Impact of the Primary Break-Up Strategy on the Morphology of GDI Sprays in 3D-CFD Simulations of Multi-Hole Injectors

Abstract

:1. Introduction

2. Experimental Data

2.1. Spray G Injector

2.2. 5-Hole Injector

3. Operating Conditions and Numerical Setup

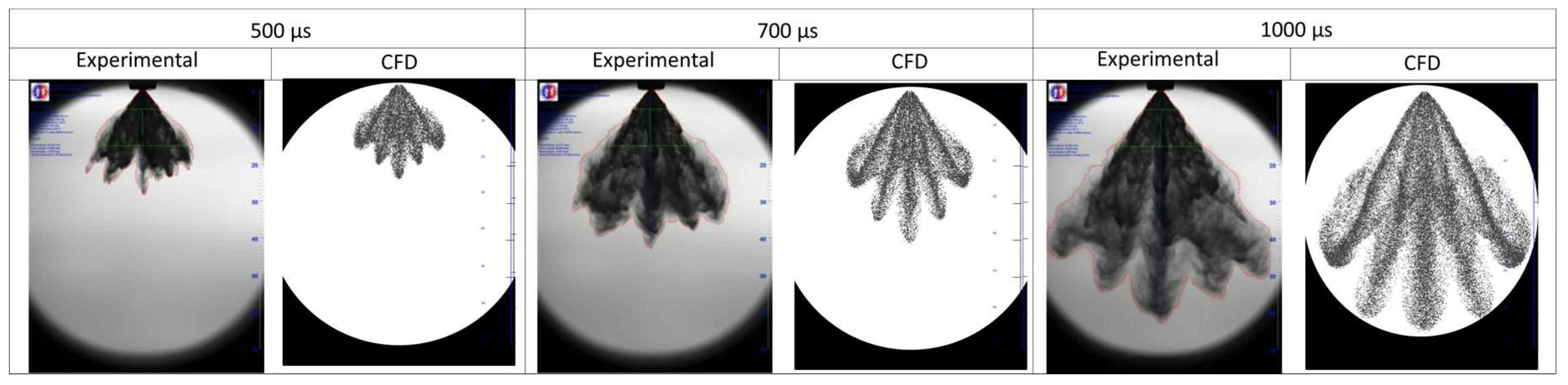

4. 5-Hole Injector Numerical Results

5. Spray G Injector Lagrangian Simulation Results

6. Inner-Nozzle Flow Simulation Setup

7. Inner-Nozzle Flow Simulation Results

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| GDI | Gasoline Direct Injection |

| PDA | Phase Doppler Anemometry |

| ROI | Rate of Injection |

| IR | Injection Rate |

| ASOI | After Start of Injection |

| SMD | Sauter Mean Diameter |

| SurfAve | Surface Average Report |

| CoV_IM | Coefficient of variation of the injected mass |

| Single hole steady state mass flow rate | |

| Liquid Density | |

| Nozzle hole geometrical area | |

| Initial droplet velocity | |

| D10 | Mean droplet diameter |

| Nozzle hole effective area | |

| Theoretical Injection Velocity | |

| Nozzle discharge coefficient | |

| Nozzle velocity coefficient | |

| Nozzle area coefficient | |

| Volume fraction of the i-th phase in the Eulerian framework | |

| Vi | Volume of the i-th phase in the cell |

| V | Volume of the cell |

| Velocity x-component at the nozzle exit | |

| Velocity y-component at the nozzle exit | |

| Velocity z-component at the nozzle exit | |

| Plume rotation around x axis | |

| Plume rotation around y axis | |

| Initial droplet diameter |

References

- Han, Z. Numerical Study of Air-Fuel Mixing in Direct-Injection Spark-Ignition and Diesel Engines; University of Wisconsin-Madison: Madison, WI, USA, 1996. [Google Scholar]

- Shi, Y.; Ge, H.W.; Reitz, R.D. Computational Optimization of Internal Combustion Engines; Springer: London, UK, 2011. [Google Scholar] [CrossRef]

- Breda, S.; D’Orrico, F.; Berni, F.; d’Adamo, A.; Fontanesi, S.; Irimescu, A.; Merola, S.S. Experimental and Numerical Study on the Adoption of Split Injection Strategies to Improve Air-Butanol Mixture Formation in a DISI Optical Engine. Fuel 2019, 104–124. [Google Scholar] [CrossRef]

- D’Adamo, A.; Breda, S.; Berni, F.; Fontanesi, S. Understanding the origin of cycle-to-cycle variation using large-eddy simulation: Similarities and differences between a homogeneous low-revving speed research engine and a production DI turbocharged engine. SAE Int. J. Engines 2018, 12, 1–22. [Google Scholar] [CrossRef]

- Shekhawat, Y.; Haworth, D.C.; D’Adamo, A.; Berni, F.; Fontanesi, S.; Schiffmann, P.; Reuss, D.L.; Sick, K. An Experimental and Simulation Study of Early Flame Development in a Homogeneous-charge Spark-Ignition Engine. Oil Gas Sci. Technol. 2017, 72. [Google Scholar] [CrossRef]

- Costa, M.; Sementa, P.; Sorge, U.; Catapano, F.; Marseglia, G.; Vaglieco, B.M. Split Injection in a GDI Engine Under Knock Conditions: An Experimental and Numerical Investigation. SAE Int. 2015. [Google Scholar] [CrossRef]

- D’Adamo, A.; Breda, S.; Berni, F.; Fontanesi, S. The potential of statistical RANS to predict knock tendency: Comparison with LES and experiments on a spark-ignition engine. Appl. Energy 2019, 249, 126–142. [Google Scholar] [CrossRef]

- Raza, M.; Chen, L.; Leach, F.; Ding, S. A Review of Particulate Number (PN) Emissions from Gasoline Direct Injection (GDI) Engines and Their Control Techniques. Energies 2018, 11, 1417. [Google Scholar] [CrossRef]

- Berni, F.; Breda, S.; Lugli, M.; Cantore, G. A numerical investigation on the potentials of water injection to increase knock resistance and reduce fuel consumption in highly downsized GDI engines. Energy Procedia 2015. [Google Scholar] [CrossRef]

- Berni, F.; Breda, S.; D’Adamo, A.; Fontanesi, S.; Cantore, G. Numerical Investigation on the Effects of Water/Methanol Injection as Knock Suppressor to Increase the Fuel Efficiency of a Highly Downsized GDI Engine. In Proceedings of the 12th International Conference on Engines & Vehicles, Capri, Italy, 13–17 September 2015. [Google Scholar] [CrossRef]

- Breda, S.; Berni, F.; d’Adamo, A.; Testa, F.; Severi, E.; Cantore, G. Effects on knock intensity and specific fuel consumption of port water/methanol injection in a turbocharged GDI engine: Comparative analysis. Energy Procedia 2015. [Google Scholar] [CrossRef]

- D’Adamo, A.; Berni, F.; Breda, S.; Lugli, M.; Fontanesi, S.; Cantore, G. A Numerical Investigation on the Potentials of Water Injection as a Fuel Efficiency Enhancer in Highly Downsized GDI Engines. In Proceedings of the SAE 2015 World Congress & Exhibition, Detroit, MI, USA, 21–23 April 2015. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R. In-cylinder fluid flow, turbulence and spray models—A review. Renew. Sustain. Energy Rev. 2009, 13, 1620–1627. [Google Scholar] [CrossRef]

- Gosman, D.A.; Clerides, D. Diesel Spray Modelling: A Review. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.45.6492&rep=rep1&type=pdf (accessed on 10 February 2018).

- Liao, Y.; Lucas, D. A literature review of theoretical models for drop and bubble breakup in turbulent dispersions. Chem. Eng. Sci. 2009, 64, 3389–3406. [Google Scholar] [CrossRef]

- Saha, K.; Agarwal, A.K.; Ghosh, K.; Som, S. Two-Phase Flow for Automotive and Power Generation Sectors; Springer: Singapore, 2018. [Google Scholar]

- Subramaniam, S. Lagrangian–Eulerian methods for multiphase flows. Prog. Energy Combust. Sci. 2013, 39, 215–245. [Google Scholar] [CrossRef]

- Wu, K.J.; Reitz, R.D.; Bracco, F.V. Measurements of drop size at the spray edge near the nozzle in atomizing liquid jets. Phys. Fluids 1986, 29, 941–951. [Google Scholar] [CrossRef]

- Desportes, A.; Zellat, M.; Desoutter, G.; Abouri, D.; Liang, Y. Validation and Application of the Eulerian-Lagrangian spray atomization (ELSA) model for the Diesel injection simulation. In Proceedings of the 20th International Multidimensional Engine User’s Meeting at the SAE Congress, Detroit, MI, USA, 14 April 2010. [Google Scholar]

- Hoyas, S.; Pastor, J.M.; Khuong-Anh, D.; Mompó-Laborda, J.M.; Ravet, F. Application and Evaluation of the Eulerian-Lagrangian Spray Atomization (ELSA) Model on CFD Diesel Spray Simulations. SAE Int. 2011. [Google Scholar] [CrossRef]

- Quan, S.; Senecal, P.K.; Pomraning, E.; Xue, Q.; Hu, B.; Rajamohan, D.; Deur, J.M.; Som, S. A One-Way Coupled Volume of Fluid and Eulerian-Lagrangian Method for Simulating Sprays. In Proceedings of the ASME 2016 Internal Combustion Engine Division Fall Technical Conference, Greenville, SC, USA, 9–12 October 2016; p. V001T06A014. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, W.G.; Reitz, R.D.; Diwakar, R. Numerical Simulation of Diesel Sprays Using an Eulerian-Lagrangian Spray and Atomization (ELSA) Model Coupled with Nozzle Flow. SAE Int. 2011. [Google Scholar] [CrossRef]

- Postrioti, L.; Cavicchi, A.; Brizi, G.; Berni, F.; Fontanesi, S. Experimental and Numerical Analysis of Spray Evolution, Hydraulics and Atomization for a 60 MPa Injection Pressure GDI System. SAE Int. 2018. [Google Scholar] [CrossRef]

- Montanaro, A.; Allocca, L. Flash Boiling Evidences of a Multi-Hole GDI Spray under Engine Conditions by Mie-Scattering Measurements. SAE Int. 2015. [Google Scholar] [CrossRef]

- Engine Combustion Network. Available online: https://ecn.sandia.gov (accessed on 10 February 2018).

- Payri, R.; Gimeno, J.; Marti-Aldaravi, P.; Vaquerizo, D. Momentum Flux Measurements on an ECN GDi Injector. SAE Int. 2015. [Google Scholar] [CrossRef]

- Postrioti, L.; Caponeri, G.; Buitoni, G. Injection Rate Measurement of GDI Systems Operating against Sub-Atmospheric and Pressurized Downstream Conditions. SAE Int. 2017. [Google Scholar] [CrossRef]

- Siemens. Star-CD v4.28 User Guide; Siemens: London, UK, 2017. [Google Scholar]

- Siemens. STAR-CCM+ 13.06 User Guide; Siemens: London, UK, 2017. [Google Scholar]

- Duke, D.J.; Kastengren, A.L.; Matusik, K.E.; Swantek, A.B.; Powell, C.F.; Payri, R.; Vaquerizo, D.; Itani, L.; Bruneaux, G.; Grover, R.O., Jr.; et al. Internal and Near Nozzle Measurements of Engine Combustion Network “Spray G” Gasoline Direct Injectors. Exp. Therm. Fluid Sci. 2017, 88. [Google Scholar] [CrossRef]

- Parrish, S.E. Evaluation of Liquid and Vapor Penetration of Sprays from a Multi-Hole Gasoline Fuel Injector Operating Under Engine-Like Conditions. SAE Int. 2014. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Martí-Aldaraví, P.; Vaquerizo, D. ECN Spray G external spray visualization and spray collapse description through penetration and morphology analysis. Appl. Therm. Eng. 2017, 112, 304–316. [Google Scholar] [CrossRef]

- Allocca, L.; Bartolucci, L.; Cordiner, S.; Lazzaro, M.; Montanaro, A.; Mulone, V.; Rocco, V. ECN Spray G Injector: Assessment of Numerical Modeling Accuracy. SAE Int. 2018. [Google Scholar] [CrossRef]

- Han, Z.; Reitz, R.D. Turbulence Modeling of Internal Combustion Engines Using RNG κ-ϵ Models. Combust. Sci. Technol. 1995, 106, 267–295. [Google Scholar] [CrossRef]

- Bracco, F.V. Modeling of Engine Sprays. SAE Int. 1985. [Google Scholar] [CrossRef]

- Linstrom, P.J.; Mallard, W.G. NIST Chemistry WebBook; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2017.

- Reitz, R.D.; Diwaker, R. Effect of Drop Breakup on Fuel Sprays. SAE Int. 1986. [Google Scholar] [CrossRef]

- Patterson, M.A.; Reitz, R.D. Modeling the Effects of Fuel Spray Characteristics on Diesel Engine Combustion and Emission. SAE Int. 1998. [Google Scholar] [CrossRef]

- Abani, N.; Munnannur, A.; Reitz, R.D. Reduction of Numerical Parameter Dependencies in Diesel Spray Models. J. Eng. Gas Turbines Power 2008, 130, 032809. [Google Scholar] [CrossRef]

- Postrioti, L.; Bosi, M.; Gioia, R.D.; Bonandrini, G. GDI spray evolution and sizing characteristics in Flash-Boiling conditions. In International Congress: SIA Powertrain; SIA: Versailles, France, 2015. [Google Scholar]

- Zhao, H.; Quan, S.; Dai, M.; Pomraning, E.; Senecal, P.K.; Xue, Q.; Battistoni, M.; Som, S. Validation of a Three-Dimensional Internal Nozzle Flow Model Including Automatic Mesh Generation and Cavitation Effects; ASME: New York, NY, USA, 2014; Volume 136. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Schnerr, G.; Sauer, J. Physical and Numerical Modeling of Unsteady Cavitation Dynamics. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May 2001. [Google Scholar]

- Menter, F. Zonal Two Equation k-w Turbulence Models for Aerodynamic Flows. In Proceedings of the 23rd Fluid Dynamics, Plasmadynamics, and Lasers Conference, Orlando, FL, USA, 6–9 July 1993. [Google Scholar] [CrossRef]

- Cicalese, G.; Berni, F.; Fontanesi, S. Integrated in-cylinder/CHT methodology for the simulation of the engine thermal field: An application to high performance turbocharged DISI engines. SAE Int. J. Engines 2016, 9. [Google Scholar] [CrossRef]

- Cicalese, G.; Berni, F.; Fontanesi, S.; D’Adamo, A.; Andreoli, E. A Comprehensive CFD-CHT Methodology for the Characterization of a Diesel Engine: From the Heat Transfer Prediction to the Thermal Field Evaluation. In Proceedings of the International Powertrains, Fuels & Lubricants Meeting, Beijing, China, 16–19 October 2017. [Google Scholar] [CrossRef]

- Berni, F.; Cicalese, G.; D’Adamo, A.; Fontanesi, S. Critical aspects on the use of thermal wall functions in CFD in-cylinder simulations of spark-ignition engines. SAE Int. J. Commer. Veh. 2017, 10. [Google Scholar] [CrossRef]

- Berni, F.; Cicalese, G.; Fontanesi, S. A modified thermal wall function for the estimation of gas-to-wall heat fluxes in CFD in-cylinder simulations of high performance spark-ignition engines. Appl. Therm. Eng. 2017, 115, 1045–1062. [Google Scholar] [CrossRef]

- Third International Workshop of The Engine Combustion Network. 2014. Available online: https://ecn.sandia.gov/ecn-workshop/ecn3-proceedings (accessed on 10 February 2018).

- Allocca, L.; Montanaro, A.; Gioia, R.D.; Bonandrini, G. Spray Characterization of a Single-Hole Gasoline Injector under Flash Boiling Conditions. SAE Int. 2014. [Google Scholar] [CrossRef]

- Schmitz, I.; Ipp, W.; Leipertz, A. Flash Boiling Effects on the Development of Gasoline Direct-Injection Engine Sprays. SAE Trans. 2002, 111, 1025–1032. [Google Scholar]

- Khan, M.M.; Hélie, J.; Gorokhovski, M.; Sheikh, N.A. Experimental and numerical study of flash boiling in gasoline direct injection sprays. Appl. Therm. Eng. 2017, 123, 377–389. [Google Scholar] [CrossRef]

| Fuel | Fuel Pressure | Fuel Temperature | Ambient Temperature | Ambient Abs. Pressure |

|---|---|---|---|---|

| Iso-Octane (C8H18) | 20 MPa | 363 K | 573 K | 0.6 MPa |

| Fuel | Fuel Pressure | Fuel Temperature | Ambient Temperature | Ambient abs. Pressure |

|---|---|---|---|---|

| n-Heptane (C7H16) | 20 MPa 40 MPa 60 MPa | 293 K | 293 K | 0.1 MPa |

| Initial Droplet Diameters | ||||

|---|---|---|---|---|

| 10 µm | 20 µm | 50 µm | 80 µm | 110 µm |

| Nozzle ID | Injection Velocity | Effective Diameter |

|---|---|---|

| 1 | 184 m/s | 133 µm |

| 2 | 184 m/s | 132 µm |

| 3 | 184 m/s | 134 µm |

| 4 | 182 m/s | 135 µm |

| 5 | 184 m/s | 133 µm |

| 6 | 183 m/s | 133 µm |

| 7 | 184 m/s | 133 µm |

| 8 | 184 m/s | 133 µm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sparacino, S.; Berni, F.; d’Adamo, A.; Krastev, V.K.; Cavicchi, A.; Postrioti, L. Impact of the Primary Break-Up Strategy on the Morphology of GDI Sprays in 3D-CFD Simulations of Multi-Hole Injectors. Energies 2019, 12, 2890. https://doi.org/10.3390/en12152890

Sparacino S, Berni F, d’Adamo A, Krastev VK, Cavicchi A, Postrioti L. Impact of the Primary Break-Up Strategy on the Morphology of GDI Sprays in 3D-CFD Simulations of Multi-Hole Injectors. Energies. 2019; 12(15):2890. https://doi.org/10.3390/en12152890

Chicago/Turabian StyleSparacino, Simone, Fabio Berni, Alessandro d’Adamo, Vesselin Krassimirov Krastev, Andrea Cavicchi, and Lucio Postrioti. 2019. "Impact of the Primary Break-Up Strategy on the Morphology of GDI Sprays in 3D-CFD Simulations of Multi-Hole Injectors" Energies 12, no. 15: 2890. https://doi.org/10.3390/en12152890