Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application

Abstract

:1. Introduction

2. WPT Design

2.1. System Configuration

2.2. WPT Equivalent Circuit

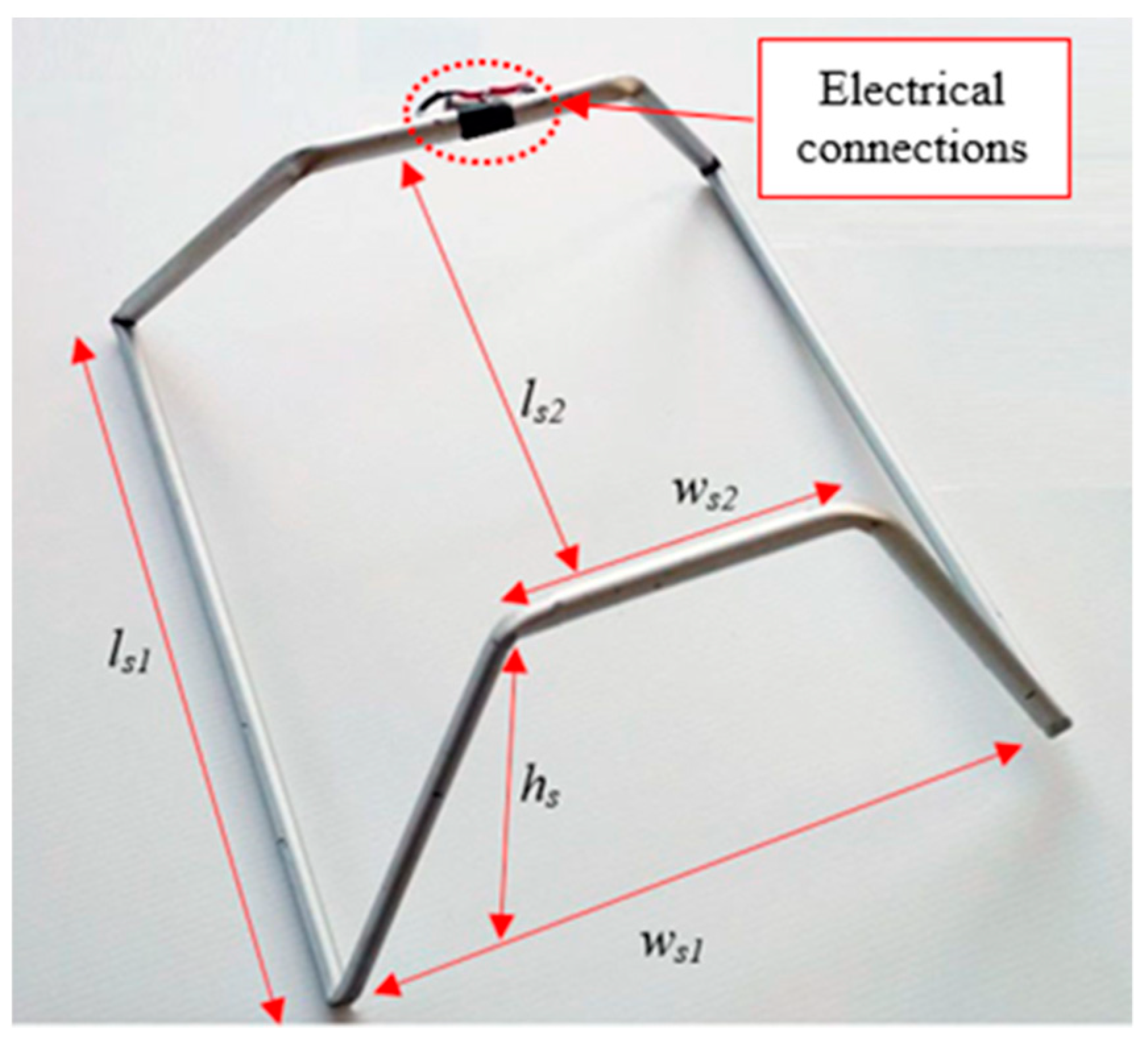

2.3. Landing Gear Design as a Secondary Coil

2.4. Design of the Primary Coil

- 1)

- Circle of diameter db;

- 2)

- Square of side sb.

3. Fabrication and Testing

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sujit, P.B.; Ghose, D. Search using multiple UAVs with flight time constraints. IEEE Trans. Aerosp. Electron. Syst. 2004, 40, 491–509. [Google Scholar] [CrossRef]

- Sarunic, P.; Evans, R. Hierarchical model predictive control of UAVs performing multitarget-multisensor tracking. IEEE Trans. Aerosp. Electron. Syst. 2014, 50, 2253–2268. [Google Scholar] [CrossRef]

- Lee, B.; Kwon, S.; Park, P.; Kim, K. Active power management system for an unmanned aerial vehicle powered by solar cells, a fuel cell, and batteries. IEEE Trans. Aerosp. Electron. Syst. 2014, 50, 3167–3177. [Google Scholar] [CrossRef]

- DIJ. Available online: https://www.dji.com/ (accessed on 14 September 2017).

- Lee, D.; Zhou, J.; Lin, W.T. Autonomous battery swapping system for quadcopter. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems (ICUAS), Denver, CO, USA, 9–12 June 2015; pp. 118–124. [Google Scholar]

- Knorr, S.; Puiatti, L.; Dallachiesa, M.; Puiatti, A. Charging Apparatus and Method for Electrically Charging Energy Storage Devices. U.S. Patent WO2015107199 A1, 23 July 2015. [Google Scholar]

- Covic, G.A.; Boys, J.T. Inductive power transfer. Proc. IEEE 2013, 101, 1276–1289. [Google Scholar] [CrossRef]

- Shinohara, N. Power without wires. IEEE Microw. Mag. 2011, 11, 64–73. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Near Field reduction in a Wireless Power Transfer System using LCC compensation. IEEE Trans. Electromagn. Compat. 2017, 59, 686–694. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; De Santis, V.; Feliziani, M. EMF safety and thermal aspects in a pacemaker equipped with a wireless power transfer system working at low frequency. IEEE Trans. Microw. Theory Tech. 2016, 64, 375–382. [Google Scholar] [CrossRef]

- Jawad, A.M.; Nordin, R.; Gharghan, S.K.; Jawad, H.M.; Ismail, M. Opportunities and Challenges for Near-Field Wireless Power Transfer: A Review. Energies 2017, 10, 1022. [Google Scholar] [CrossRef]

- Vijayakumaran Nair, V.; Choi, J.R. An Efficiency Enhancement Technique for a Wireless Power Transmission System Based on a Multiple Coil Switching Technique. Energies 2016, 9, 156. [Google Scholar] [CrossRef]

- Feliziani, M.; Campi, T.; Cruciani, S.; Maradei, F.; Grasselli, U.; Macellari, M.; Schirone, L. Robust LCC compensation in wireless power transfer with variable coupling factor due to coil misalignment. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015. [Google Scholar]

- Campi, T.; Cruciani, S.; Feliziani, M. Wireless Power Transfer Technology Applied to an Autonomous Electric UAV with a Small Secondary Coil. Energies 2018, 11, 352. [Google Scholar] [CrossRef]

- Campi, T.; Dionisi, F.; Cruciani, S.; De Santis, V.; Feliziani, M.; Maradei, F. Magnetic field levels in drones equipped with wireless power transfer technology. In Proceedings of the Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; pp. 544–547. [Google Scholar]

- Junaid, A.B.; Konoiko, A.; Zweiri, Y.; Sahinkaya, M.N.; Seneviratne, L. Autonomous Wireless Self-Charging for Multi-Rotor Unmanned Aerial Vehicles. Energies 2017, 10, 803. [Google Scholar] [CrossRef]

- Choi, C.H.; Jang, H.J.; Lim, S.G.; Lim, H.C.; Cho, S.H.; Gaponov, I. Automatic wireless drone charging station creating essential environment for continuous drone operation. In Proceedings of the 2016 International Conference on Control, Automation and Information Sciences (ICCAIS 2016), Ansan, Korea, 27–29 October 2016; pp. 132–136. [Google Scholar]

- He, X.; Bito, J.; Tentzeris, M.M. A drone-based wireless power transfer and communications platform. In Proceedings of the IEEE Wireless Power Transfer Conference (WPTC), Taipei, Taiwan, 10–12 May 2017; pp. 1–4. [Google Scholar]

- Mostafa, T.M.; Muharam, A.; Hattori, R. Wireless battery charging system for drones via capacitive power transfer. In Proceedings of the 2017 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Chongqing, China, 20–22 May 2017; pp. 1–6. [Google Scholar]

- Simic, M.; Bil, M.; Vojisavljevic, V. Investigation in Wireless Power Transmission for UAV Charging. Proc. Comput. Sci. 2015, 40, 1846–1855. [Google Scholar] [CrossRef]

- Lu, M.; Bagheri, M.; James, A.P.; Phung, T. Wireless Charging Techniques for UAVs: A Review, Reconceptualization, and Extension. IEEE Access 2018, 6, 29865–29884. [Google Scholar] [CrossRef]

- Aldhaher, S.; Mitcheson, P.D.; Arteaga, J.M.; Kkelis, G.; Yates, D.C. Light-weight wireless power transfer for mid-air charging of drones. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; pp. 336–340. [Google Scholar]

- Song, C.; Kim, H.; Kim, Y.; Kim, D.; Jeong, S.; Cho, Y.; Lee, S.; Ahn, S.; Kim, J. EMI Reduction Methods in Wireless Power Transfer System for Drone Electrical Charger Using Tightly Coupled Three-Phase Resonant Magnetic Field. IEEE Trans. Ind. Electron. 2018, 65, 6839–6849. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, B.; Xiao, W.; Qiu, D.; Chen, Y. Nonlinear Parity-Time-Symmetric Model for Constant Efficiency Wireless Power Transfer: Application to a Drone-in-Flight Wireless Charging Platform. IEEE Trans. Ind. Electron. 2019, 66, 4097–4107. [Google Scholar] [CrossRef]

- Wang, C.; Ma, Z. Design of wireless power transfer device for UAV. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation (IEEE ICMA 2016), Harbin, China, 7–10 August 2016; pp. 2449–2454. [Google Scholar]

- Muharam, A.; Mostafa, T.M.; Hattori, R. Design of power receiving side in wireless charging system for UAV application. In Proceedings of the ICSEEA 2017 International Conference on Sustainable Energy Engineering and Application, Jakarta, Indonesia, 23–24 October 2017; pp. 133–139. [Google Scholar]

- Rohan, A.; Rabah, M.; Talha, M.; Kim, S.-H. Development of Intelligent Drone Battery Charging System Based on Wireless Power Transmission Using Hill Climbing Algorithm. Appl. Syst. Innov. 2018, 1, 44. [Google Scholar] [CrossRef]

- Ure, N.K.; Chowdhary, G.; Toksoz, T.; How, J.P.; Vavrina, M.A.; Vian, J. An automated battery management system to enable persistent missions with multiple aerial vehicles. IEEE/ASME Trans. Mechatron. 2015, 20, 275–286. [Google Scholar] [CrossRef]

- Ke, D.; Liu, C.; Jiang, C.; Zhao, F. Design of an effective wireless air charging system for electric unmanned aerial vehicles. In Proceedings of the Proceedings IECON 2017 - 43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Campi, T.; Feliziani, M. Carrello di Atterraggio Per Aereomobili (Droni). IT Patent, 102018000001311, 18 January 2018. [Google Scholar]

- Hadi, G.S.; Varianto, R.; Trilaksono, B.R.; Budiyono, A. Autonomous UAV System Development for Payload Dropping Mission. J. Instrum. Autom. Syst. 2015, 1, 72–77. [Google Scholar] [CrossRef]

- Muskardin, T.; Balmer, G.; Persson, L.; Wlach, S.; Laiacker, M.; Ollero, A.; Kondak, K. A Novel Landing System to Increase Payload Capacity and Operational Availability of High Altitude Long Endurance UAVs. J. Intell. Robot. Syst. Theory Appl. 2017, 88, 597–618. [Google Scholar] [CrossRef]

- Hou, Y.X.; Guan, Y.L.; Jia, H.G.; Bo, L.; Ma, W.Y. The dynamics research on the composite undercarriage of the Unmanned Aerial Vehicle. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA 2015), Beijing, China, 2–5 August 2015. [Google Scholar]

- Zhang, W.; Mi, C.C. Compensation topologies of high-power wireless power transfer systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; De Santis, V.; Maradei, F.; Feliziani, M. Numerical Calculation of the Near Field Shielding for Carbon Fiber Reinforced Polymer (CFRP) Panels at Wireless Power Transfer Automotive Frequencies. In Proceedings of the 2018 IEEE Symposium on Electromagnetic Compatibility, Signal Integrity and Power Integrity (EMC, SI & PI), Long Beach, CA, USA, 30 July–3 August 2018; pp. 444–447. [Google Scholar]

- Tatum, J.B. Physics Topics: Electricity and Magnetism. 6 September 2006. Available online: http://astrowww.phys.uvic.ca/~tatum/elmag.html (accessed on 27 May 2019).

- Wireless Power Consortium. Available online: https://www.wirelesspowerconsortium.com/ (accessed on 15 March 2019).

- Cruciani, S.; Campi, T.; Feliziani, M. Parametric analysis of load variation in WPT systems applied to AIMDs. In Proceedings of the 46th European Microwave Conference (EuMC), London, UK, 3–7 October 2016. [Google Scholar]

| Calculated | Measured | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| L1 (μH) | L2 (μH) | M (μH) | R1 (μΩ) | R2 (μΩ) | L1 (μH) | L2 (μH) | M (μH) | R1 (μΩ) | R2 (mΩ) |

| 2.20 | 1.33 | 0.28 | - | 28 | 2.25 | 1.27 | 0.29 | 65 | 33 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application. Energies 2019, 12, 3483. https://doi.org/10.3390/en12183483

Campi T, Cruciani S, Maradei F, Feliziani M. Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application. Energies. 2019; 12(18):3483. https://doi.org/10.3390/en12183483

Chicago/Turabian StyleCampi, Tommaso, Silvano Cruciani, Francesca Maradei, and Mauro Feliziani. 2019. "Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application" Energies 12, no. 18: 3483. https://doi.org/10.3390/en12183483

APA StyleCampi, T., Cruciani, S., Maradei, F., & Feliziani, M. (2019). Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application. Energies, 12(18), 3483. https://doi.org/10.3390/en12183483