Cooling and Energy-Saving Performance of Different Green Wall Design: A Simulation Study of a Block

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Simulation Tool

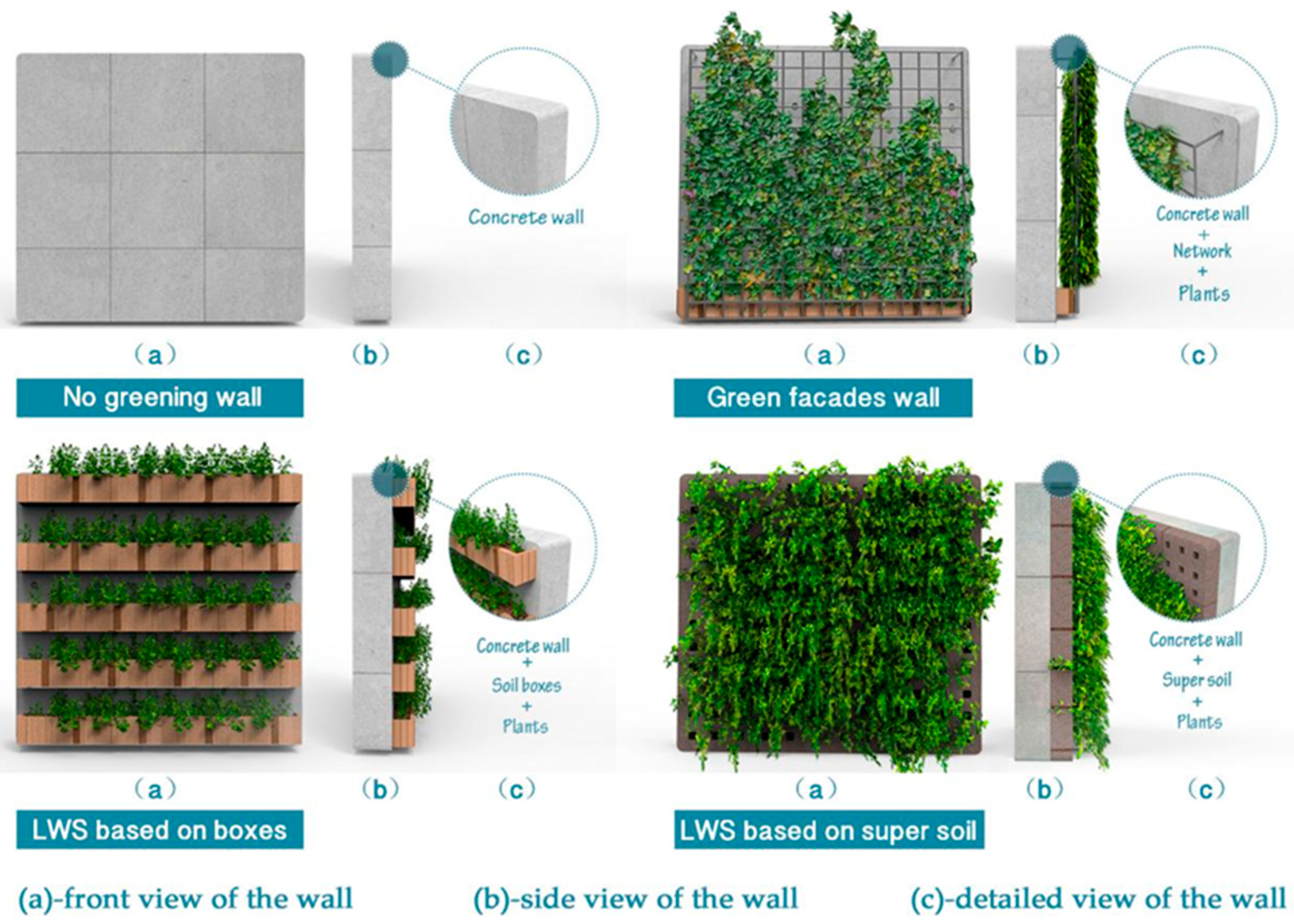

2.2. Description of the Scenarios

2.3. Date Selection and Parameter Setting

3. Cooling Performance Results

3.1. Cooling Performance on Air Temperature Outdoors

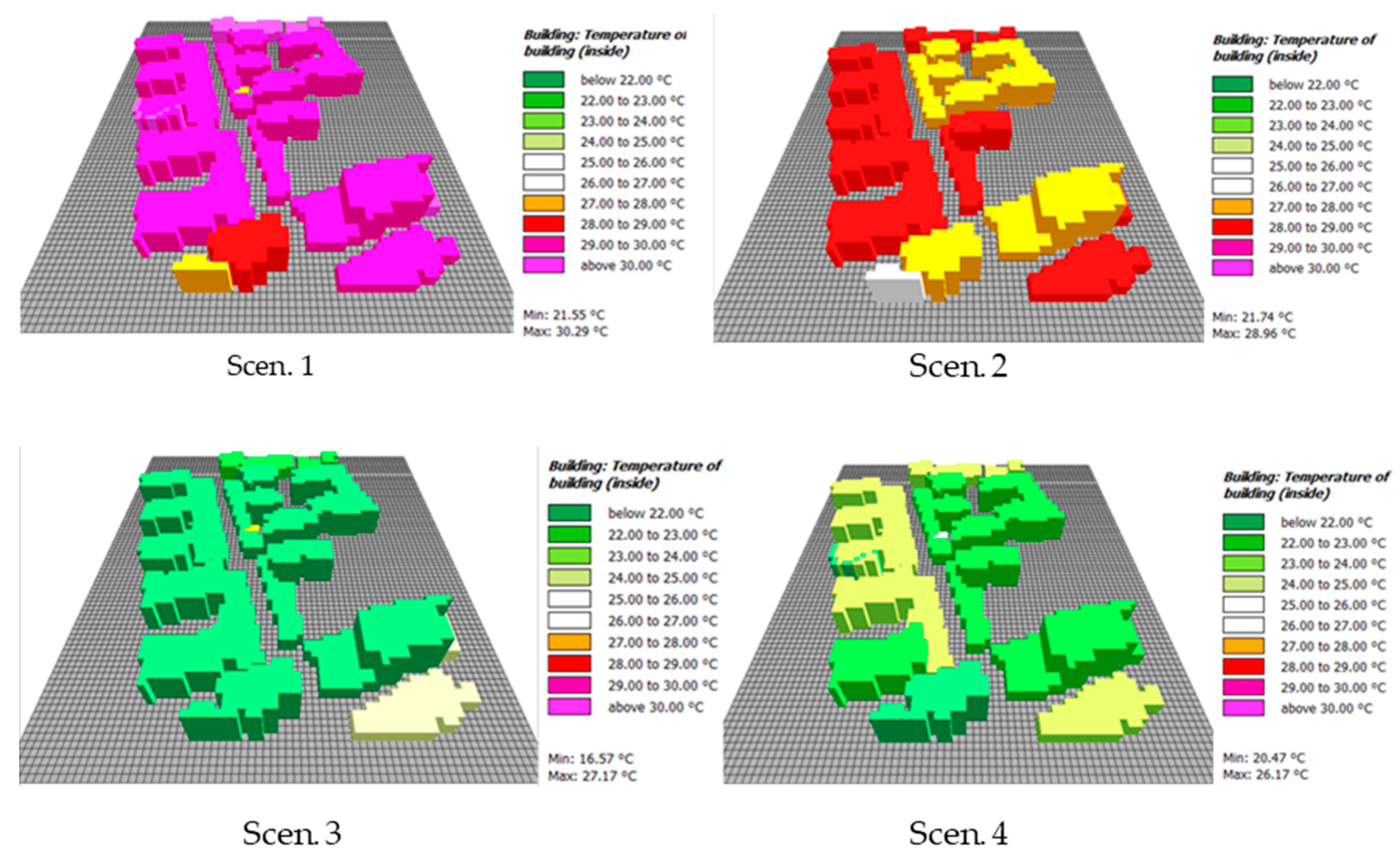

3.2. Cooling Performance on the Air Temperature inside

3.3. Cooling Performance on the outside Wall Surface Temperature

3.4. Cooling Performance on inside Wall Surface Temperature

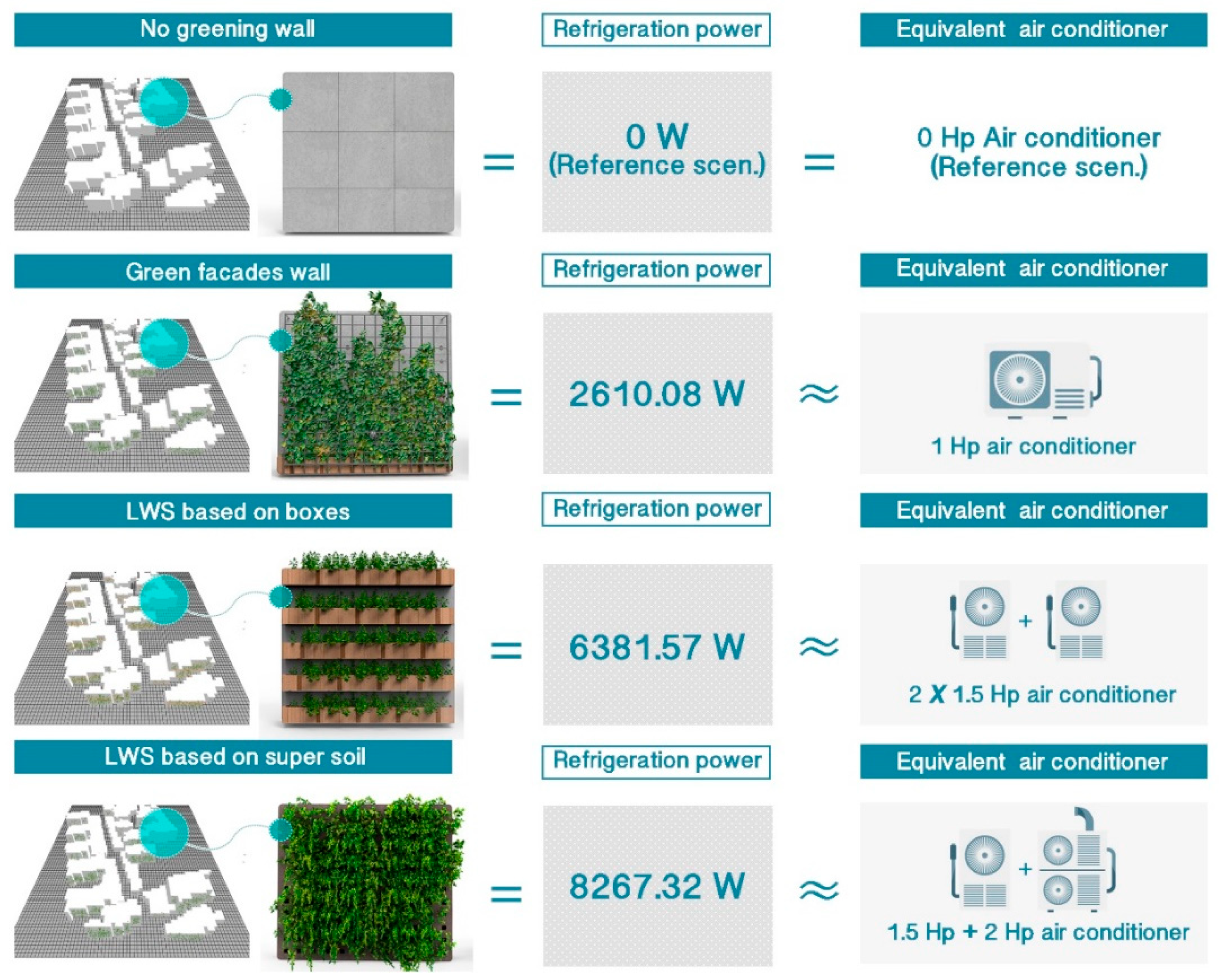

4. Energy Saving Results

4.1. Cavity Volume and Green Wall Area

4.2. Energy Calculation and Conversion

5. Discussion

- (1)

- The simulated scenarios were created according to the actual scale and spatial layout, but there were no doors and windows on the facade wall, which had a certain influence on the simulated temperatures, especially the time when the peak value appeared.

- (2)

- This paper studied the influence of different green walls on the temperatures of Yuhou Street. The temperatures referred to the highest temperatures at different times in different scenarios. Except for the cooling performance of peak temperature in this study, it is necessary to conduct a study to explore the cooling effect of different greening walls on the average temperature of blocks.

- (3)

- Our study only explored the cooling and energy-saving performance of green walls on a typical summer day. Heat preservation and energy savings in winter of the three green walls will be studied further.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grover, A.; Singh, R. Analysis of urban heat island (uhi) in relation to normalized difference vegetation index (ndvi): A comparative study of delhi and mumbai. Environments 2015, 2, 125–138. [Google Scholar] [CrossRef]

- Varotsos, C.; Ondov, J.; Efstathiou, M.; Cracknell, A. The local and regional atmospheric oxidants at athens (greece). Environ. Sci. Pollut. Res. 2014, 21, 4430–4440. [Google Scholar] [CrossRef] [PubMed]

- Mohajerani, A.; Bakaric, J.; Jeffrey-Bailey, T. The urban heat island effect, its causes, and mitigation, with reference to the thermal properties of asphalt concrete. J. Environ. Manag. 2017, 197, 522–538. [Google Scholar] [CrossRef] [PubMed]

- Varotsos, C.; Melnikova, I.; Cracknell, A.; Tzanis, C.; Vasilyev, A. New spectral functions of the near-ground albedo derived from aircraft diffraction spectrometer observations. Atmos. Chem. Phys. 2014, 14, 6953–6965. [Google Scholar] [CrossRef]

- Kondratyev, K.Y.; Varotsos, C. Atmospheric greenhouse effect in the context of global climate change. LL Nuovo Cimento C 1995, 18, 123–151. [Google Scholar] [CrossRef]

- Roman, K.K.; O’Brien, T.; Alvey, J.B.; Woo, O. Simulating the effects of cool roof and pcm (phase change materials) based roof to mitigate uhi (urban heat island) in prominent us cities. Energy 2016, 96, 103–117. [Google Scholar] [CrossRef]

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Res. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- De Groot-Reichwein, M.; Van Lammeren, R.; Goosen, H.; Koekoek, A.; Bregt, A.; Vellinga, P. Urban heat indicator map for climate adaptation planning. Mitig. Adapt. Strateg. Glob. Chang. 2018, 23, 169–185. [Google Scholar] [CrossRef]

- Morakinyo, T.E.; Lai, A.; Lau, K.K.-L.; Ng, E. Thermal benefits of vertical greening in a high-density city: Case study of hong kong. Urban For. Urban Green. 2019, 37, 42–55. [Google Scholar] [CrossRef]

- Yang, F.; Yuan, F.; Qian, F.; Zhuang, Z.; Yao, J. Summertime thermal and energy performance of a double-skin green facade: A case study in shanghai. Sustain. Cities Soc. 2018, 39, 43–51. [Google Scholar] [CrossRef]

- Halawa, E.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Trombley, J.; Hassan, N.; Baig, M.; Yusoff, S.Y.; Azzam Ismail, M. A review on energy conscious designs of building façades in hot and humid climates: Lessons for (and from) Kuala Lumpur and Darwin. Renew. Sustain. Energy Rev. 2018, 82, 2147–2161. [Google Scholar] [CrossRef]

- Kolokotsa, D. Smart cooling systems for the urban environment. Using renewable technologies to face the urban climate change. Sol. Energy 2017, 154, 101–111. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.; Fadlallah, S.; Al-Rashdi, M. Evaluation of the impact of ground-level concentrations of so2, nox, co, and pm10 emitted from a steel melting plant on muscat, oman. Sustain. Cities Soc. 2018, 38, 675–683. [Google Scholar] [CrossRef]

- Raji, B.; Tenpierik, M.J.; van den Dobbelsteen, A. The impact of greening systems on building energy performance: A literature review. Renew. Sustain. Energy Rev. 2015, 45, 610–623. [Google Scholar] [CrossRef]

- Takebayashi, H.; Ishii, E.; Moriyama, M.; Sakaki, A.; Nakajima, S.; Ueda, H. Study to examine the potential for solar energy utilization based on the relationship between urban morphology and solar radiation gain on building rooftops and wall surfaces. Sol. Energy 2015, 119, 362–369. [Google Scholar] [CrossRef]

- Manso, M.; Castro-Gomes, J. Green wall systems: A review of their characteristics. Renew. Sustain. Energy Rev. 2015, 41, 863–871. [Google Scholar] [CrossRef]

- Giridharan, R.; Emmanuel, R. The impact of urban compactness, comfort strategies and energy consumption on tropical urban heat island intensity: A review. Sustain. Cities Soc. 2018, 40, 677–687. [Google Scholar] [CrossRef]

- Perini, K.; Ottelé, M.; Haas, E.M.; Raiteri, R. Greening the building envelope, facade greening and living wall systems. Open J. Ecol. 2011, 1, 1–8. [Google Scholar] [CrossRef]

- Charoenkit, S.; Yiemwattana, S. Living walls and their contribution to improved thermal comfort and carbon emission reduction: A review. Build. Environ. 2016, 105, 82–94. [Google Scholar] [CrossRef]

- Hunter, A.M.; Williams, N.S.G.; Rayner, J.P.; Aye, L.; Hes, D.; Livesley, S.J. Quantifying the thermal performance of green façades: A critical review. Ecol. Eng. 2014, 63, 102–113. [Google Scholar] [CrossRef]

- Acero, J.A.; Arrizabalaga, J. Evaluating the performance of envi-met model in diurnal cycles for different meteorological conditions. Theor. Appl. Climatol. 2018, 131, 455–469. [Google Scholar] [CrossRef]

- Salata, F.; Golasi, I.; Vollaro, A.d.L.; Vollaro, R.d.L. How high albedo and traditional buildings’ materials and vegetation affect the quality of urban microclimate. A case study. Energy Build. 2015, 99, 32–49. [Google Scholar] [CrossRef]

- Huttner, S. Further Development and Application of the 3D Microclimate Simulation Envi-Met; Mainz University: Mainz, Germany, 2012. [Google Scholar]

- Yang, X.; Zhao, L.; Bruse, M.; Meng, Q. Evaluation of a microclimate model for predicting the thermal behavior of different ground surfaces. Build. Environ. 2013, 60, 93–104. [Google Scholar] [CrossRef]

- Lahme, E.; Bruse, M. Microclimatic effects of a small urban park in densely built-up areas: Measurements and model simulations. In Proceedings of the 5th International Conference on Urban Climate, Lodz, Poland, 1–5 September 2003. [Google Scholar]

- Szucs, Ã.; Gál, T.; Andrade, H. Comparison of measured and simulated mean radiant temperature. Case study in Lisbon (Portugal). Finisterra-Revista Portuguesa de Geografia 2014, 53, 95–111. [Google Scholar] [CrossRef]

- Lee, H.; Mayer, H.; Chen, L. Contribution of trees and grasslands to the mitigation of human heat stress in a residential district of freiburg, southwest germany. Landsc. Urban Plan. 2016, 148, 37–50. [Google Scholar] [CrossRef]

- Bruse, M.; Fleer, H. Simulating surface–plant–air interactions inside urban environments with a three dimensional numerical model. Environ. Model. Softw. 1998, 13, 373–384. [Google Scholar] [CrossRef]

- Nasir, D.S.N.M.; Hughes, B.R.; Calautit, J.K. A cfd analysis of several design parameters of a road pavement solar collector (rpsc) for urban application. Appl. Energy 2017, 186, 436–449. [Google Scholar] [CrossRef]

- Perini, K.; Ottelé, M.; Giulini, S.; Magliocco, A.; Roccotiello, E. Quantification of fine dust deposition on different plant species in a vertical greening system. Ecol. Eng. 2017, 100, 268–276. [Google Scholar] [CrossRef]

- De Carvalho Gomes, S.; Zhou, J.L.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A. review. Res. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (pcm) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Enescu, D. A review of thermal comfort models and indicators for indoor environments. Renew. Sustain. Energy Rev. 2017, 79, 1353–1379. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, J.; Yuan, X.; Zhang, K.; Yang, Y.; Wang, Y. Air-conditioning system with underfloor air distribution integrated solar chimney in data center. Procedia Eng. 2017, 205, 3420–3427. [Google Scholar] [CrossRef]

- Ortigosa, R.; Gil, A.J. A new framework for large strain electromechanics based on convex multi-variable strain energies: Conservation laws, hyperbolicity and extension to electro-magneto-mechanics. Comput. Method Appl. Mech. Eng. 2016, 309, 202–242. [Google Scholar] [CrossRef]

- Dutton, S.M.; Fisk, W.J. Energy and indoor air quality implications of alternative minimum ventilation rates in california offices. Build. Environ. 2014, 82, 121–127. [Google Scholar] [CrossRef]

- Fossati, J.P.; Galarza, A.; Martín-Villate, A.; Fontan, L. A method for optimal sizing energy storage systems for microgrids. Renew. Energy 2015, 77, 539–549. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Mourshed, M.; Mundow, D.; Sisinni, M.; Rezgui, Y. Building energy metering and environmental monitoring-a state-of-the-art review and directions for future research. Energy Build. 2016, 120, 85–102. [Google Scholar] [CrossRef]

- Hajidavalloo, E.; Eghtedari, H. Performance improvement of air-cooled refrigeration system by using evaporatively cooled air condenser. Int. J. Refrig. 2010, 33, 982–988. [Google Scholar] [CrossRef]

| Components | Parameter | Scen.1 | Scen.2 | Scen.3 | Scen.4 |

|---|---|---|---|---|---|

| Wall | Substrate | Concrete | Concrete | Concrete | Concrete |

| Thickness (m) | 0.3 | 0.3 | 0.3 | 0.3 | |

| Roughness Length | 0.02 | 0.02 | 0.02 | 0.02 | |

| Plant | Species | - | Lvy | Lvy | Lvy |

| Thickness | - | 0.3 | 0.3 | 0.3 | |

| LAI | - | 1.5 | 1.5 | 1.5 | |

| LAD | - | 0.7 | 0.7 | 0.7 | |

| Substrate | Species | - | - | Loam | Super soil |

| Thickness | - | - | 0.2 | 0.2 | |

| Emissivity | - | - | 0.05 | 0.03 | |

| Albedo | - | - | 0.18 | 0.15 | |

| Water coefficient of substrate for plant | - | - | 0.18 | 0.7 | |

| Air Gap between substrate and wall (m) | - | - | 0 | 0 |

| Position | data |

|---|---|

| Longitude (°) | 113.02 |

| Latitude (°) | 25.48 |

| Start and Duration of the Model | data |

| Date of simulation | 23 July 2016 |

| Start time | 3:00 |

| Total simulation time (h) | 30 |

| Initial Meteorological Conditions | data |

| Wind speed measured at 10 m height (m/s) | 3 |

| Wind direction (deg) | 158° |

| Roughness length at measurement site | 0.01 |

| Min relative humidity at 2 m height (%) | 50 |

| Max relative humidity at 2 m height (%) | 70 |

| Min air temperature (Night) | 22 |

| Min air temperature (Day) | 34 |

| Solar Radiation and Clouds | data |

| Adjustment factor for solar radiation | 0.85 |

| Cover of low clouds (octas) | 3 |

| Cover of medium clouds (octas) | 4 |

| Cover of high clouds | 7 |

| Soil Data | data |

| Initial temperature in all layers: 0–0.2 m; 0.2–0.5 m; >0.5 m (k) | 293 |

| Relative humidity upper layer (0–20 cm) | 70 |

| Relative humidity middle layer (20–50 cm) | 75 |

| Relative humidity deep layer (below 50 cm) | 75 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zheng, B.; Shen, W.; Xiang, Y.; Chen, X.; Qi, Z. Cooling and Energy-Saving Performance of Different Green Wall Design: A Simulation Study of a Block. Energies 2019, 12, 2912. https://doi.org/10.3390/en12152912

Li J, Zheng B, Shen W, Xiang Y, Chen X, Qi Z. Cooling and Energy-Saving Performance of Different Green Wall Design: A Simulation Study of a Block. Energies. 2019; 12(15):2912. https://doi.org/10.3390/en12152912

Chicago/Turabian StyleLi, Jiayu, Bohong Zheng, Wenquan Shen, Yanfen Xiang, Xiao Chen, and Zhiyong Qi. 2019. "Cooling and Energy-Saving Performance of Different Green Wall Design: A Simulation Study of a Block" Energies 12, no. 15: 2912. https://doi.org/10.3390/en12152912

APA StyleLi, J., Zheng, B., Shen, W., Xiang, Y., Chen, X., & Qi, Z. (2019). Cooling and Energy-Saving Performance of Different Green Wall Design: A Simulation Study of a Block. Energies, 12(15), 2912. https://doi.org/10.3390/en12152912