Nano-Based Drilling Fluids: A Review

Abstract

:1. Introduction

2. Rheology and Fluid Loss Control

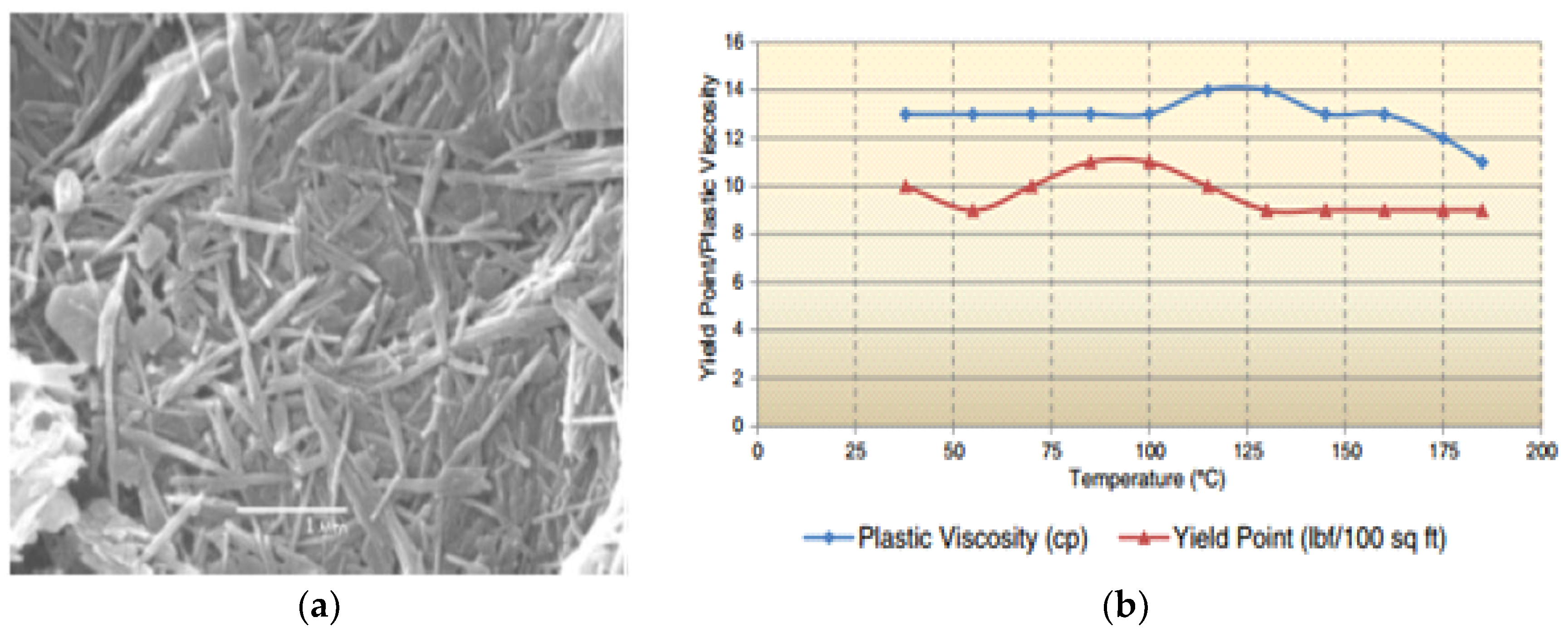

2.1. Experimental Studies

2.2. Field Applications

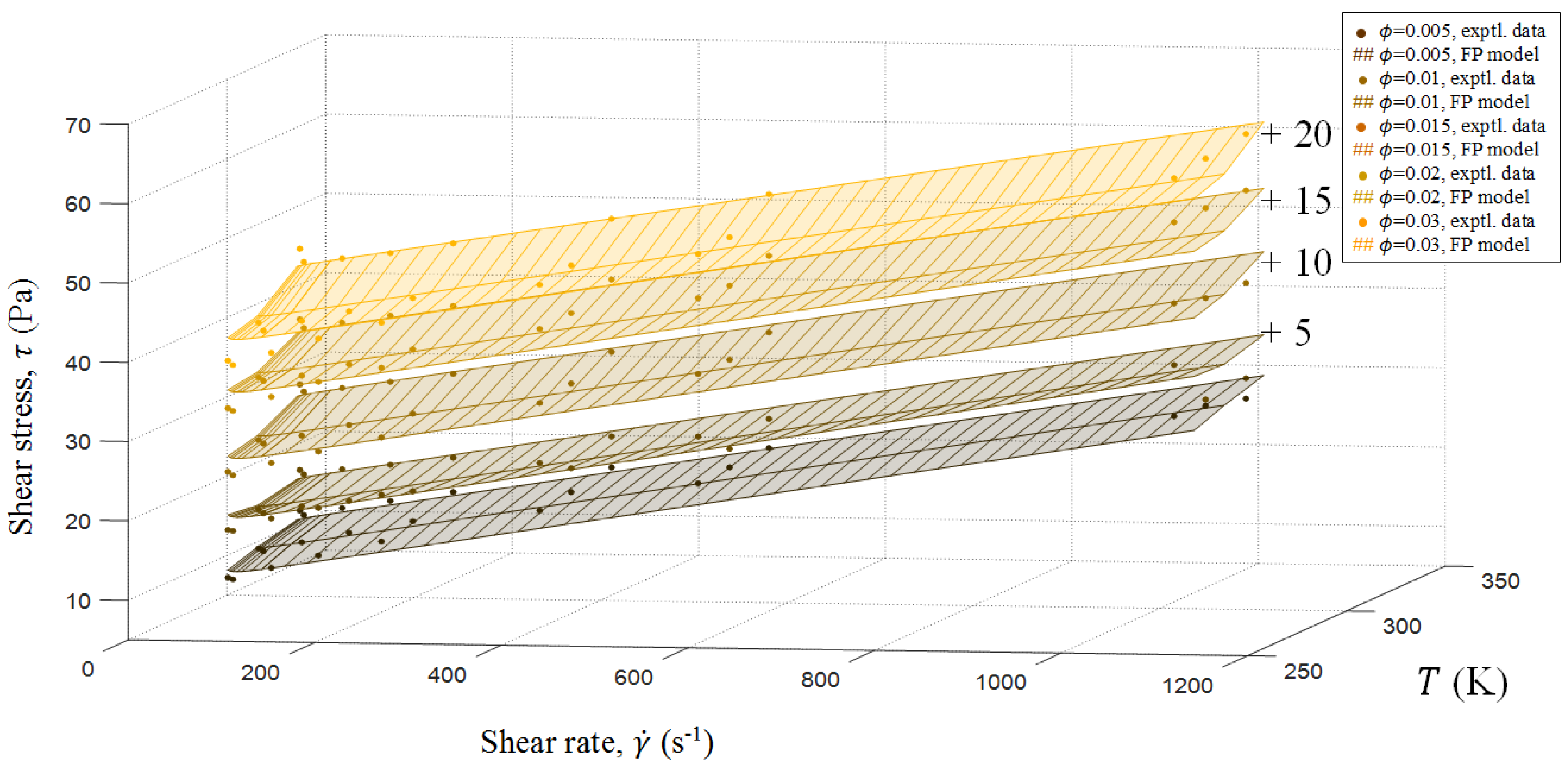

2.3. Modeling of Rheology

3. Shale and Wellbore Stability

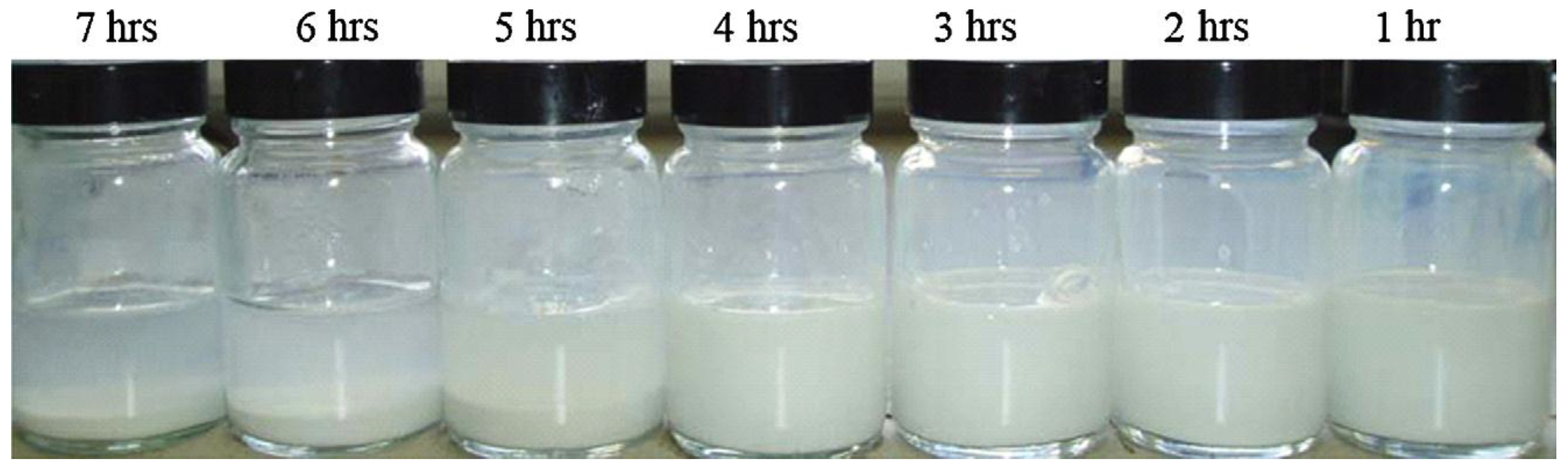

4. Wellbore Strengthening

5. Cutting Lifting Capacity and Cuttings Suspension

6. Thermal Properties

7. Effect of Magnetic Field

8. Challenges of Nanofluids

9. Recommendations for Future Work

10. Conclusions

- Nanoparticle shape, size and concentration have been identified as driving factors affecting the performance of nano-based drilling fluids.

- The major effect of the use of nanoparticles in drilling fluids is the significant enhancement of fluid loss particularly at HP/HT conditions. This can lead the drilling industry to great cost savings. Optimal concentrations reported range at lower than 1 wt %, and typically range around 0.5 wt %.

- Nanoparticles affect rheological properties of various water or oil base drilling fluids at different temperatures (up to 300 °F) and at relatively low concentrations (<0.5 wt %). The reported effects are not detrimental for the use of such nanoparticles as drilling fluid additives.

- Nano-enhanced drilling fluids exhibited flat type gel strength profile while maintaining optimal yield stress values, which reveals their great potential for better cuttings suspension properties as well as improved cuttings lifting capacity of drilling fluids.

- Promising attempts were reported to model the modification of rheological behavior of drilling fluids upon addition of nanoparticles at different temperatures, confirming their potential for modeling complex drilling fluid systems toward commercial application.

- Nanoparticles have the capability to reduce shale permeability by efficiently plugging the pores and thus their use is going to play a vital role for future shale explorations and exploitations.

- Wellbore strengthening is possible with the use of different nanoparticles because reported results proved that nanoparticle-based drilling fluids can lead to increased fracture pressures offering thus more efficient and safer drilling activities.

- Researchers attempted to quantify the enhancement of drilling fluid thermal properties with nanoparticles for utilization in the heat transfer studies of the flow of these fluids in the wellbore and found that nanoparticles can significantly improve their thermal conductivity, especially at high temperatures.

- The incorporation of magnetic nanoparticles as drilling fluid additives shows great potential for the development of smart drilling fluids with in-situ rheological controllability upon application of an external magnetic field.

- Stability and cost of nanofluids should be properly addressed in order for nanoparticles to make substantial impact on drilling fluid industry.

- Future directions should focus on the interfacial phenomena taking place and the modes of interaction between nanoparticles and other drilling fluid additives aided by macroscopic measurements, so that researchers can better understand the reasons behind such a good performance in order to optimize their effect.

- The ability to synthesize custom-made nanoparticles by changing their surface properties or by optimizing their terminal units in order to accomplish different functional tasks promises to substantially influence the landscape of drilling fluid industry by developing smarter and greener drilling fluids that can aid significantly the drilling industry.

Conflicts of Interest

References

- Amanullah, M.; AlArfaj, M.K.; Al-abdullatif, Z.A. Preliminary test results of nano-based drilling fluids for oil and gas field application. In Proceedings of the SPE/IADC Conference and Exhibition, Amsterdam, The Netherlands, 1–3 March 2011. [Google Scholar]

- Borisov, A.S.; Husein, M.; Hareland, G. A field application of nanoparticle-based invert emulsion drilling fluids. J. Nanopart. Res. 2015, 17, 340. [Google Scholar] [CrossRef]

- Taha, N.M.; Lee, S. Nano graphene application improving drilling fluids performance. IPTC 18539. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 6–9 December 2015. [Google Scholar]

- Friedheim, J.; Young, S.; De Stefano, G.; Lee, J.; Guo, Q. Nanotechnology for oilfield applications—Hype or reality? In Proceedings of the SPE International Nanotechnology Conference, Noordwjik, The Netherlands, 12–14 June 2012. [Google Scholar]

- Hoelscher, K.P.; Young, S.; Friedheim, J.; De Stefano, G. Nanotechnology application in drilling fluids. In Proceedings of the 11th Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 20–22 March 2013. [Google Scholar]

- Gerogiorgis, D.I.; Clark, C.; Vryzas, Z.; Kelessidis, V.C. Development and parameter estimation for an enhanced multivariate herschel-bulkley rheological model of a nanoparticle-based smart drilling fluid. Comput. Aided Chem. Eng. 2015, 37, 2405–2410. [Google Scholar]

- Reilly, S.I.; Vryzas, Z.; Kelessidis, V.C.; Gerogiorgis, D.I. First-principles rheological modelling and parameter estimation for nanoparticle-based smart drilling fluids. Comput. Aided Chem. Eng. 2016, 38, 1039–1044. [Google Scholar]

- Gerogiorgis, D.I.; Reilly, S.I.; Vryzas, Z.; Kelessidis, V.C. Experimentally validated first-principles multivariate modelling for rheological study and design of complex drilling nanofluid systems. In Proceedings of the SPE/IADC Drilling Conference and Exhibition (SPE/IADC), The Hague, The Netherlands, 14–16 March 2017. [Google Scholar]

- Vryzas, Z.; Wubulikasimu, Y.; Gerogiorgis, D.; Kelessidis, V.C. Understanding the temperature effect on the rheology of water-bentonite suspensions. In Proceedings of the Nordic Polymer Days and Nordic Rheological Conference, Helsinki, Finland, 30 May–1 June 2016. [Google Scholar]

- Vryzas, Z.; Mahmoud, O.; Nasr-El-Din, H.A.; Kelessidis, V.C. Development and testing of novel drilling fluids using Fe2O3 and SiO2 nanoparticles for enhanced drilling operations. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 7–9 December 2015. [Google Scholar]

- Mahmoud, O.; Nasr-El-Din, H.A.; Vryzas, Z.; Kelessidis, V.C. Nanoparticle-based drilling fluids for minimizing formation damage in HP/HT applications. In Proceedings of the International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 24–26 February 2016. [Google Scholar]

- Jung, Y.; Barry, M.; Lee, J.-K.; Tran, P.; Soong, Y.; Martello, D.; Chyu, M. Effect of nanoparticle-additives on the rheological properties of clay-based fluids at high temperature and high pressure. In Proceedings of the AADE National Technical Conference and Exhibition, Houston, TX, USA, 12–14 April 2011. [Google Scholar]

- Barry, M.M.; Jung, Y.; Lee, J.K.; Phuoc, T.X. Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J. Petrol. Sci. Eng. 2015, 127, 338–346. [Google Scholar] [CrossRef]

- Contreras, O.; Hareland, G.; Husein, M.; Nygaard, R.; Mortadha, A. Application of in-house prepared nanoparticles as filtration control additive to reduce formation damage. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. [Google Scholar]

- Mahmoud, O.; Nasr-El-Din, H.A.; Vryzas, Z.; Kelessidis, V.C. Characterization of filter cake generated by nanoparticle-based drilling fluid for HP/HT applications. In Proceedings of the International Conference on Oilfield Chemistry, Montgomery, TX, USA, 3–5 April 2016. [Google Scholar]

- Zakaria, M.F.; Husein, M.; Hareland, G. Novel nanoparticle-based drilling fluid with improved characteristics. In Proceedings of the SPE International Nanotechnology Conference, Noordwjik, The Netherlands, 12–14 June 2012. [Google Scholar]

- Vryzas, Z.; Arkoudeas, P.; Mahmoud, O.; Nasr-El-Din, H.A.; Kelessidis, V.C. Utilization of iron oxide nanoparticles in drilling fluids improves fluid loss and formation damage characteristics. In Proceedings of the First EAGE Workshop on Well Injectivity & Productivity in Carbonates (WIPIC), Doha, Qatar, 31 March–1 April 2015. [Google Scholar]

- Vryzas, Z.; Mahmoud, O.; Nasr-El-Din, H.A.; Kelessidis, V.C. Development of Novel Drilling-Fluid Nanoparticles for Enhanced Drilling Operations. J. Petrol. Technol. 2016, 68, 48–50. [Google Scholar]

- Vryzas, Z.; Arkoudeas, P.; Kelessidis, V.C. Improvement of drilling fluid flow parameters using nanoparticles for optimization of drilling process. In Proceedings of the International Conference on Safe and Sustainable Nanotechnology, Phitsanulok, Thailand, 14–17 October 2014. [Google Scholar]

- Vryzas, Z.; Mahmoud, O.; Nasr-El-Din, H.A.; Zaspalis, V.; Kelessidis, V.C. Incorporation of Fe3O4 nanoparticles as drilling fluid additives for improved drilling operations. In Proceedings of the ASME-OMAE International Conference, Busan, Korea, 19–24 June 2016. [Google Scholar]

- Vryzas, Z.; Zaspalis, V.; Nalbantian, L.; Mahmoud, O.; Nasr-El-Din, H.A.; Kelessidis, V.C. A comprehensive approach for the development of new magnetite nanoparticles giving smart drilling fluids with superior rheological and fluid loss properties for HP/HT applications. In Proceedings of the International Petroleum Technology Conference (IPTC), Bangkok, Thailand, 14–16 November 2016. [Google Scholar]

- Vryzas, Z.; Kelessidis, V.C.; Nalbantian, L.; Zaspalis, V.; Gerogiorgis, D.I.; Wubulikasimu, Y. Effect of temperature on the rheological properties of neat aqueous wyoming sodium bentonite dispersions. Appl. Clay Sci. 2017, 136, 26–36. [Google Scholar] [CrossRef]

- Mao, H.; Qiu, Z.; Shen, Z.; Huang, W.; Zhong, H.; Dai, W. Novel hydrophobic associated polymer based nano-silica composite with core-shell structure for intelligent drilling fluid under ultra-high temperature and ultra-high pressure. Prog. Nat. Sci. Mater. 2015, 25, 90–93. [Google Scholar] [CrossRef]

- Li, S.; Osisanya, S.; Haroun, M. Development of new smart drilling fluids using nano-materials for unconventional reservoirs. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 7–10 November 2016. [Google Scholar]

- Salih, A.H.; Elshehabi, T.A.; Bilgesu, H.I. Impact of nanomaterials on the rheological and filtration properties of water-based drilling fluids. In Proceedings of the SPE Eastern Regional Meeting, Canton, OH, USA, 13–15 September 2016. [Google Scholar]

- Anoop, K.; Sadr, R.; Al-Jubouri, M.; Amani, M. Rheology of mineral oil-SiO2 nanofluids at high pressure and high temperatures. Int. J. Therm. Sci. 2014, 77, 108–115. [Google Scholar] [CrossRef]

- Javeri, S.M.; Haindade, Z.W.; Jere, C.B. Mitigation loss circulation and differential sticking problems using silicon nanoparticles. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Muscat, Oman, 24–26 October 2011. [Google Scholar]

- Ismail, A.R.; Aftab, A.; Ibupoto, Z.H.; Zolkifile, N. The novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. J. Petrol. Sci. Eng. 2016, 139, 264–275. [Google Scholar] [CrossRef]

- Belayneh, M.; Aadnoy, B.S. Effect of nano-silicon dioxide (SiO2) on polymer/salt treated bentonite drilling fluid systems. In Proceedings of the ASME-OMAE International Conference, Busan, Korea, 19–24 June 2016. [Google Scholar]

- Agarwal, S.; Tran, P.; Soong, Y.; Martello, D.; Gupta, R.K. Flow Behavior of nanoparticle stabilized drilling fluids and effect of high temperature aging. In Proceedings of the AADE National Technical Conference and Exhibition, Houston, TX, USA, 12–14 April 2011. [Google Scholar]

- Abdo, J.; Haneef, M.D. Nano-enhanced drilling fluids: Pioneering approach to overcome uncompromising drilling problems. J. Energ. Resour. Technol. 2012, 134, 014501. [Google Scholar] [CrossRef]

- Abdo, J.; Haneef, M.D. Clay nanoparticles modified drilling fluids for drilling of deep hydrocarbon wells. Appl. Clay Sci. 2013, 86, 76–82. [Google Scholar] [CrossRef]

- Kosynkin, D.V.; Ceriotti, G.; Wilson, K.C.; Lomeda, J.R.; Scorsone, J.T.; Patel, A.D.; Friedheim, J.E.; Tour, J.M. Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS Appl. Mater. Interfaces 2012, 4, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Nasser, J.; Jesil, A.; Mohiuddin, T.; Al Ruqeshi, M.; Devi, G.; Mohataram, S. Experimental investigation of drilling fluid performance as nanoparticles. World J. Nano Sci. Eng. 2013, 3, 57–61. [Google Scholar] [CrossRef]

- Manea, M. Design of drilling fluids using nano scale polymer Additives. Rev. Roum. Chim. 2012, 57, 197–202. [Google Scholar]

- Saboori, R.; Sabbaghi, S.; Mowla, D.; Soltani, A. Decreasing of water loss and mud cake thickness by CMC nanoparticles in mud drilling. Int. J. Nano Dimens. 2012, 3, 101–104. [Google Scholar]

- Fereydouni, M.; Sabbaghi, S.; Saboori, R.; Zeinali, S. Effect of polyanionic cellulose polymer nanoparticles on rheological properties of drilling mud. J. Nanosci. Nanotechnol. 2012, 8, 171–174. [Google Scholar]

- Li, M.-C.; Wu, Q.; Song, K.; De Hoop, C.F.; Lee, S.; Qing, Y.; Wu, Y. Cellulose nanocrystals and polyanionic cellulose as additives in bentonite water-based drilling fluids: Rheological modeling and filtration mechanisms. Ind. Eng. Chem. Res. 2015, 55, 133–143. [Google Scholar] [CrossRef]

- Li, M.-C.; Wu, Q.; Song, K.; Qing, Y.; Wu, Y. Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl. Mater. Interfaces. 2015, 7, 5006–5016. [Google Scholar] [CrossRef] [PubMed]

- Sadeghalvaad, M.; Sabbaghi, S. The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol. 2015, 272, 113–119. [Google Scholar] [CrossRef]

- William, J.K.; Ponmani, S.; Samuel, R.; Nagarajan, R.; Sangwai, J.S. Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J. Petrol. Sci. Eng. 2014, 117, 15–27. [Google Scholar] [CrossRef]

- Ponmani, S.; Nagarajan, R.; Sangwai, J.S. Effect of nanofluids of CuO and ZnO in polyethylene glycol and polyvinylpyrrolidone on the thermal, electrical, and filtration-loss properties of water-based drilling fluids. SPE J. 2016, 405–415. [Google Scholar] [CrossRef]

- Aftab, A.; Ismail, A.R.; Khokhar, S.; Ibupoto, Z.H. Novel zinc oxide nanoparticles deposited acrylamide composite used for enhancing the performance of water-based drilling fluids at elevated temperature conditions. J. Petrol. Sci. Eng. 2016, 146, 1142–1157. [Google Scholar] [CrossRef]

- Ho, C.Y.; Yusup, S.; Soon, C.V.; Arpin, M.T. Rheological behavior of graphene nano-sheets in hydrogenated oil-based drilling fluid. Procedia Eng. 2016, 148, 49–56. [Google Scholar] [CrossRef]

- Ismail, A.R.; Rashid, N.M.; Jaafar, M.Z. 2014. Effect of nanomaterial on the rheology of drilling fluids. J. Appl. Sci. 2014, 14, 1192–1197. [Google Scholar]

- Parizad, A.; Shahbazi, K. Experimental investigation of the effects of SnO2 nanoparticles and KCl salt on a water base drilling fluid properties. Can. J. Chem. Eng. 2016, 94, 1924–1938. [Google Scholar] [CrossRef]

- Li, M.-C.; Wu, Q.; Song, K.; Lee, S.; Jin, C.; Ren, S.; Lei, T. Soy protein isolate as fluid loss additive in bentonite-water-based drilling fluids. ACS Appl. Mater. Interfaces. 2015, 7, 24799–24809. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, S.; Sabbaghi, S.; Soleymani, M. Synthesis of alumina/polyacrylamide nanocomposite and its influence on viscosity of drilling fluid. Int. J. Nano Dimens. 2015, 6, 271–276. [Google Scholar]

- Amarfio, E.M.; Abdulkadir, M. Effect of Al2O3 nanoparticles on the rheological properties of water based mud. Int. J. Sci. Eng. Appl. 2016, 5, 7–11. [Google Scholar]

- Afolabi, R.O.; Orodu, O.D.; Efeovbokhan, V.E.; Rotimi, O.J. Optimizing the rheological properties of silica nano-modified bentonite mud using overlaid contour plot and estimation of maximum or upper shear stress limit. Cogent Eng. 2017, 4, 1287248. [Google Scholar] [CrossRef]

- Sensoy, T.; Chenevert, M.E.; Sharma, M.M. Minimizing water invasion in shale using nanoparticles. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Taraghikhah, S.; Kalhor Mohammadi, M.; Tahmasbi Nowtaraki, K. Multifunctional nanoadditive in water based drilling fluid for improving shale stability. SPE 18323. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 6–9 December 2015. [Google Scholar]

- Hoelscher, K.P.; De Stefano, G.; Riley, M.; Young, S. Application of nanotechnology in drilling fluids. In Proceedings of the SPE International Nanotechnology Conference, Noordwjik, The Netherlands, 12–14 June 2012. [Google Scholar]

- Sharma, M.M.; Chenevert, M.E.; Guo, Q.; Ji, L.; Friedheim, J.; Zhang, R. A new family of nanoparticle based drilling fluids. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Srivatsa, J.T.; Ziaja, M.B. An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant-polymer based drilling fluid. In Proceedings of the International Technology Conference, Bangkok, Thailand, 7–9 February 2012. [Google Scholar]

- Akhtarmanesh, S.; Ameri Shahrabi, M.J.; Atashnezhad, A. Improvement of wellbore stability in shale using nanoparticles. J. Petrol. Sci. Eng. 2013, 112, 290–295. [Google Scholar] [CrossRef]

- Kang, Y.; She, J.; Zhang, H.; You, L.; Song, M. Strengthening shale wellbore with silica nanoparticles drilling fluid. Petroleum 2016, 2, 189–195. [Google Scholar] [CrossRef]

- Shahri, M.P. Quantification of wellbore strengthening mechanisms: comprehensive parametric analysis. SPE 174770. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Growcock, F. How to Stabilize and Strengthen the Wellbore during Drilling Operations. SPE Distinguished Lecturer Program. 2010. Available online: http://www.spe.org/dl/docs/2010/FredGrowcock.pdf (accessed on 6 March, 2017).

- Nwaoji, C.O.; Hareland, G.; Husein, M.; Nygaard, R.; Zakaria, M.F. Wellbore strengthening-nano-particle drilling fluid experimental design using hydraulic fracture apparatus. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 5–7 March 2013. [Google Scholar]

- Contreras, O.; Hareland, G.; Nygaard, R.; Alsaba, M. Experimental investigation on wellbore strengthening in shales by means of nanoparticle-based drilling fluids. SPE 170589. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Contreras, O.; Hareland, G.; Husein, M.; Nygaard, R.; Alsaba, M. Wellbore strengthening in sandstones by means of nanoparticle-based drilling fluids. SPE 170263. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 10–11 September 2014. [Google Scholar]

- Samsuri, A.; Hamzah, A. Water based mud lifting capacity improvement by multiwall carbon nanotubes additive. J. Petrol. Gas Eng. 2011, 2, 99–107. [Google Scholar]

- Angayarkanni, S.A.; Philip, J. Review on thermal properties of nanofluids: Recent developments. Adv. Colloid Interface Sci. 2015, 225, 146–176. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and comparison of nanofluid thermal conductivity and heat transfer enhancements. Heat Transf. Eng. 2011, 29, 432–460. [Google Scholar] [CrossRef]

- Sabbaghi, S.; Saboori, R.; Barahoei, M. Enhanced heat transfer of drilling fluid with titania nanofluid. Res. Rev. J. Eng. Technol. 2015, 4, 12–17. [Google Scholar]

- Sedaghatzadeh, M.; Khodadali, A.A.; Tahmasebi Birgani, M.R. An improvement in thermal and rheological properties of water-based drilling fluids using multiwall carbon nanotube. Iran. J. Oil Gas Sci. Technol. 2012, 1, 55–65. [Google Scholar]

- Halali, M.A.; Ghotbi, C.; Tahmasbi, K.; Ghazanfari, M.H. The role of carbon nanotubes in improving thermal stability of polymeric fluids: Experimental and modeling. Ind. Eng. Chem. Res. 2016, 55, 7514–7534. [Google Scholar] [CrossRef]

- Fazelabdolabadi, B.; Khodadadi, A.A.; Sedaghatzadeh, M. Thermal and rheological properties improvement of drilling fluids using functionalized carbon nanotubes. Appl. Nanosci. 2015, 5, 651–659. [Google Scholar] [CrossRef]

- Ho, C.Y.; Yusup, S.; Soon, C.V. Study on the effect of nanoparticle loadings in base fluids for improvement of drilling fluid properties. J. Adv. Chem. Eng. 2014, 4, 115. [Google Scholar] [CrossRef]

- Li, D.; Hong, B.; Fang, W.; Guo, Y.; Lin, R. Preparation of well-dispersed silver nanoparticles for oil-based nanofluids. Ind. Eng. Chem. Res. 2010, 49, 1697–1702. [Google Scholar] [CrossRef]

- Lee, J.K.; Sefzik, T.; Son, Y.H.; Phuoc, T.H.; Soong, Y.; Martello, D.; Chyu, M.K. Use of magnetic nanoparticles for smart drilling fluids. In Proceedings of the AADE National Technical Conference and Exhibition, New Orleans, LA, USA, 31 Mar–2 April 2009. [Google Scholar]

- Vryzas, Z.; Kelessidis, V.C.; Bowman, M.; Nalbantian, L.; Zaspalis, V.; Mahmoud, O.; Nasr-El-Din, H.A. Smart magnetic drilling fluid with in-situ rheological controllability using Fe3O4 nanoparticles. In Proceedings of the Middle East Oil & Gas Show and Conference, Manama, Bahrain, 6–9 March 2017. [Google Scholar]

- Wen, D.; Lin, G.; Vafaei, S.; Zhang, K. Review of nanofluids for heat transfer applications. Particuology 2009, 7, 141–150. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Mohammed, H.A.; Alawi, O.A.; Samion, S. A Review on preparation methods and chahallenges of nanofluids. Int. Commun. Heat Mass Transf. 2014, 54, 115–125. [Google Scholar] [CrossRef]

- Choi, C.; Yoo, H.S.; Oh, J.M. Preparation and heat transfer properties of nanoparticle-in-transformer oil dispersions as advanced energy-efficient coolants. Curr. Appl. Phys. 2008, 8, 710–712. [Google Scholar] [CrossRef]

- Tighe, C.J.; Cabrera, R.Q.; Gruar, R.I.; Darr, J.A. Scale up production of nanoparticles: Continuous supercritical water synthesis of Ce–Zn oxides. Ind. Eng. Chem. Res. 2013, 52, 5522–5528. [Google Scholar] [CrossRef]

- Charitidis, C.A.; Georgiou, P.; Koklioti, M.A.; Trompeta, A.F.; Markakis, V. Manufacturing nanomaterials: From research to industry. Manuf. Rev. 2014, 1, 11. [Google Scholar] [CrossRef]

- Specification for Drilling Fluid Materials; API Specifications 13A, 2010; API: Washington, DC, USA, 2010.

- Recommended Practice for Field Testing Water Based Drilling Fluids; API Specifications 13B-1, 2003; API: Washington, DC, USA, 2003.

- Recommended Practice Standard Procedure for Laboratory Testing Drilling Fluids; API Specifications 13I, 2000; API: Washington, DC, USA, 2000.

- Clark, P.E. Drilling mud rheology and the API recommended measurements. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, Oklahoma, 2–4 April 1995. [Google Scholar]

| Samples | Yield Stress (Pa) |

|---|---|

| BF | 1.27 |

| BF + 0.5 wt % Fe2O3 NP (30 nm) | 1.80 |

| BF + 5.0 wt % Fe2O3 NP (30 nm) | 7.67 |

| BF + 0.5 wt % Fe2O3 NP (3 nm) | 3.33 |

| BF + 5.0 wt % Fe2O3 NP (3 nm) | 36.89 |

| Iron Oxide Nanoparticles | |||||

|---|---|---|---|---|---|

| Concentration | Mode | Filter Cake Thickness | Percentage Change In Thickness | Cumulative Filtrate Volume | Percentage Change In Filtrate Volume |

| (wt %) | (in.) | (%) | (cm3) | (%) | |

| 0.0 | Static | 0.3084 | - | 12.0 | - |

| 0.3 | Static | 0.3123 | 1.25 | 10.0 | −16.67 |

| 0.5 | Static | 0.3618 | 17.32 | 6.9 | −42.50 |

| 1.5 | Static | 0.4330 | 40.40 | 9.0 | −25.00 |

| 2.5 | Static | 0.4760 | 54.35 | 11.9 | −0.83 |

| 0.5 | Dynamic | 0.2958 | −18.24 | 12.4 | 79.71 |

| Silica Nanoparticles | |||||

| 0.5 | Static | 0.3462 | 12.26 | 13.6 | 13.33 |

| 1.5 | Static | 0.4280 | 38.78 | 18.9 | 57.50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vryzas, Z.; Kelessidis, V.C. Nano-Based Drilling Fluids: A Review. Energies 2017, 10, 540. https://doi.org/10.3390/en10040540

Vryzas Z, Kelessidis VC. Nano-Based Drilling Fluids: A Review. Energies. 2017; 10(4):540. https://doi.org/10.3390/en10040540

Chicago/Turabian StyleVryzas, Zisis, and Vassilios C. Kelessidis. 2017. "Nano-Based Drilling Fluids: A Review" Energies 10, no. 4: 540. https://doi.org/10.3390/en10040540

APA StyleVryzas, Z., & Kelessidis, V. C. (2017). Nano-Based Drilling Fluids: A Review. Energies, 10(4), 540. https://doi.org/10.3390/en10040540