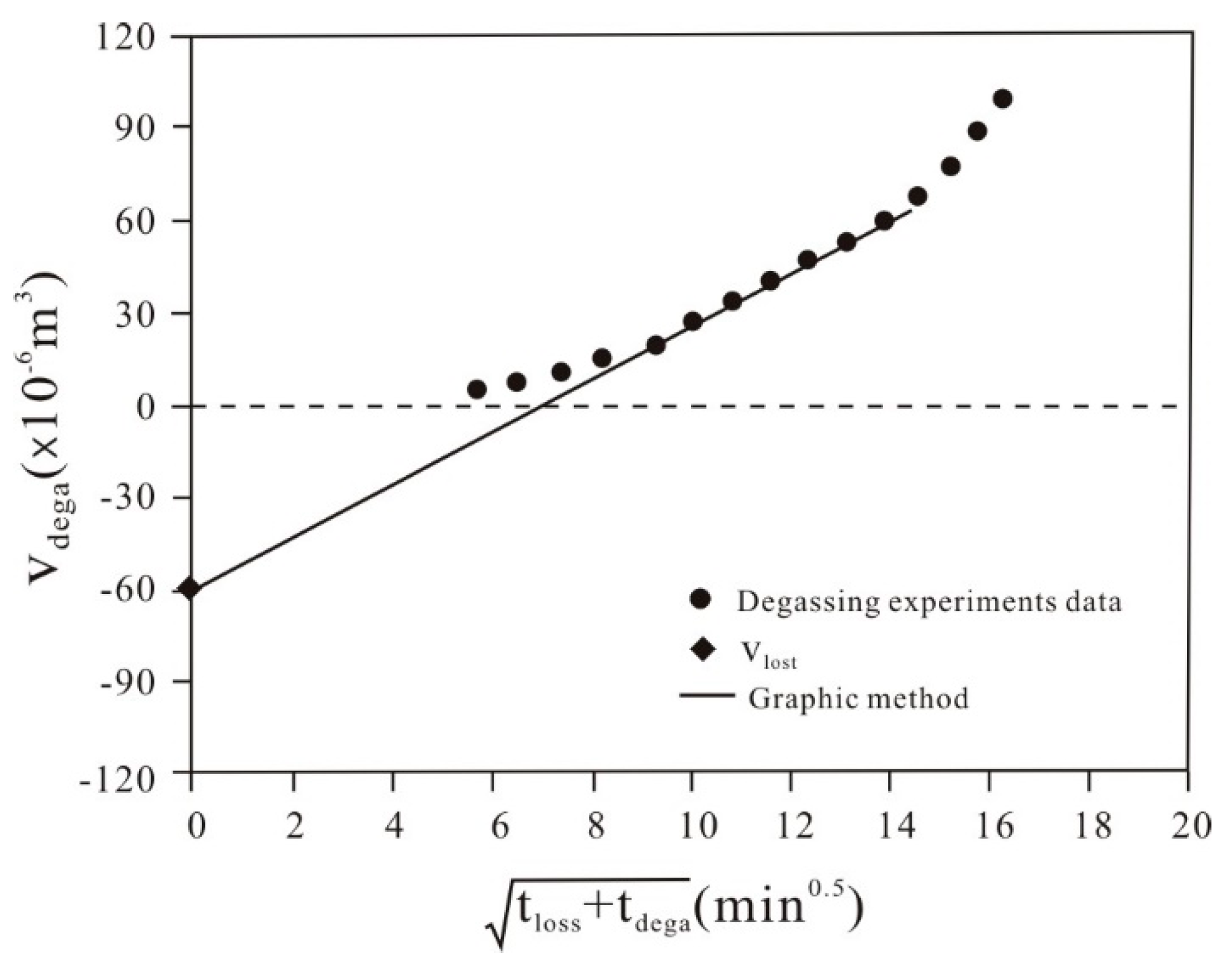

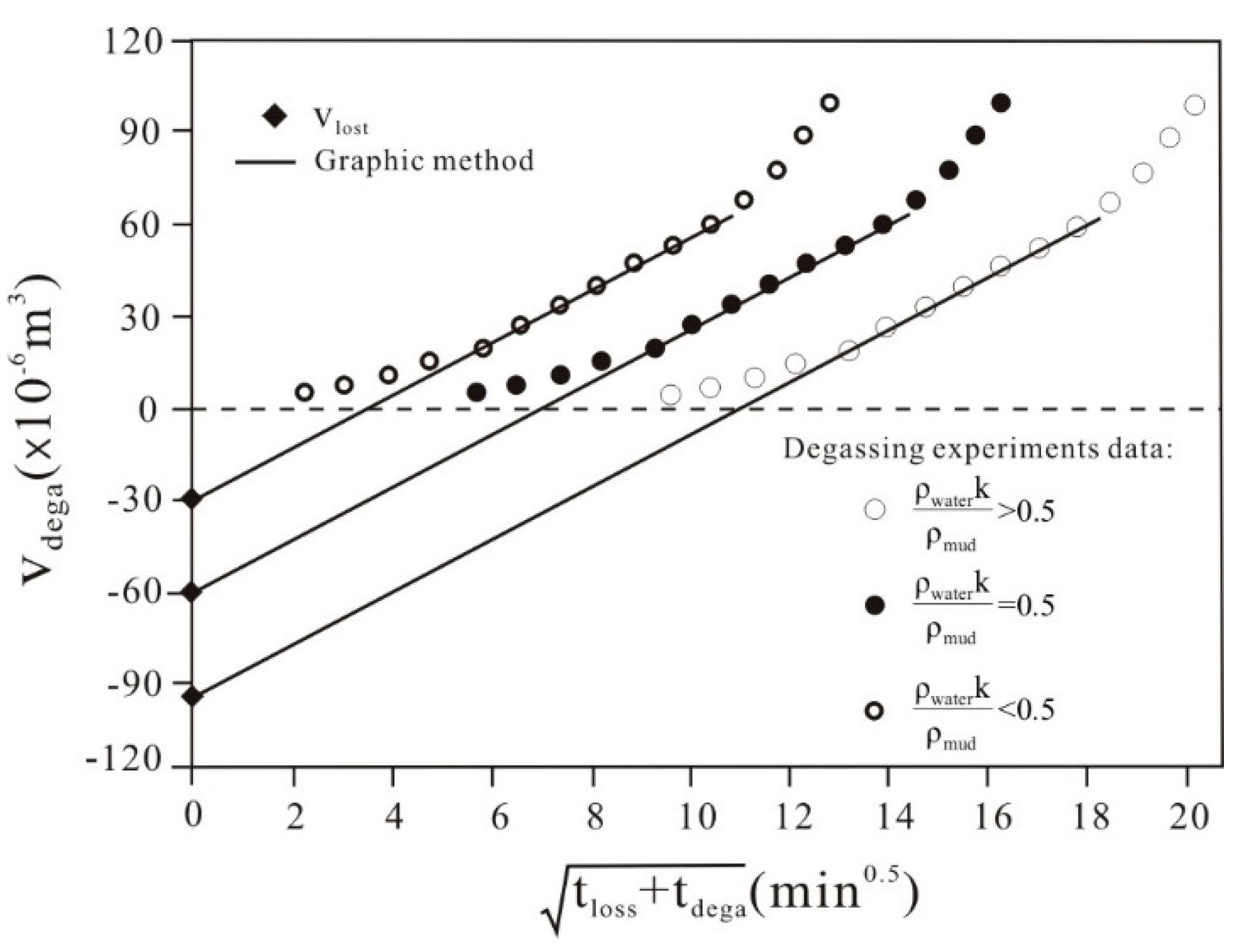

USBM Method

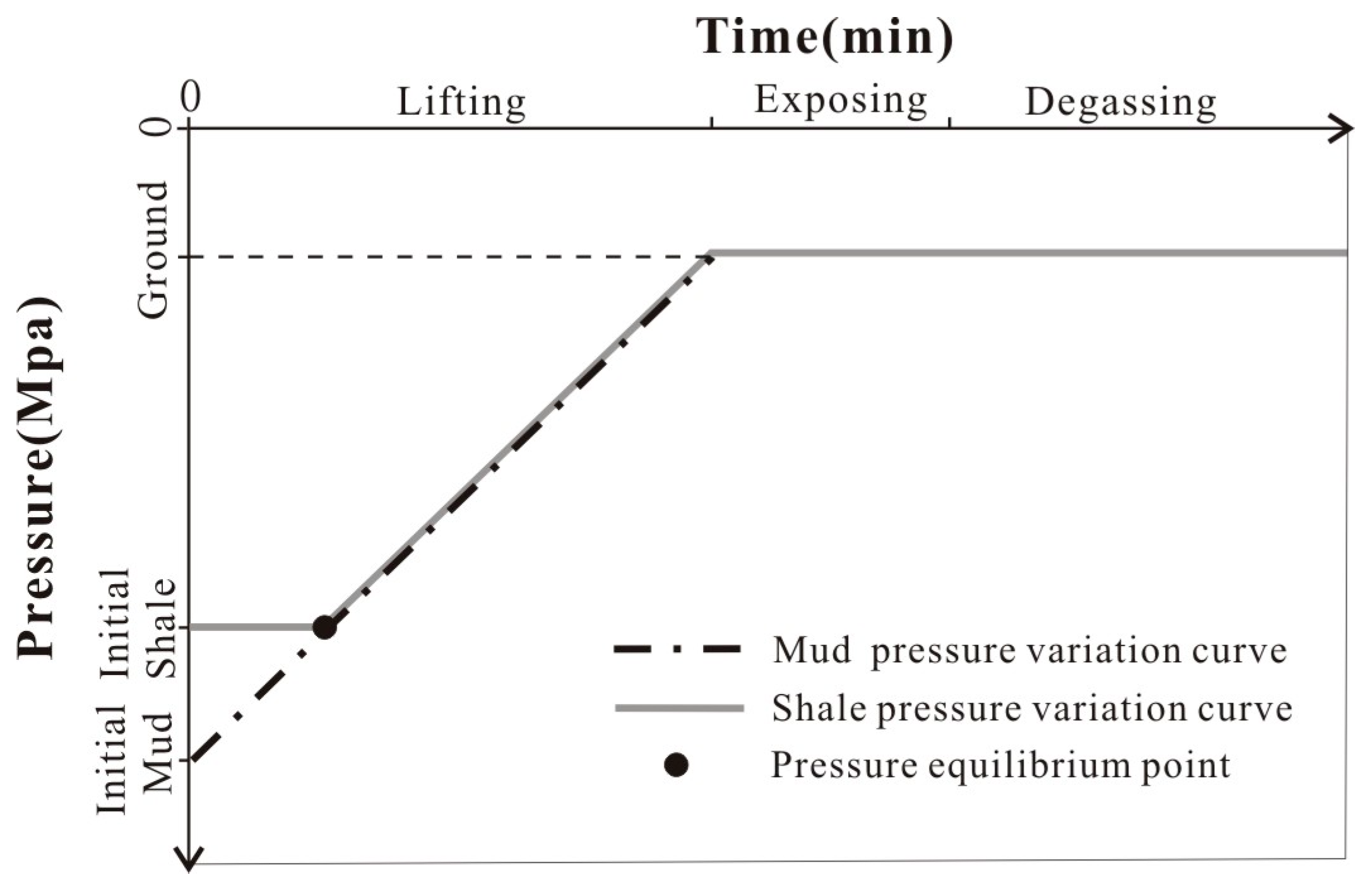

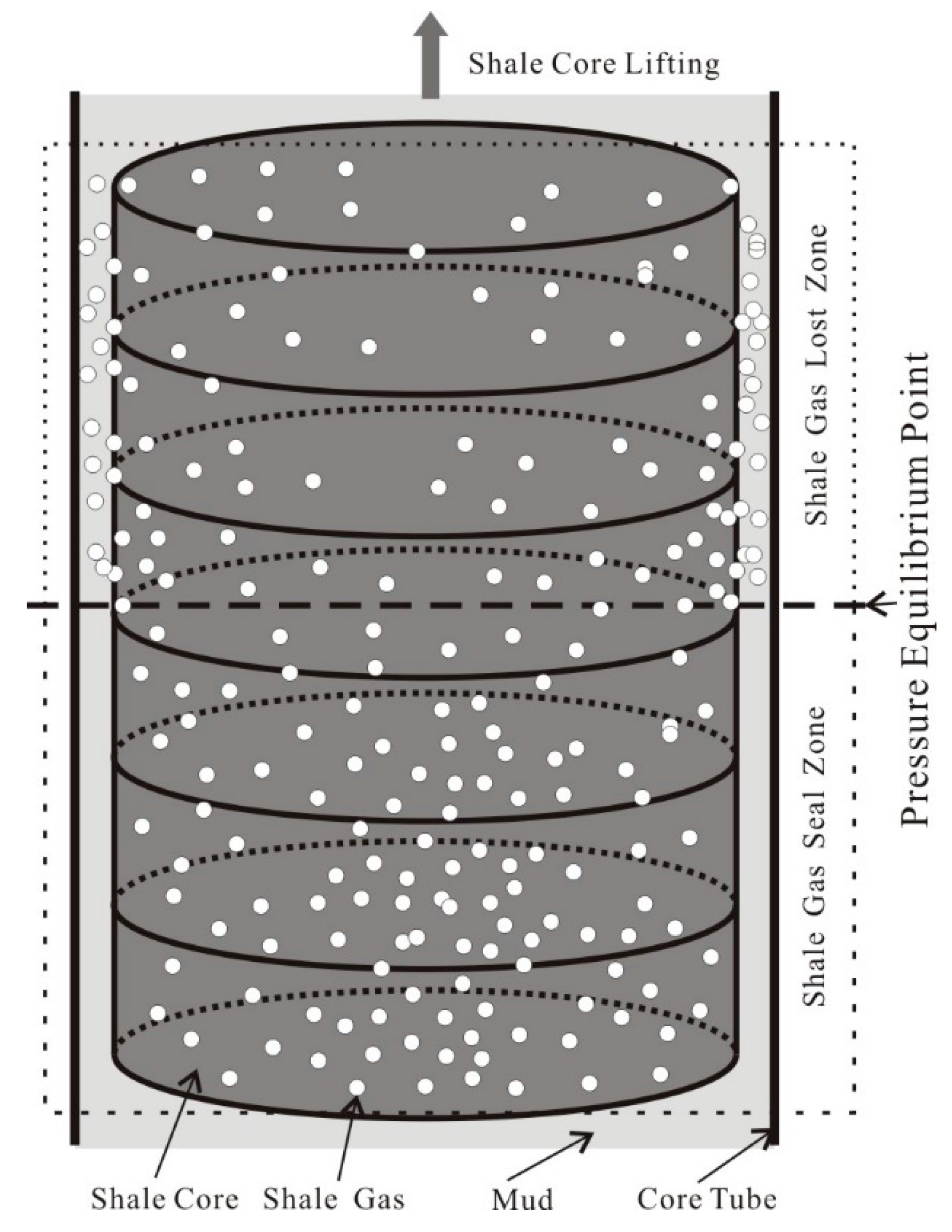

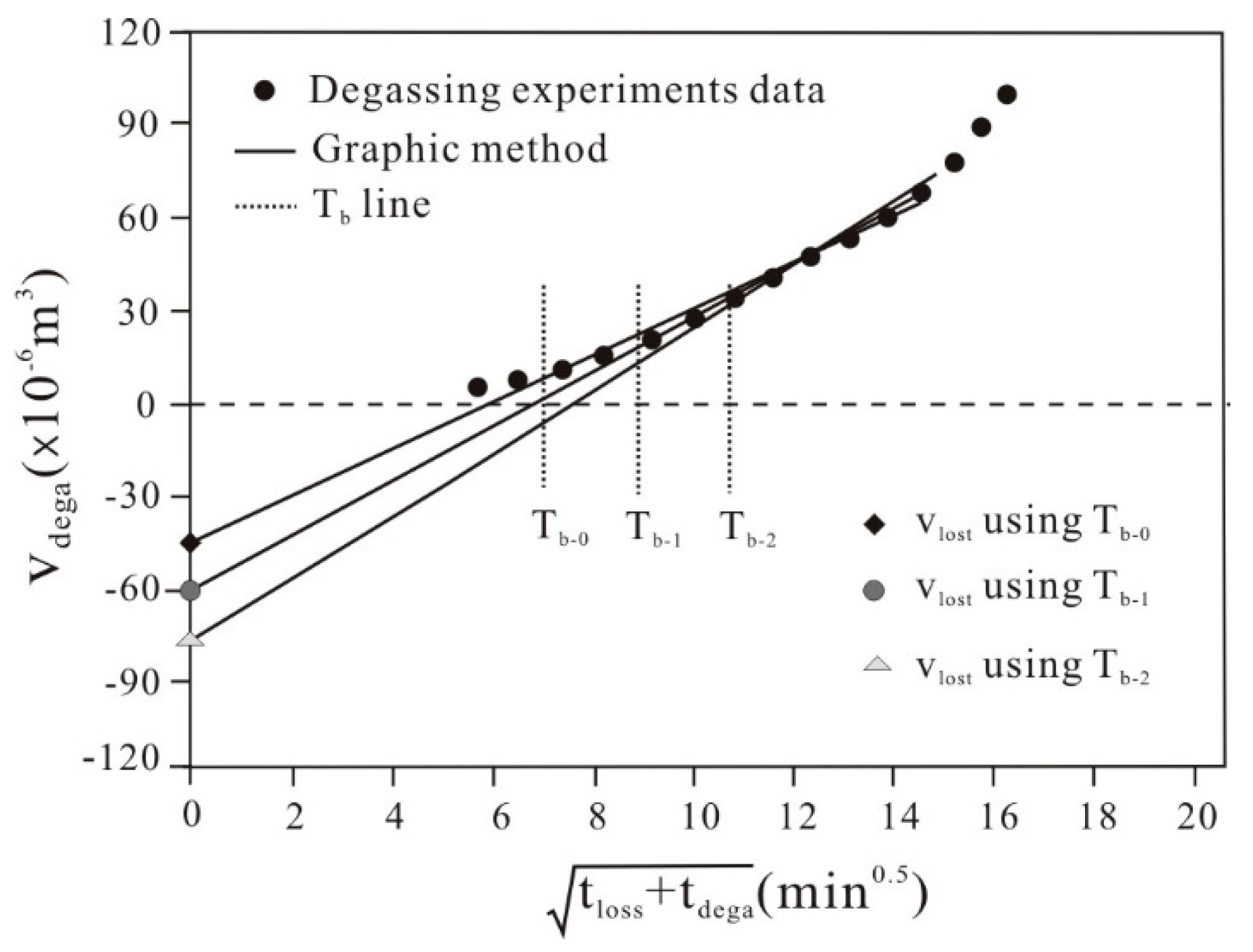

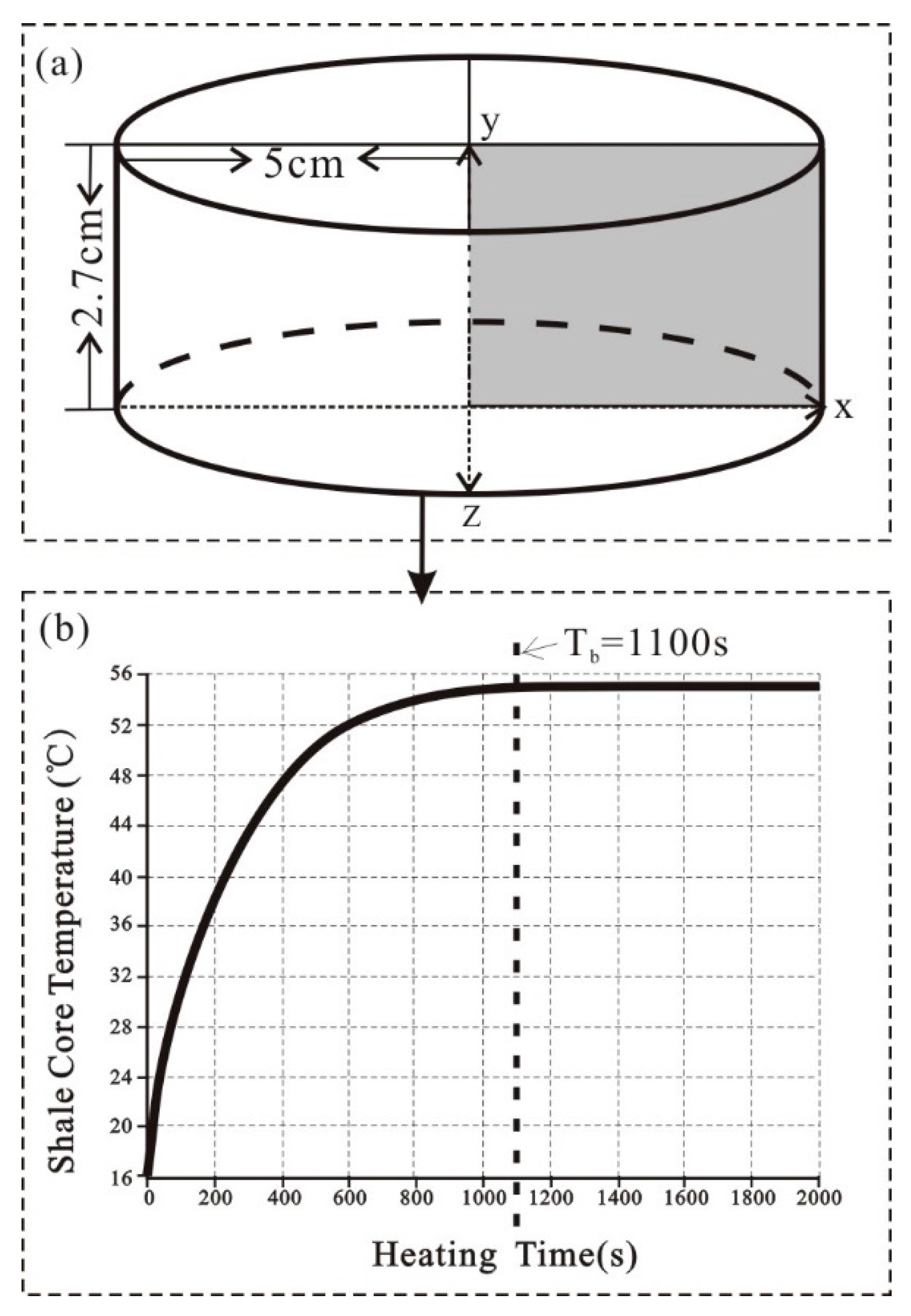

Improved USBM Method

3.2. Indirect Method

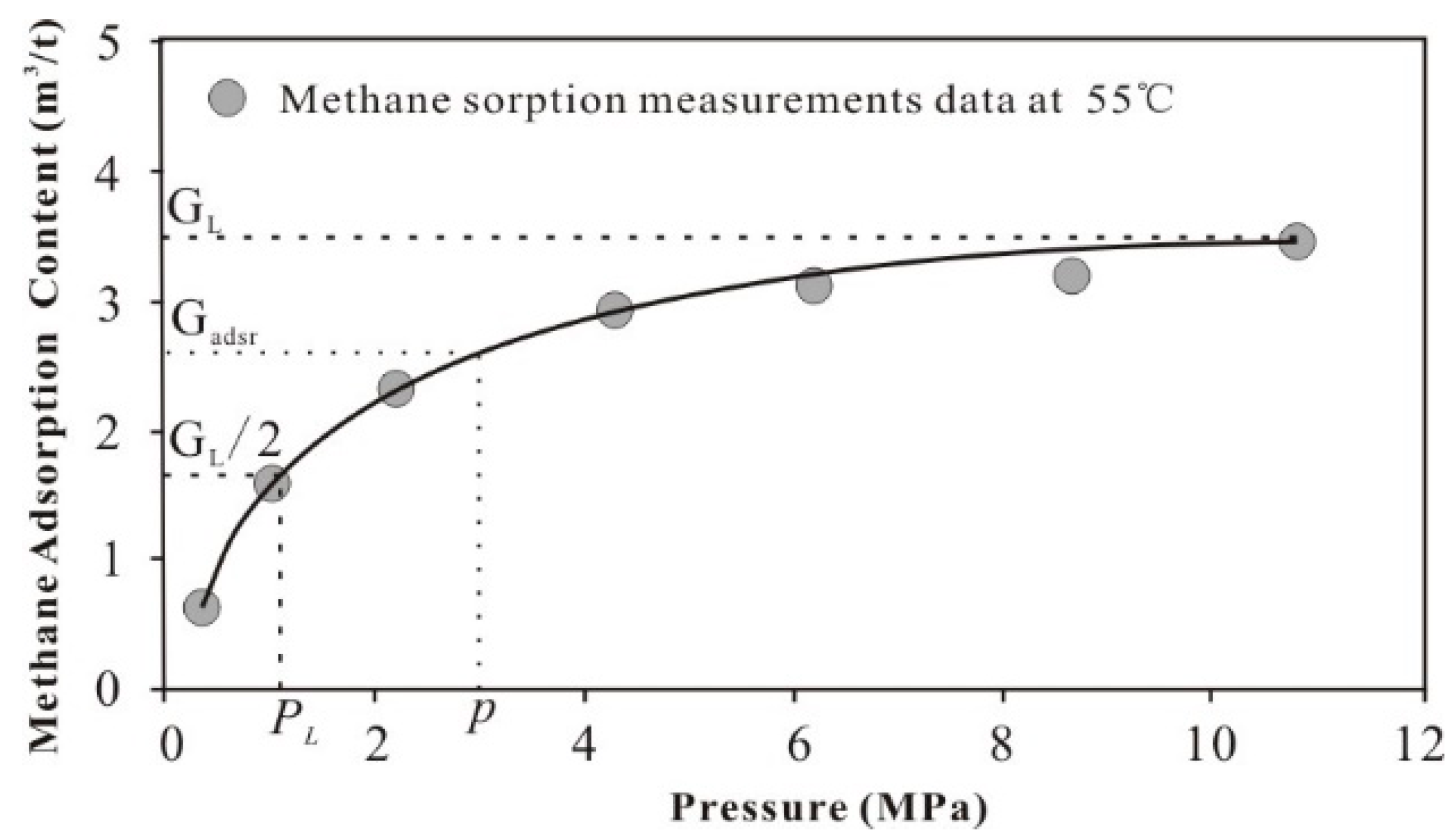

3.2.1. Adsorption Shale Gas Content

3.2.2. Free Shale Gas Content

3.2.3. Dissolved Shale Gas Content

4. Results and Discussion

4.1. Direct Method

4.2. Indirect Method

4.3. Comparison of Two Methods

5. Conclusions

- (1)

- In order to make the USBM method more suitable for shale reservoirs, an improved USBM method is put forward. On the one hand, the shale core pressure history and drilling mud pressure history were systematically analyzed to identify the pressure equilibrium point and to determine the gas loss time quantitatively; on the other hand, the shale core temperature history was analyzed to obtain an accurate temperature balance time using the ANSYS software. The gas loss time during core lifting is determined by the density of water, the density of drilling mud and the formation pressure coefficient. The finite element analysis method allowed us to determine the temperature balance time accurately and avoid human error.

- (2)

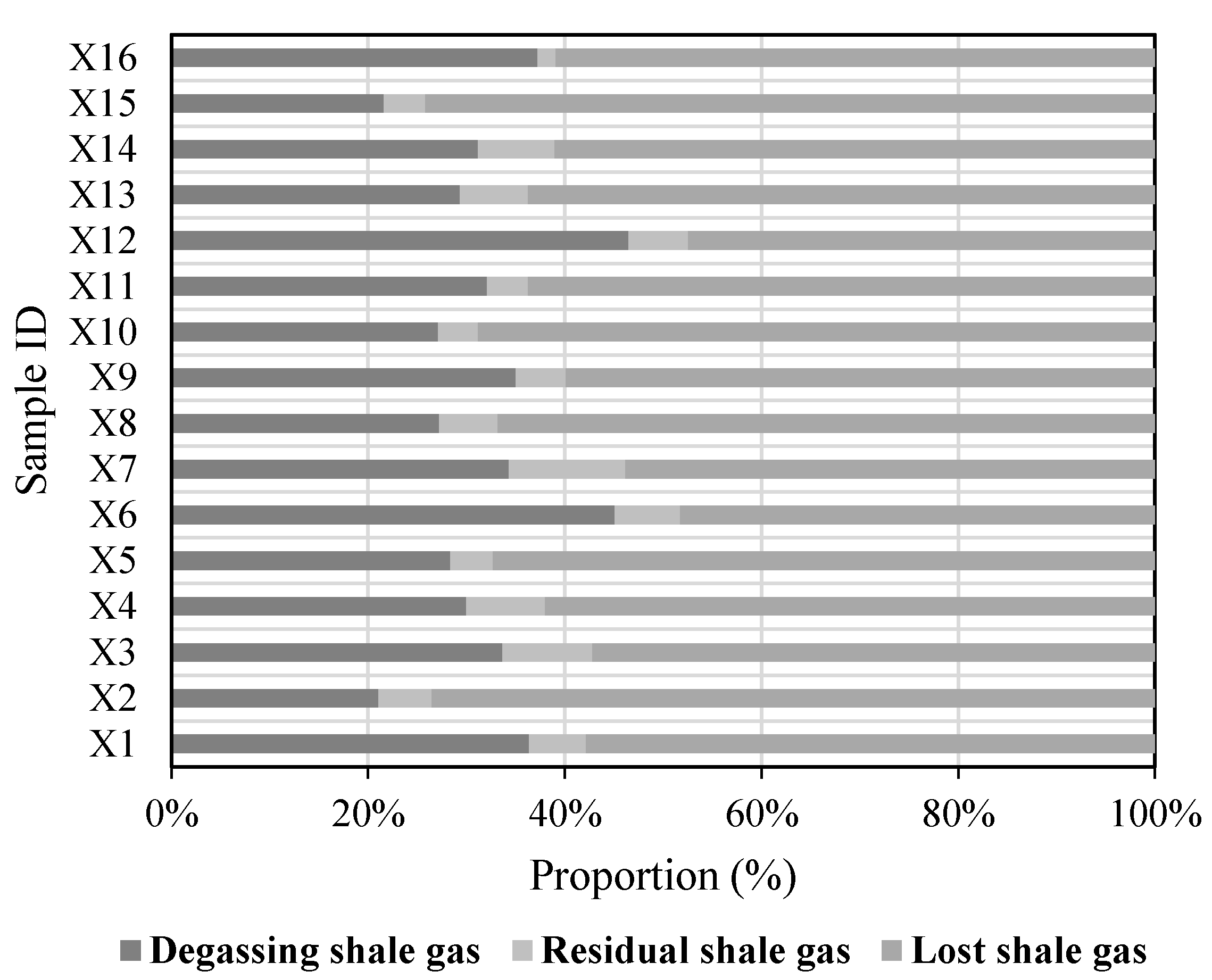

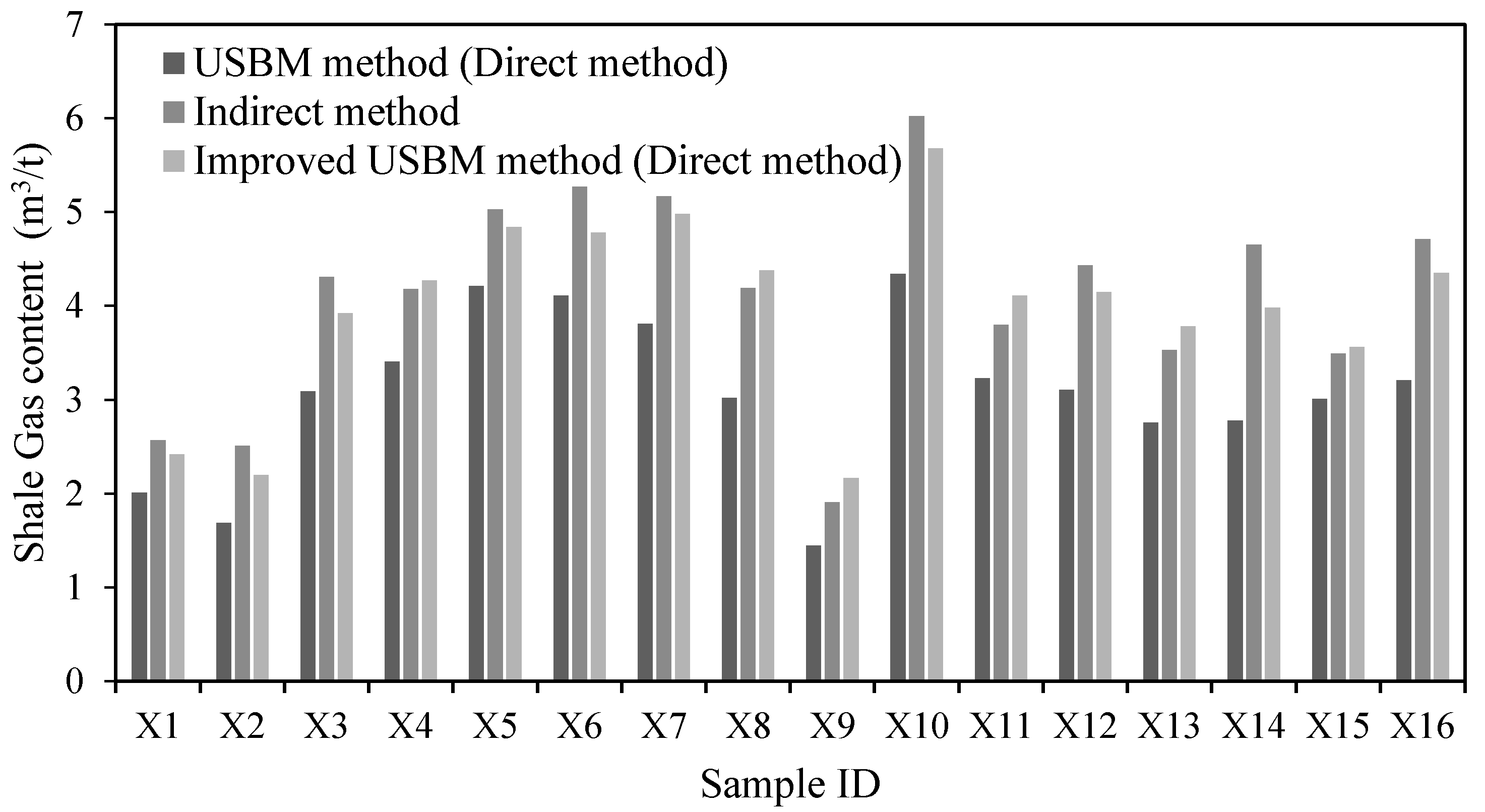

- The direct method was used to calculate the shale gas content of 16 shale samples from the Triassic Yanchang Formation in the Southeastern Ordos Basin, China. The shale gas content of this area is very high according to the improved USBM method, with an average of 3.97 m3/t. The lost shale gas content is the largest proportion, with an average of 62%. Both the lost shale gas content and the total shale gas content determined by the improved USBM method are larger than those determined by the USBM method. In the studied area, a large gas loss time and a large temperature balance time make a large lost shale gas content.

- (3)

- The indirect method was used to calculate the shale gas content of 16 shale samples from the Triassic Yanchang Formation in the Southeastern Ordos Basin, China. The shale gas content of this area is very high according to the indirect method, with an average of 4.11 m3/t. The adsorption shale gas content is the largest proportion, with an average of 71%. The dissolved shale gas content is mainly the oil-dissolved shale gas content, which accounts for about 7.8%. Attention should be paid to the oil-dissolved shale gas content and the water-dissolved shale gas content can be neglected in the studied area.

- (4)

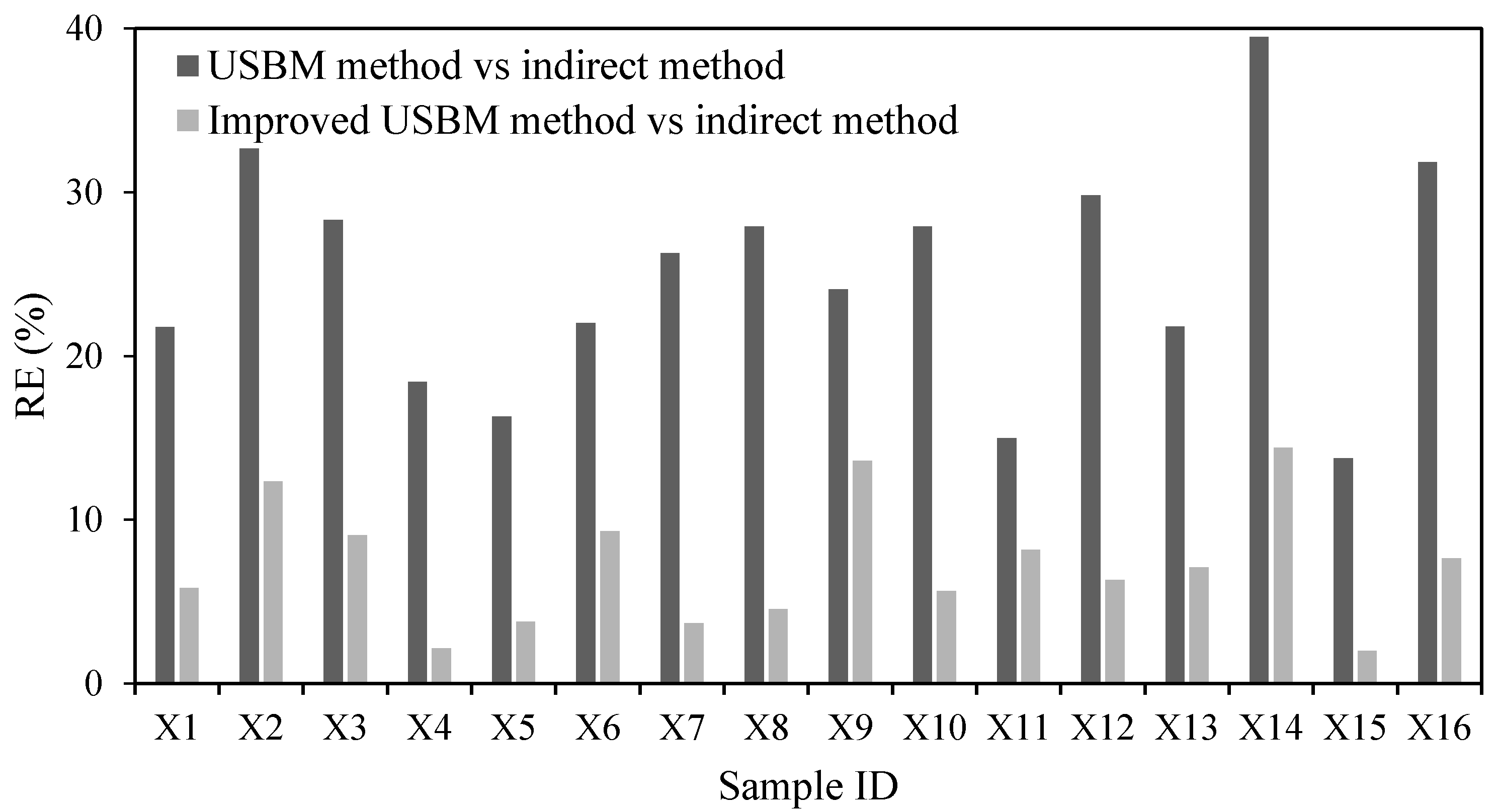

- The shale gas content of the direct method and the indirect method were compared. The discrepancy between the direct method and the indirect method is reduced by using the improved USBM method, and the improved USBM method could be more practical and accurate than the USBM method.

Author Contributions

Conflicts of Interest

References

- Mavor, M. ABSTRACT: Barnett Shale Gas-in-Place Volume including Sorbed and Free Gas Volume; Fort Worth Geological Society: Houston, TX, USA, 2003. [Google Scholar]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Brittenham, M.D. Geologic analysis of the Upper Jurassic Haynesville Shale in east Texas and west Louisiana: Discussion. AAPG Bull. 2013, 97, 525–528. [Google Scholar] [CrossRef]

- Zhang, J.C.; Xu, B.; Nie, H.K.; Wang, Z.Y.; Lin, T. Exploration potential of shale gas resources in China. Nat. Gas Ind. 2008, 28, 136–140. [Google Scholar]

- Dong, D.Z.; Zou, C.N.; Li, J.Z.; Wang, S.J.; Li, X.J.; Wang, Y.M.; Li, D.H.; Huang, J.L. Resource potential, exploration and development prospect of shale gas in the whole world. Geol. Bull. China 2011, 31, 324–336. [Google Scholar]

- Zhou, C.N.; Dong, D.Z.; Wang, S.J.; Li, J.Z.; Li, X.J.; Wang, Y.M.; Li, D.H.; Cheng, K.M. Geological characteristics characteristics, formation mechanism and resource potential of shale gas in China. Pet. Explor. Dev. 2010, 37, 641–653. [Google Scholar] [CrossRef]

- Yang, Y.T.; Zhang, J.C.; Wang, X.Z.; Cao, J.Z.; Tang, X.; Wang, L.; Yang, S.Y. Source rock evaluation of continental shale gas: A case study of Chang 7 of Mesozoic Yangchang Formation in Xia Siwan area of Yanchang. J. Northeast Pet. Univ. 2012, 36, 10–17. [Google Scholar]

- Wang, Z.G. Breakthrough of Fuling shale gas exploration and development and its inspiration. Oil Gas Geol. 2015, 36, 1–6. [Google Scholar]

- Wu, Q.; Liang, X.; Xian, C.G.; Li, X. Geoscience-to-production integration ensures effective and efficient south China marine shale gas development. China Pet. Explor. 2015, 20, 1–23. [Google Scholar]

- Guo, X.S. Rules of Two-Factor enrichment for marine shale gas in southern China: Understanding from the Longmaxi formation shale gas in Sichuan basin and its surrounding area. Acta Geol. Sin. 2014, 8, 1209–1218. [Google Scholar]

- Guo, T.L.; Zhang, H.R. Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin. Pet. Explor. Dev. 2014, 41, 28–36. [Google Scholar] [CrossRef]

- Zhang, D. Future Development Trend of China’s Unconventional Oil and Gas Resources and Shale Gas. Land Resour. Inf. 2016, 11, 3–7. [Google Scholar]

- Zou, C.; Zhao, Q.; Zhang, G.S.; Xiong, B. Energy revolution: From a fossil energy era to a new energy era. Nat. Gas Ind. B 2016, 3, 1–11. [Google Scholar] [CrossRef]

- Jia, C. Breakthrough and significance of unconventional oil and gas to classical petroleum geological theory. Pet. Explor. Dev. 2017, 44, 1–11. [Google Scholar] [CrossRef]

- Montgomery, S.L.; Jarvie, D.M.; Bowker, K.A.; Pollastro, R.M. Mississippian Barnett Shale, Fort Worth basin, north-central Texas: Gas-shale play with multi-trillion cubic foot potential. AAPG Bull. 2005, 89, 155–175. [Google Scholar] [CrossRef]

- Bowker, K.A. Barnett shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. Characterizing the shale gas resource potential of Devonian—Mississippian strata in the Western Canada sedimentary basin: Application of an integrated formation evaluation. AAPG Bull. 2008, 92, 87–125. [Google Scholar] [CrossRef]

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Li, Y.X.; Qiao, D.W.; Jiang, W.L.; Zhang, C.H. Gas content of gas-bearing shale and its geological evaluation summary. Geol. Bull. China 2011, 30, 308–317. [Google Scholar]

- Zeng, W.; Zhang, J.; Ding, W.; Wang, X.; Zhu, D.; LIU, Z. The gas content of continental Yanchang shale and its main controlling factors: A case study of Liuping-171 well in Ordos Basin. Nat. Gas Geosci. 2014, 25, 291–301. [Google Scholar]

- Dong, Q.; Liu, X.P.; Li, W.G.; D, Q.Y. Determination of gas content in shale. Nat. Gas Oil 2012, 30, 34–37. [Google Scholar]

- Tang, Y.; Zhang, J.C.; Li, L.Z. Use and improvement of the desorption method in shale gas content tests. Nat. Gas Ind. 2011, 31, 108–112. [Google Scholar]

- Wilson, K.; Padmakar, A.S.; Mondegarian, F. Simulation of core lifting process for lost gas calculation in shale reservoirs. In Proceedings of the International Symposium of the Society of Core Analysts, Napa Valley, CA, USA, 16–19 September 2013; SCA: Milpitas, CA, USA, 2013. [Google Scholar]

- Kissell, F.N.; Mcculloch, C.M.; Elder, C.H. The Direct Method of Determining Methane Content of Coal Beds for Ventilation Design; Technical Report; Pittsburgh Mining and Safety Research Center: Pittsburgh, PA, USA, 1973. [Google Scholar]

- Smith, D.M.; Williams, F.L. New technique for determining the methane content of coal. In Proceedings of the 16th Intersociety Energy Conversion Engineering Conference, Atlanta, GA, USA, 9–14 August 1981; ASME: New York, NY, USA, 1981. [Google Scholar]

- Smith, D.M.; Williams, F.L. Diffusion models for gas production from coal: Determination of diffusion parameters. Fuel 1984, 63, 256–261. [Google Scholar] [CrossRef]

- Dan, Y.; Seidle, J.P.; Hanson, W.B. Gas Sorption on Coal and Measurement of Gas Content. In SG 38: Hydrocarbons from Coal; El discurso civilizador en Derecho Internacional; Cinco estudios y tres comentarios; Instituto Fernando el Católico (IFC): Zaragoza, Spain, 1993; pp. 203–218. [Google Scholar]

- Zhang, J.; Xue, H.; Zhang, D. Shale gas and its accumulation mechanism. Geoscience 2003, 17, 466. [Google Scholar]

- Lewis, R.; Ingraham, D.; Pearcy, M.; Williamson, J.; Sawyer, W.; Frantz, J. New evaluation techniques for gas shale reservoirs. In Reservoir Symposium; Schlumberger: Houston, TX, USA, 2004. [Google Scholar]

- Hao, J.F.; Zhou, C.C.; Li, X.; Cheng, X.Z.; Song, L.T. Summary of shale gas evaluation applying geophysical logging. Prog. Geophys. 2012, 27, 1624–1632. [Google Scholar]

- Zhong, G.H.; Xie, B.; Zhou, X.; Peng, X.; Tian, C. A logging evaluation method for gas content of shale gas reservoirs in the Sichuan Basin. Nat. Gas Ind. 2016, 36, 43–51. [Google Scholar]

- Li, W.G.; Yang, S.L.; Xu, J.; D, Q. A new model for shale adsorptive gas amount under a certain geological conditions of temperature and pressure. Nat. Gas Geosci. 2012, 23, 791–796. [Google Scholar]

- Zhang, Q.; Liu, H.I.; Bai, W.H.; Lin, W. Shale gas content and its main controlling factors in Longmaxi shale in southeastern Chongqing. Nat. Gas Ind. 2013, 33, 35–39. [Google Scholar]

- Lau, H.C.; Li, H.; Huang, S. Challenges and Opportunities of Coalbed Methane Development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Li, H.; Lau, H.C.; Huang, S. Coalbed Methane Development in China: Engineering Challenges and Opportunities. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Meng, Z.; Liu, C.; Ji, Y. Geological conditions of coalbed methane and shale gas exploitation and their comparison analysis. J. China Coal Soc. 2013, 38, 728–736. [Google Scholar]

- GB/T 19560-2008. Experimental Method of High-Pressure Isothermal Adsorption to Coal; Standardization Administration of the People’s Republic of China: Beijing, China, 2008. [Google Scholar]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Chem. Phys. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Xue, H.Q.; Wang, H.Y.; Liu, H.L.; Yan, G. The Measurement of Shale Gas Content. Appl. Mech. Mater. 2013, 288, 333–337. [Google Scholar] [CrossRef]

- Liu, H.L.; Deng, Z.; Liu, D.X.; Zhao, Q.; Kang, Y.S.; Zhao, H.X. Discussion on lost gas calculating methods in shale gas content testing. Oil Drill. Prod. Technol. 2010, 322, 156–158. [Google Scholar]

- Gregg, S.J.; Sing, K.S.W. Adsorption, Surface Area, and Porosity; Academic Press: Cambridge, MA, USA, 1982. [Google Scholar]

- Bandosz, T.J. Gas Adsorption EquiIibria: Experimental Methods and Adsorptive Isotherms. J. Am. Chem. Soc. 2005, 127, 7655–7656. [Google Scholar] [CrossRef]

- Wang, F.Y.; He, Z.Y.; Meng, X.H.; Bao, L.Y.; Zhang, H. Occurrence of Shale Gas and Prediction of Original Gas In-place (OGIP). Nat. Gas Geosci. 2011, 22, 501–510. [Google Scholar]

- Li, Y. Calculation Methods of Shale Gas Reserves. Nat. Gas Geosci. 2009, 20, 466–470. [Google Scholar]

- Dodson, C.R.; Standing, M.B. Pressure-volume-temperature and solubility relations for natural-gas-water mixtures. In Drilling and Production Practice; American Petroleum Institute: Washington, DC, USA, 1944. [Google Scholar]

- Vazquez, M.; Beggs, H.D. Correlations for fluid physical property prediction. J. Pet. Technol. 1980, 32, 968–970. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Radius | 5 cm | Surface heat coefficient | 15 W/(m2·°C) |

| Thickness | 2.7 cm | Specific heat capacity | 876 J/kg·°C |

| Initial temperature | 15 °C | Density | 2430 kg/m3 |

| Water heating temperature | 55 °C | Thermal conductivity | 5 W/(m·°C) |

| Sample ID | Depth (m) | Gdesr (m3/t) | Gresi (m3/t) | Calculating Glost | Gdirect (m3/t) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| tloss (min) | Tb (min)a | Glost (m3/t) | |||||||||

| USBM | Improved | USBM | Improved | USBM | Improved | USBM | Improved | ||||

| X1 | 1336.72 | 0.88 | 0.14 | 177 | 217 | 12 | 18 | 0.99 | 1.40 | 2.01 | 2.42 |

| X2 | 1409.04 | 0.46 | 0.12 | 262 | 321 | 14 | 23 | 1.11 | 1.62 | 1.69 | 2.20 |

| X3 | 1419.83 | 1.32 | 0.36 | 342 | 401 | 8 | 20 | 1.41 | 2.24 | 3.09 | 3.92 |

| X4 | 1392.11 | 1.28 | 0.34 | 227 | 281 | 12 | 22 | 1.79 | 2.65 | 3.41 | 4.27 |

| X5 | 1390.25 | 1.37 | 0.21 | 240 | 297 | 10 | 16 | 2.63 | 3.26 | 4.21 | 4.84 |

| X6 | 1400.71 | 2.15 | 0.32 | 188 | 227 | 14 | 20 | 1.64 | 2.31 | 4.11 | 4.78 |

| X7 | 1338.48 | 1.71 | 0.59 | 264 | 300 | 10 | 19 | 1.51 | 2.68 | 3.81 | 4.98 |

| X8 | 1346.75 | 1.19 | 0.26 | 183 | 223 | 9 | 21 | 1.57 | 2.93 | 3.02 | 4.38 |

| X9 | 1456.31 | 0.76 | 0.11 | 231 | 301 | 11 | 20 | 0.58 | 1.30 | 1.45 | 2.17 |

| X10 | 1387.61 | 1.54 | 0.23 | 198 | 253 | 12 | 21 | 2.57 | 3.91 | 4.34 | 5.68 |

| X11 | 1466.87 | 1.32 | 0.17 | 212 | 307 | 7 | 18 | 1.74 | 2.62 | 3.23 | 4.11 |

| X12 | 1478.24 | 1.93 | 0.25 | 277 | 354 | 8 | 17 | 0.93 | 1.97 | 3.11 | 4.15 |

| X13 | 1354.12 | 1.11 | 0.26 | 241 | 321 | 14 | 23 | 1.39 | 2.41 | 2.76 | 3.78 |

| X14 | 1423.27 | 1.24 | 0.31 | 331 | 412 | 12 | 22 | 1.23 | 2.43 | 2.78 | 3.98 |

| X15 | 1321.34 | 0.77 | 0.15 | 245 | 332 | 8 | 17 | 2.09 | 2.64 | 3.01 | 3.56 |

| X16 | 1378.23 | 1.62 | 0.08 | 168 | 243 | 13 | 24 | 1.51 | 2.65 | 3.21 | 4.35 |

| Sample ID | Depth (m) | Gadsr (m3/t) | Gfree (m3/t) | Dissolved Gas Content | Gindirect (m3/t) | ||

|---|---|---|---|---|---|---|---|

| Godiss (m3/t) | Gwdiss (m3/t) | Gdiss (m3/t) | |||||

| X1 | 1336.72 | 1.75 | 0.64 | 0.17 | 0.01 | 0.18 | 2.57 |

| X2 | 1409.04 | 1.72 | 0.53 | 0.24 | 0.02 | 0.26 | 2.51 |

| X3 | 1419.83 | 3.25 | 0.71 | 0.33 | 0.02 | 0.35 | 4.31 |

| X4 | 1392.11 | 2.95 | 0.81 | 0.40 | 0.02 | 0.42 | 4.18 |

| X5 | 1390.25 | 3.62 | 1.11 | 0.29 | 0.01 | 0.30 | 5.03 |

| X6 | 1400.71 | 3.98 | 0.82 | 0.44 | 0.03 | 0.47 | 5.27 |

| X7 | 1338.48 | 3.68 | 0.96 | 0.51 | 0.02 | 0.53 | 5.17 |

| X8 | 1346.75 | 2.89 | 0.99 | 0.30 | 0.01 | 0.31 | 4.19 |

| X9 | 1456.31 | 1.45 | 0.35 | 0.10 | 0.01 | 0.11 | 1.91 |

| X10 | 1387.61 | 4.12 | 1.42 | 0.46 | 0.02 | 0.48 | 6.02 |

| X11 | 1466.87 | 2.67 | 0.72 | 0.38 | 0.03 | 0.41 | 3.80 |

| X12 | 1478.24 | 3.12 | 1.03 | 0.27 | 0.01 | 0.28 | 4.43 |

| X13 | 1354.12 | 1.99 | 0.96 | 0.56 | 0.02 | 0.58 | 3.53 |

| X14 | 1423.27 | 3.48 | 0.85 | 0.29 | 0.03 | 0.32 | 4.65 |

| X15 | 1321.34 | 2.43 | 0.94 | 0.11 | 0.01 | 0.12 | 3.49 |

| X16 | 1378.23 | 3.53 | 0.87 | 0.29 | 0.02 | 0.31 | 4.71 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Shen, Y.; Hao, J.; Liu, B. Shale Gas Content Calculation of the Triassic Yanchang Formation in the Southeastern Ordos Basin, China. Energies 2017, 10, 1949. https://doi.org/10.3390/en10121949

Su J, Shen Y, Hao J, Liu B. Shale Gas Content Calculation of the Triassic Yanchang Formation in the Southeastern Ordos Basin, China. Energies. 2017; 10(12):1949. https://doi.org/10.3390/en10121949

Chicago/Turabian StyleSu, Jiao, Yingchu Shen, Jin Hao, and Bo Liu. 2017. "Shale Gas Content Calculation of the Triassic Yanchang Formation in the Southeastern Ordos Basin, China" Energies 10, no. 12: 1949. https://doi.org/10.3390/en10121949

APA StyleSu, J., Shen, Y., Hao, J., & Liu, B. (2017). Shale Gas Content Calculation of the Triassic Yanchang Formation in the Southeastern Ordos Basin, China. Energies, 10(12), 1949. https://doi.org/10.3390/en10121949