An Improved Torque Control Strategy of PMSM Drive Considering On-Line MTPA Operation

Abstract

:1. Introduction

- Variable parameter PI control. A third-order characteristic curve of the relationship between the parameters of the PI controller and the load torque is established by the interpolation fitting method. The parameters of the PI controller will be adjusted according to the curve mentioned before to eliminate the impact of load torque on the performance of PI control [21].

- Nonlinear control. Back-stepping control [22], variable structure control [23], sliding mode control [24,25] and other nonlinear controllers are utilized to realize torque control. The nonlinear controller has the advantages of a rapid dynamic response and good adaptability against external disturbances and nonlinearity of the parameters. The dynamic performance of the motor is rapid and consistent under different load conditions.

- Deadbeat torque control [26,27,28] and predictive torque control [29,30,31]. The deviation of the torque is used as the input, and the required stator voltage for torque control can be obtained by the predictive mechanism. In these kinds of strategies, the stator voltage is adjusted online to eliminate the impact of load on the performance of torque by the predictive/deadbeat controller according to the mathematical model and load condition of the motor.

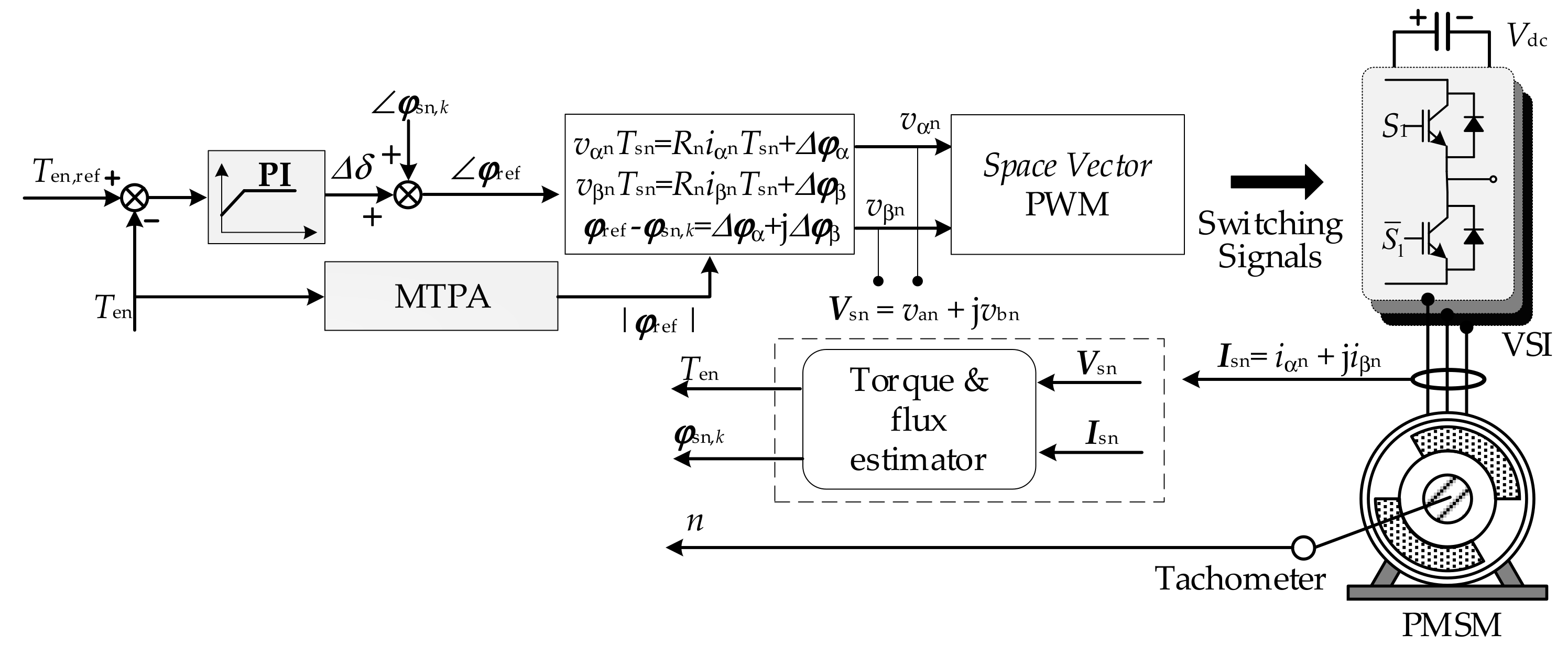

2. Examination of Conventional DTC-SVM Scheme

2.1. Selection of Reference Flux Amplitude Based on the MTPA Criterion

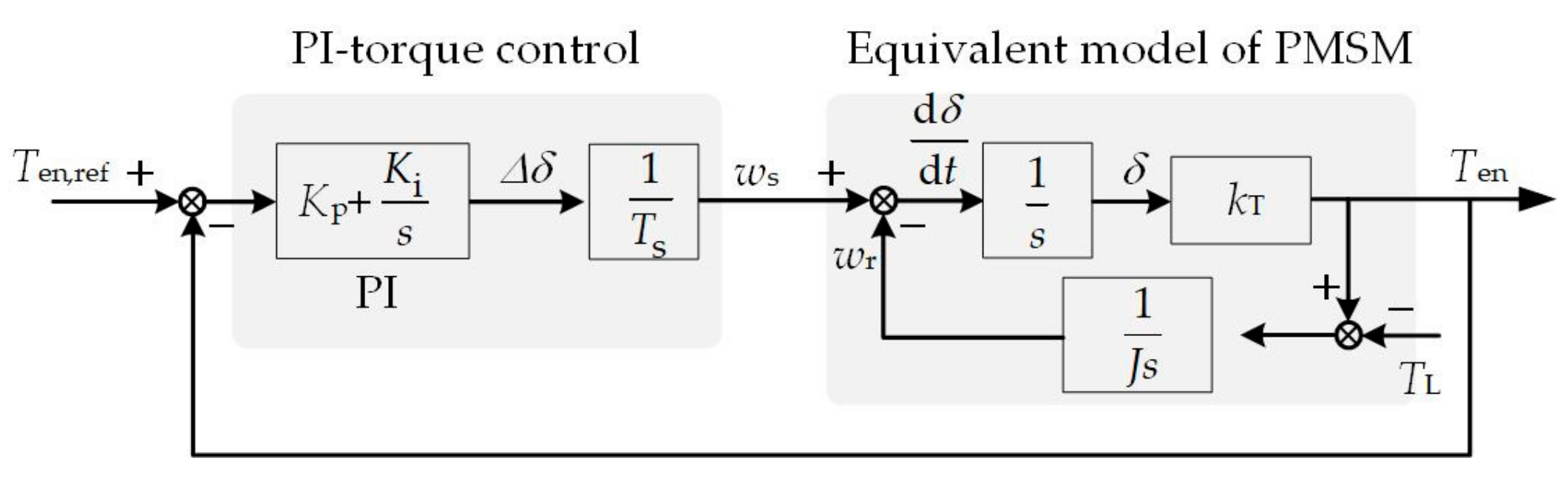

2.2. Torque Control Based on the PI Controller

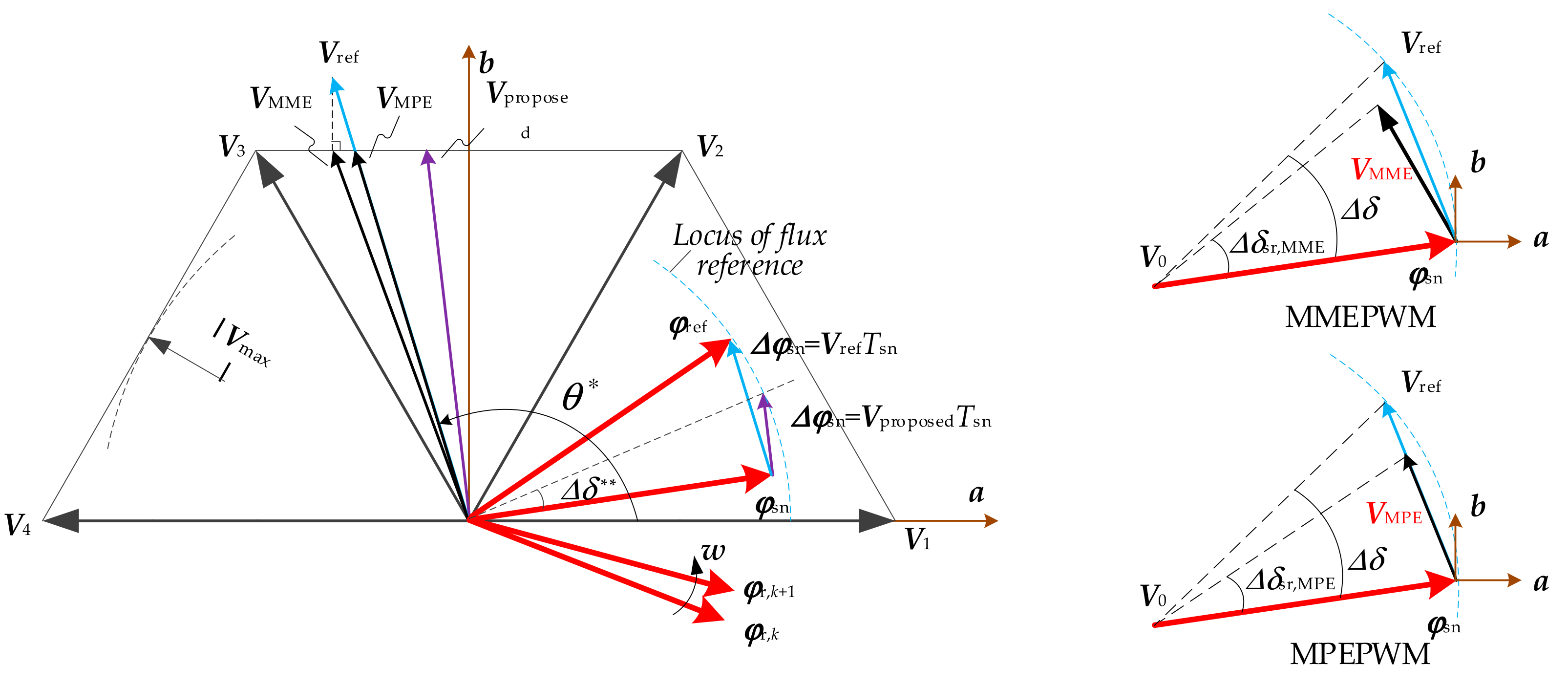

3. An Improved DTC-SVM Scheme

3.1. Novel Online MPTA Scheme

- To ensure stable operation of the PMSM, the reference value of the flux amplitude [20],

- 2.

- If the PMSM works under no-load conditions, the electromagnetic torque and stator current are almost zero. According to (3),

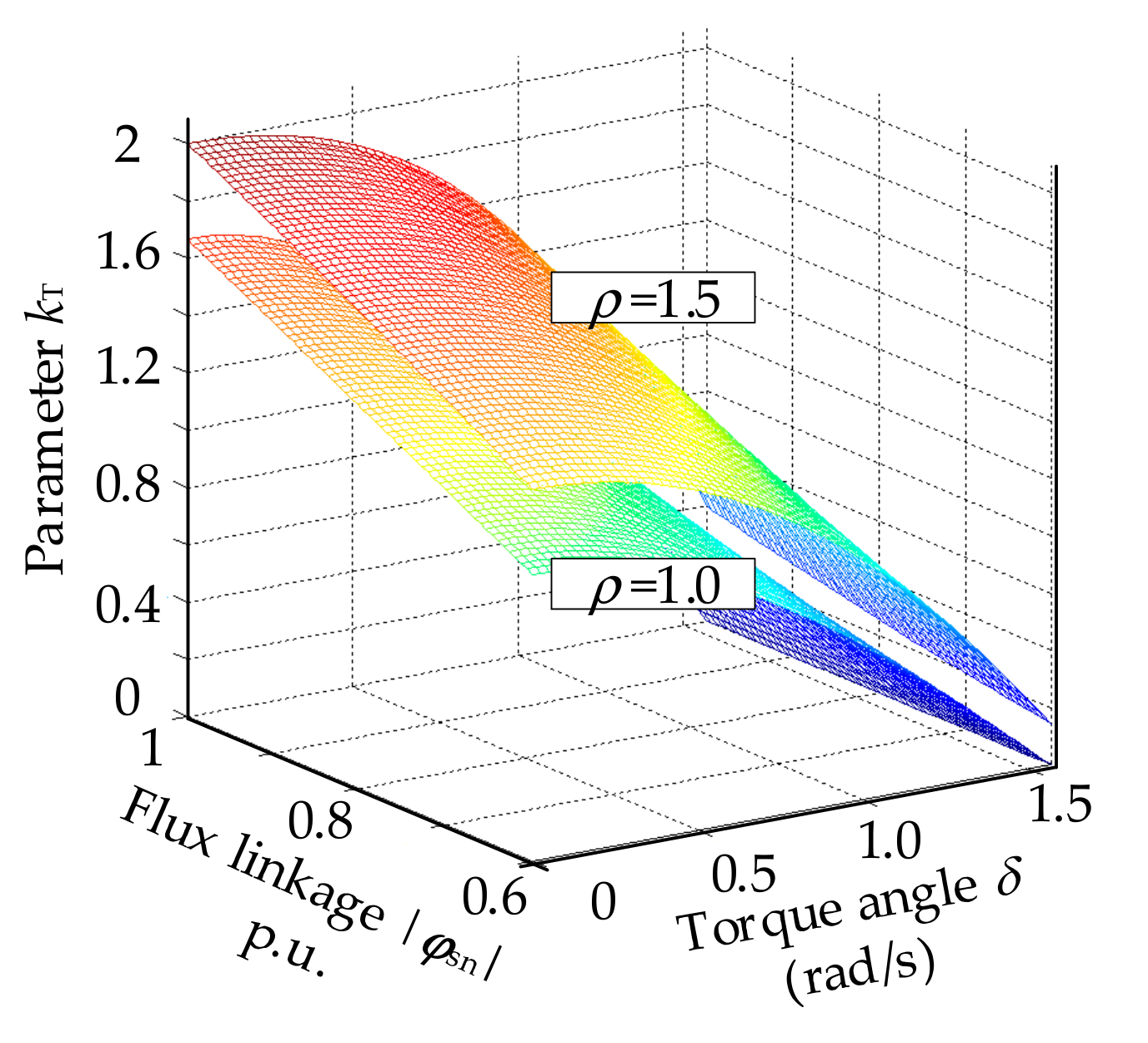

3.2. Torque Controller with Load Angle Estimation (TC-LAE)

3.3. Correction, Compensation and Limitations of ∆δ

3.3.1. Correction

3.3.2. Compensation

3.3.3. Limitation

4. Simulation Results

4.1. The Correction and Compensation for ∆δ

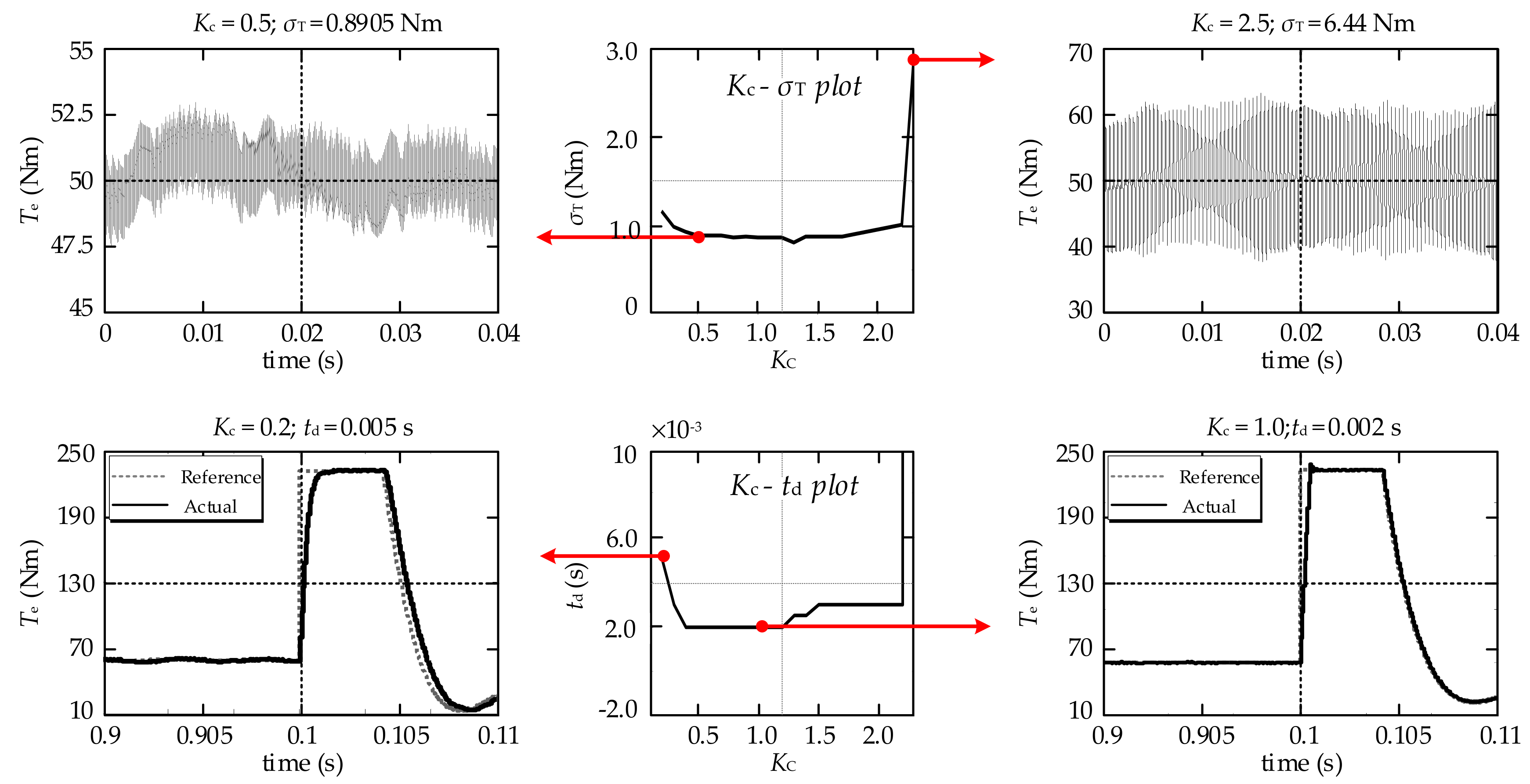

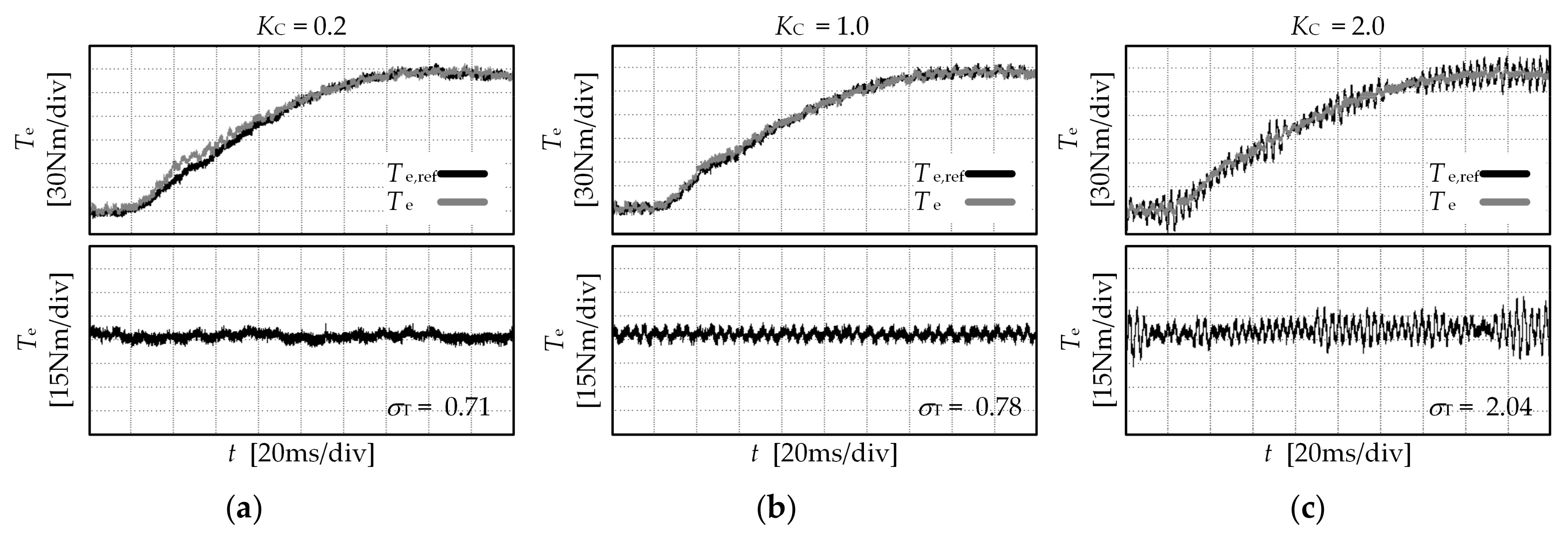

4.2. Selection of the Torque Controller Parameter, Kc

- When the value of Kc is less than 2.0, the torque ripple of the motor is small. When the value of Kc is greater than 2.0, the static oscillation of the electromagnetic torque appears.

- When the value of Kc is between 0.5 and 2.0, the dynamic performance of the electromagnetic torque is basically consistent. When the value of Kc is less than 0.5, the regulating time of the torque becomes longer. So, the dynamic performance of the system is degraded.

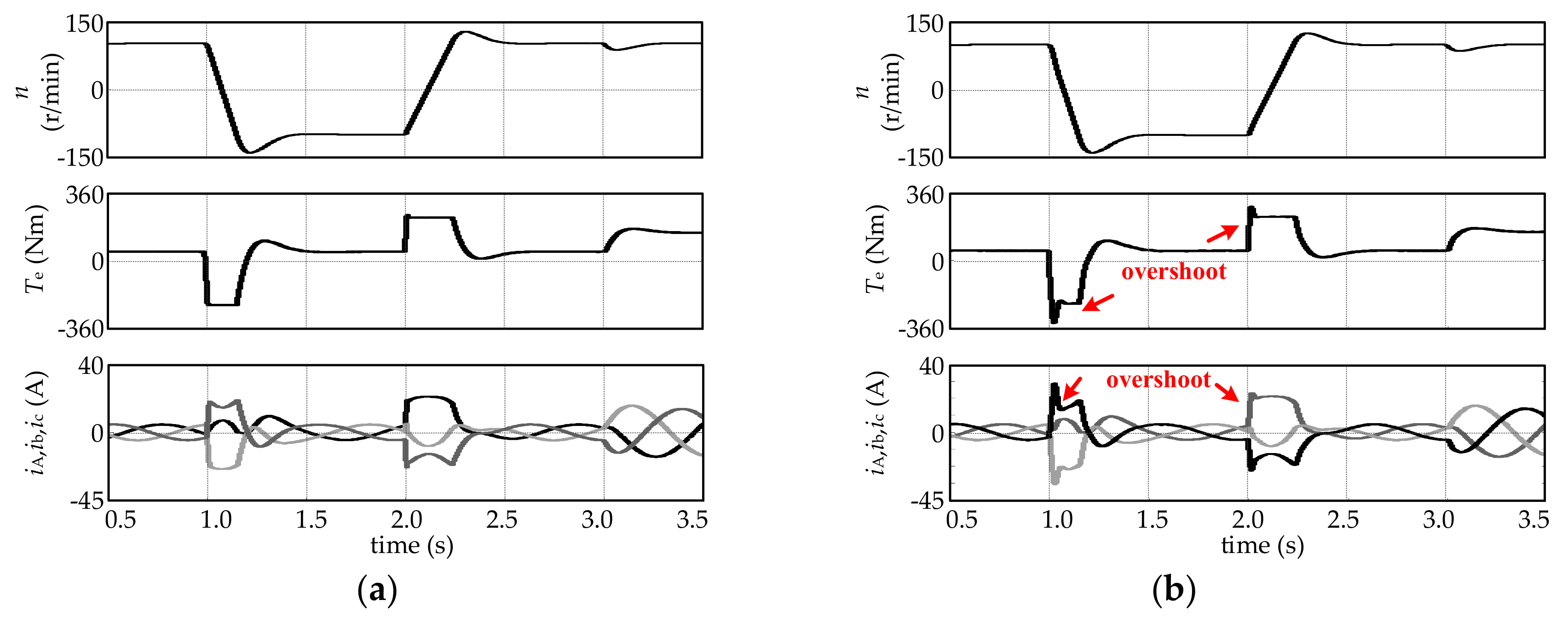

4.3. Dynamic Characteristic of the Motor Control System

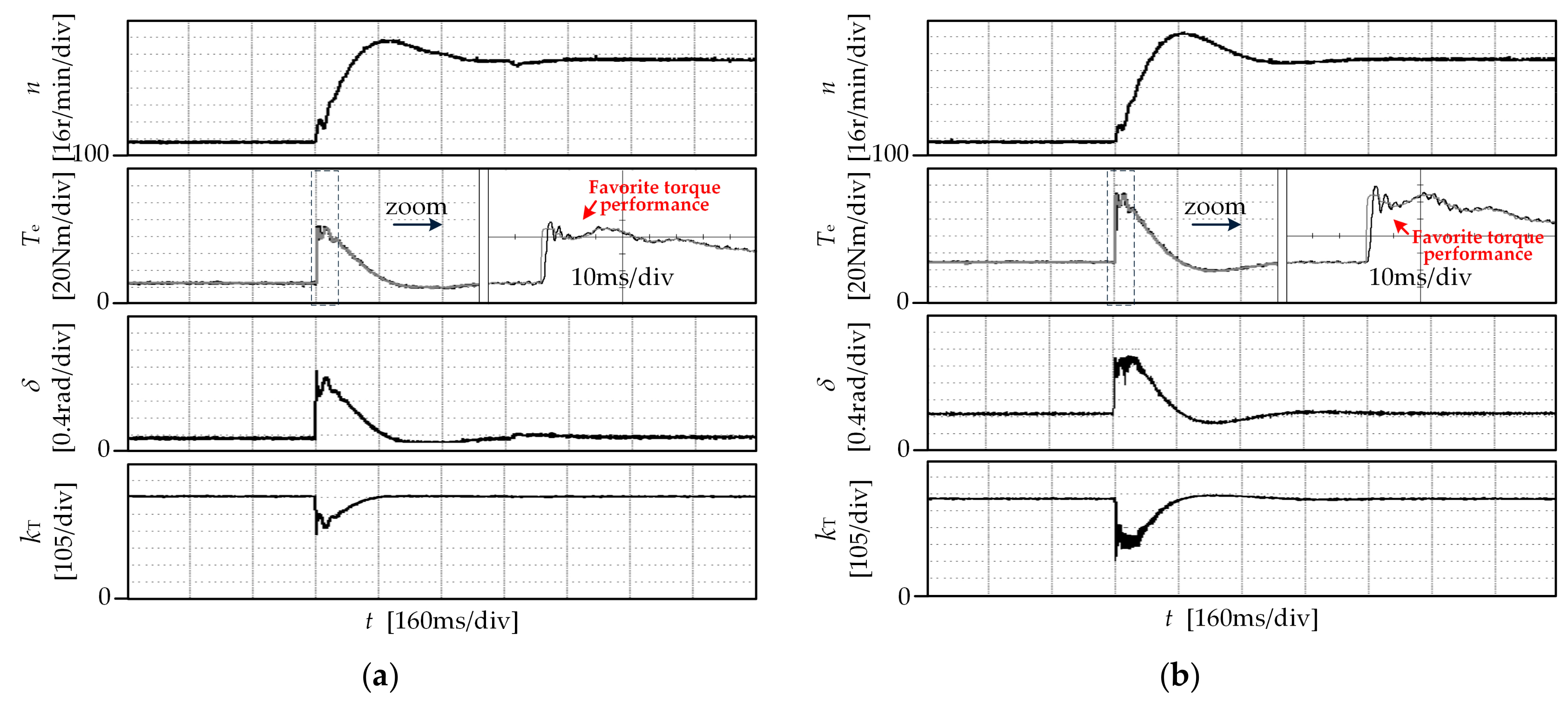

5. Experimental Results

5.1. MTPA Operation

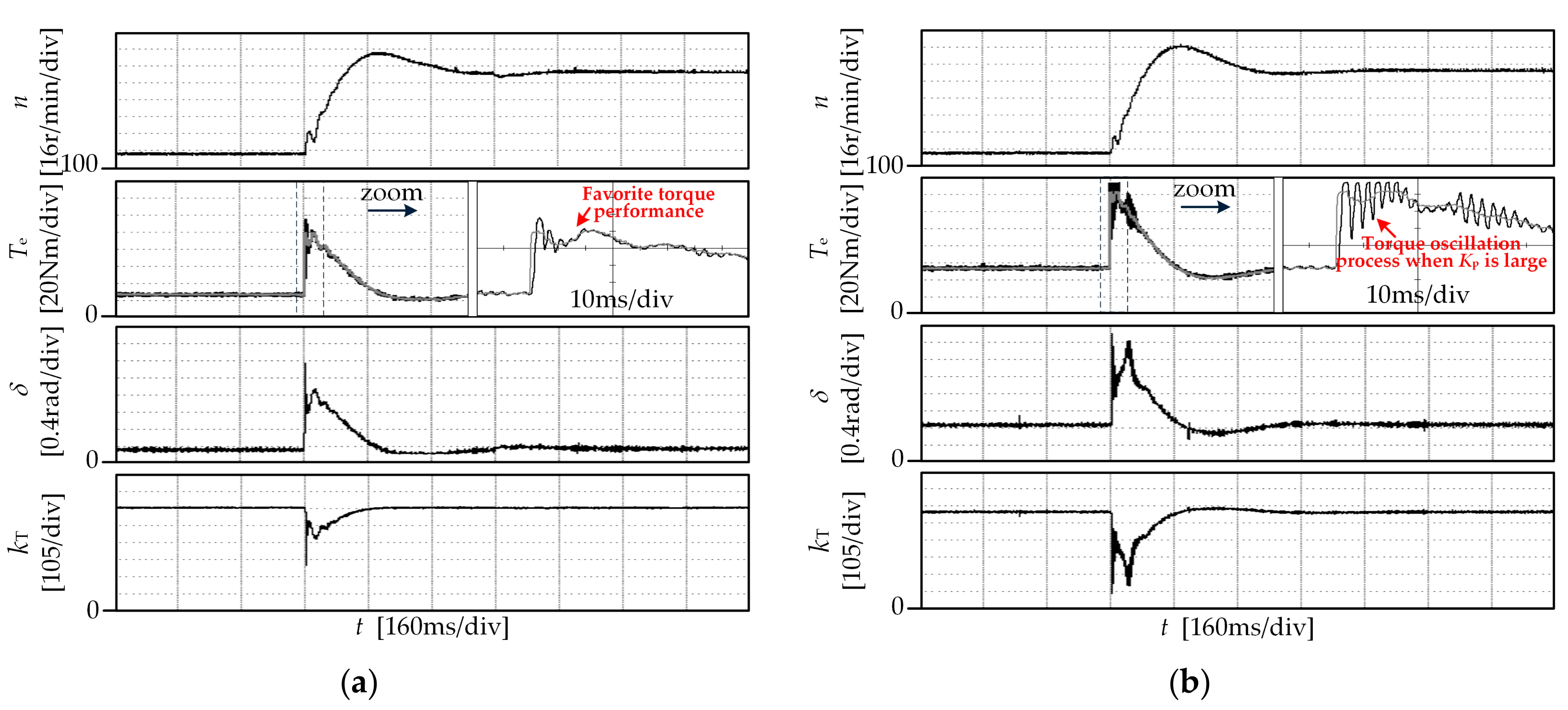

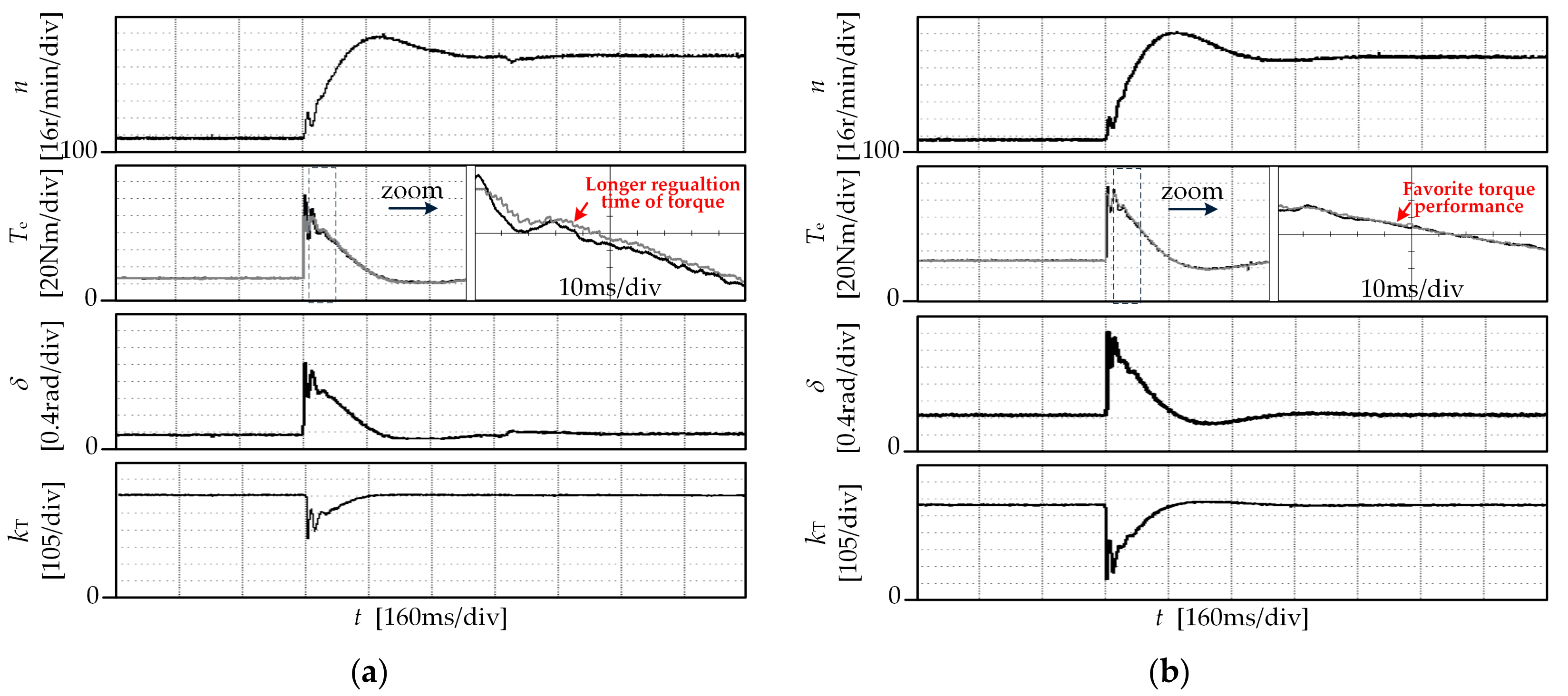

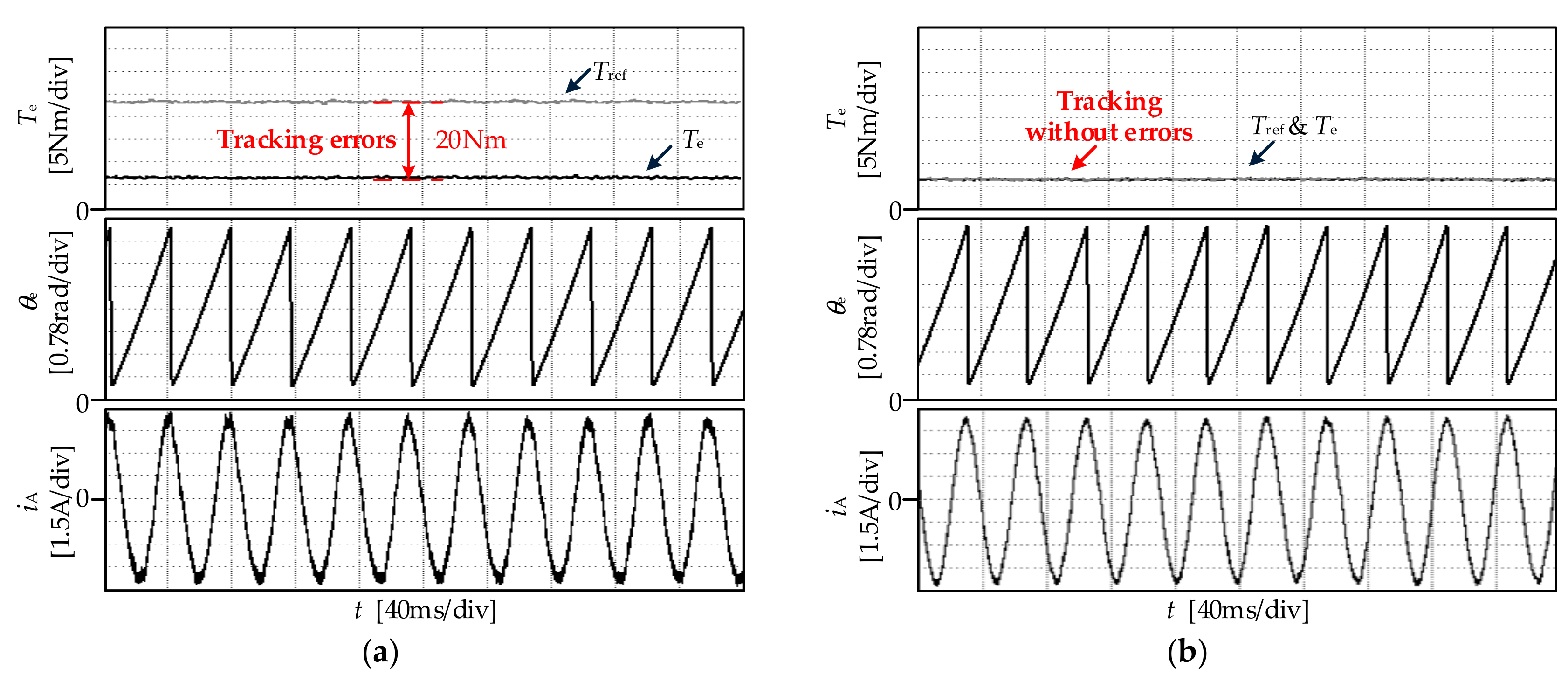

5.2. Torque Control Performance

5.3. Characteristics of the Torque Controller

6. Conclusions

- The improved scheme inherits the advantages of the conventional DTC-SVM scheme. The torque control ability under different load conditions has been improved; the impact of load variation on torque performance has been eliminated.

- The reference value of the stator voltage given by the torque controller maybe exceed the range of the voltage limitation circle when the electromagnetic torque is changed suddenly. Then, the tracking deviation of the flux occurs and causes an impulse of the current. With the corresponding correction algorithm, the impact of the voltage limitation circle on the performance of torque control is eliminated.

- To eliminate the deviation of torque control resulting from the rotation of the permanent magnet; a compensation term was added to the reference value of the flux phase angle in the improved scheme, and a no-error control of the electromagnetic torque was realized.

- The selection of the torque control parameter Kc will impact the torque control performance in the improved scheme. The selection of Kc is analyzed by the simulation and experiment. The analysis results show that the torque ripple becomes greater when the Kc is large; the dynamic performance of the torque is degraded when the Kc is small.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| v, i, φs, φr | Stator voltage, current and flux, permanent magnet flux |

| φs, Vs, Is | Stator flux, voltage and current vector |

| ωm, ω | Mechanical and electrical angular velocity |

| Te, δ, ρ | Electromagnetic torque, load angle and salient rate of the motor |

| p, L, R | Number of pole pairs, stator inductance, stator resistance |

| kT, Kc | Change rate of torque, control parameter of load angle controller |

| Kp, Ki, Ts | Proportionality coefficient, integral coefficient and control period |

| ABC, αβ, dq | Three-phase, two-phase stationary frame and rotating reference frame |

| |·|, ∠, ∆ | Amplitude and phase angle of vector, Incremental quantity of variables |

| b, n, N (subscript) | Base value, per-unit value and rated value |

| k, (subscript) | Variables at the instant kTs |

| ref, 0 (subscript) | Reference value and balance point value |

References

- Wang, D.; Yuan, T.; Wang, X.; Wang, X.; Ni, Y. Performance improvement of servo control system driven by dovel PMSM-DTC based on fixed sector division criterion. Energies 2019, 12, 2154. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Mei, X.; Rodríguez, J.; Kennel, R. Advanced control strategies of induction machine: Field oriented control direct torque control and model predictive control. Energies 2018, 11, 120. [Google Scholar] [CrossRef]

- Pavel, K.; Jiri, L. Induction motor drive direct torque control and predictive torque control comparison based on switching pattern analysis. Energies 2018, 11, 1793. [Google Scholar]

- Wang, D.; Yuan, T.; Wang, X.; Wang, X.; Li, W. A Composite vectors modulation strategy for PMSM DTC systems. Energies 2018, 11, 2729. [Google Scholar] [CrossRef]

- Milutin, P.; Nebojša, M.; Vojkan, K.; Bojan, B. An improved scheme for voltage sag override in direct torque controlled induction motor drives. Energies 2017, 10, 663. [Google Scholar] [CrossRef]

- Li, H.; Lin, J.; Lu, Z. Three vectors model predictive torque control without weighting factor based on electromagnetic torque feedback compensation. Energies 2019, 12, 1393. [Google Scholar] [CrossRef]

- Xu, Y.; Shi, T.; Yan, Y.; Gu, X. Dual-vector predictive torque control of permanent magnet synchronous motors based on a candidate vector table. Energies 2019, 12, 163. [Google Scholar] [CrossRef]

- Song, Q.; Li, Y.; Jia, C. A novel direct torque control method based on asymmetric boundary layer sliding mode control for PMSM. Energies 2018, 11, 657. [Google Scholar] [CrossRef]

- Hoang, K.D.; Ren, Y.; Zhu, Z.Q.; Foster, M. Modified switching-table strategy for reduction of current harmonics in direct torque controlled dual-three phase permanent magnet synchronous machine drives. IET Electr. Power Appl. 2015, 9, 10–19. [Google Scholar] [CrossRef]

- Xia, C.; Zhao, J.; Yan, Y.; Shi, T. A novel direct torque control of matrix converter-fed PMSM drives using duty cycle control for torque ripple reduction. IEEE Trans. Ind. Electron. 2014, 61, 2700–2713. [Google Scholar] [CrossRef]

- Yan, Y.; Zhao, J.; Xia, C.; Shi, T. Direct torque control of matrix converter-fed permanent magnet synchronous motor drives based on master and slave vectors. IEEE Trans. Power Electron. 2015, 8, 288–296. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Ren, Y.; Liu, J. Improved torque regulator to reduce steady-state error of torque response for direct torque control of permanent magnet synchronous machine drives. IET Trans. Electr. Power Appl. 2014, 8, 108–116. [Google Scholar] [CrossRef]

- Buja, G.S.; Kazmierkowski, M.P. Direct torque control of PWM inverter-fed AC motors-a survey. IEEE Trans. Ind. Electron. 2004, 51, 744–757. [Google Scholar] [CrossRef]

- Tang, L.; Zhong, L.; Rahman, M.F.; Hu, Y. Novel direct torque controlled interior permanent magnet synchronous machine drive with low ripple in flux and torque and fixed switching frequency. IEEE Trans. Power Electron. 2004, 19, 346–354. [Google Scholar] [CrossRef]

- Inoue, Y.; Morimoto, S.; Sanada, M. Control method suitable for direct-torque-control-based motor drive system satisfying voltage and current limitations. IEEE Trans. Ind. Appl. 2012, 48, 970–976. [Google Scholar] [CrossRef]

- Krishnan, B. Permanent Magnet Synchronous and Brushless DC Motor Drives; CRC Press: Boca Raton, FL, USA, 2009; Chapter 7. [Google Scholar]

- Jung, S.Y.; Hong, J.; Nam, K. Current minimizing torque control of the IPMSM using Ferrari’s method. IEEE Trans. Power Electron. 2014, 28, 5603–5617. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Optimal state reference computation with constrained MTPA criterion for PM motor drives. IEEE Trans. Power Electron. 2015, 30, 4524–4535. [Google Scholar] [CrossRef]

- Lemmens, J.; Vanassche, P.; Driesen, J. PMSM drive current and voltage limiting as a constraint optimal control problem. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 326–338. [Google Scholar] [CrossRef]

- Rahman, M.F.; Zhang, L.; Lim, K.W. A direct torque-controlled interior permanent magnet synchronous motor drive incorporating field weakening. IEEE Trans. Ind. Appl. 1998, 34, 1246–1253. [Google Scholar] [CrossRef]

- Inoue, Y.; Morimoto, S.; Sanada, M. Examination and linearization of torque control system for direct torque controlled IPMSM. IEEE Trans. Ind. Appl. 2010, 46, 159–166. [Google Scholar] [CrossRef]

- Foo, G.; Rahman, M.F. Direct torque and flux control of an IPM synchronous motor drive using a backstepping approach. IET Trans. Electr. Power Appl. 2009, 3, 413–421. [Google Scholar] [CrossRef]

- Chen, S.Z.; Cheung, N.C.; Wong, K.C.; Wu, J. Integral variable structure direct torque control of doubly fed induction generator. IET Trans. Electr. Power Appl. 2011, 5, 18–25. [Google Scholar] [CrossRef]

- Liu, Y. Suppressing stick-slip oscillation in underactuated multibody dril-strings with parametric uncertainties using sliding-mode control. IET Trans. Control Theory Appl. 2015, 9, 91–102. [Google Scholar] [CrossRef]

- Lascu, C.; Trzynadlowski, A.M. Combining the principles of sliding mode, direct torque control, and space-vector modulation in a high-performance sensorless AC drive. IEEE Trans. Ind. Appl. 2004, 40, 170–177. [Google Scholar] [CrossRef]

- Xu, W.; Lorenz, R.D. Dynamic loss minimization using improved deadbeat-direct torque and flux control for interior permanent magnet synchronous machines. IEEE Trans. Ind. Appl. 2014, 50, 1053–1065. [Google Scholar] [CrossRef]

- Zhu, H.; Xiao, X.; Li, Y. Torque ripple reduction of the torque predictive control scheme for permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2012, 59, 871–877. [Google Scholar] [CrossRef]

- Song, W.; Ma, J.; Zhou, L.; Feng, X. Deadbeat predictive power control of single phase three level neutral-point-clamped converters using space-vector modulation for electric railway traction. IEEE Trans. Power Electron. 2015, 31, 721–732. [Google Scholar] [CrossRef]

- Cho, Y.; Lee, K.; Song, J.; Lee, Y. Torque-ripple minimization and fast dynamic scheme for torque predictive control of permanent-magnet synchronous motors. IEEE Trans. Power Electron. 2015, 30, 2182–2190. [Google Scholar] [CrossRef]

- Lee, J.S.; Choi, C.H.; Seok, J.K.; Lorenz, R.D. Deadbeat direct torque and flux control of interior permanent magnet machines with discrete time stator current and stator flux linkage observer. IEEE Trans. Ind. Appl. 2011, 47, 1749–1758. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Model predictive direct torque control with finite control set for PMSM drive systems, part 1: Maximum torque per ampere operation. IEEE Trans. Ind. Inform. 2013, 9, 1912–1921. [Google Scholar] [CrossRef]

- Doncker, R.; Pulle, D.; Veltman, A. Advanced Electrical Drives Analysis, Modeling, Control; Springer: New York, NY, USA, 2010; Chapter 4. [Google Scholar]

- Burden, R.; Faires, J. Numerical Analysis; Cengage Learning: Boston, MA, USA, 2010; Chapter 3. [Google Scholar]

- Tang, R. Modern Permanent Magnet Machines: Theory and Design; China Machine Press: Beijing, China, 2000; Chapters 3–4. [Google Scholar]

- Hinkkanen, M.; Luomi, J. Modified integrator for voltage model flux estimation of induction motors. IEEE Trans. Ind. Electron. 2003, 50, 818–820. [Google Scholar] [CrossRef] [Green Version]

- Luukko, J.; Pyrhonen, O.; Niemela, M.; Pyrhonen, J. Limitation of the load angle in a direct-torque-controlled synchronous machine drive. IEEE Trans. Ind. Electron. 2004, 51, 793–798. [Google Scholar] [CrossRef]

- Jidin, A.; Idris, N.; Yatim, A.; Sutikno, T.; Elbuluk, M. An optimized switching strategy for quick dynamic torque control in DTC-hysteresis-based induction machines. IEEE Trans. Ind. Electron. 2011, 58, 3391–3400. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Number of pole-pairs | p | 8 |

| Permanent magnet flux of PMSM | ϕρ | 0.9031 Wb |

| Stator resistance of PMSM | Rs | 0.76 Ω |

| d-axis inductance of PMSM | Ld | 23.05 mH |

| q-axis inductance of PMSM | Lq | 24.26 mH |

| Rated speed of PMSM | nN | 300 r/min |

| Rated torque of PMSM | TN | 192 Nm |

| Rated voltage of PMSM | vN | 380 V |

| Rated current of PMSM | IN | 11.8 A |

| DC voltage of VSI | Vdc | 560 V |

| Switching frequency of VSI | fsw | 5 kHz |

| Sampling period of controller | Ts | 200 μs |

| Proportional coefficient of speed PI controller | Kpw | 100 |

| Integral coefficient of speed PI controller | Kiw | 50 Ts |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Gu, X.; Wang, Z.; Zhang, G.; Geng, Q. An Improved Torque Control Strategy of PMSM Drive Considering On-Line MTPA Operation. Energies 2019, 12, 2951. https://doi.org/10.3390/en12152951

Zhou Z, Gu X, Wang Z, Zhang G, Geng Q. An Improved Torque Control Strategy of PMSM Drive Considering On-Line MTPA Operation. Energies. 2019; 12(15):2951. https://doi.org/10.3390/en12152951

Chicago/Turabian StyleZhou, Zhanqing, Xin Gu, Zhiqiang Wang, Guozheng Zhang, and Qiang Geng. 2019. "An Improved Torque Control Strategy of PMSM Drive Considering On-Line MTPA Operation" Energies 12, no. 15: 2951. https://doi.org/10.3390/en12152951

APA StyleZhou, Z., Gu, X., Wang, Z., Zhang, G., & Geng, Q. (2019). An Improved Torque Control Strategy of PMSM Drive Considering On-Line MTPA Operation. Energies, 12(15), 2951. https://doi.org/10.3390/en12152951