1. Introduction

As concerns about energy crisis and environmental issues mount, electric vehicles (EVs) have been considered as the most promising substitutes for internal combustion engine vehicles. EVs’ performance is strongly effected by their energy storage sources (ESS) [

1,

2]. ESSs for EVs must simultaneously possess high specific energy, high specific power and long cycle life, which is impossible for a single ESS. Consequently, hybrid energy storage system (HESS) have becomes favorable options. Among all ESSs, Li-ion batteries (LiB) are the most extensively used for their high specific energy, however, low specific power and short cycle lives limit their application [

3]. Compared with LiB, ultracapacitors (UCs) have longer cycle life and higher specific power [

4]. Therefore utilizing HESSs that include LiB and UC and possess both the high specific energy of LiB and high specific power of UC is an advisable choice. In this way, the LiB burden would be reduced remarkably by the assistance of UC, and LiB lifetime would be effectively extended.

HESS performance in extending LiB life is mainly influenced by three factors: HESS structure selection, parameter matching and the energy management strategy (EMS). Among all structures, passive, semi-active and active structures have been widely researched [

5,

6,

7,

8,

9,

10]. In passive structures, the LiB and UC are directly combined in parallel, and the power distribution between them only depends on their internal resistances. This structure is the most cost effective, yet the controllability is poor. In active structures, both the LiB and UC are connected to a direct current (DC) bus by two full-size bi-directional DC/DC converters, and they can be controlled independently, although the need for two converters increases the HESS cost significantly. In semi-active structures, either the LiB or UC are connected to the DC bus with a bi-directional DC/DC converter as the controlled component, and this structure provides a tradeoff between cost, controllability and complexity. As the control process gives rise to a slight delay, peak HESS power demand will result in a pulsed current to the passive component and cause damage. For this reason, LiB is chosen as the controlled component in this paper, and UC is left to deal with the pulsed current passively.

After determining the structure, the priority for the HESS is to develop an appropriate energy management strategy (EMS) to decide how the HESS power demand is allocated to LiB and UC. Lots of EMSs have been put forward, and they can mainly be classified into two categories: rule-based controllers (RBCs) and optimization-based strategies. With off-line optimization [

11,

12,

13], an optimal power distribution can be obtained, but it’s not viable for real-time application since the whole future driving conditions must be known a priori. Instead, RBC is suitable for real-time application, because the future conditions are not needed.

In [

14], RBC is proposed for the active HESS structure. After optimizing both UC parameters and RBC parameters under a certain cycle, the proposed RBC is capable of reducing the battery peak current by 49%. In [

15], a fuzzy-logic energy management based on Markov random prediction is designed for a semi-active HESS structure. Simulation results show that the average battery current rate is effectively reduced. In [

16], an optimal power distribution for minimizing HESS energy consumption is solved by gradient method. Based on the optimal distribution, a neural network (NN) controller is developed, and the performance is near-optimal. The aforementioned EMSs are easily implemented online, and the performance are satisfactory under certain cycle. Nevertheless, due to the stiffness of parameters, their performance would degrade when applied to other cycles. In [

17,

18,

19], wavelet transform (generally a 3-level Haar wavelet) is adopted to split HESS power demand into high as well as low frequency parts. Different parts are allocated to different sources based on their characteristics. This method is easy to implement online, yet both power demand prediction and the ultracapacitor state of charge (USOC) adjustment remain challenges.

The RBCs mentioned above do not guarantee optimal performance. Besides, the robustness is poor when the driving cycle is uncertain. To conquer the weaknesses, online optimization-based strategies are increasingly getting attention. Optimization-based EMSs artificially design a cost function with constraints, and solve its minimum online by using different kinds of algorithms: model predictive control (MPC), dynamic programming (DP), convex optimization (CVX) or some evolutionary algorithms [

20,

21]. Among them, model predictive control (MPC) is a kind of model-based control design method which has been introduced in the EMSs for HESS recently. In [

22,

23], a detailed control-oriented state space model of an active HESS is constructed for MPC, and the battery current magnitude/fluctuation were minimized successfully. In [

24], an explicit MPC (EMPC) was designed by solving piecewise linear functions of states and control laws offline to replace online QP calculation, reducing the computational burden dramatically. MPC and EMPC are suitable for designing EMSs of linear HESS. Conversely, it’s difficult for MPC and EMC to design proper EMSs for highly nonlinear semi-active HESS. To handle the nonlinearity of multi-sources, some researchers have adopted DP instead of quadratic programming (QP) in MPC [

25,

26]. Unfortunately, a large states number or a small states discretization step size would cause a heavy computational burden for real-time implementation. As DP has computational problems when handling nonlinear multi-states optimization problems, CVX could be a reasonable substitute. In [

27,

28], HESS parameters and EMS are optimized simultaneously to extend battery life, as well as reduce total energy consumption. In [

29,

30], EMS for HESS is designed based on CVX to minimize battery current magnitude/ fluctuation. CVX is an effective tool in dealing with optimization problems with multi-states, whereas, it is only applicable to convex cost functions with convex constraints, and its application in non-convex models is limited.

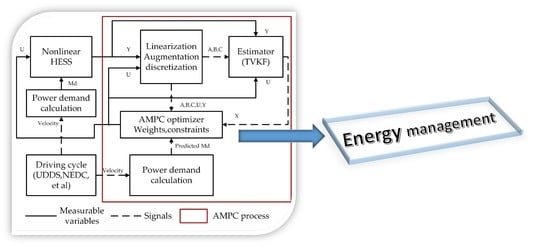

From the literature described above, optimization-based EMSs are preferred over RBC-based EMSs for their optimality and adaptability to driving condition uncertainty, but due to the strong nonlinearity of semi-active HESS, the mentioned optimization methods are not applicable. In this paper, an AMPC-based EMS for semi-active HESS is proposed to handle the model nonlinearity. The proposed AMPC minimizes LiB Ah-throughput in the prediction horizon and ensures HESS operation within constraints. Three aspects of research are conducted on the proposed AMPC. Firstly, a module for generating control-oriented model is designed, including linearization, direct feedthrough elimination, discretization and state augmentation. Secondly, a time-varying Kalman filter (TVKF) is introduced as state estimator to improve the state estimation accuracy. In this way, both control-oriented model and estimated states improve the control action accuracy calculated by the QP solver. Finally, sampling time, prediction horizon and scaling factors of AMPC are determined through simulation. The proposed EMS is created and verified on the Matlab/Simulink (The MathWorks, Natick, MA, USA) platform. Compared with standard MPC (SMPC), TVKF reduces estimation errors by 1~3 order of magnitude, AMPC reduces LiB Ah-throughput by 4.3% under UDDS conditions, indicating superior model adaptivity. Furthermore, simulation results under various driving cycles differ from those of DP by an average of 6.5% and reduce an average of 10.6% compared to RBC, indicating that AMPC is able to minimize the LiB Ah-throughput online effectively when the HESS is nonlinear and the driving conditions are uncertain.

The rest of the paper is organized as follows: in

Section 2, the detailed HESS model is introduced. In

Section 3, the control-oriented model updating process is performed, and TVKF is specified. In

Section 4, AMPC parameters are discussed, and AMPC is compared with SMPC, RBC and DP to verify the model adaptivity and adaptability to driving condition uncertainty. Moreover, the influence of the weights is researched and a suggested range is given.

Section 5 presents the conclusions.

3. AMPC-Based Energy Management Implementation

When the C-rate is within 2C,

BSOC is within the range of [0.2, 0.9], Ah-throughput is capable of representing numerically the ageing condition of batteries [

36]. The purpose of the EMS is: (1) to minimize LiB current (or plus current variation), thereby reduce LiB Ah-throughput and extend battery life; (2) to ensure HESS is operating within the constraints. This is a finite horizon optimization problem with constraints, and MPC is excellent for managing optimization problems like this. In SMPC, the control-oriented model is designed off-line, and remains unchanged during simulation. If the plant is linear or weak nonlinear, the model prediction accuracy is acceptable. However, as the proposed semi-active HESS is highly nonlinear, the constant prediction model isn’t accurate, AMPC is used to address the degradation by adapting the prediction model for changing the working conditions. Intrinsically, AMPC has the same structure as SMPC but allows the model parameters and optimization cost function to evolve with time. At each interval, a state space model is obtained by linearizing the HESS model around current working conditions. The original HESS model is:

To ensure

ib and

iu have real solutions, the following two expressions are added to outputs:

As AMPC is able to set limits for inputs and outputs only, states Vbb and Vub who have engineering constraints are also added to outputs. Besides, as state estimator is required, the model observability must be guaranteed. To this end, Vbl and Vul are added to outputs as measured variables. By this means, two current sensors and two voltage sensors are needed. The final model is with inputs U = [Pb, Pd], internal states X = [Vbb, Vbp, Vub, Vup] and outputs Y = [Vbb, ib, Vbl, yb, Vub, iu, Vul, yu].

3.1. Control-Oriented Model Implementation

3.1.1. Linearization

At each control interval, the plant is linearized around current operation point (

Xt,

Ut) by first approximation of Taylor expansion. The linearized plant is described as:

where, the constant matrices

f(

X0,

U0) −

AX0 −

BU0 and

g(

X0,

U0) −

CX0 −

DU0 are set as measured disturbances with constant inputs of 1, and the new inputs are augmented as

U = [

Pb, Pd, Md]. The state space model is augmented as:

Matrix

A,

B,

C and

D are calculated as:

3.1.2. Eliminating Direct Feedthrough

Non-empty matrix

D which causes direct feedthrough from inputs to outputs is unacceptable by AMPC. To eliminate the feedthrough, the linearized plant in Equation (13) is augmented by adding first-order filters with time constant

Ta to inputs, as shown in Equation (15).

Ta is chosen as one-tenth or smaller of the AMPC sampling time [

37,

38]. With this method, the original inputs are turned into new states and new inputs are identical to old ones except a slight delay:

The linearized model is augmented by:

Augmented states now are Xa = [Vbb, Vbp, Vub, Vup, Pb, Pd, Md], and new inputs are Ua = [Pba, Pda, Mda]. The delay in the inputs intrinsically causes a slight model mismatch, which AMPC is good at dealing with.

3.1.3. Model Discretization

The Zero-Order Hold method is used to discretize the state space model with sample time

Ts, the discrete state space is represented as:

where:

The matrix exponential of G (Ts) is calculated using Padé approximant and integral of H (Ts) is implemented using Simpson’s Rule.

3.1.4. LiB Current Fluctuation Suppression

To avoid LiB damage caused by enormous current fluctuation, the current variation is also considered as a control target [

27]. Here we define a state:

Based on the discrete state space, and output increments are represented as:

∆

ib is expressed by the second row of ∆

Y, in which coefficients vector of

Xa is expressed by

Gdib, coefficients vector of

Ua is expressed by

Hdib. ∆

ib is expressed as:

The discrete state space model is augmented again:

The final state space model for AMPC is obtained with internal states XA = [Vbb, Vbp, Vub, Vup, Pb, Pd, Md, ∆ib], inputs Ua = [Pba, Pda, Mda] and outputs YA = [Vbb, ib, Vbl, yb, Vub, iu, Vul, yu, ∆ib], as well as control-oriented model matrices GA, HA and CA.

3.2. Optimization Problem

The AMPC is designed based on the model shown in Equation (22), in which Pba is the only manipulated variable, Pda and Mda are measured disturbances, ib, iu, Vbl and Vul are measured outputs, Vbb, Vub, yb, yu and ∆ib are unmeasured outputs.

The AMPC solves a QP problem at each control interval and determines the control action of next interval. The QP problem here includes outputs reference tracking and constraints violation, the cost function to be minimized is as follows [

39,

40]:

where,

ny is the number of outputs,

p is prediction horizon,

wj is the weight of jth output,

is the constraints violation penalty weight, and

ε is the slack variable at interval

k.

J involves a trade-off between the output reference tracking and constraint violation by weighting, and corresponding QP decision is [

Ua (

k|

k)

Ua(

k + 1|

k) …

Ua (

k +

p − 1|

k)

ε]. The first part of

J represents the output reference tracking with weight matrix

wj, while the second part shows the constraint violation with weight

. When

increases,

ε tends to be smaller or zero, meaning

J is more inclined to suppress constraint violation. If

ε is zero,

Ua and

Ya are strictly limited within constraints; if

ε is positive, at least one soft constraint is reached. While, when

is smaller, ε tends to be greater, soft constraints are more likely to be activated, and the controller performance can be substandard.

Sy,j and

su are scaling factors (SFs) whose roles are to scale inputs and outputs to the same magnitude. ECRs are nonnegative parameters used to soften inputs and outputs constraints, the larger the ECRs are, the greater constraints violation are allowed to obtain optimal solution.

Suppose

HAu is coefficient matrix of

Pba, and

HAv is coefficient matrix of [

Pda, Mda], the model in Equation (22) is rewritten as:

Assign

Uau =

Pba and

Uav = [

Pda, Mda], based on Equation (23), the predicted output is:

Define

, we can derive that

. Then substitute Δ

Uau into Equation (25), the predicted output is expressed as:

where,

HAu is coefficient matrix of

Pba from

HA,

HAv is coefficient matrix of [

Pda,

Mda] from

HA. As shown in Equation (26),

GA,

HA (

HAu and

HAv) and

CA are used by QP solver for calculation.

ECRs for inputs and outputs are decided based on whether their upper or lower bounds are allowed to be violated or how great their bounds are allowed to be violated. Constraints for Pb are not set for they are limited intrinsically by the limitation of Vbb and ib, and their ECRs are set as 1 by default. Vbb is limited to the range of 0.18 V~0.81 V based on BSOC constraints, both constraints leave some margin and can be violated, ECR1,min and ECR1,max are set as 1. Constraints for ib are −3.2 A~6.4 A according to the manual, the lower bound is strictly limited by the manufacturer, while the upper bound can be set as high as 10 A in our experiment, ECR2,min is 0 and ECR2,max is 1. Constraints for Vbl and Vul are not set for they are intrinsically limited by other states, corresponding ECRs are set as 1. Outputs yb and yu must be non-negative, and the constraints are not allowed to be violated. Considering linearization error, the lower bounds for yb and yu are set as 0.5, ECR3,min and ECR6,min are 0. Vub is limited to meet the voltage range of DC bus, cell voltage range is thus between 1.5 V~2.7 V. As the energy stored in the UC increases exponentially with Vub, the upper bound would be violated slightly by absorbing much energy, which is acceptable, ECR4,max is 1. While the lower bound would be violated severely by even delivering little energy, which is unacceptable, ECR4,min is 0. Constraints for iu are −1200 A~1200 A and can be violated, for huge current do not harm the UC cell obviously, ECR5,min and ECR5,max are 10. Constraints for ∆ib are not set for the constraints of ib intrinsically avoid severe variation of ∆ib, meanwhile weights for ib and ∆ib prevent them from wide variation.

3.3. Controller State Estimation

QP solver receives states for calculation, as shown in Equation (26). As HESS states can’t be measured directly, a state estimator is needed. Currents and terminal voltages of LiB and UC are related to all four states to be estimated, and they are all measured variables. By gathering voltage and current signals, the HESS observability is guaranteed.

TVKF is applied to construct the estimator. Different from the standard Kalman filter, TVKF calculates the gain matrix with varying model matrices

GA,

HA and

CA. The model in Equation (22) is augmented with noise vector

w(

k) and

v(

k) [

26]:

where,

w(

k) is process noise with covariance matrix

Q, its gaining matrix is the same as inputs, and

v(

k) is measurement noise with covariance matrix

R.

Q is

n-by-

n diagonal matrix,

n is equal to the number of states.

R is m-by-m diagonal matrix, m is equal to the number of measured outputs. Suppose

w(

k) and

v(

k) are driven by white noise with unity gain,

Q =

, and

R is diagonal matrix with diagonal elements [

SF2,

SF3,

SF6,

SF7] considering influence of scaling.

The estimation process at control interval k is as follows:

- (1)

- (2)

Measurement correction:

where

is the corrected states prediction of previous interval,

is the uncorrected states prediction of current interval,

is the corrected states estimation error covariance matrix of previous interval,

is the uncorrected error covariance matrix of current interval,

Kg(

k) is gain matrix for measurement correction,

is the corrected states prediction of current interval,

P(

k|

k) is the corrected error covariance matrix of current interval. It’s obvious that time-varying

GA,

HA and

CA influence the value of

Kg significantly.

3.4. Measured Disturbance

The control-oriented model of AMPC has two measured disturbances:

Pda and

Mda.

Mda is a constant set as 1, while

Pda is HESS power demand determined by vehicle power balance equation shown below:

where,

v is vehicle velocity from driving cycle,

m is vehicle mass,

f is rolling resistance coefficient,

CD is drag coefficient,

A is windward area,

δ is correction coefficient of rotating mass,

a is vehicle acceleration.

As AMPC solves the QP problem with the assumption that measured disturbances in the prediction horizon are known, the velocity needs to be predicted. Yet, model prediction inevitably causes errors, and the predicted power demand wouldn’t improve AMPC efficiency, and sometimes it may even deteriorate the efficiency if the velocity prediction is not that accurate. As a result, current power demand is applied to AMPC, and remains unchanged in prediction horizon. The whole process of the AMPC is shown in

Figure 4, in the red box is the AMPC.