Analytical Study of the Electrical Output Characteristics of c-Si Solar Cells by Cut and Shading Phenomena

Abstract

:1. Introduction

2. Comparison of Electrical Output Characteristics of Cut and Shading Phenomena of c-Si Solar Cells Considering

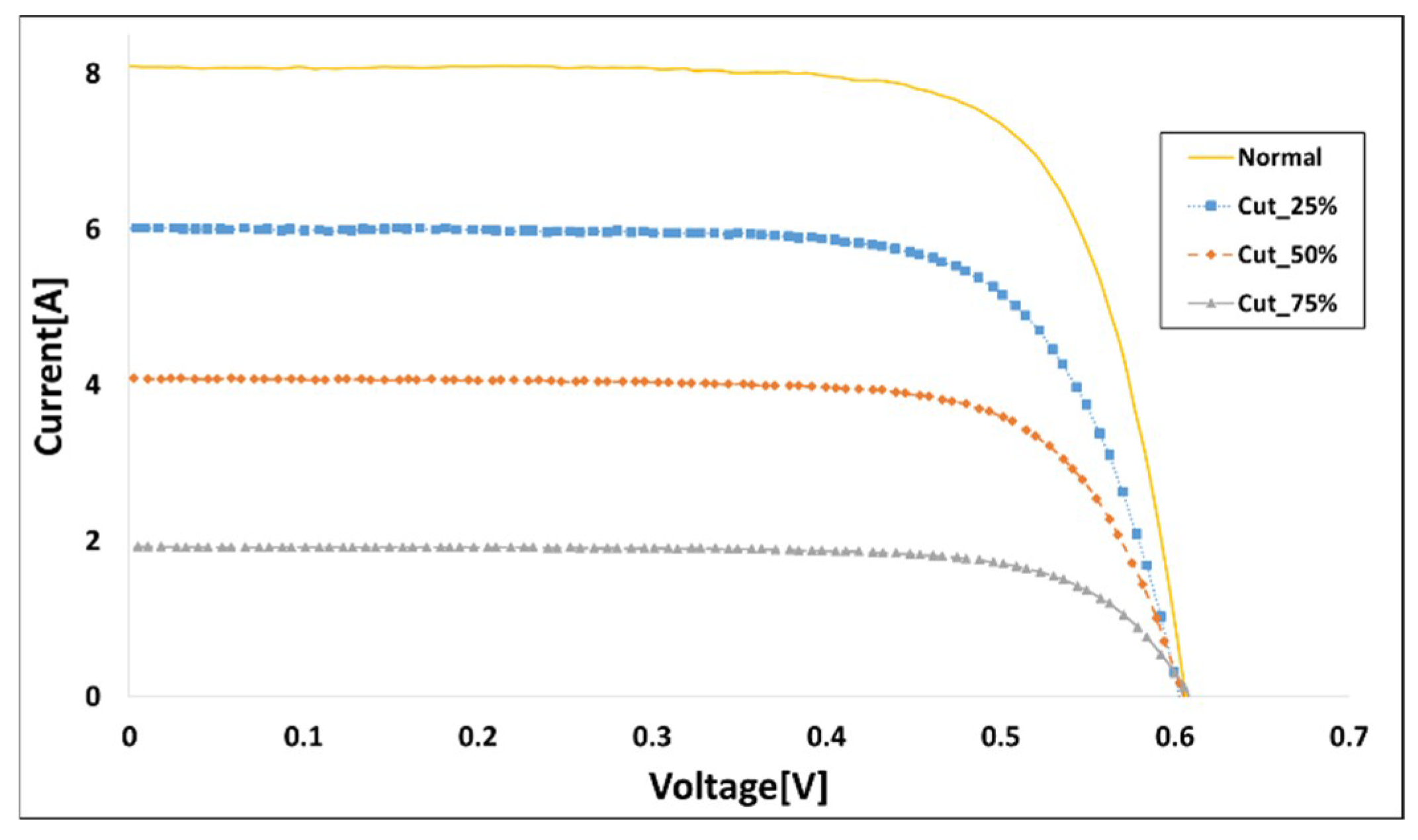

3. Comparison of Current-Voltage Characteristic by Cut and Shading Effect of a c-Si Solar Cell

3.1. Experimental Method

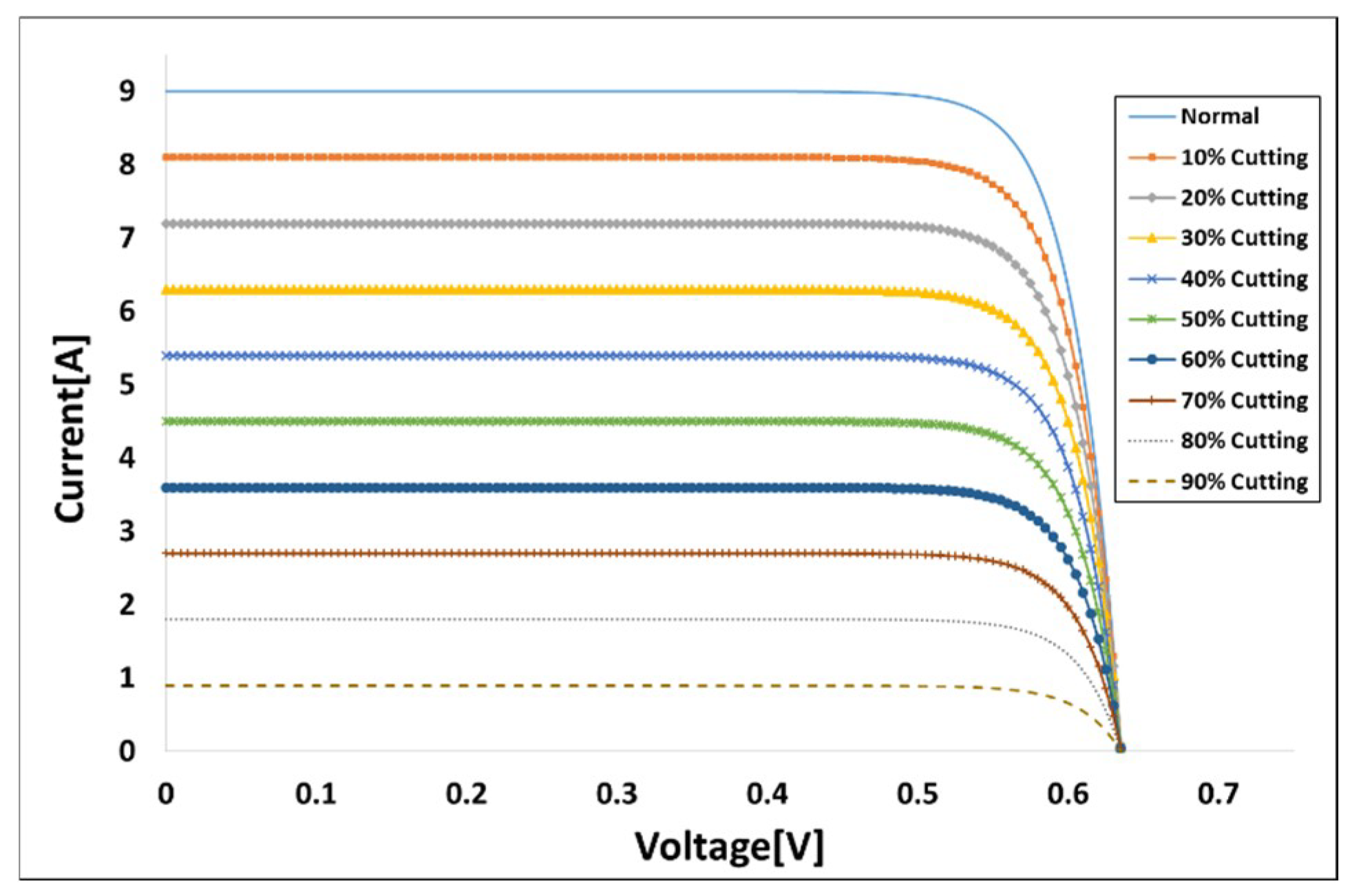

3.2. Results of Electrical Output Experiment for the Cut and Shading Effect c-Si Solar Cells

3.3. Limitations of the Analysis of Electrical Output Characteristics of a Cut c-Si Solar Cell Considering the Photo-Generation Current

4. Analysis of Electric Output Characteristics of a Cut c-Si Solar Cell

4.1. Theoretical Analysis of the Electrical Output of a Cut c-Si Solar Cell

4.2. Experimental and Simulation Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature:

| open circuit voltage | FF | Fill Factor (%) | |

| short circuit current | n | diode ideality constant | |

| photo current | current flowing to the diode | ||

| saturation current | voltage applied to the diode | ||

| series resistance | carrier generation rate by light | ||

| shunt resistance | optical power density | ||

| current value of the cut solar cell | number of photons moving at one point | ||

| α | absorption coefficient | photovoltaic current | |

| Planck constant | diffusion length of electron | ||

| energy of the photon | minority carrier lifetime of hole | ||

| wavelength of light | minority carrier lifetime of electron | ||

| diffusion length of hole | concentration of electron on p-side | ||

| q | electron charge | concentration of holes on n-side | |

| k | Boltzmann constant | total current value of a c-Si solar cell | |

| T | temperature | cut c-Si solar cell is part of the total c-Si solar cell |

References

- Hajighorbani, S.; Radzi, M.A.M.; Ab Kadir, M.Z.A.; Shafie, S.; Khanaki, R.; Maghami, M.R. Dual search maximum power point (dsmpp) algorithm based on mathematical analysis under shaded conditions. Energies 2015, 8, 12116–12146. [Google Scholar] [CrossRef]

- Pei, Y.; Guo, J.; Kou, D.; Zhou, W.; Zhou, Z.; Tian, Q.; Meng, Y.; Wu, S. Precise-tuning the In content to achieve high fill factor in hybrid buffer structured Cu2ZnSn (S, Se) 4 solar cells. Sol. Energy 2017, 148, 157–163. [Google Scholar] [CrossRef]

- Isabella, O.; Vismara, R.; Linssen, D.N.P.; Wang, K.X.; Fan, S.; Zeman, M. Advanced light trapping scheme in decoupled front and rear textured thin-film silicon solar cells. Sol. Energy 2018, 162, 344–356. [Google Scholar] [CrossRef]

- Poursafar, J.; Bashirpour, M.; Kolahdouz, M.; Vakilipour Takaloo, A.; Masnadi-Shirazi, M.; Asl-Soleimani, E. Ultrathin solar cells with Ag meta-material nanostructure for light absorption enhancement. Sol. Energy 2018, 166, 98–102. [Google Scholar] [CrossRef]

- Tada, H.Y.; Carter, J.R., Jr.; Anspaugh, B.E.; Downing, R.G. Solar Cell Radiation Handbook; NASA: Washington, DC, USA, 1982.

- Halavani, Z.; Lang, J.F.; Summhammer, J. Results of pressure-only cell interconnections in high voltage PV-Modules. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014; pp. 64–68. [Google Scholar]

- Summhammer, J.; Halavani, Z. Cell interconnection without glueing or soldering for crystalline Si photovoltaic modules. EPJ Photovolt. 2016, 7, 75401. [Google Scholar] [CrossRef] [Green Version]

- Summhammer, J.; Halavani, Z. High-voltage PVmodules with crystalline silicone solar cells. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Villepinte, France, 30 September–4 October 2013; pp. 3119–3122. [Google Scholar]

- Zhao, J.; Wang, A.; Abbaspour-Sani, E.; Yun, F.; Green, M.A. Improved efficiency silicon solar cell module. IEEE Electron Device Lett. 1997, 18, 48–50. [Google Scholar] [CrossRef]

- Song, Y.-H.; Kang, G.-H.; Yu, G.-J.; Ahn, H.-G.; Han, D.-Y. A Study on the Electrical Characteristics of Photovoltaic Module Depending on Micro-Crack Patterns of Crystalline Silicon Solar Cell. Trans. Korean Inst. Electr. Eng. 2012, 61, 407–412. [Google Scholar] [CrossRef] [Green Version]

- Anurag, S.Y.; Mukherjee, V. Line losses reduction techniques in puzzled PV array configuration under different shading conditions. Sol. Energy 2018, 171, 774–783. [Google Scholar]

- Seyedmahmoudian, M.; Mekhilef, S.; Rahmani, R.; Yusof, R.; Renani, E.T. Analytical modeling of partially shaded photovoltaic systems. Energies 2013, 6, 128–144. [Google Scholar]

- Bingöl, O.; Özkaya, B. Analysis and comparison of different PV array configurations under partial shading conditions. Sol. Energy 2018, 160, 336–343. [Google Scholar] [CrossRef]

- Horoufiany, M.; Ghandehari, R. Optimization of the Sudoku based reconfiguration technique for PV arrays power enhancement under mutual shading conditions. Sol. Energy 2018, 159, 1037–1046. [Google Scholar] [CrossRef]

- Jung, T.H.; Ko, J.W.; Kang, G.H.; Ahn, H.K. Output characteristics of PV module considering partially reverse biased conditions. Sol. Energy 2013, 92, 214–220. [Google Scholar] [CrossRef]

- Kim, D.M. Microelectronic Semiconductor Physics and Devices, 2nd ed.; Hanbit Media: Seoul, Korea, 2011; pp. 948–977. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, J.R.; Shin, W.G.; Hwang, H.; Ju, Y.-C.; Ko, S.W.; Yoon, H.S.; Kang, G.H. Analytical Study of the Electrical Output Characteristics of c-Si Solar Cells by Cut and Shading Phenomena. Energies 2018, 11, 3397. https://doi.org/10.3390/en11123397

Lim JR, Shin WG, Hwang H, Ju Y-C, Ko SW, Yoon HS, Kang GH. Analytical Study of the Electrical Output Characteristics of c-Si Solar Cells by Cut and Shading Phenomena. Energies. 2018; 11(12):3397. https://doi.org/10.3390/en11123397

Chicago/Turabian StyleLim, Jong Rok, Woo Gyun Shin, Hyemi Hwang, Young-Chul Ju, Suk Whan Ko, Hee Sang Yoon, and Gi Hwan Kang. 2018. "Analytical Study of the Electrical Output Characteristics of c-Si Solar Cells by Cut and Shading Phenomena" Energies 11, no. 12: 3397. https://doi.org/10.3390/en11123397