Activation of Carbon Porous Paper for Alkaline Alcoholic Fuel Cells

Abstract

:1. Introduction

2. Experimental Methods

2.1. Treatment of the Membrane

2.2. Preparation of the Electrode

2.2.1. Preparation of the Pt/C-Coated Carbon Porous Electrode

2.2.2. Thermal Treatment to Activate the Carbon Porous Electrode

2.2.3. Chemical Treatment to Activate the Carbon Porous Electrode

2.2.4. Nitrogen Doping to Activate the Carbon Porous Electrode

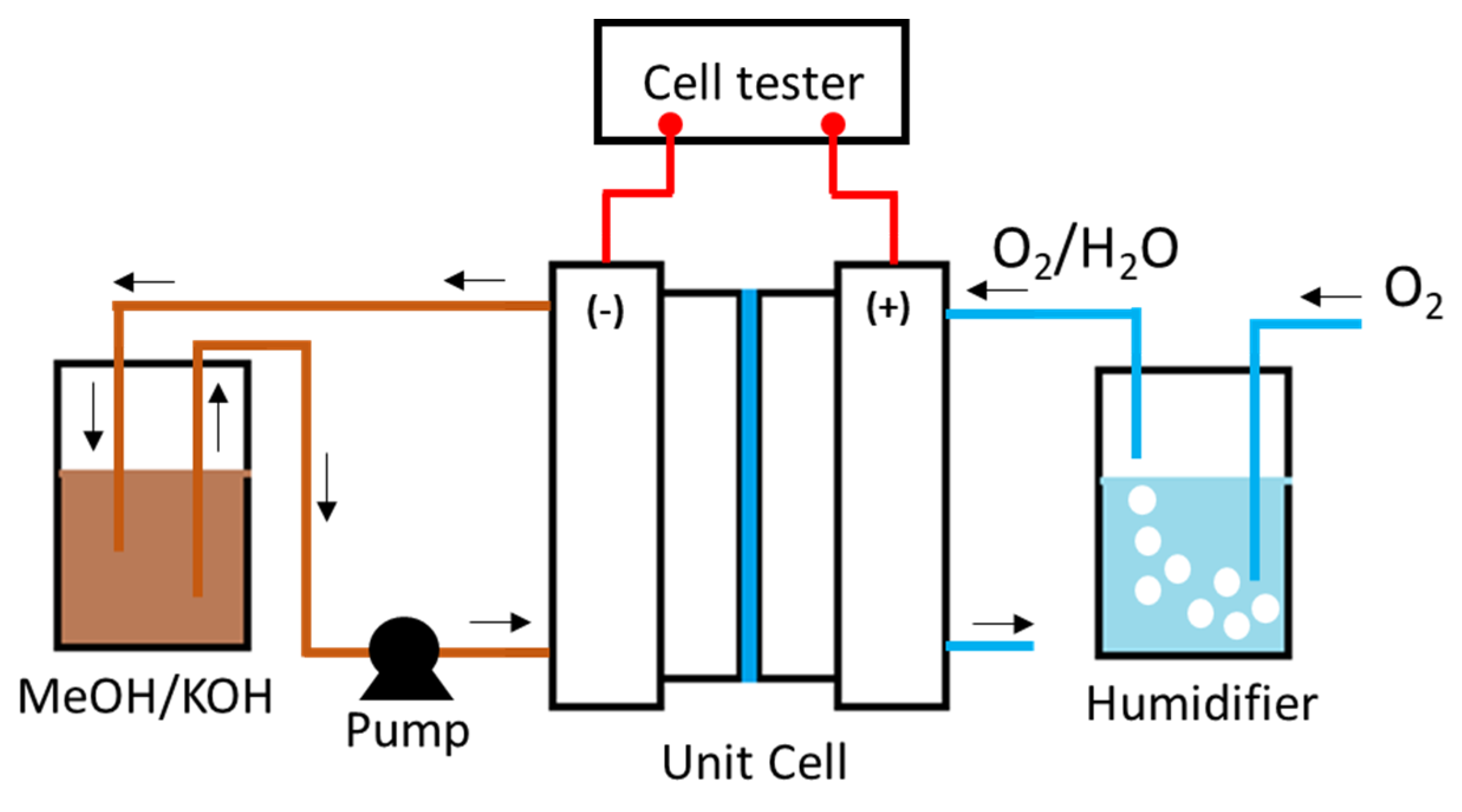

2.3. Cell Structure and Test

3. Results and Discussion

3.1. Baseline Performance of the Carbon Electrode and Pt/C-Coated Electrode

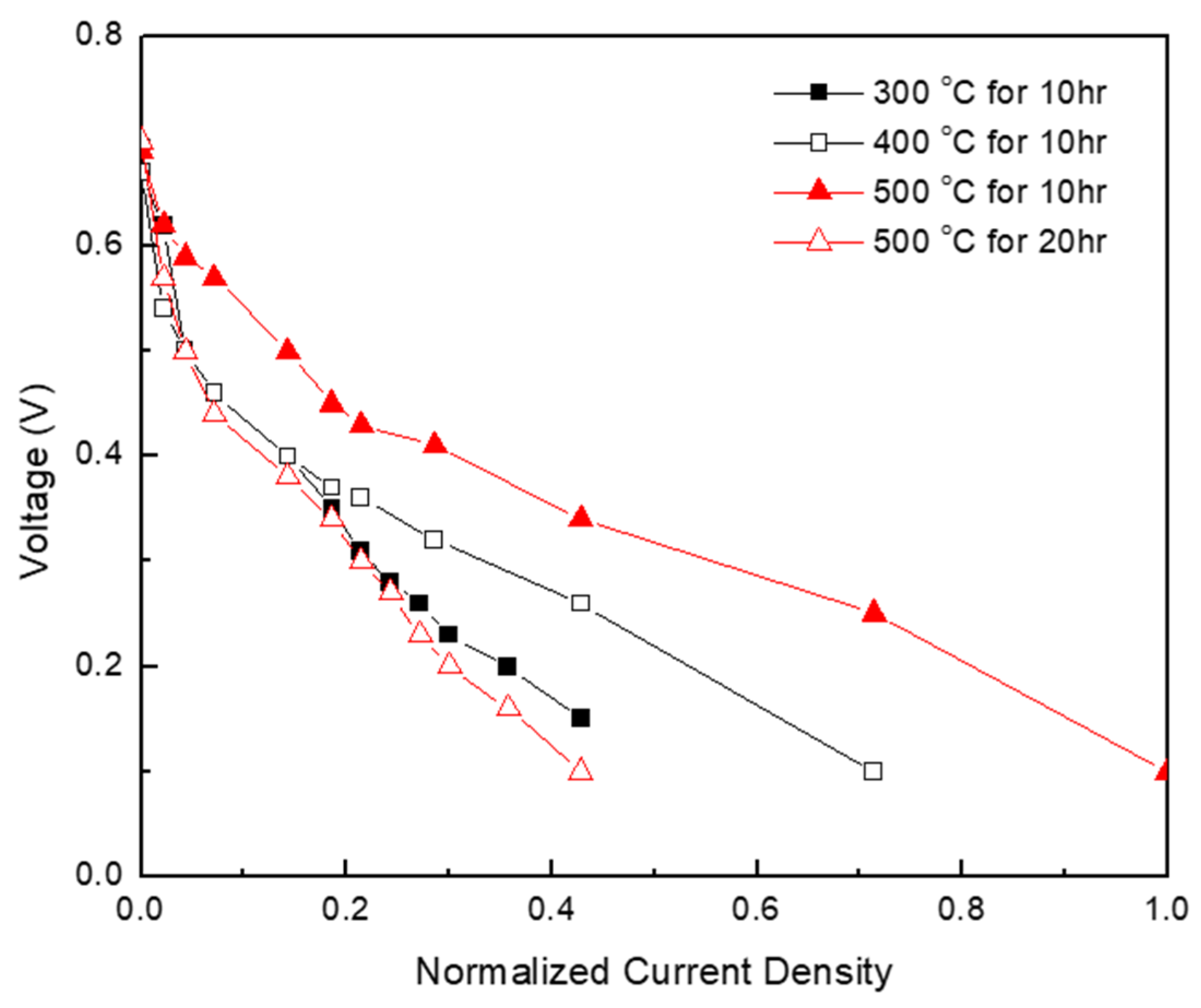

3.2. Thermal Treatment (Thermal Oxidation)

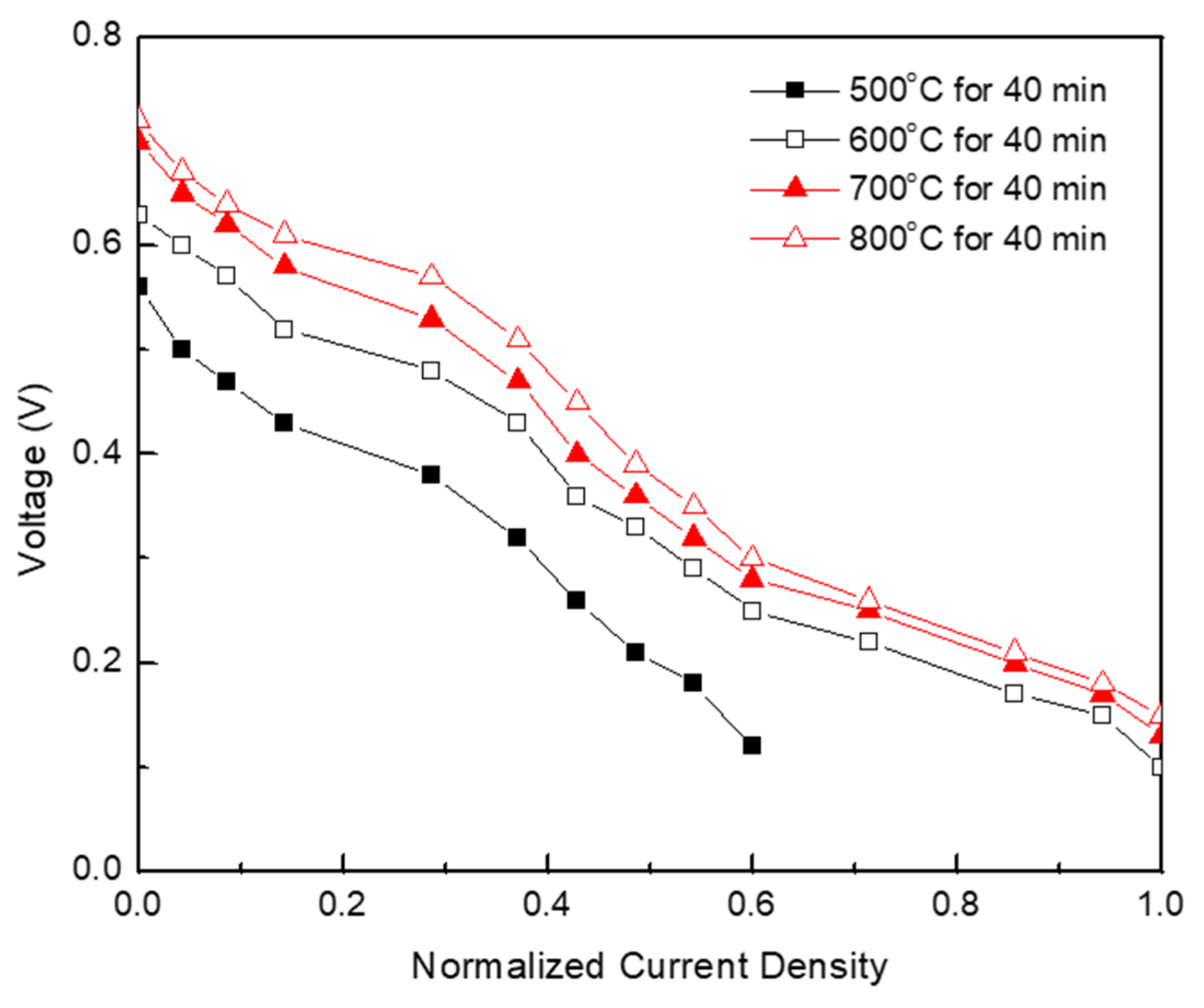

3.3. Chemical Treatment (KOH-Heat Treatment)

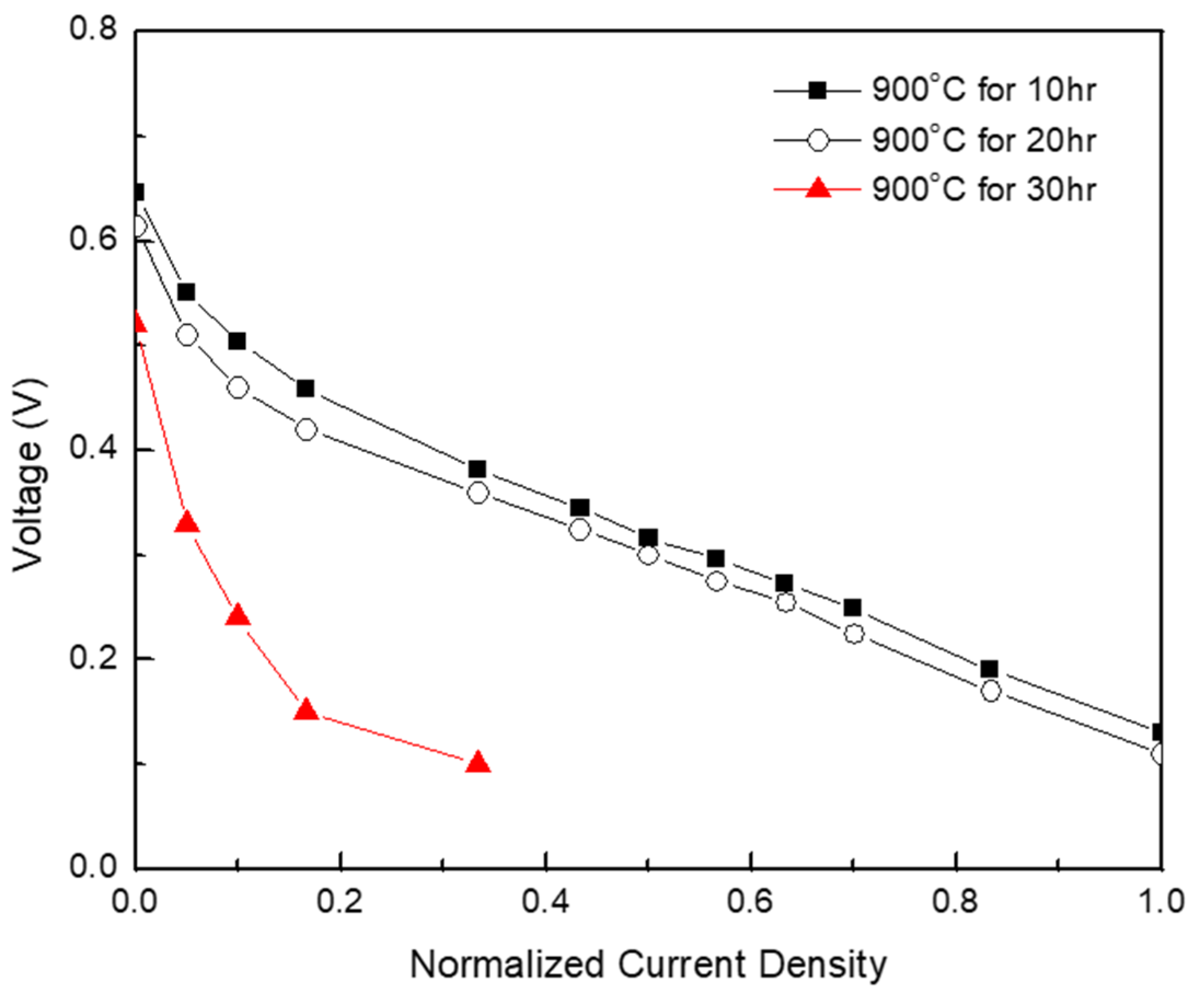

3.4. Nitrogen Doping

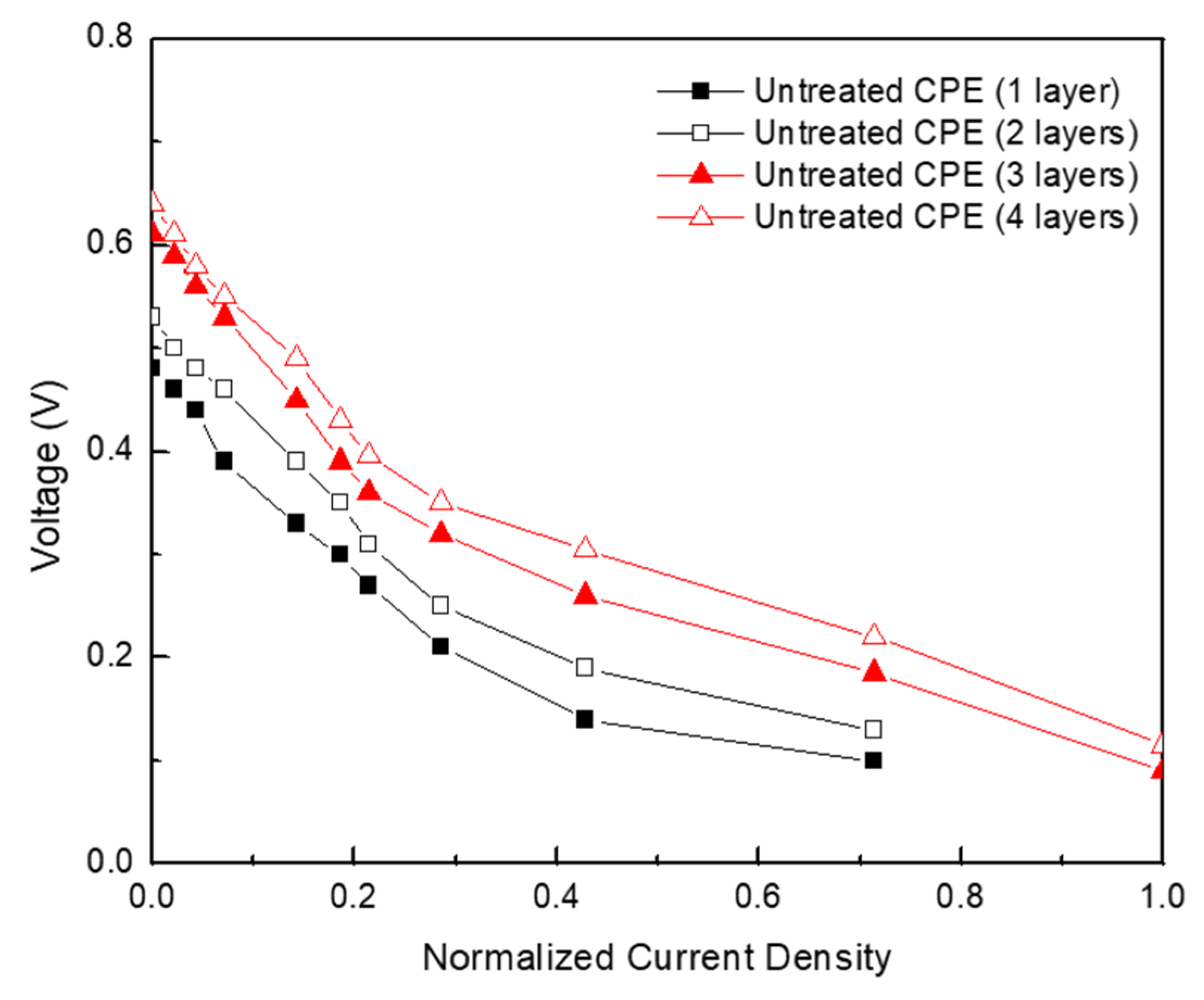

3.5. Reaction-Area Control via a Multi-Layered Structure

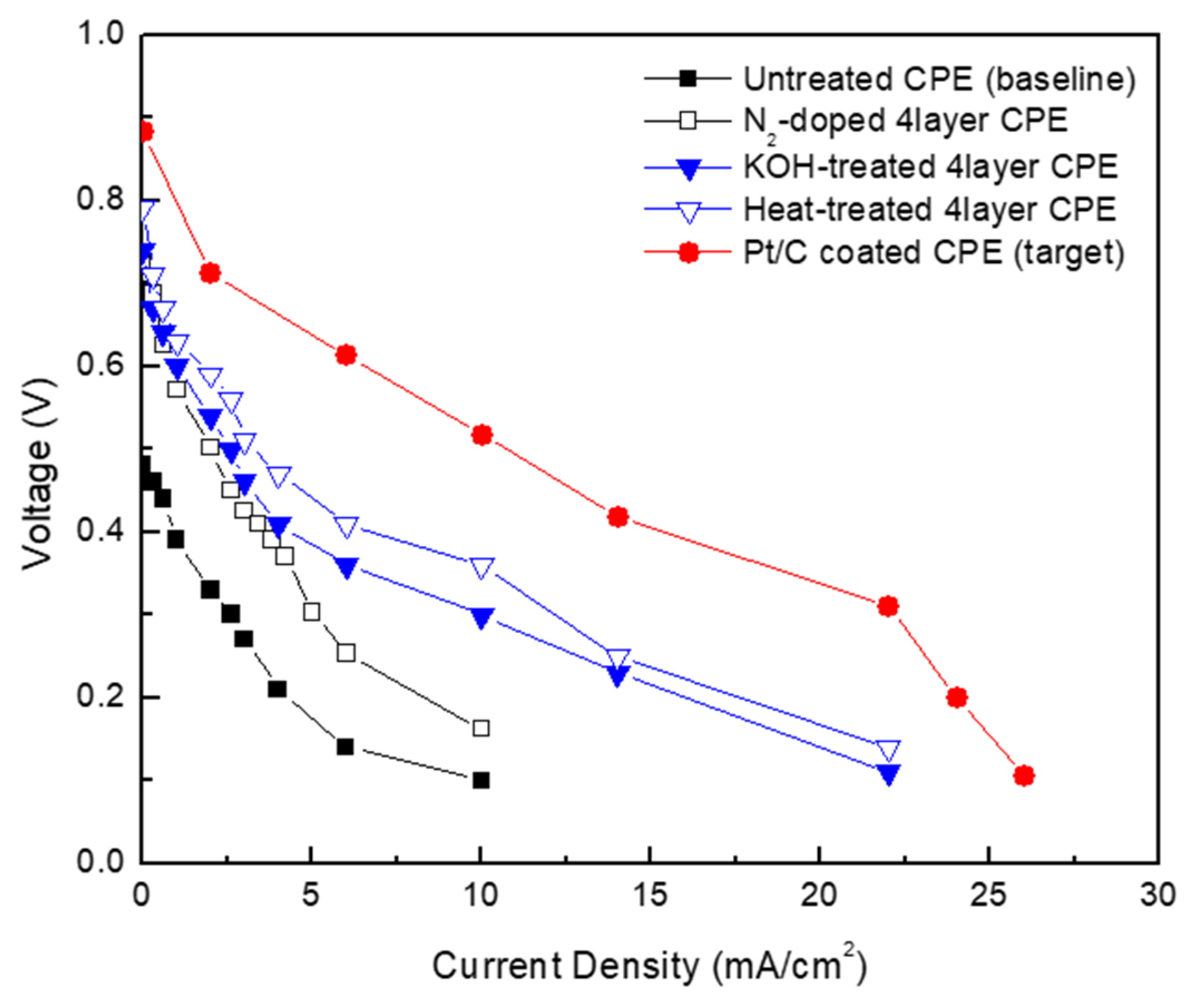

3.6. Optimal Treatment Condition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- An, L.; Zhao, T.S.; Li, Y.S. Carbon-neutral sustainable energy technology: Direct ethanol fuel cells. Renew. Sustain. Energy Rev. 2015, 50, 1462–1468. [Google Scholar] [CrossRef]

- Zhiani, M.; Gasteiger, H.A.; Piana, M.; Catanorchi, S. Comparative study between platinum supported on carbon and non-noble metal cathode catalyst in alkaline direct ethanol fuel cell (ADEFC). Int. J. Hydrog. Energy 2011, 36, 5110–5116. [Google Scholar] [CrossRef]

- García-Nieto, D.; Barragán, V.M. A comparative study of the electro-osmotic behavior of cation and anion exchange membranes in alcohol-water media. Electrochim. Acta 2015, 154, 166–176. [Google Scholar] [CrossRef]

- Hou, H.; Sun, G.; Wu, Z.; Jin, W.; Xin, Q. Zirconium phosphate/Nafion115 composite membrane for high-concentration DMFC. Int. J. Hydrog. Energy 2008, 33, 3402–3409. [Google Scholar] [CrossRef]

- Hou, H.; Wang, S.; Jin, W.; Jiang, Q.; Sun, L.; Jiang, L.; Sun, G. KOH modified Nafion112 membrane for high performance alkaline direct ethanol fuel cell. Int. J. Hydrog. Energy 2011, 36, 5104–5109. [Google Scholar] [CrossRef]

- Goswami, G.K.; Nandan, R.; Barman, B.K.; Nanda, K.K. Excellent performance of Pt-free cathode in alkaline direct methanol fuel cell at room temperature. J. Mater. Chem. A 2013, 1, 3133–3139. [Google Scholar] [CrossRef]

- Lee, K.; Zhang, L.; Zhang, J. A novel methanol-tolerant Ir-Se chalcogenide electrocatalyst for oyxgen reduction. J. Power Sour. 2007, 165, 108–113. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, H.M.; Wang, M.R.; Zhong, H.X.; Chen, J. Preparation, characterization of ZrOxNy/C and its application in PEMFC as an electrocatalyst for oxygen reduction. J. Power Sour. 2007, 172, 503–510. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Cochell, T.; Manthiram, A. Nitrogen-Doped Carbon Nanotube/Graphite Felts as Advanced Electrode Materials for Vanadium Redox Flow Batteries. J. Phys. Chem. Lett. 2012, 3, 2164–2167. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, X.; Li, H.; Yuan, C.; Cao, G. Design and Tailoring of a Three-Dimensional TiO2–Graphene–Carbon Nanotube Nanocomposite for Fast Lithium Storage. J. Phys. Chem. Lett. 2011, 2, 3096–3101. [Google Scholar] [CrossRef]

- Kannan, R.; Aher, P.P.; Palaniselvam, T.; Kurungot, S.; Kharul, U.K.; Pillai, V.K. Artificially Designed Membranes Using Phosphonated Multiwall Carbon Nanotube−Polybenzimidazole Composites for Polymer Electrolyte Fuel Cells. J. Phys. Chem. Lett. 2010, 1, 2109–2113. [Google Scholar] [CrossRef]

- Sun, B.; Skyllas-Kazacos, M. Modification of graphite electrode materials for vanadium redox flow battery application—I. Thermal treatment. Electrochim. Acta 1992, 37, 1253–1260. [Google Scholar] [CrossRef]

- Liu, Q.H.; Grim, G.M.; Papandrew, A.B.; Turhan, A.; Zawodzinski, T.A.; Mench, M.M. High Performance Vanadium Redox Flow Batteries with Optimized Electrode Configuration and Membrane Selection. J. Electrochem. Soc. 2012, 159, A1246–A1252. [Google Scholar] [CrossRef]

- Pezeshki, A.M.; Clement, J.T.; Veith, G.M.; Zawodzinski, T.A.; Mench, M.M. High performance electrodes in vanadium redox flow batteries through oxygen-enriched thermal activation. J. Power Sour. 2015, 294, 333–338. [Google Scholar] [CrossRef] [Green Version]

- Cho, K.T.; Ridgway, P.; Weber, A.Z.; Haussener, S.; Battaglia, V.; Srinivasan, V. High Performance Hydrogen/Bromine Redox Flow Battery for Grid-Scale Energy Storage. J. Electrochem. Soc. 2012, 159, A1806–A1815. [Google Scholar] [CrossRef]

- Cho, K.T.; Albertus, P.; Battaglia, V.; Kojic, A.; Srinivasan, V.; Weber, A.Z. Optimization and Analysis of High-Power Hydrogen/Bromine-Flow Batteries for Grid-Scale Energy Storage. Energy Technol. 2013, 1, 596–608. [Google Scholar] [CrossRef]

- Karim, N.A.; Kamarudin, S.K. An overview on non-platinum cathode catalysts for direct methanol fuel cell. Appl. Energy 2013, 103, 212–220. [Google Scholar] [CrossRef]

- Gojković, S.L.; Gupta, S.; Savinell, R.F. Heat-treated iron(III) tetramethoxyphenyl porphyrin chloride supported on high-area carbon as an electrocatalyst for oxygen reduction: Part III. Detection of hydrogen-peroxide during oxygen reduction. Electrochim. Acta 1999, 45, 889–897. [Google Scholar] [CrossRef]

- Gojković, S.L.; Gupta, S.; Savinell, R.F. Heat-treated iron(III) tetramethoxyphenyl porphyrin chloride supported on high-area carbon as an electrocatalyst for oxygen reduction: Part II. Kinetics of oxygen reduction. J. Electroanal. Chem. 1999, 462, 63–72. [Google Scholar] [CrossRef]

- Praats, R.; Kruusenberg, I.; Käärik, M.; Joost, U.; Aruväli, J.; Paiste, P.; Saar, R.; Rauwel, P.; Kook, M.; Leis, J.; et al. Electroreduction of oxygen in alkaline solution on iron phthalocyanine modified carbide-derived carbons. Electrochim. Acta 2019, 299, 999–1010. [Google Scholar] [CrossRef]

- Yoshinaga, N.; Sugimoto, W.; Takasu, Y. Oxygen reduction behavior of rutile-type iridium oxide in sulfuric acid solution. Electrochim. Acta 2008, 54, 566–573. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Huang, Q.; Zou, Z.; Xia, B.; Yang, H. Low temperature preparation of carbon-supported PdCo alloy electrocatalysts for methanol-tolerant oxygen reduction reaction. Electrochim.Acta 2008, 53, 6662–6667. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Cui, Z.; Liu, C.; Lu, T.; Xing, W. Pd nanoparticles supported on WO3/C hybrid material as catalyst for oxygen reduction reaction. J. Power Sour. 2008, 185, 941–945. [Google Scholar] [CrossRef]

- El-Deab, M.S.; Ohsaka, T. Hydrodynamic voltammetric studies of the oxygen reduction at gold nanoparticles-electrodeposited gold electrodes. Electrochim. Acta 2002, 47, 4255–4261. [Google Scholar] [CrossRef]

- Vázquez-Huerta, G.; Ramos-Sánchez, G.; Rodríguez-Castellanos, A.; Meza-Calderón, D.; Antaño-López, R.; Solorza-Feria, O. Electrochemical analysis of the kinetics and mechanism of the oxygen reduction reaction on Au nanoparticles. J. Electroanal. Chem. 2010, 645, 35–40. [Google Scholar] [CrossRef]

- Sung, H.; Sharma, M.; Jang, J.; Lee, S.-Y.; Choi, M.; Lee, K.; Jung, N. Boosting the oxygen reduction activity of a nano-graphene catalyst by charge redistribution at the graphene–metal interface. Nanoscale 2019, 11, 5038–5047. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, H. Graphite Felt Coated with Dopamine-Derived Nitrogen-Doped Carbon as a Positive Electrode for a Vanadium Redox Flow Battery. J. Electrochem. Soc. 2015, 162, A1675–A1681. [Google Scholar] [CrossRef]

- Babel, K.; Jurewicz, K. KOH activated carbon fabrics as supercapacitor material. J. Phys. Chem. Solids 2004, 65, 275–280. [Google Scholar] [CrossRef]

- Sun, B.; Skyllas-Kazacos, M. Chemical modification of graphite electrode materials for vanadium redox flow battery application—Part II. Acid treatments. Electrochim. Acta 1992, 37, 2459–2465. [Google Scholar] [CrossRef]

- Marma, K.; Kolli, J.; Cho, K.T. Membrane-Less Hydrogen Iron Redox Flow Battery. J. Electrochem. Energy. Conv. Stor. 2019, 16, 011005. [Google Scholar] [CrossRef]

- Jin, J.; Tanaka, S.; Egashira, Y.; Nishiyama, N. KOH activation of ordered mesoporous carbons prepared by a soft-templating method and their enhanced electrochemical properties. Carbon 2010, 48, 1985–1989. [Google Scholar] [CrossRef]

- Lv, Y.; Zhang, F.; Dou, Y.; Zhai, Y.; Wang, J.; Liu, H.; Xia, Y.; Tu, B.; Zhao, D. A comprehensive study on KOH activation of ordered mesoporous carbons and their supercapacitor application. J. Mater. Chem. 2011, 22, 93–99. [Google Scholar] [CrossRef]

- Mathias, M.F.; Roth, J.; Fleming, J.; Lehnert, W. Diffusion media materials and characterisation. In Handbook of Fuel Cells; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-97400-1. [Google Scholar]

- Aaron, D.S.; Liu, Q.; Tang, Z.; Grim, G.M.; Papandrew, A.B.; Turhan, A.; Zawodzinski, T.A.; Mench, M.M. Dramatic performance gains in vanadium redox flow batteries through modified cell architecture. J. Power Sour. 2012, 206, 450–453. [Google Scholar] [CrossRef]

- Tucker, M.C.; Srinivasan, V.; Ross, P.N.; Weber, A.Z. Performance and cycling of the iron-ion/hydrogen redox flow cell with various catholyte salts. J. Appl. Electrochem. 2013, 43, 637–644. [Google Scholar] [CrossRef]

| Performance | Untreated CPE | N2-Doped CPE | KOH-Treated CPE | Thermal Treated CPE | Pt/C-Coated CPE |

|---|---|---|---|---|---|

| Open Circuit Voltage (V) | 0.48 | 0.725 | 0.74 | 0.79 | 0.88 |

| Max Current Density (mA/cm2) | 10 | 10 | 22 | 22 | 26 |

| Max Power Density (mW/cm2) | 0.84 | 1.62 | 3.24 | 3.6 | 6.82 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perugupalli, D.H.; Xu, T.; Cho, K.T. Activation of Carbon Porous Paper for Alkaline Alcoholic Fuel Cells. Energies 2019, 12, 3207. https://doi.org/10.3390/en12173207

Perugupalli DH, Xu T, Cho KT. Activation of Carbon Porous Paper for Alkaline Alcoholic Fuel Cells. Energies. 2019; 12(17):3207. https://doi.org/10.3390/en12173207

Chicago/Turabian StylePerugupalli, Deva Harsha, Tao Xu, and Kyu Taek Cho. 2019. "Activation of Carbon Porous Paper for Alkaline Alcoholic Fuel Cells" Energies 12, no. 17: 3207. https://doi.org/10.3390/en12173207

APA StylePerugupalli, D. H., Xu, T., & Cho, K. T. (2019). Activation of Carbon Porous Paper for Alkaline Alcoholic Fuel Cells. Energies, 12(17), 3207. https://doi.org/10.3390/en12173207