Gen-Set Control in Stand-Alone/RES Integrated Power Systems

Abstract

:1. Introduction

2. Case Study: Ponza Island

3. Methodology

3.1. Base Energy System Scenarios

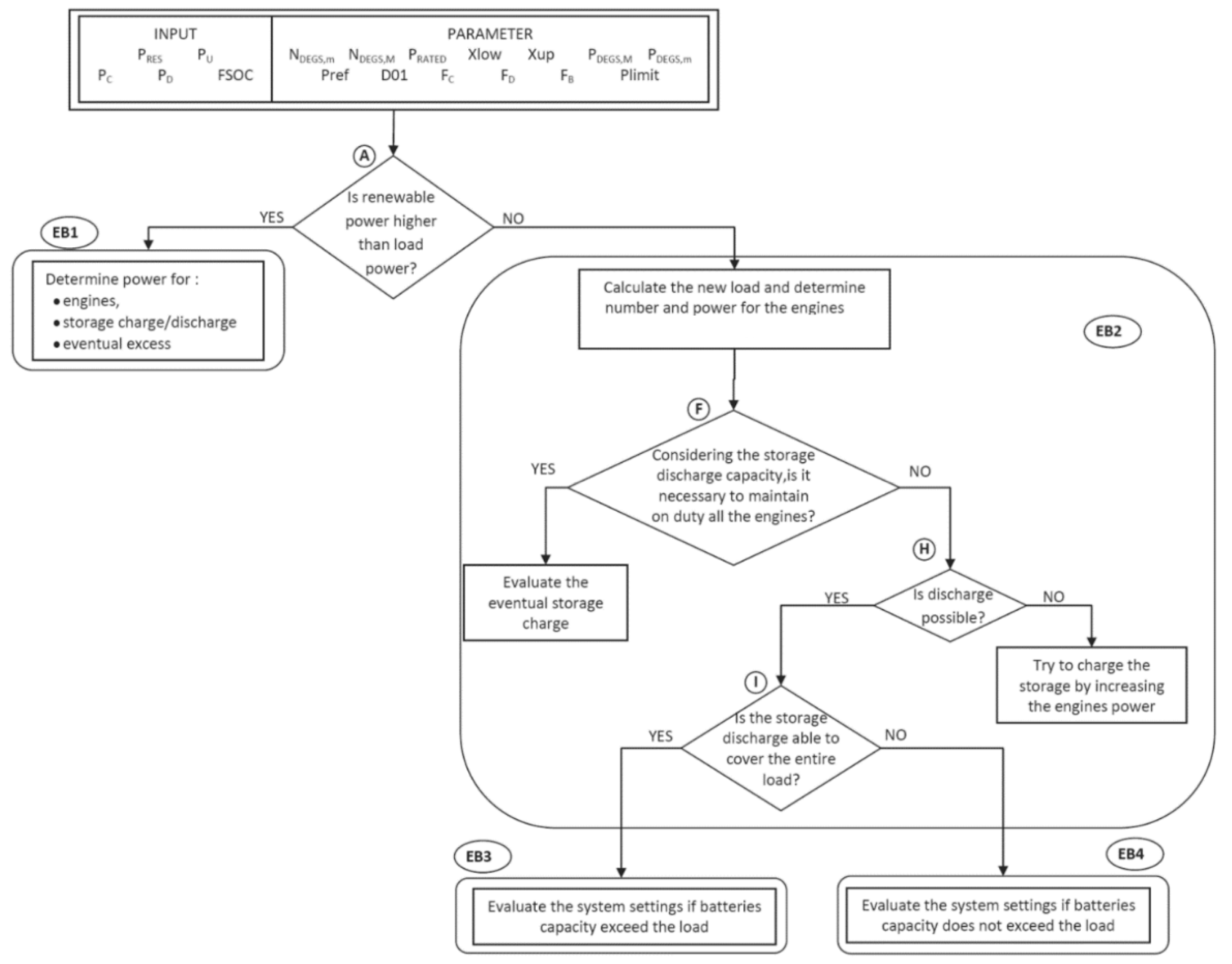

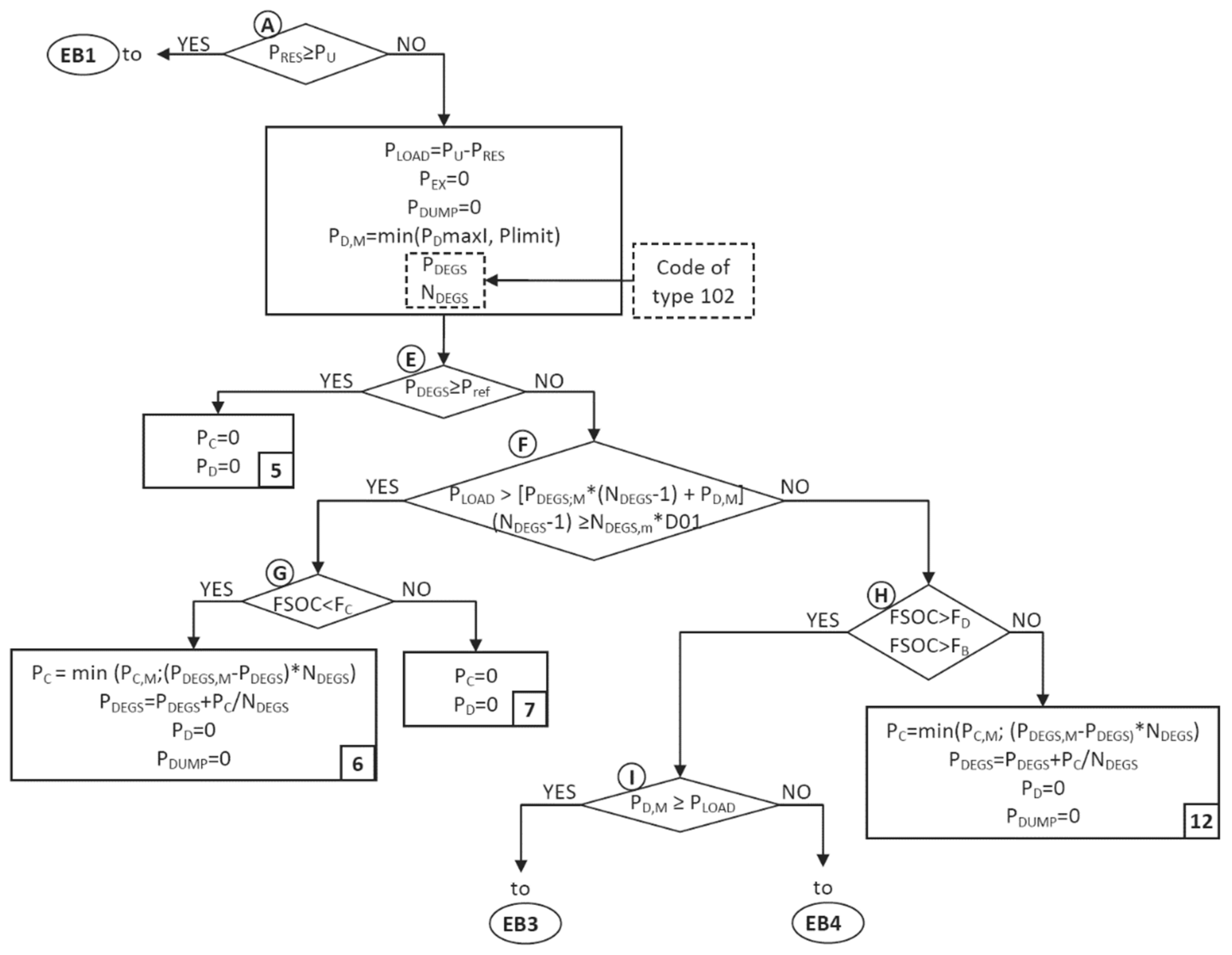

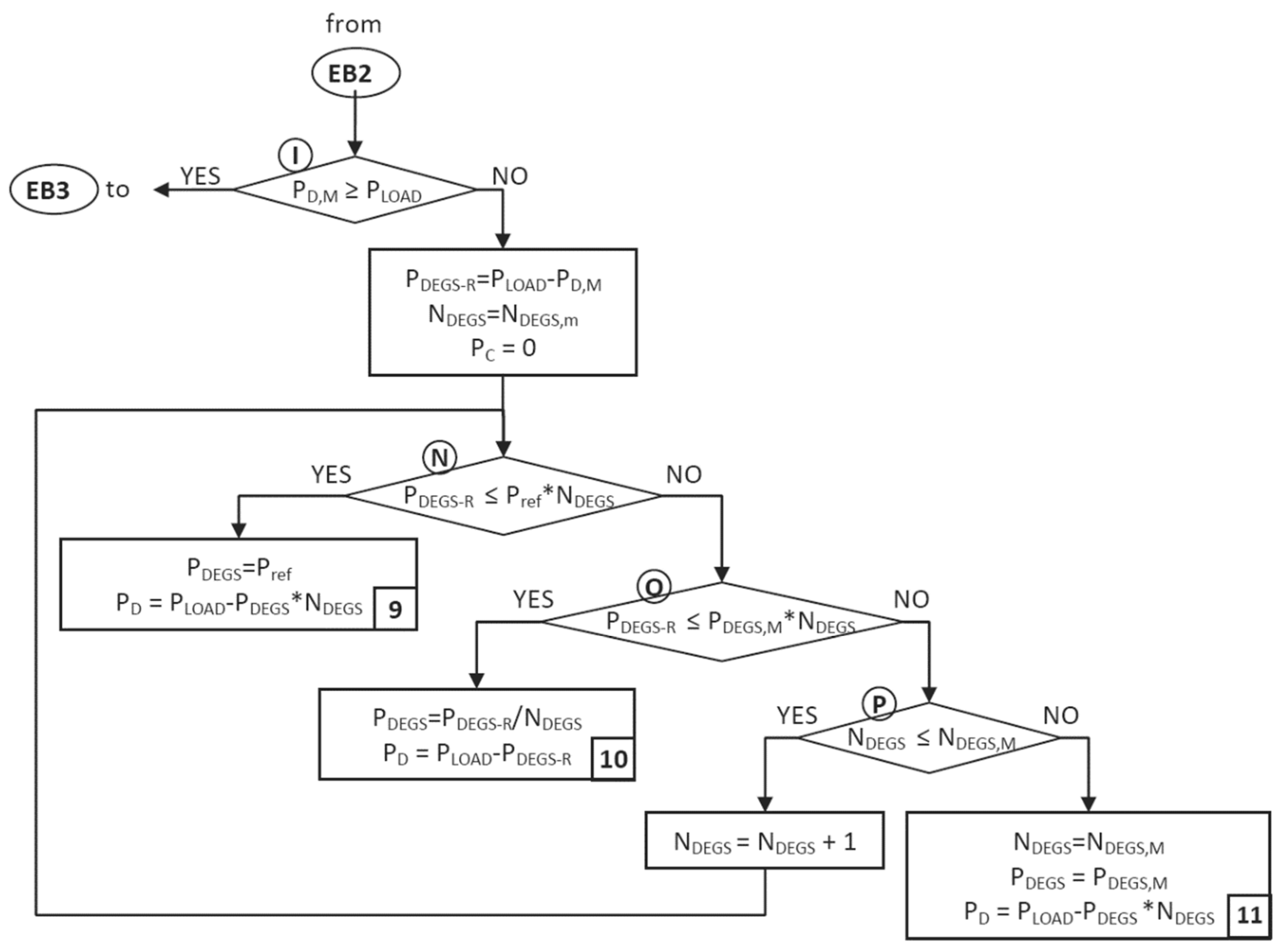

3.2. Advanced Energy System Scenarios and Control Logics

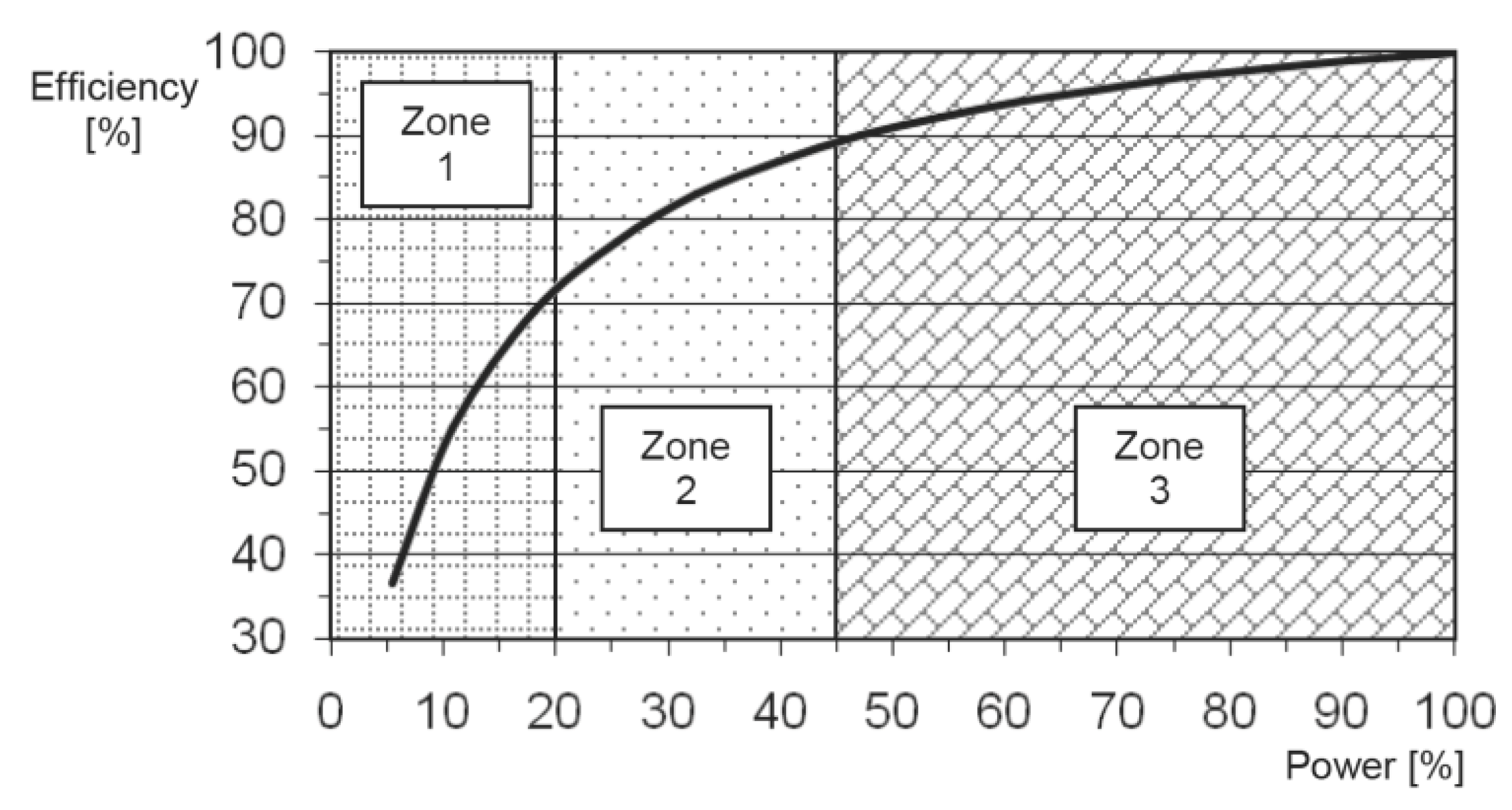

3.3. Technologies and Working Parameters

4. Results

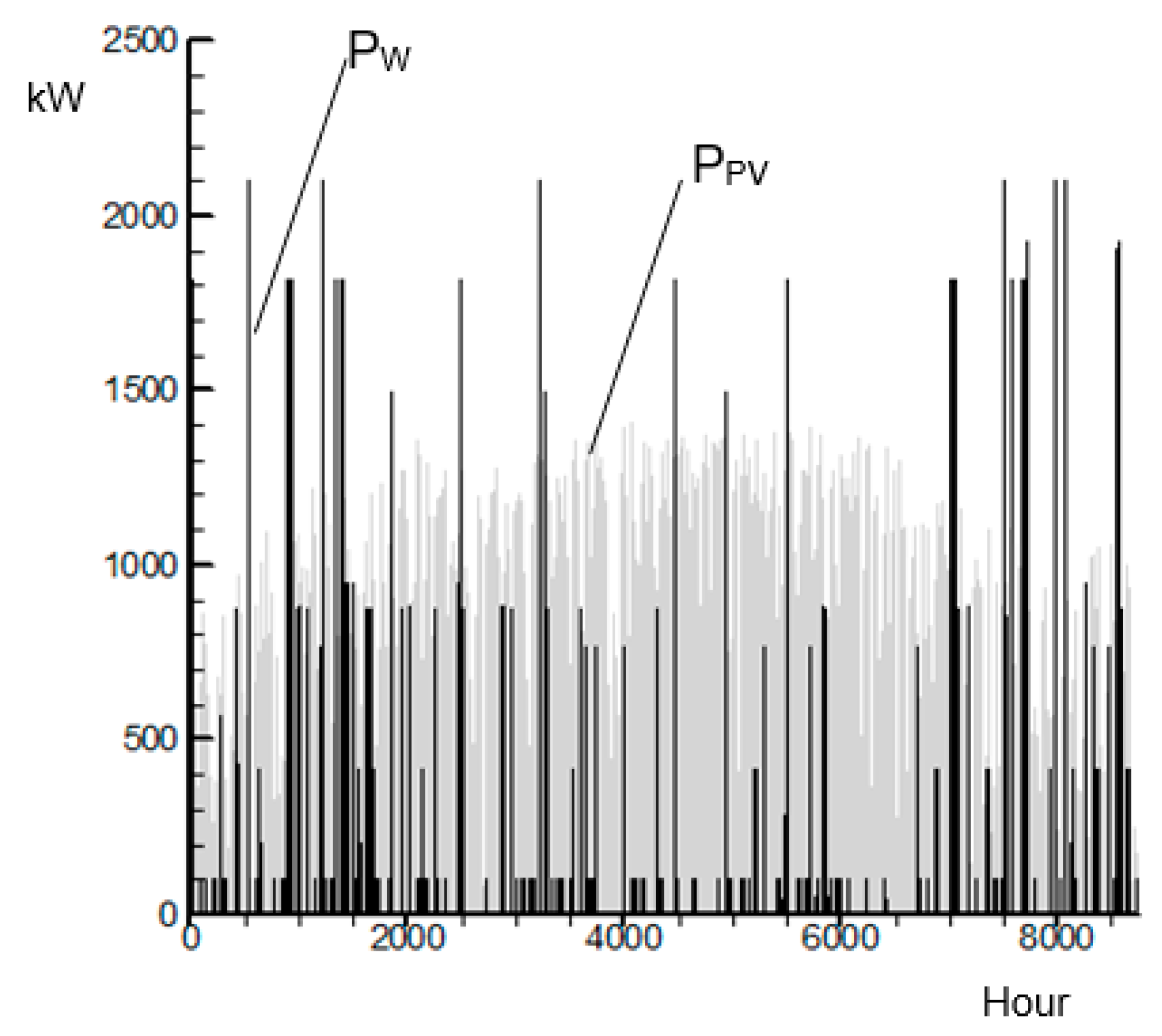

4.1. RES Generation

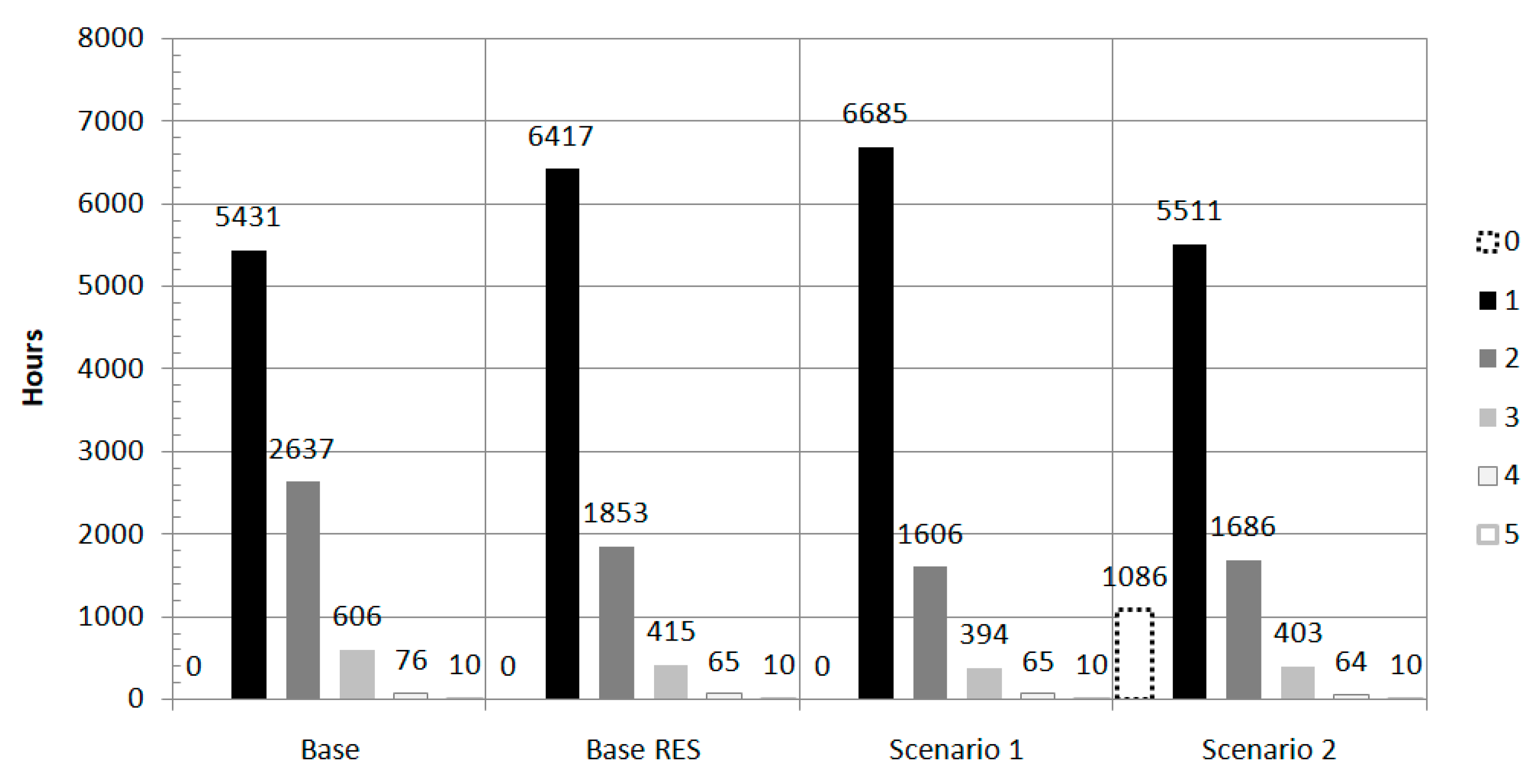

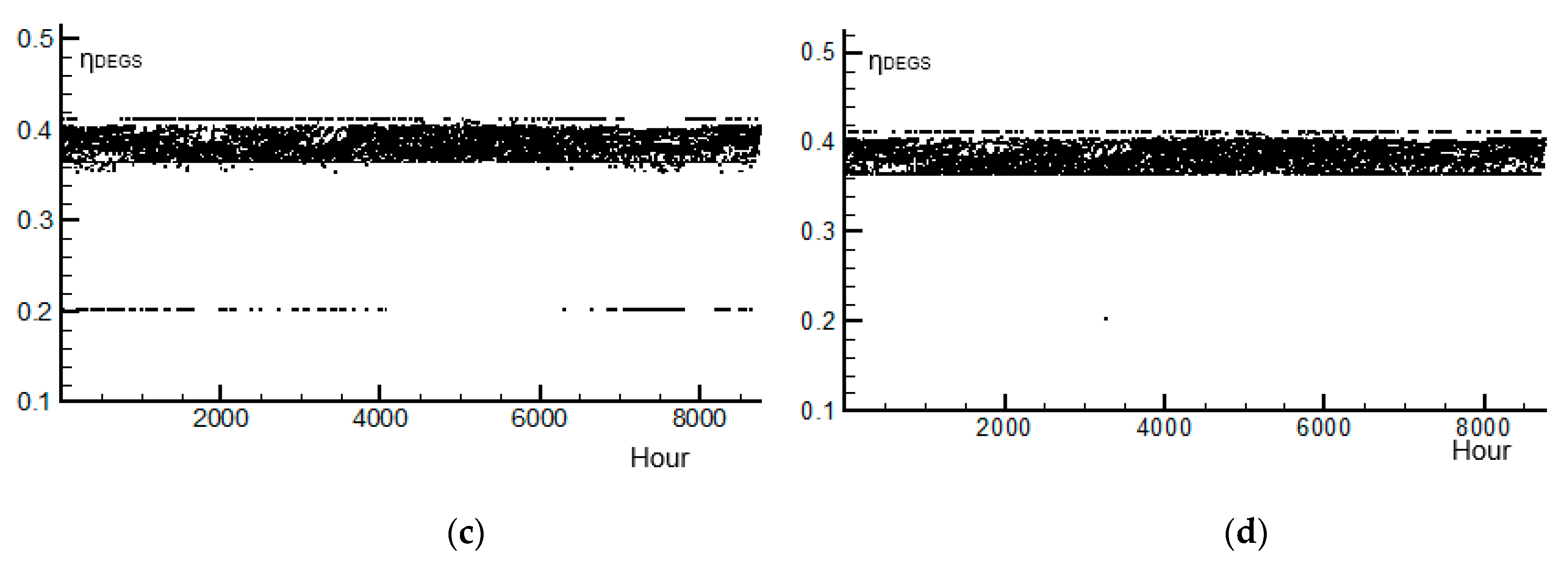

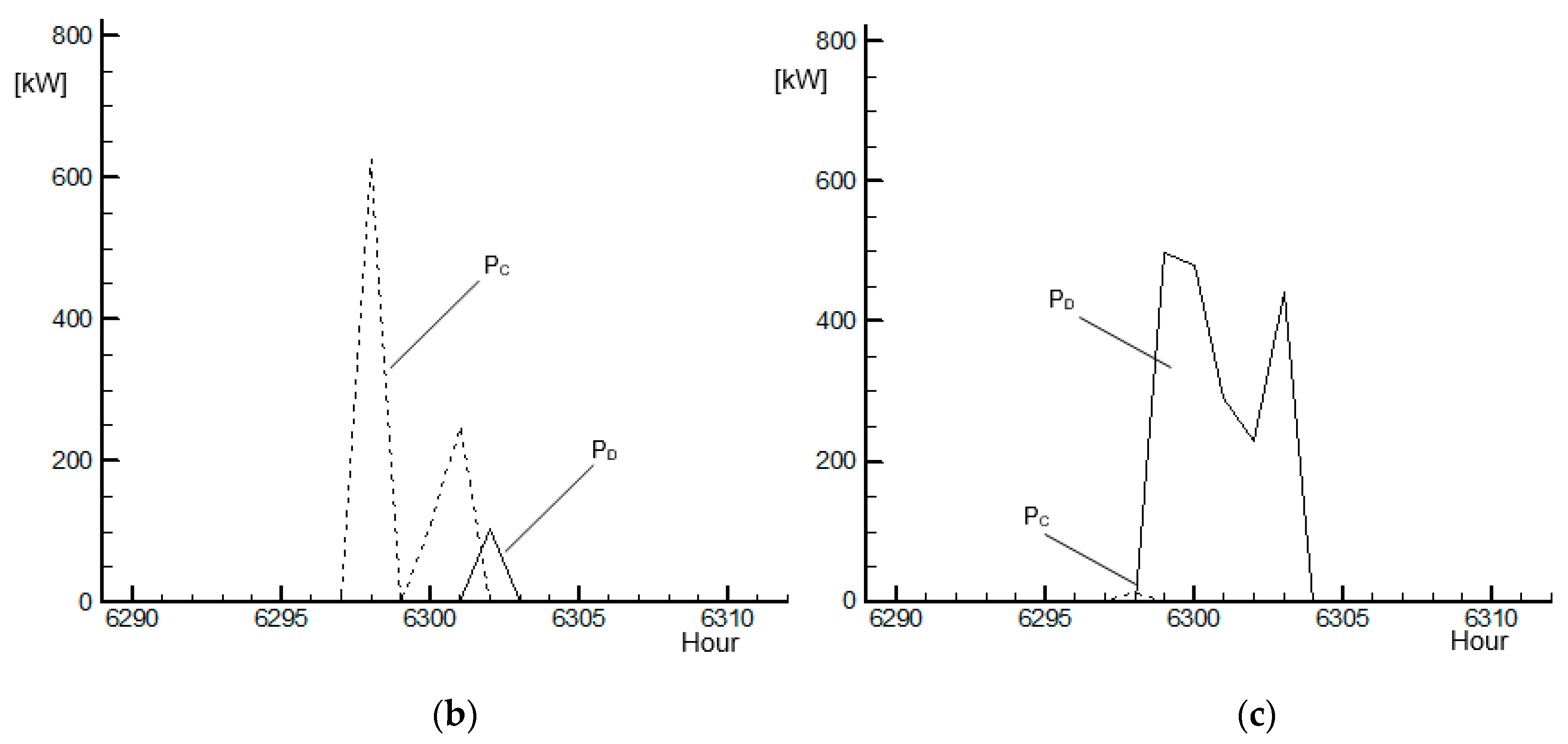

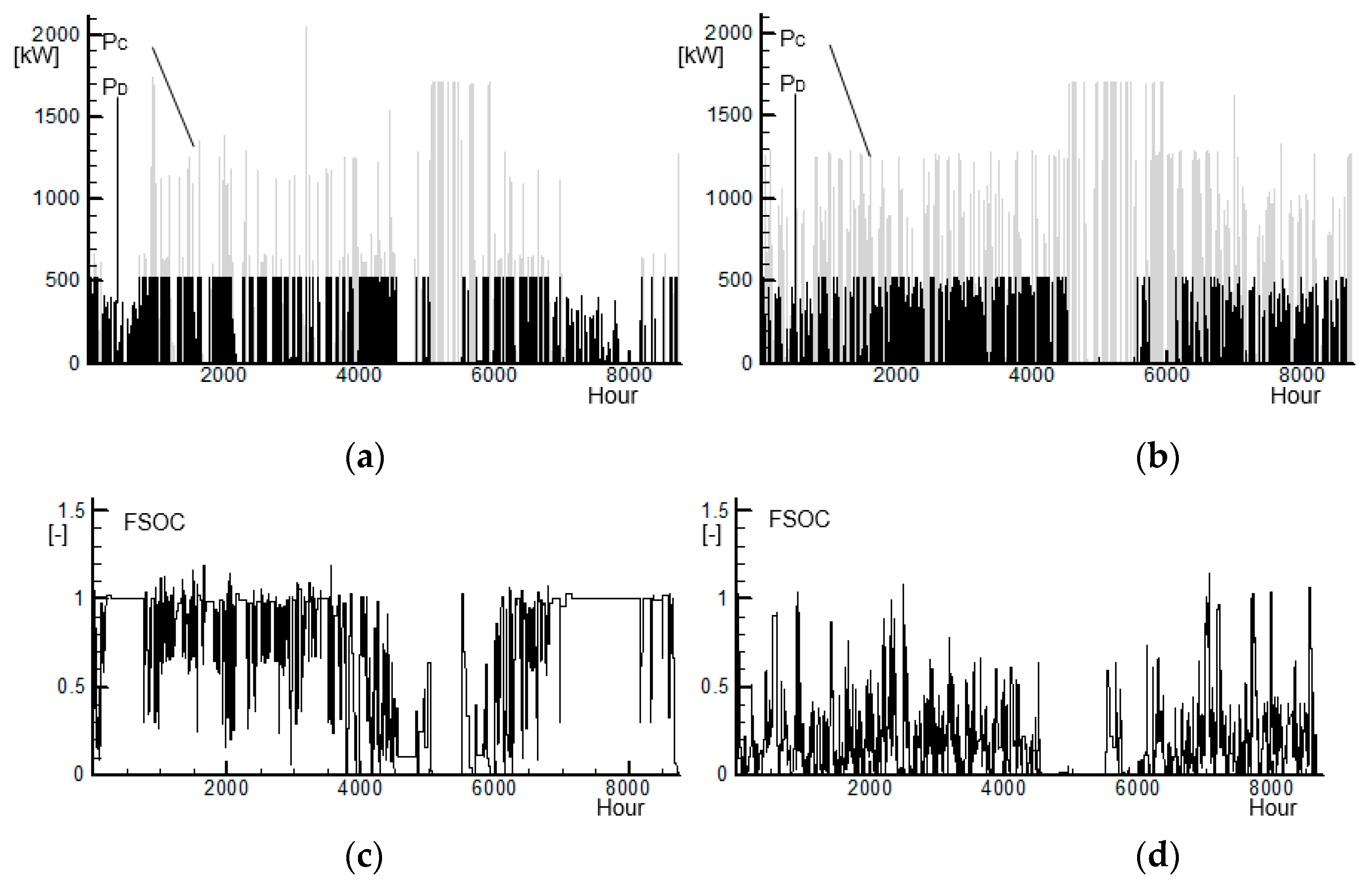

4.2. Analysis of Dispatch Strategies

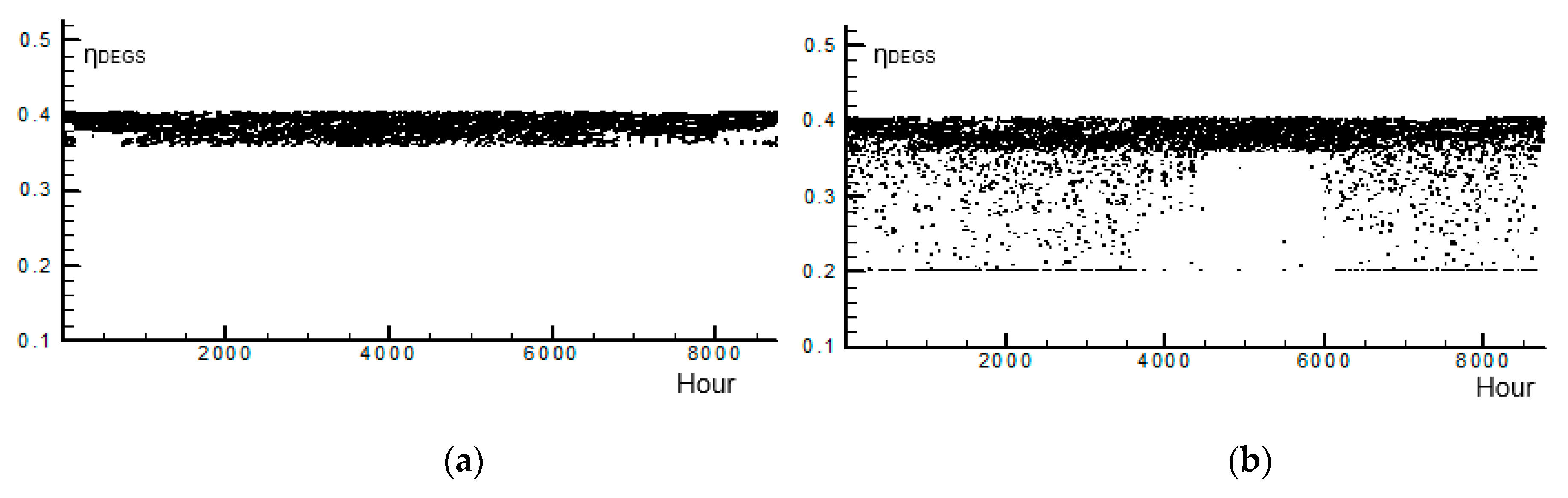

4.3. Energy System Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| D01 | On-off flag for diesel engines e.g. D01 = 1 on; D01 = 0 off |

| DEGS | Diesel engine gen-set |

| E | Energy |

| FB | Charge/discharge limit |

| FC | Upper limit on FSOC. If FSOC > FC charging is not allowed |

| FD | Lower limit on FSOC. If FSOC < FD discharging is not allowed |

| FSOC | Fractional State of Charge |

| ISWEC | Inertial Sea Wave Energy Converter |

| NDEGS | Number of diesel engines |

| P | Power |

| PLIMIT | Inverter maximum power limit |

| PDmaxI | Maximum discharge power allowed |

| PRATED | Engine’s rated power |

| PREF | Engine’s reference power |

| RES | Renewable Energy Sources |

| XLOW | Lower engine power set point |

| XUP | Upper engine power set point |

| ηDEGS | Diesel engine efficiency |

| Subscripts | |

| C | Charge |

| C-DEGS | DEGS power share to contribution to storage |

| D | Discharge |

| DEGS-R | Residual power from DEGS (after RES and storage contributions) |

| DUMP | Energy dump from RES/DEGS |

| EXR | Surplus energy from RES |

| EXRD | Surplus from RES and DEGS |

| IN | Input |

| LOAD | Net load |

| m | Minimum |

| M | Maximum |

| OUT | Output |

| PV | Photovoltaic |

| U | End user demand |

References

- Kuang, Y.; Zhang, Y.; Zhou, B.; Li, C.; Cao, Y.; Li, L.; Zeng, L. A review of renewable energy utilization in islands. Renew. Sustain. Energy Rev. 2016, 59, 504–513. [Google Scholar] [CrossRef]

- Bénard-Sora, F.; Praene, J.P. Territorial analysis of energy consumption of a small remote island: Proposal for classification and highlighting consumption profiles. Renew. Sustain. Energy Rev. 2016, 59, 636–648. [Google Scholar] [Green Version]

- Marín, C.; Alves, L.M.; Zervos, A. 100% RES-A Challenge for Island Sustainable Development; Instituto Superior Tecnico; Mechanical Engineering Department: Lisboa, Portugal, 2005. [Google Scholar]

- Leal Filho, W.; Mannke, F.; Mohee, R.; Schulte, V. Climate-Smart Technologies: Integrating Renewable Energy Efficiency in Mitigation and Adaptation Responses; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Eurelectric EU. Islands: Towards a Sustainable Energy Future; Report; Eurelectric EU: Brussels, Belgium, June 2012. [Google Scholar]

- IRENA. GREIN-Global Renewable Energy Islands Network. Supporting Island Transitions to a Renewable Energy Future. Available online: http://www.irena.org/ (accessed on 26 August 2019).

- Rocky Mountain Institute and Carbon War Room. The Ten Island Renewable Challenge. Available online: http://carbonwarroom.com/content/islands-energy-program (accessed on 26 August 2019).

- Legambiente. Smart Energy Islands-11 Islands in Transition Toward 100% Renewable; Legambiente: Rome, Italy, 2018. (In Italian) [Google Scholar]

- Mwangi, J.K.; Lee, W.J.; Chang, Y.C.; Chen, C.Y.; Wang, L.C. An overview: Energy saving and pollution reduction by using green fuel blends in diesel engines. Appl. Energy 2015, 159, 214–236. [Google Scholar]

- Corsini, A.; Rispoli, F.; Gamberale, M.; Tortora, E. Assessment of H2- and H2O-based renewable energy buffering systems in minor islands. Renew. Energy 2009, 34, 279–288. [Google Scholar]

- Kusakana, K. Optimization of the daily operation of a hydrokinetic–diesel hybrid system with pumped hydro storage. Energy Convers. Manag. 2015, 106, 901–910. [Google Scholar] [CrossRef]

- Ibrahim, H.; Younès, R.; Basbous, T.; Ilinca, A.; Dimitrova, M. Optimization of diesel engine performances for a hybrid wind-diesel system with compressed air energy storage. Energy 2011, 3079–3091. [Google Scholar] [CrossRef]

- Phuangpornpitak, N.; Kumar, S. User acceptance of diesel/PV hybrid system in an island community. Renew. Energy 2011, 36, 125–131. [Google Scholar] [CrossRef]

- Razak, J.A.; Sopian, K.; Nopiah, Z.M.; Zaharim, A.; Ali, Y. Optimal operational strategy for hybrid renewable energy system using genetic algorithms. In Proceedings of the 12th WSEAS International Conference on Applied Mathematics, Cairo, Egypt, 29–31 December 2007. [Google Scholar]

- Kaldellis, J.K.; Kapsali, M.; Tiligadas, D. Presentation of a stochastic model estimating the wind energy contribution in remote island electrical networks. Appl. Energy 2012, 97, 68–76. [Google Scholar]

- Parisio, A.; Rikos, E.; Tzamalis, G.; Glielmo, L. Use of model predictive control for experimental micro-grid optimization. Appl. Energy 2014, 115, 37–46. [Google Scholar] [CrossRef]

- Rezzouk, H.; Mellit, A. Feasibility study and sensitivity analysis of a stand-alone photovoltaic-diesel-battery hybrid energy system in the north of Algeria. Renew. Sustain. Energy Rev. 2015, 1134–1150. [Google Scholar]

- Dufo-López, R.; Bernal-Agustín, J.L.; Contreras, J. Optimization of control strategies for stand-alone renewable energy systems with hydrogen storage. Renew. Energy 2007, 1102–1126. [Google Scholar]

- Neves, D.; Silva, C.A. Optimal electricity dispatch on isolated mini-grids using a demand response strategy for thermal storage backup with genetic algorithms. Energy 2015, 82, 436–445. [Google Scholar] [CrossRef]

- Garcia, R.S.; Weisser, D. A wind-diesel system with hydrogen storage: Joint optimisation of design and dispatch. Renew Energy 2006, 31, 2296–2320. [Google Scholar] [CrossRef]

- Di Silvestre, M.L.; La Cascia, D.; Riva Sanseverino, E.; Zizzo, G. Improving the energy efficiency of an islanded distribution network using classical and innovative computation methods. Util. Policy 2016, 40, 58–66. [Google Scholar] [CrossRef]

- Alvarez, E.; Campos, A.M.; Arboleya, P.; Gutiérrez, A.J. Microgrid management with a quick response optimization algorithm for active power dispatch. Electr. Power Energy Syst. 2012, 43, 465–473. [Google Scholar] [CrossRef]

- Cozzolino, R.; Tribioli, L.; Bella, G. Power management of a hybrid renewable system for artificial islands: A case study. Energy 2016, 106, 774–789. [Google Scholar]

- Hu, Y.; Morales, J.M.; Pineda, S.; Sánchez, M.J.; Solana, P. Dynamic multi-stage dispatch of isolated wind–diesel power systems. Energy Convers. Manag. 2015, 103, 605–615. [Google Scholar] [CrossRef]

- Drouilhet, S.M.; Shirazi, M. Wales Alaska High-Penetration Wind-Diesel Hybrid Power System: Theory of Operation; National Renewable Energy Laboratory: Golden, CO, USA, 2002. [Google Scholar]

- Corsini, A.; Tortora, E. Sea-Water Desalination for Load Levelling of Gen-Sets in Small Off-Grid Islands. Energies 2018, 11, 2068. [Google Scholar] [CrossRef]

- Italian Military Air Force-Meteorological Service. Italian Climate Atlas for Years 1971–2000; Ministero della Difesa, Aeronautica Militare: Roma, Italy, 2009. [Google Scholar]

- Italian Military Air Force-Experimental Aeronautical Meteorology Department. Global Solar Radiation and Insolation Duration in Italy from Year 1991 to 2010; Ministero della Difesa, Aeronautica Militare: Roma, Italy, 2012. [Google Scholar]

- Latina Province Web-Gis Atlas. 2019. Available online: https://sit.provincia.latina.it/web-gis.html (accessed on 26 August 2019).

- Corsini, A.; Tortora, E.; Cima, E. Preliminary assessment of wave energy use in an off-grid minor island desalination plant. Energy Proced. 2015, 82, 789–796. [Google Scholar]

- Latina Province Energy and Environment Plan. 2007. Available online: www.provincia.latina.it (accessed on 26 August 2019).

- Klein, S.A.; Beckam, W.A.; Mitchell, J.W.; Braun, J.E.; Evans, B.L.; Kummert, J.P. TRNSYS–A Transient System Simulation Program; Version 15.1; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2000. [Google Scholar]

- Barley, C.D.; Byron Winn, C. Optimal dispatch strategy in remote hybrid power systems. Sol. Energy 1996, 58, 165–179. [Google Scholar] [CrossRef]

- Manchester, S.C.; Swan, L.G.; Groulx, D. Regenerative air energy storage for remote wind-diesel micro-grid communities. Appl. Energy 2015, 137, 490–500. [Google Scholar]

- Municipality of Ponza. Tender Notice for the Launch of a Competitive Dialog Procedure for the Proposal Selection Aimed at the Realization. Management and Operation of the Energy Generation Plant in “Monte Pagliaro”; Attachment N.1—General Technical Prescriptions; Ponza Municipality: Ponza, Italy, November 2014. [Google Scholar]

- Bracco, G.; Cagninei, A.; Giorcelli, E.; Mattiazzo, G.; Poggi, D.; Raffero, M. Experimental validation of the ISWEC wave to PTO model. Ocean Eng. 2016, 120, 40–51. [Google Scholar] [CrossRef]

| Month | Mean Temp. [27] | Min. Temp. [27] | Max. Temp [27] | Min Humidity [27] | Max Humidity [27] | Global Solar Radiation [28] |

|---|---|---|---|---|---|---|

| (°C) | (°C) | (°C) | (%) | (%) | (MJ/m2/d) | |

| 1 | 10.4 | 8.8 | 12.1 | 62 | 88 | 6.8 |

| 2 | 10.3 | 8.4 | 12.1 | 59 | 88 | 10.2 |

| 3 | 11.4 | 9.3 | 13.5 | 59 | 90 | 15.0 |

| 4 | 13.3 | 11.0 | 15.7 | 61 | 92 | 19.5 |

| 5 | 17.5 | 14.8 | 20.3 | 59 | 93 | 23.8 |

| 6 | 21.4 | 18.4 | 24.5 | 56 | 92 | 26.6 |

| 7 | 24.2 | 21.1 | 27.4 | 54 | 92 | 27.3 |

| 8 | 25.0 | 21.9 | 28.0 | 57 | 92 | 23.3 |

| 9 | 22.0 | 19.4 | 24.6 | 61 | 90 | 17.7 |

| 10 | 18.3 | 16.2 | 20.3 | 63 | 90 | 12.2 |

| 11 | 14.2 | 12.5 | 16.0 | 61 | 88 | 7.7 |

| 12 | 11.7 | 10.0 | 13.2 | 62 | 87 | 5.9 |

| Main Power Plant—Provisional Plant of Monte Pagliaro | |

| DEUTZ TCD 2020 | 1.5 MW |

| DEUTZ 620 | 1.5 MW |

| DEUTZ TZ 2046 | 1.6 MW |

| Caterpillar 3516 I | 1.6 MW |

| Sub-tot | 6.2 MW |

| Peak Shaving Power Plant—Plant of Cala dell’Acqua (Le Forna) | |

| Caterpillar 3516 HD | 1.3 MW |

| Caterpillar 3516 HD | 1.3 MW |

| Sub-tot | 2.6 MW |

| Tot | 8.8 MW |

| Power Technology | Units | Nominal Power |

|---|---|---|

| DEGS | Six units of 1380 kWp | 8.30 MW |

| PV array | 7018 panels of 285 Wp | 2.00 MW |

| ISWEC array | 35 units of 60 kWp | 2.10 MW |

| Battery storage | 90 modules of 6.25 kW Capacity 22.5 kWh Round trip efficiency 90% | 0.56 MW |

| Month | EPV | EW | ERES | EU |

|---|---|---|---|---|

| MWh | MWh | MWh | MWh | |

| 1 | 110.28 | 20.93 | 131.21 | 694.60 |

| 2 | 124.86 | 51.17 | 176.03 | 642.85 |

| 3 | 184.81 | 22.43 | 207.25 | 718.53 |

| 4 | 211.77 | 22.18 | 233.95 | 712.34 |

| 5 | 245.04 | 19.74 | 264.78 | 757.03 |

| 6 | 252.91 | 8.00 | 260.92 | 1055.88 |

| 7 | 281.57 | 7.79 | 289.35 | 1391.95 |

| 8 | 268.42 | 15.20 | 283.62 | 1710.82 |

| 9 | 222.02 | 3.29 | 225.31 | 1010.48 |

| 10 | 174.71 | 16.79 | 191.49 | 670.32 |

| 11 | 119.73 | 49.58 | 169.31 | 612.17 |

| 12 | 100.17 | 25.85 | 126.03 | 685.71 |

| Total | 2296.30 | 262.95 | 2559.26 | 10662.69 |

| End-Points | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 80 | 81 | 82 | 83 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scen. 1 h | 0 | 331 | 0 | 194 | 6484 | 166 | 103 | 0 | 198 | 873 | 102 | 25 | 253 | 0 | 31 |

| Scen. 2 h | 503 | 0 | 0 | 22 | 6484 | 0 | 0 | 561 | 0 | 0 | 0 | 532 | 173 | 0 | 485 |

| Scenario | Base | Base-RES | 1 | 2 |

|---|---|---|---|---|

| Output (MWh/y) | 10,663.68 | 8326.761 | 9042.86 | 8734.78 |

| Overall duty time (h/y) | 12,877 | 11,678 | 11,389 | 10,398 |

| Mean power (kW) | 828.12 | 713.03 | 794.00 | 840.04 |

| Mean electric efficiency | 0.3842 | 0.3638 | 0.3753 | 0.3842 |

| Fuel consumption (103 L) | 2802.17 | 2242.73 | 2390.98 | 2288.36 |

| Specific fuel consumption (L/kWh) | 0.2649 | 0.2693 | 0.2644 | 0.2620 |

| Carbon Dioxide emissions (tCO2eq/y) | 8530.91 | 6772.17 | 7219.84 | 6909.96 |

| Active Engines | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Base | 899.50 | 761.72 | 810.94 | 809.02 | 818.90 |

| Base RES | 681.71 | 724.66 | 802.96 | 816.62 | 818.90 |

| Scenario 1 | 801.90 | 755.32 | 839.16 | 850.24 | 862.67 |

| Scenario 2 | 869.72 | 786.19 | 849.50 | 846.36 | 862.67 |

| Month | Scenario 1 | Scenario 2 | ||||

|---|---|---|---|---|---|---|

| EC | ED | EDump | EC | ED | EDump | |

| MWh | MWh | MWh | MWh | MWh | MWh | |

| 1 | 7.55 | 13.70 | 8.58 | 34.25 | 14.75 | 0.49 |

| 2 | 22.72 | 16.16 | 17.52 | 51.11 | 15.36 | 13.18 |

| 3 | 28.90 | 18.92 | 5.16 | 66.08 | 26.42 | 0.00 |

| 4 | 19.10 | 11.14 | 1.86 | 57.87 | 20.96 | 4.65 |

| 5 | 22.97 | 15.90 | 9.29 | 55.93 | 29.43 | 0.00 |

| 6 | 30.62 | 18.50 | 0.00 | 46.13 | 22.62 | 0.00 |

| 7 | 13.45 | 12.03 | 0.00 | 42.13 | 5.46 | 0.00 |

| 8 | 31.88 | 2.14 | 0.00 | 32.47 | 3.61 | 0.00 |

| 9 | 33.54 | 22.15 | 0.00 | 77.56 | 12.39 | 0.00 |

| 10 | 10.82 | 12.94 | 11.73 | 55.09 | 18.21 | 2.79 |

| 11 | 0.00 | 7.57 | 27.32 | 54.78 | 15.00 | 12.49 |

| 12 | 9.66 | 6.49 | 10.80 | 38.69 | 14.81 | 3.10 |

| Total | 231.20 | 157.65 | 92.27 | 612.09 | 199.03 | 36.70 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corsini, A.; Cedola, L.; Lucchetta, F.; Tortora, E. Gen-Set Control in Stand-Alone/RES Integrated Power Systems. Energies 2019, 12, 3353. https://doi.org/10.3390/en12173353

Corsini A, Cedola L, Lucchetta F, Tortora E. Gen-Set Control in Stand-Alone/RES Integrated Power Systems. Energies. 2019; 12(17):3353. https://doi.org/10.3390/en12173353

Chicago/Turabian StyleCorsini, Alessandro, Luca Cedola, Francesca Lucchetta, and Eileen Tortora. 2019. "Gen-Set Control in Stand-Alone/RES Integrated Power Systems" Energies 12, no. 17: 3353. https://doi.org/10.3390/en12173353

APA StyleCorsini, A., Cedola, L., Lucchetta, F., & Tortora, E. (2019). Gen-Set Control in Stand-Alone/RES Integrated Power Systems. Energies, 12(17), 3353. https://doi.org/10.3390/en12173353