For comparison purposes, the basic simulation conditions in this study are taken similar to those of [

22]. The source fluid is considered as air with

Ts = 150 °C and

ms = 1 kg/s, while the latter in [

22] is 20 kg/s. The basic simulation conditions are as follows: separator pressure

PH = 24 bar; separator temperature

TH = 139.9 °C; condensation temperature

TL = 40 °C; coolant temperature

Tc = 25 °C; dead state temperature

T0 = 25 °C; pinch point temperature differences at heat recovery vapor generator (HRVG) ∆

Tpp1 = 10 °C and at regenerator ∆

Tpp2 = 5 °C; isentropic efficiencies of pump

ηp = 0.60 and of turbines

ηt = 0.75.

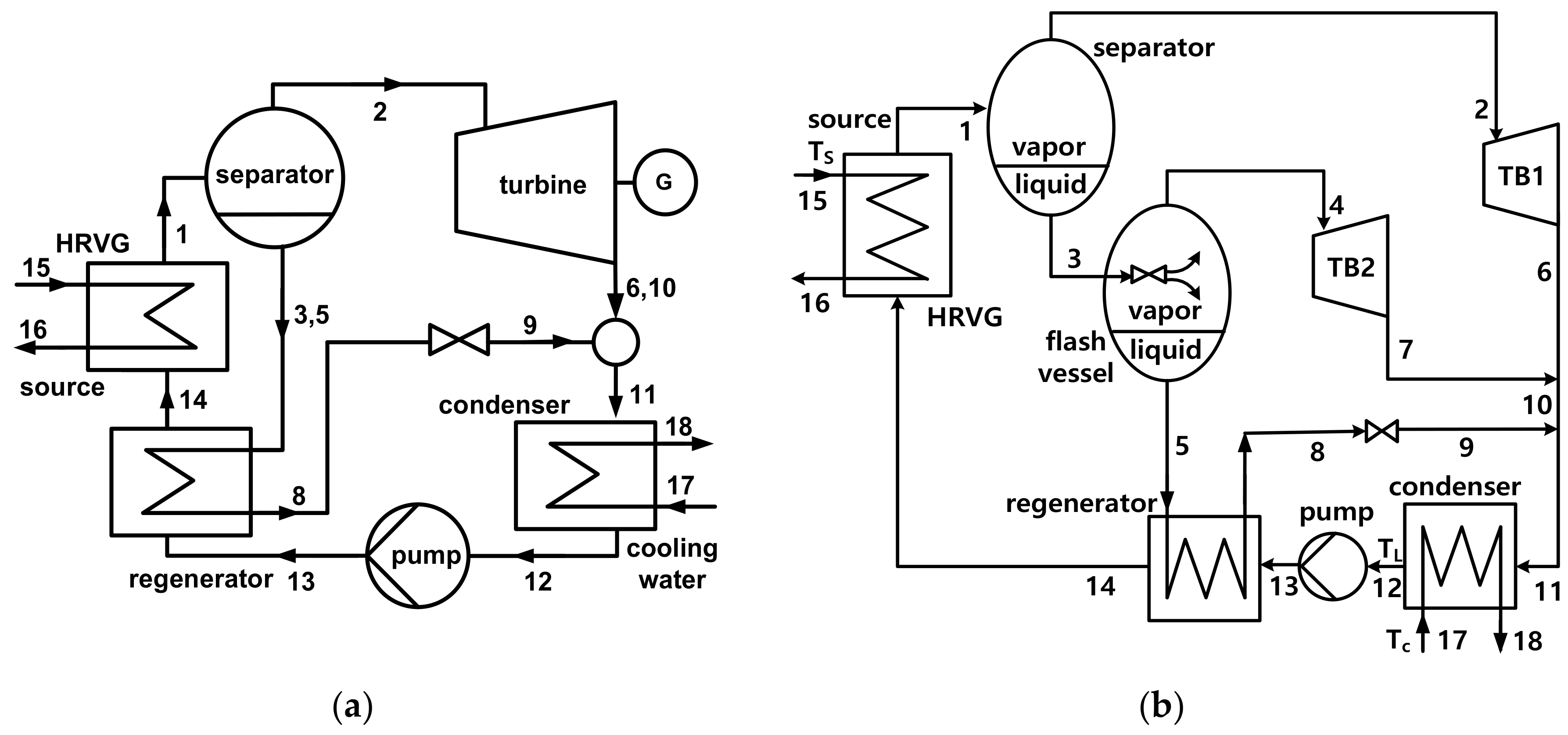

3.1. Effects of Flash Pressure in KFC

In order to compare the thermodynamic performance of the Kalina flash cycle (KFC) with that of the Kalina cycle (KC), the performance of KFC is analyzed first. This approach is reasonable since the KC does not have a flash vessel and its effect should be resolved for a direct comparison. In this section, the effects of flash pressure on the mass flow rates, heat transfer rates, pump and turbine powers, and cycle efficiencies are investigated for the representative separator pressure (PH) of 24 bar and ammonia mass fractions (xb) of 40%, 45%, and 50%. Then, the dependence of the optimal flash pressure, based on the exergy efficiency, on separator pressure and ammonia mass fraction is investigated. An investigation of the effects of separator pressure and ammonia mass fraction on the power of the second turbine of KFC for optimal flash pressure concludes this section.

Figure 2 shows the effect of flash pressure on the mass flow rates at HRVG of

m1, at turbines 1 and 2 of

m2 and

m4, and at regenerator of

m5 for the separator pressure of 24 bar and ammonia mass fractions of 40%, 45% in KFC. Since the states at the inlet and outlets of the separator are completely determined by the separator pressure, separator temperature, and ammonia mass fraction, the mass flow rates at HRVG (

m1), turbine 1 (

m2), and flash vessel (

m3) do not change with the flash pressure. Hence the curves for

m1 and

m2 are horizontal lines for a constant value of separator pressure. Raising flash pressure makes the mass flow rate at turbine 2 (

m4) diminish because the reduced pressure difference between the separator and flash vessel reduces the degree of expansion during flash process. On the contrary mass flow at regenerator (

m5) increases since the sum of the mass flow rates to turbine 2 and to regenerator remains constant. As ammonia gets richer for the same flash pressure,

m1 and

m4 decrease slightly but increase of

m2 and decrease of

m5 are appreciable. The reason is as follows:

m1 is proportional to (

Ts −

Tsout)/(

h1 −

h14). Since the bubble point of the mixture is lower for higher ammonia concentrations, both (

Ts −

Tsout) and (

h1 −

h14) increase, leading to a slight decrease of

m1. As ammonia concentration increases, dryness factor becomes higher in separator and lower in flash vessel, which result in an increase of

m2 and a decrease of

m5. However,

m4 decreases slightly, since it has both increasing factor and decreasing factor.

Figure 3 shows the effect of flash pressure on the rates of heat transfer at HRVG of

Qs, at regenerator of

Qr, and at condenser of

Qc for the separator pressure of 24 bar and ammonia mass fractions of 40%, 45%, 50% in KFC. Here, rate of heat transfer at HRVG is equal to the rate of heat input to the cycle from the source fluid. If the flash pressure is raised for the fixed separator pressure, then the pressure drop during the flash process diminishes and the liquid from flash vessel enters the regenerator with higher temperature. This brings about enhancement of heat transfer at the regenerator and elevation of the temperature of the mixture entering HRVG. Hence the heat transfers at regenerator and HRVG are monotonically increasing and decreasing functions of flash pressure, respectively. The heat transfer at condenser decreases with the increase of flash pressure since the temperature of the mixture entering condenser gets lower. On the other hand, if the concentration of ammonia-water mixture gets higher, then its temperature gets lower at HRVG inlet and consequently the temperature of source exhaust also drops. In addition condensation pressure rises and consequently the temperature of the mixture entering condenser rises. These factors make heat transfers at HRVG and condenser larger for the higher ammonia concentration. Ammonia richer mixture makes heat transfers at regenerator smaller, since the flow rate of mixture at regenerator is lower for higher ammonia concentration.

Figure 4 shows the effect of flash pressure on the powers produced by turbines 1 and 2 of

Wt1 and

Wt2, consumed power at pump of

Wp, and net power production of the cycle of

Wnet, for the separator pressure of 24 bar and ammonia mass fractions of 40%, 45% in KFC. Powers of turbine 1 and pump are constant with respect to flash pressure, since they are completely determined by the thermodynamic states in the separator. Power of turbine 2 exhibits an increasing-decreasing behavior respect to flash pressure and has an extremum for each ammonia mass fraction. This behavior results from a competition between the positive effect of increased enthalpy drop across turbine 2 and the negative effect of decreased flow rate through turbine 2. As net power is equal to the difference of the sum of turbine powers and pump power, and powers of turbine 1 and pump do not change with flash pressure, net power shows the same topological behavior as power of turbine 2. When ammonia mass fraction is raised from 40% to 45%, mass flow rate increases at turbine 1 but decreases at turbine 2. On the other hand, specific works of both turbines decrease. Therefore, power of turbine 1 increases because of the dominant mass effect, while power of pump decreases very slightly such that two graphs are nearly indistinguishable. Power of turbine 2 naturally decreases but net power increases. This means that the positive effect of the difference of the powers of turbine 1 and pump is larger than the negative effect of the power of turbine 2.

Figure 5 shows the effect of flash pressure on the thermal efficiency, exergy efficiency, and inner exergy efficiency, for the separator pressure of 24 bar and ammonia mass fractions of 40%, 45%, and 50% in KFC. For any of 40%, 45%, and 50%, each of three efficiencies has an extremum in the considered range of flash pressures. For the same pair of separator pressure and ammonia mass fraction, the optimizing flash pressures for the peak points of cycle efficiencies are much higher than that of the net power. This is because all terms in the denominator, i.e., supplied heat, supplied exergy, and exergy input, decrease with the increase of flash pressure. For example, when the separator pressure is 24 bar and ammonia mass fraction is 45%, net power has a maximum value of 3.60 kW at the optimizing flash pressure of 11 bar, and thermal efficiency, exergy efficiency, and inner exergy efficiency have maxima of 11.0%, 40.6%, and 45.0%, respectively, at the optimizing flash pressures of 22 bar, 20 bar, and 20 bar, respectively. If the flash pressure is high enough, all of three efficiencies are higher for lower ammonia mass fraction. However this trend is reversed at the flash pressures of about 9 bar and lower.

The next consideration is to investigate the dependence of the exergy efficiency based optimal flash pressure on the separator pressure and ammonia mass fraction. This pressure will be used as the value of flash pressure of KFC to directly compare with KC in the next section. The exergy efficiency of KFC for fixed values of separator pressure and ammonia mass fraction shows a similar behavior to

Figure 5 and it always has one peak point with respect to the change of flash pressure.

Figure 6 shows the dependence of this optimal flash pressure on ammonia mass fraction for various values of separator pressure from 16 bar to 48 bar with an increment of 8 bar. The exergy efficiency- based optimal flash pressure is a monotonically increasing function of ammonia mass fraction and approaches to separator pressure at high enough values of ammonia mass fraction. The gap between separator pressure and optimal flash pressure widens as separator pressure is raised. A little surprisingly, optimal flash pressure decreases with the increase of separator pressure at low ammonia concentrations.

Figure 7 shows the effects of ammonia mass fraction and separator pressure on the power of turbine 2 in KFC operating at the optimal flash pressure based on the cycle exergy efficiency. Since optimal flash pressure increases with ammonia mass fraction and the mass flow rate at turbine 2 decreases with ammonia mass fraction, power of turbine 2 is a monotonically decreasing function of ammonia mass fraction for each value of separator pressure. As expected, power of turbine 2 is strongly dependent on separator pressure and rapidly increases with the rise of separator pressure. The main reason of this behavior is that the pressure ratio across the turbine 2 increases with the rise of separator pressure.

3.2. Comparison of KFC Operating at Optimal Flash Pressure with KC

In this section, the thermodynamic performances of KFC and KC are comparatively investigated. As the flash vessel is integrated only in KFC, KFC is considered to be operated at the exergy efficiency-based optimal flash pressure for the purpose of definite comparison with KC. These optimal values were presented in the previous section.

Figure 8 shows the effects of ammonia mass fraction and separator pressure on the rate of heat transfer at regenerator in KC and KFC. In KC, the rate of heat transfer at regenerator declines almost linearly with ammonia concentration but gets higher as separator pressure is raised. This behavior results from the simultaneous reduction effect of the rate of mass flow and the heat transfer per kg of mixture at regenerator for higher ammonia concentrations and at lower separator pressures. When ammonia concentration is high enough or separator pressure is low (16 to 24 bar), the overall behavior of heat transfer at regenerator in KFC is qualitatively same as in KC. However, a hill with gentle slope is formed in each heat transfer vs. ammonia concentration curve in the relatively low concentration region for high separator pressures (32–48 bar). In addition the heat transfer for higher separator pressure can be larger than that for lower separator pressure in this region. Comparing the results for KC and KFC, the heat transfer at regenerator of KC is seen to be larger than in KFC. This is consistent with the expectation because a part of liquid from the separator is used for additional power generation at turbine 2 in KFC instead of preheating the working fluid to HRVG. The difference of heat transfer between KC and KFC diminishes as ammonia mass fraction increases while it grows as separator pressure increases.

Figure 9 shows the effects of ammonia mass fraction and separator pressure on the rate of heat transfer at HRVG in KC and KFC. KC and KFC show the qualitatively same behavior in heat transfer at HRVG with respect to the changes of ammonia concentration and separator pressure. Moreover the discrepancy in numerical value is not so big; it becomes more significant as ammonia concentration decreases and as separator pressure increases. In both cycles heat transfer at HRVG is an almost linearly increasing function of ammonia concentration. This is because the specific heat transfer increases owing to the drop of mixture temperature entering HRVG. However, the effect of separator pressure on heat transfer at HRVG is a little complicated. If the separator pressure is high enough (32–48 bar) or ammonia concentration is low enough (below about 60%), then the heat transfer at HRVG decreases with the increase of separator pressure. When the separator pressure is low (16–24 bar) and ammonia concentration is high, it begins to increase with the separator pressure. This implies that there exists a peak point in the heat transfer vs. separator pressure curve for ammonia concentrations above 63%.

Figure 10 shows the effects of ammonia mass fraction and separator pressure on the net power produced in KC and KFC. As a whole, there is no qualitative difference in the characteristics of the change of net power with respect to the changes of ammonia concentration and separator pressure for two cycles. Only a quantitative difference exits between them. KFC produces more power than KC for any combination of ammonia concentration and separator pressure. The superiority of KFC in power production becomes clearer at higher separator pressure and at lower ammonia concentration. In the considered range of ammonia mass fraction, there exists a peak point in the net power vs. ammonia concentration curve for relatively low separator pressure from 16 to 24 bar in both KC and KFC. This point shifts to the upper-right direction as separator pressure increases. However, for high separator pressures from 32 to 48 bar and ammonia mass fractions below 80%, net power is a simply increasing function of ammonia concentration and its maximum value is attained at the right limit. Maximum net powers and the corresponding ammonia mass fractions of KFC are summarized as follows in an increasing order of separator pressures of 16, 24, 32, 40, and 48 bar: 3.62 kW at 46%, 4.41 kW at 64%, 4.91 kW at 80%, 5.05 kW at 80%, and 4.76 kW at 80%. Maximum net power of KC is to a certain degree lower than that of KFC having the same separator pressure.

Figure 11 shows the effects of ammonia mass fraction and separator pressure on the thermal efficiencies of KC and KFC. As seen in

Figure 9 and

Figure 10, the net power production and the rate of heat transfer at HRVG show the same qualitative behaviors for KC and KFC. The ratio of the former to the latter corresponding to the rate of heat supply to the cycle defines thermal efficiency. Therefore the same trend of thermal efficiency for KC and KFC appearing in

Figure 11 results naturally. For low separator pressures (16–24 bar) thermal efficiency simply decreases with the increase of ammonia concentration because of the dominant negative effect of rapidly growing heat transfer. On the other hand for high separator pressures (32–48 bar), both positive effect and negative effect increase with the increase of ammonia concentration and make thermal efficiency show an increasing-decreasing behavior with a peak value. The value of ammonia mass fraction at the peak of thermal efficiency is lower than that of net power corresponding to the same separator pressure, and is higher at higher separator pressure. However, the value of maximum thermal efficiency declines very gradually with respect to the increasing of separator pressure. Thermal efficiency of KFC is higher to a certain degree than that of KC for any same pair of ammonia mass fraction and separator pressure; The difference shrinks at high ammonia concentration and at low separator pressures.

Figure 12 shows the effects of ammonia mass fraction and separator pressure on the exergy efficiencies of KC and KFC. Except for the high ceiling values around 40% which is more than three times of that of thermal efficiency, the dependencies of exergy efficiency on ammonia mass fraction and separator pressure are similar to thermal efficiency. Although the gap shrinks at high ammonia concentrations or at low separator pressures, KFC exhibits a better performance in exergy efficiency than KC operating at the same condition. Over the considered ammonia concentration range, the values of maximum exergy efficiency and the corresponding ammonia mass fraction in KFC attainable at separator pressures of 16, 24, 32, 40, and 48 bar are 38.6% at 40%, 41.5% at 40%, 40.2% at 50%, 39.6% at 59%, and 39.9% at 70%, respectively. As is clear from

Figure 12, the maximum values of exergy efficiency sought by varying ammonia concentration are weakly dependent on separator pressure. Therefore, a straightforward optimization by merely extending the range of separator pressure to high pressure region is apt to result in an insignificant gain at the expense of additional facility and operation costs. According to the thermodynamic optimization results of [

22], the KC has an optimum exergy efficiency of 38.04% at the separator pressure of 43.0 bar and ammonia mass fraction of 79.2%; while the KFC has an optimum exergy efficiency of 38.90% at the very high separator pressure of 51.5 bar and ammonia mass fraction of 79.5%.