The Effect of Temperature on Flowback Data Analysis in Shale Gas Reservoirs: A Simulation-Based Study

Abstract

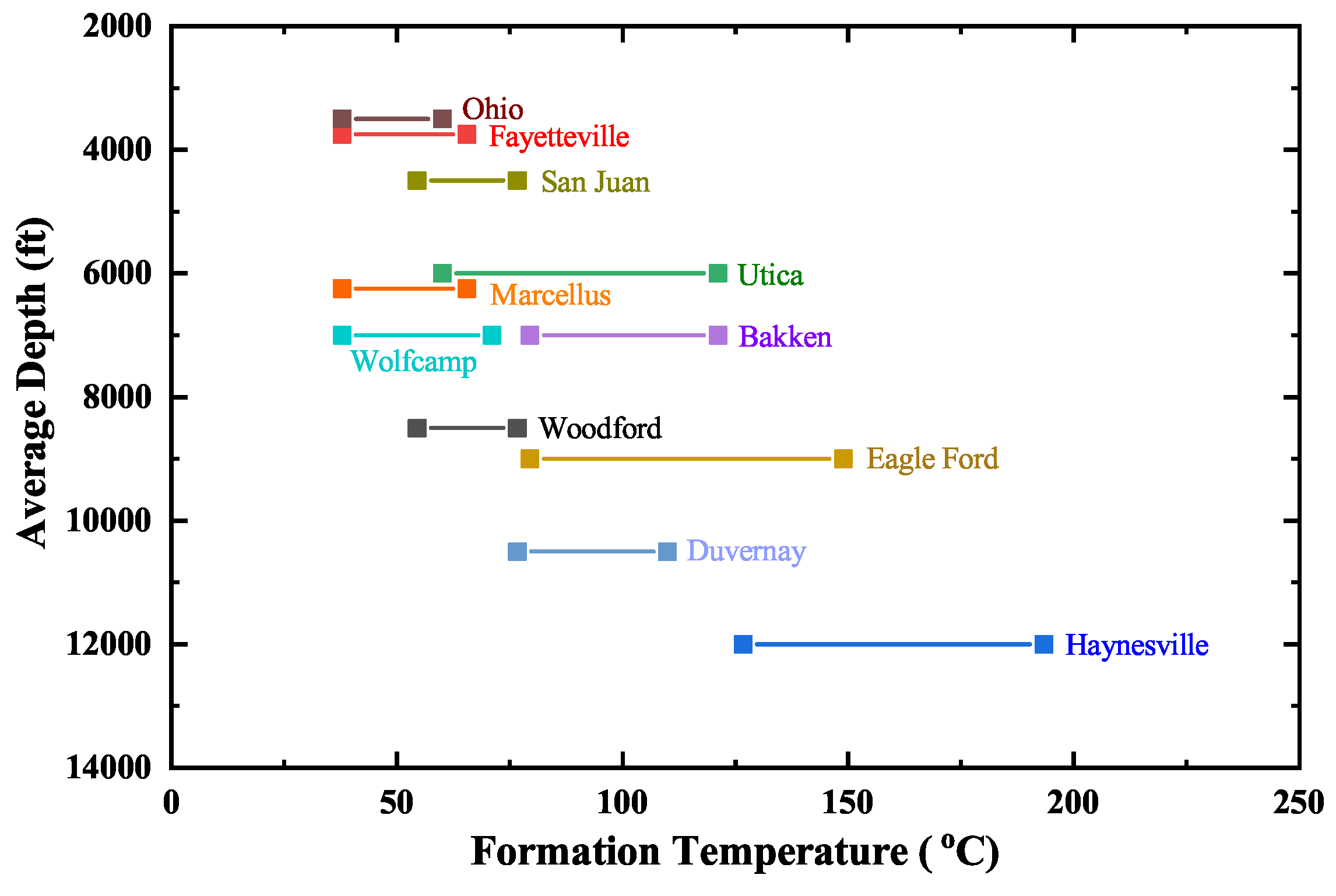

:1. Introduction

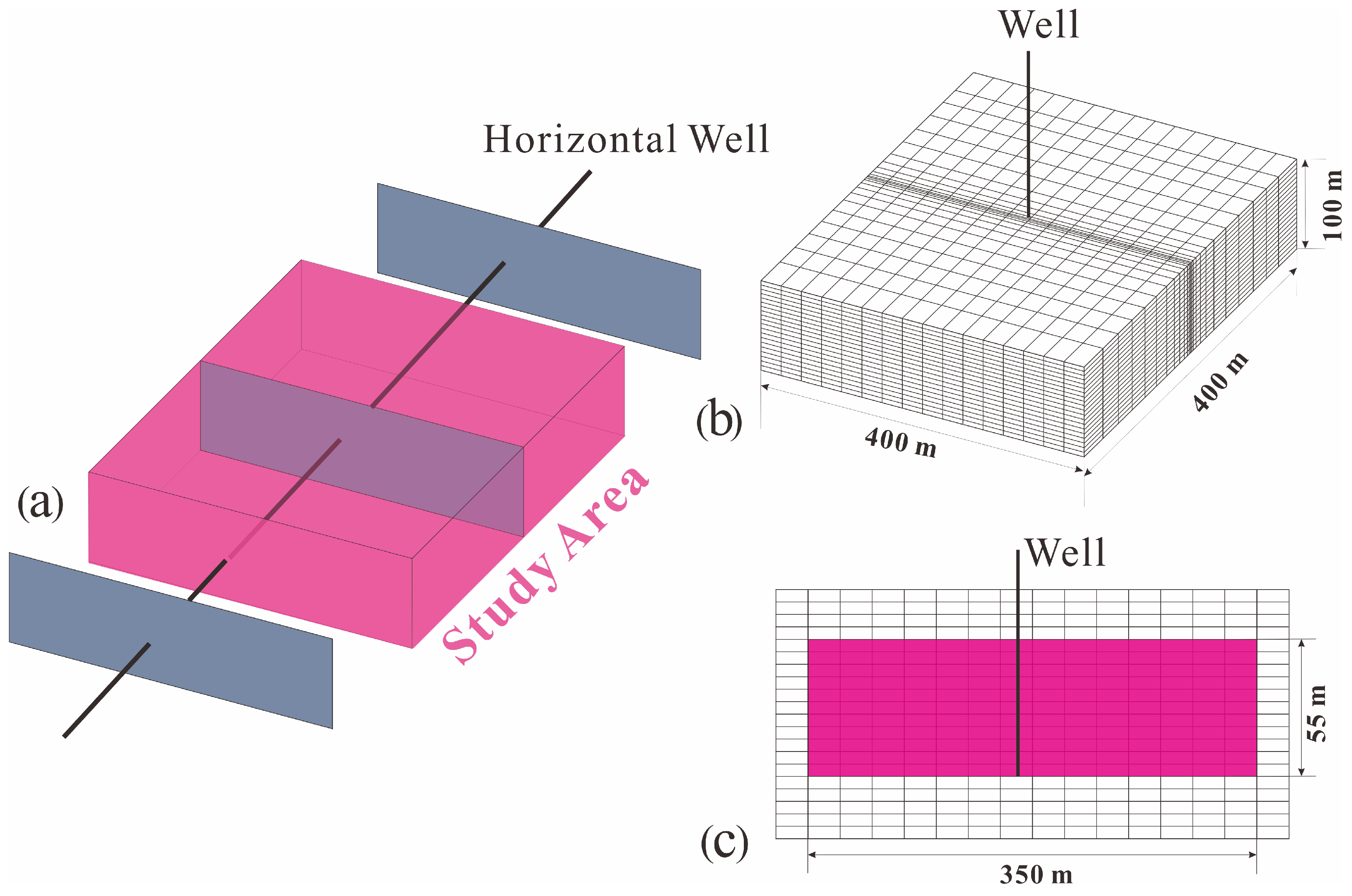

2. Model Descriptions

2.1. Reservoir and Fracture Models

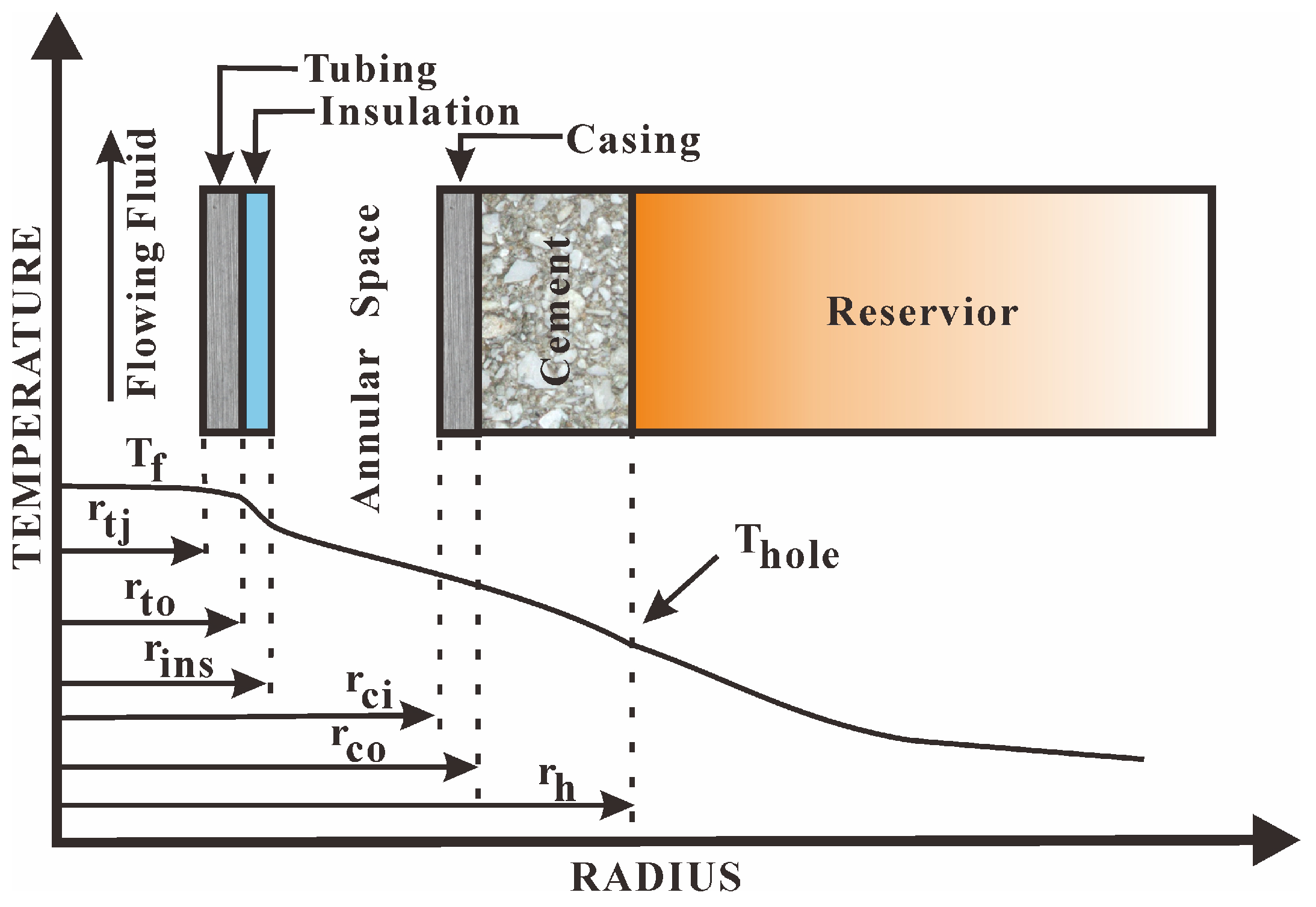

2.2. Wellbore Model

2.3. Initialization

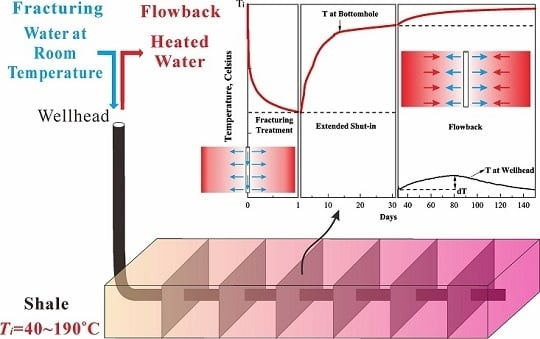

3. Temperature Changes with Time and Space

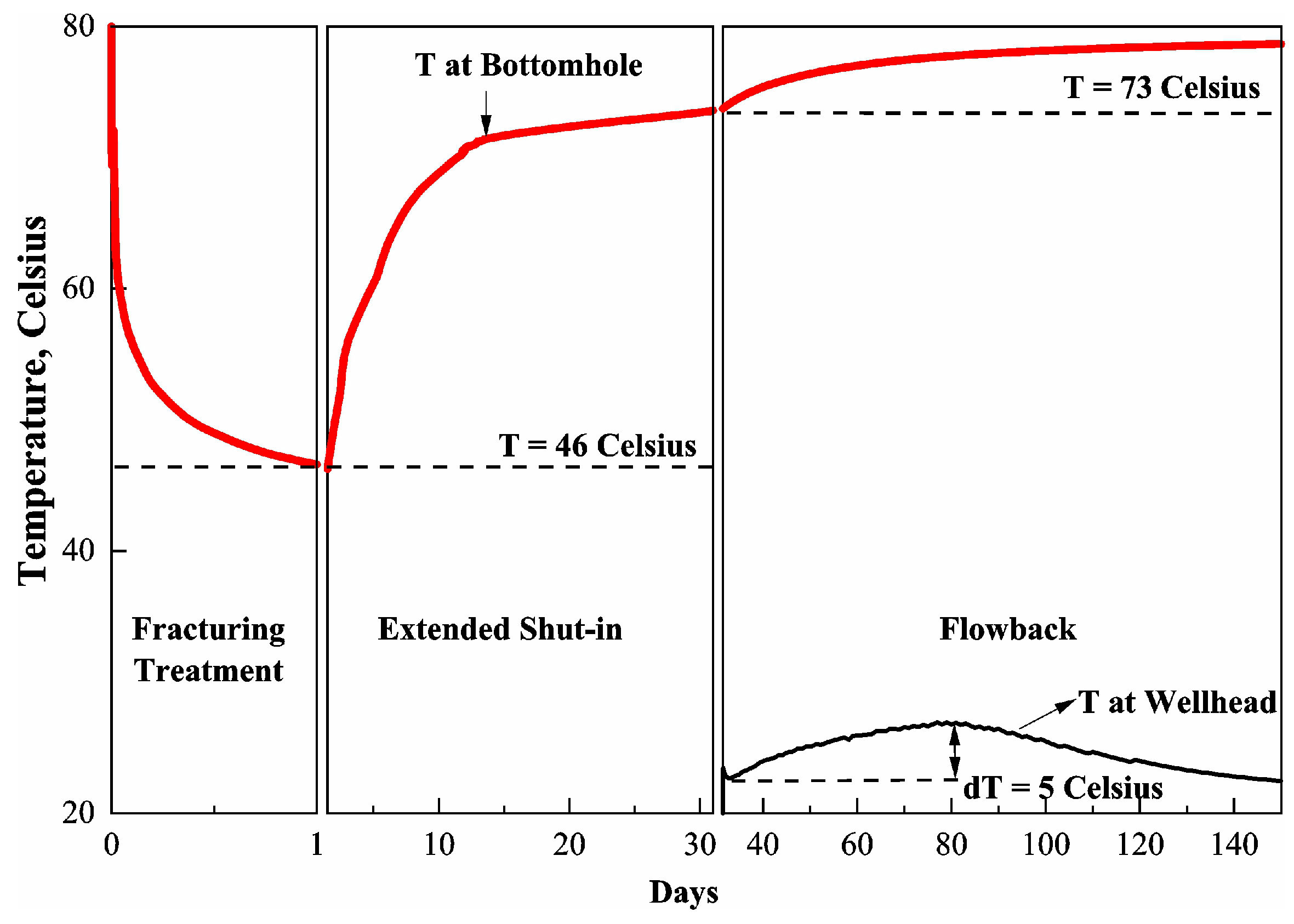

3.1. The Changes in Temperature with Time

3.2. Temperature Distribution

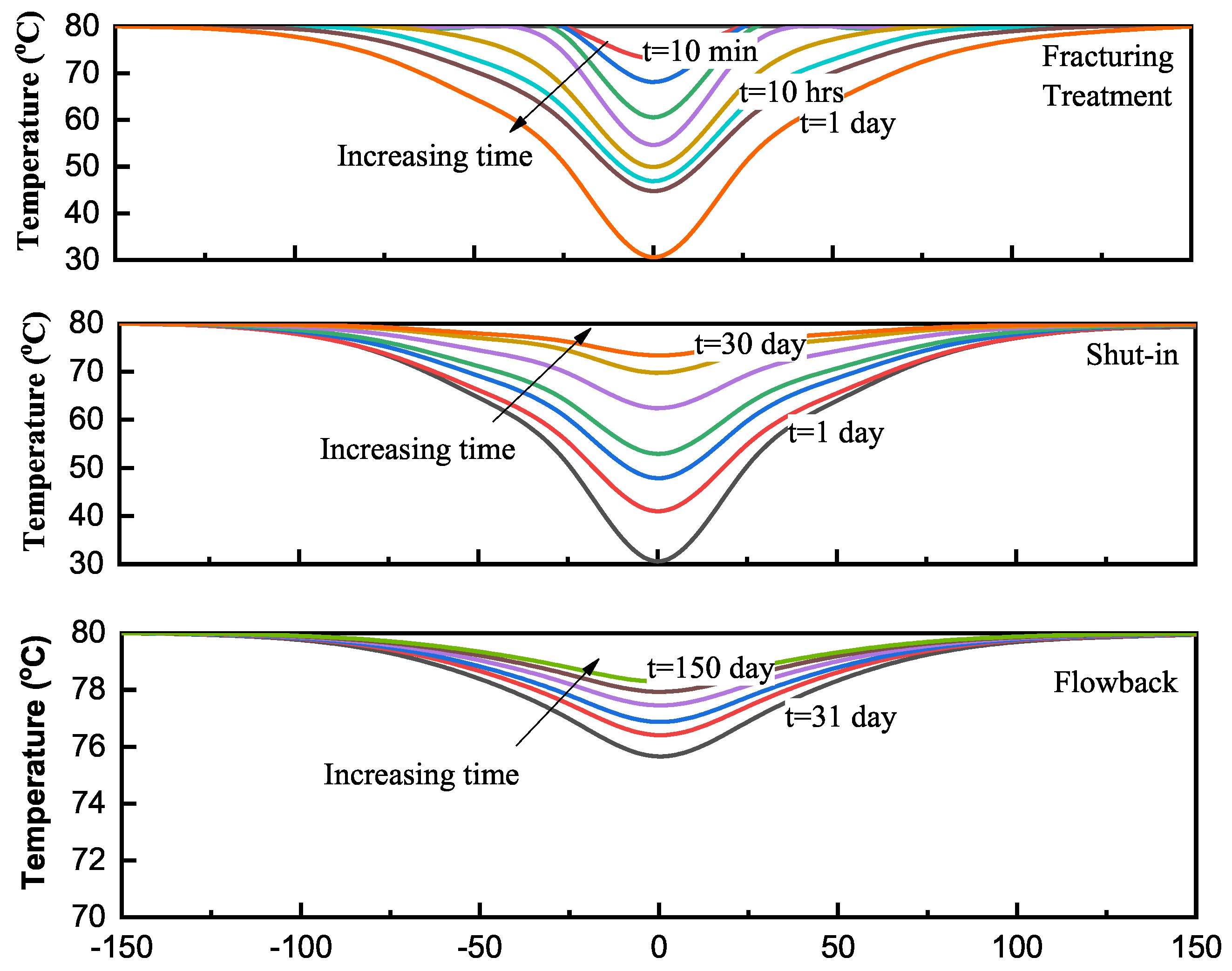

3.2.1. Temperature Profiles along Fracture

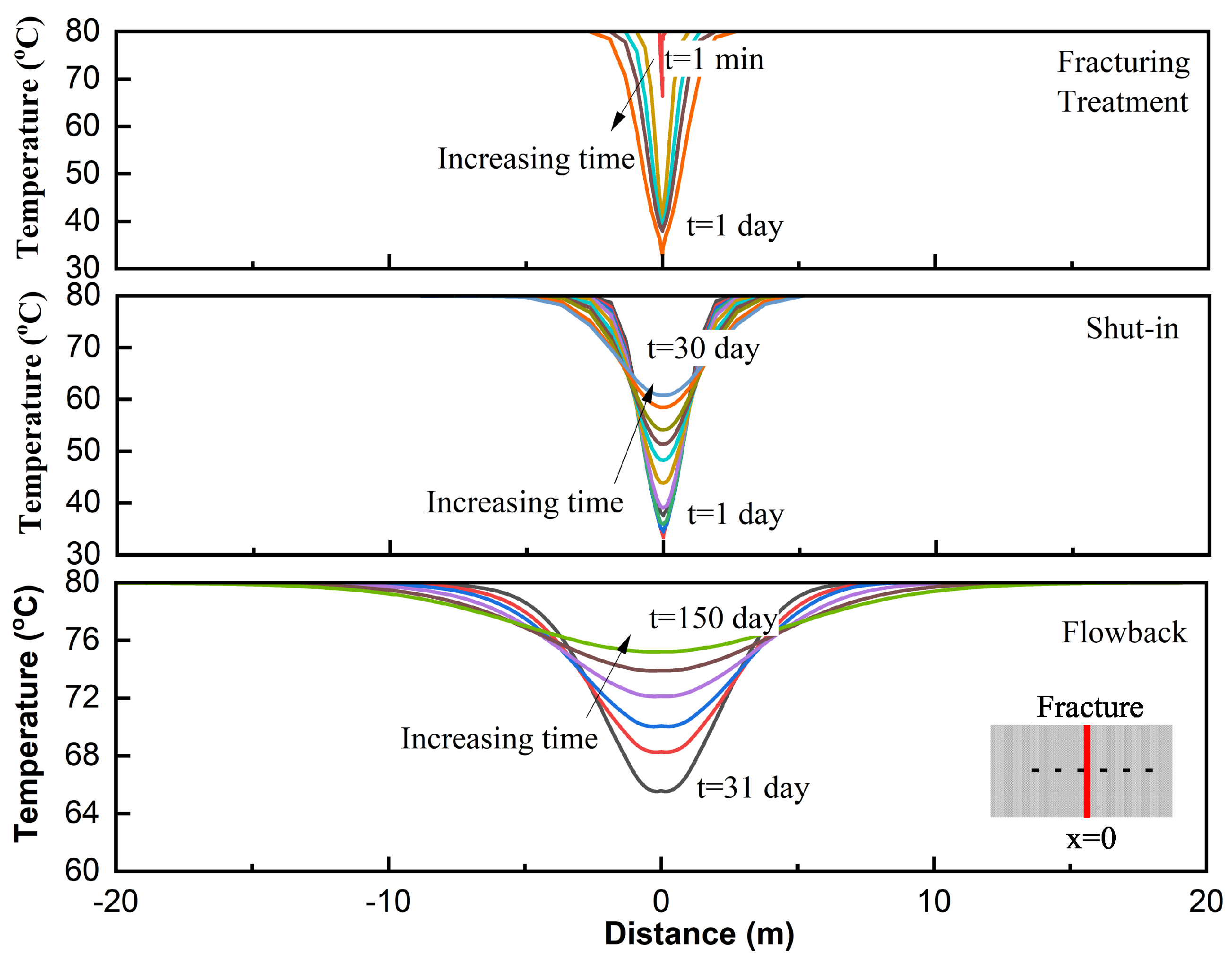

3.2.2. Temperature Profiles in Formation

3.3. Sensitivity Analysis

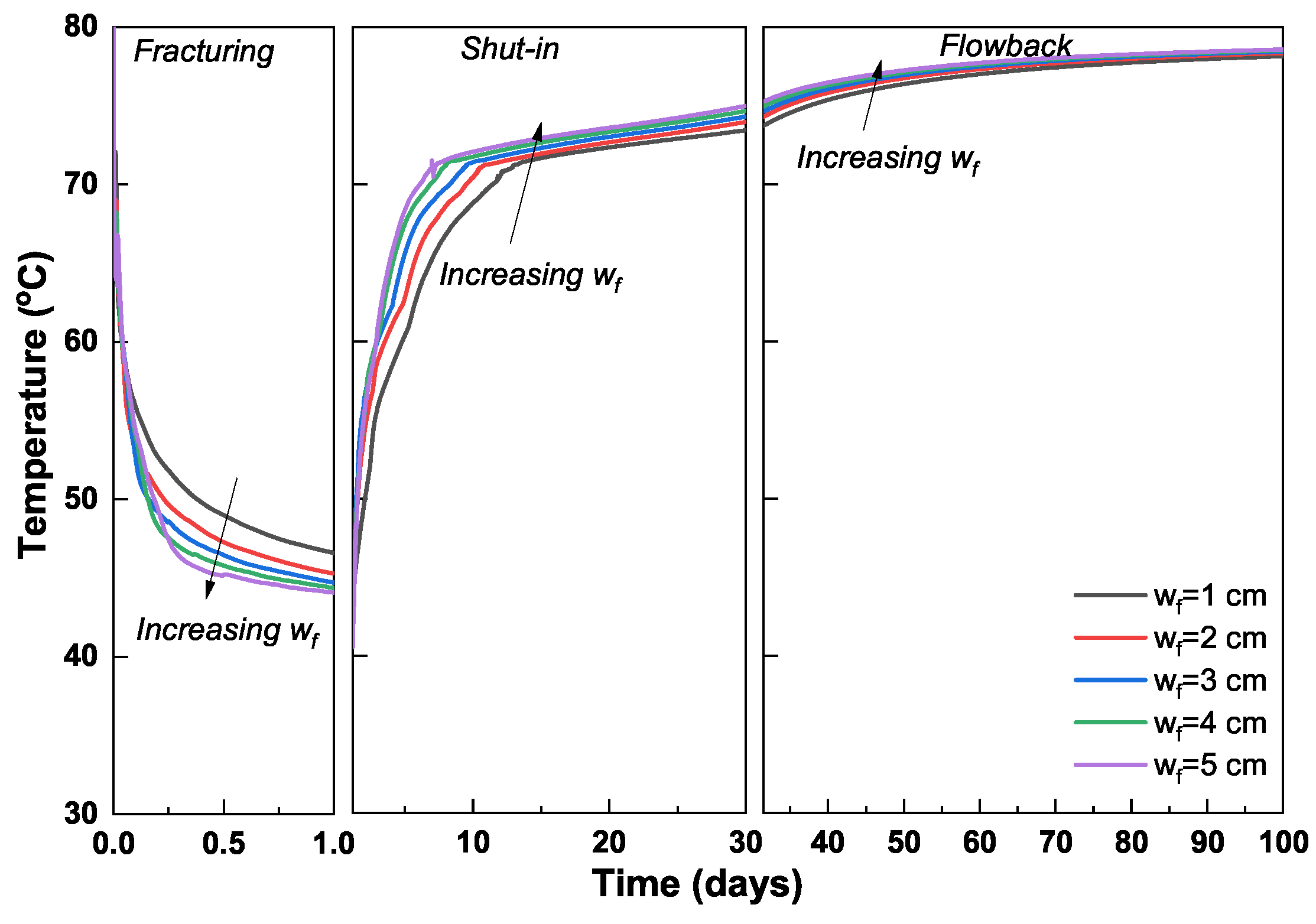

3.3.1. Case 1: Impact of Fracture Width

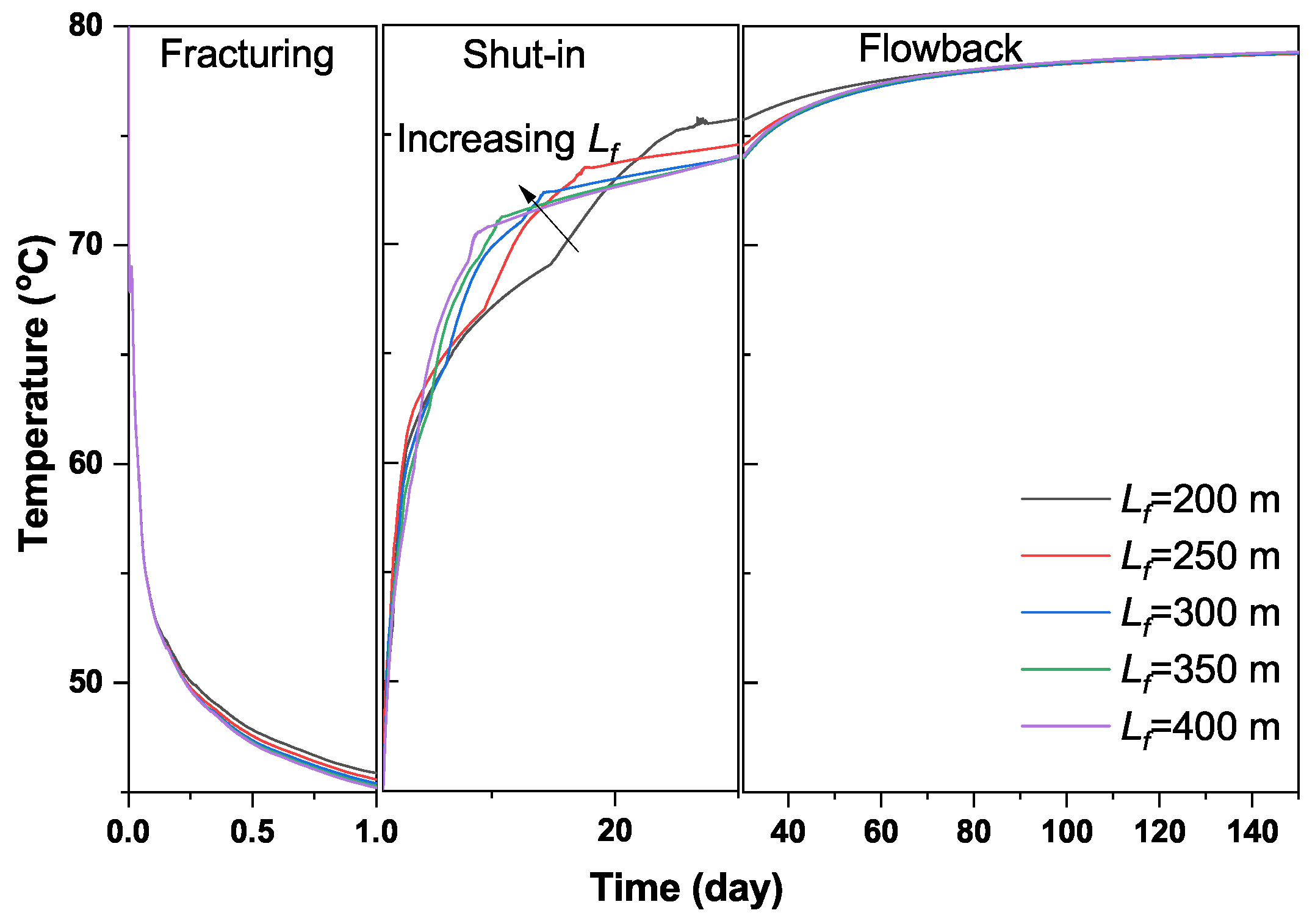

3.3.2. Case 2: Impact of Fracture Length

3.3.3. Case 3: Impact of Thermal Conductivity

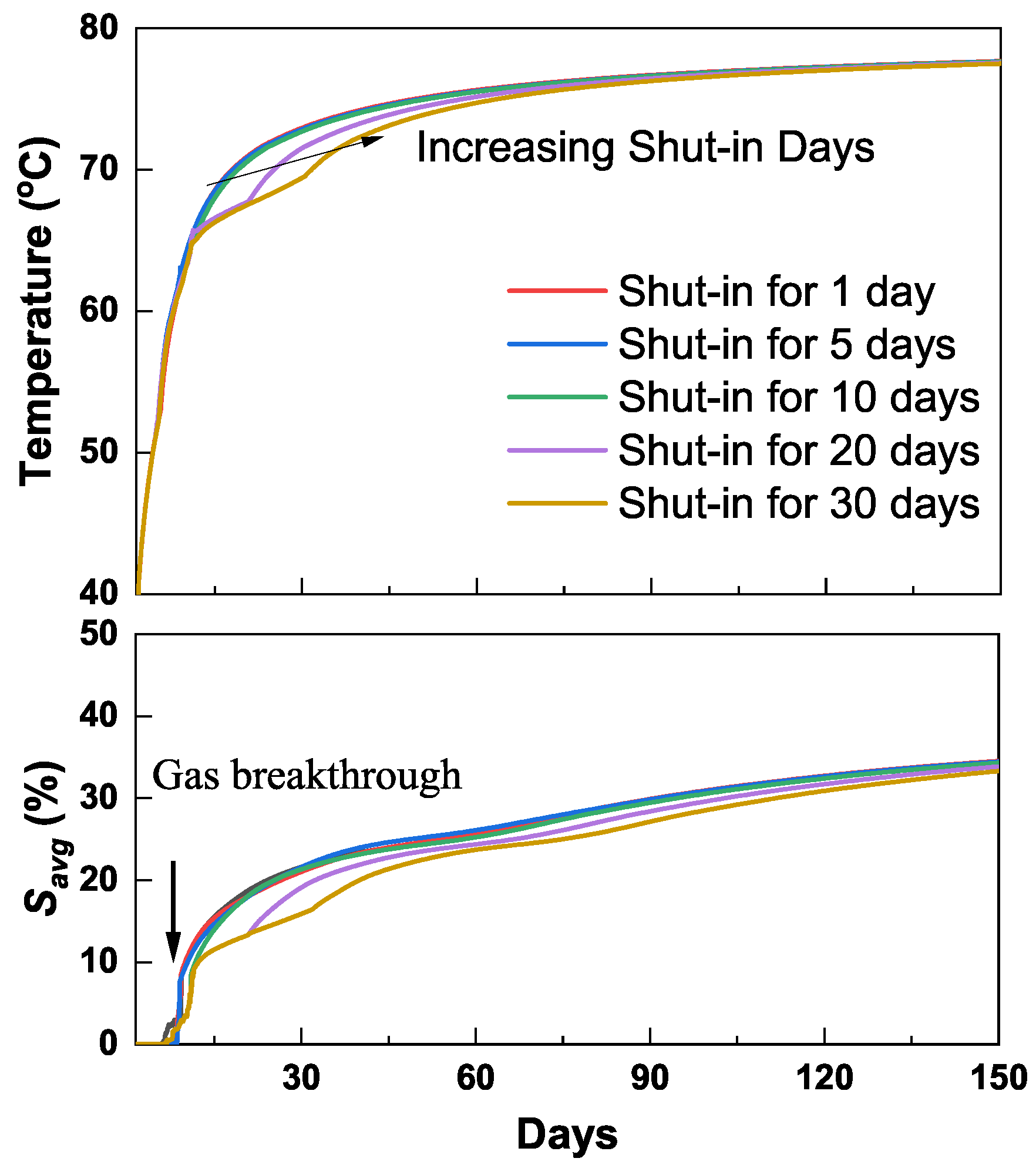

3.3.4. Case 4: Impact of Shut-in Days

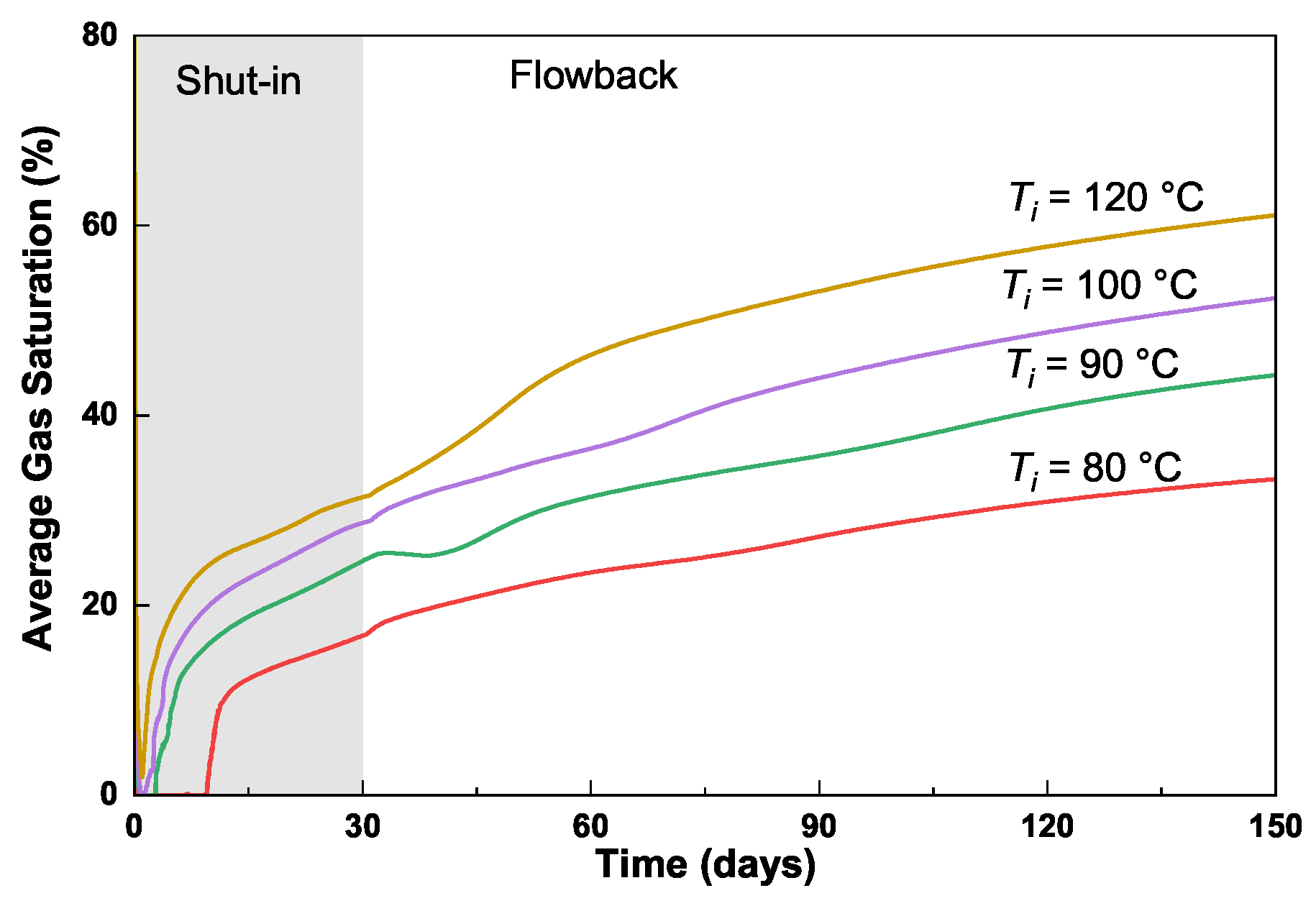

3.3.5. Case 5: Initial Reservoir Temperature

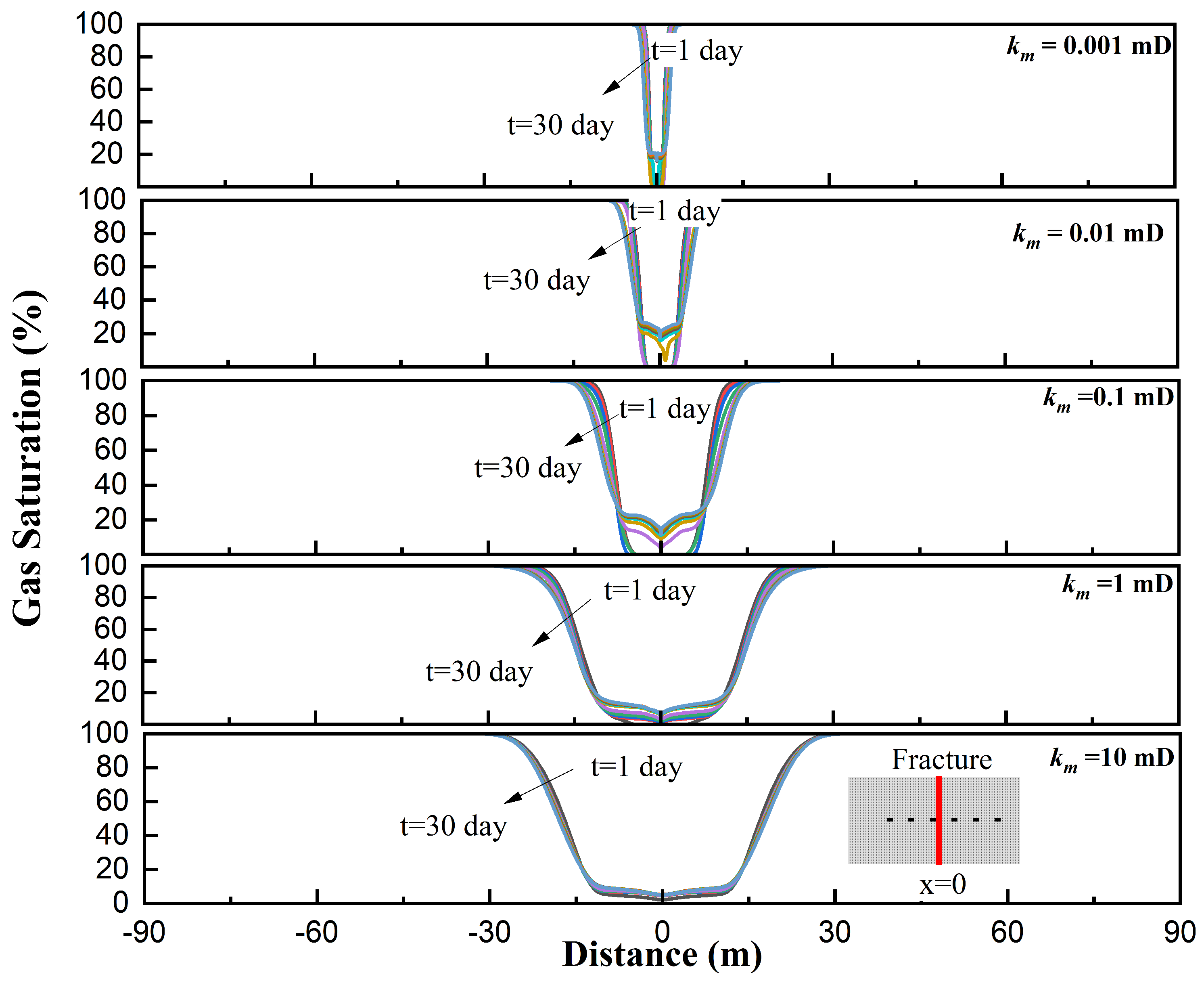

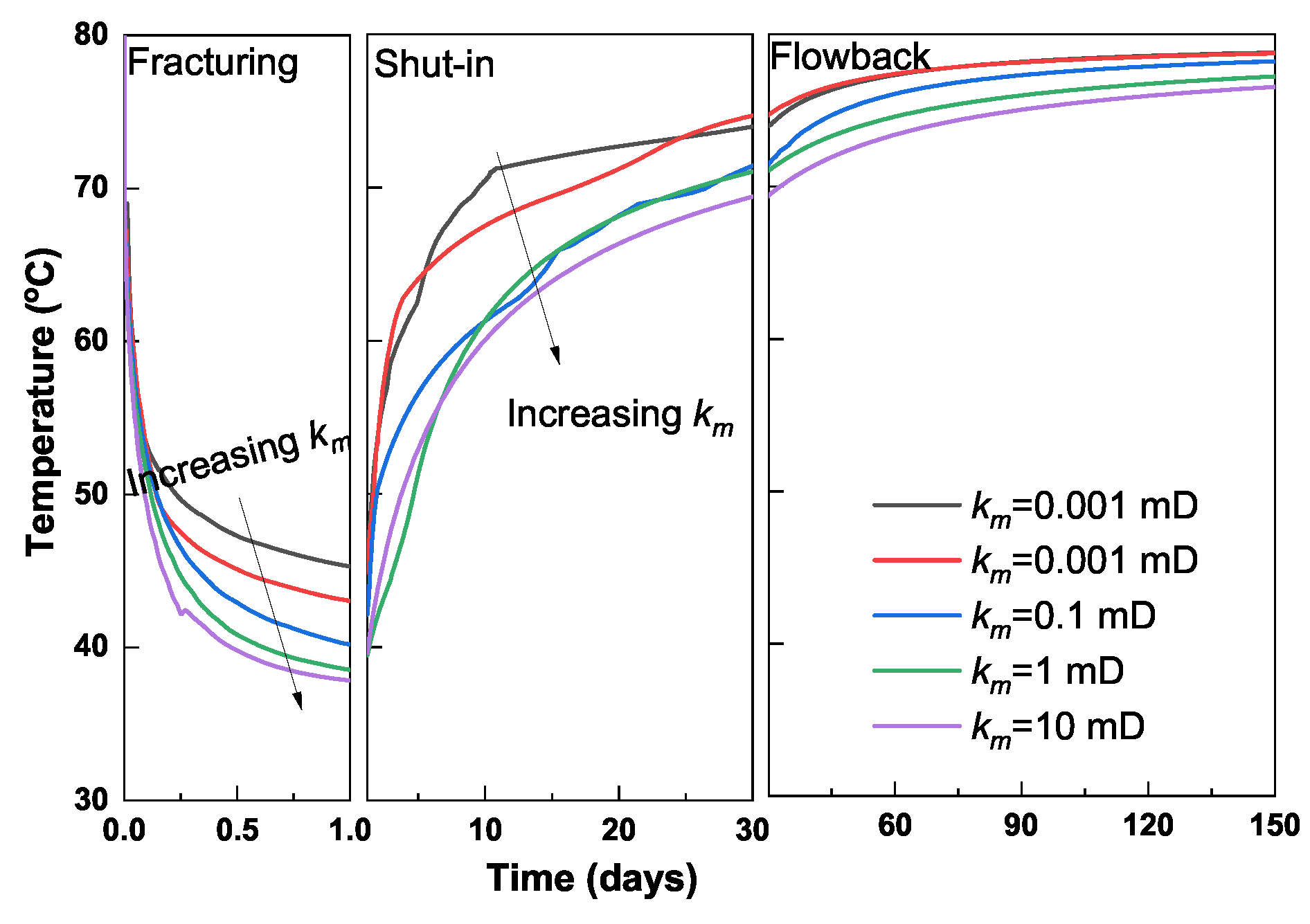

3.3.6. Case 6: Impact of Matrix Permeability

4. Temperature Impacts Flowback Data Analysis

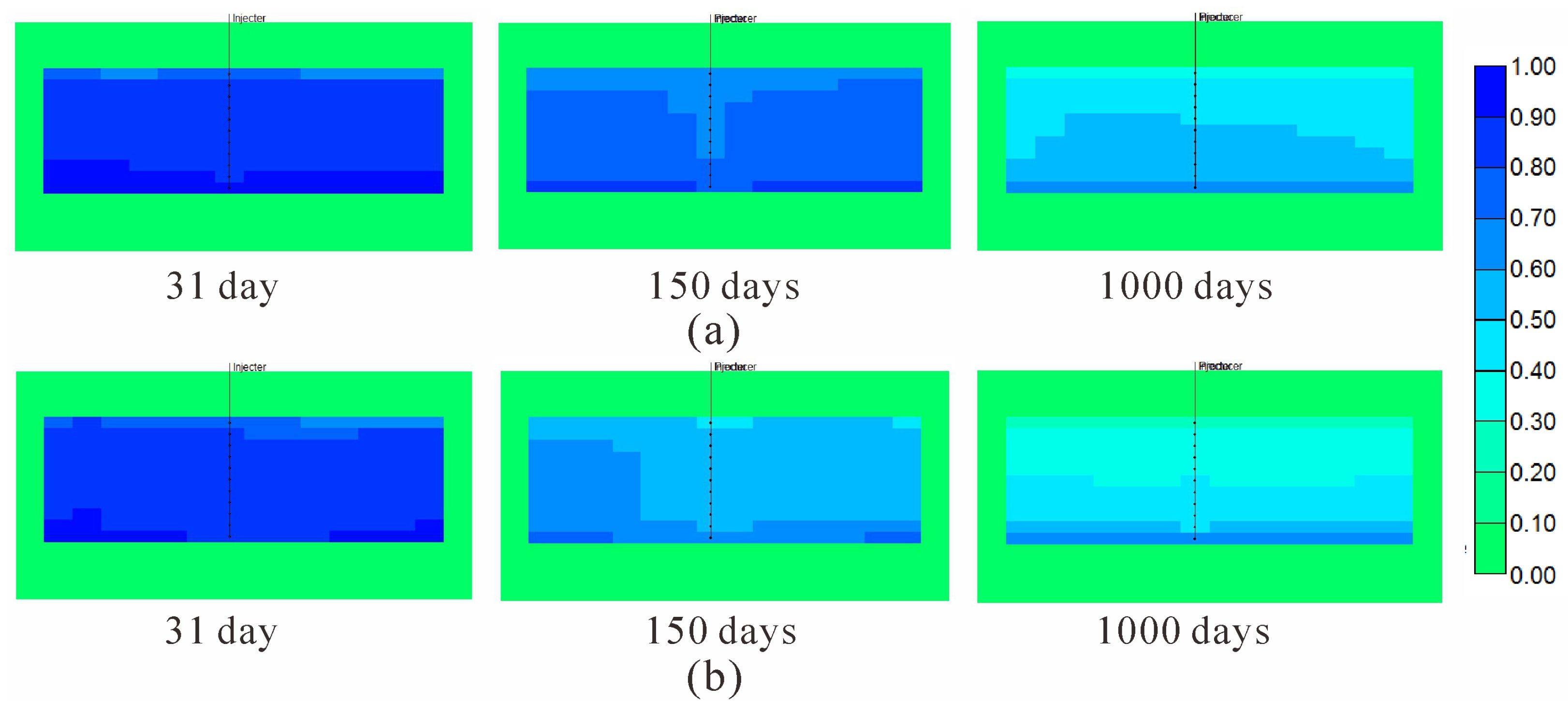

4.1. Flowback Well Performance

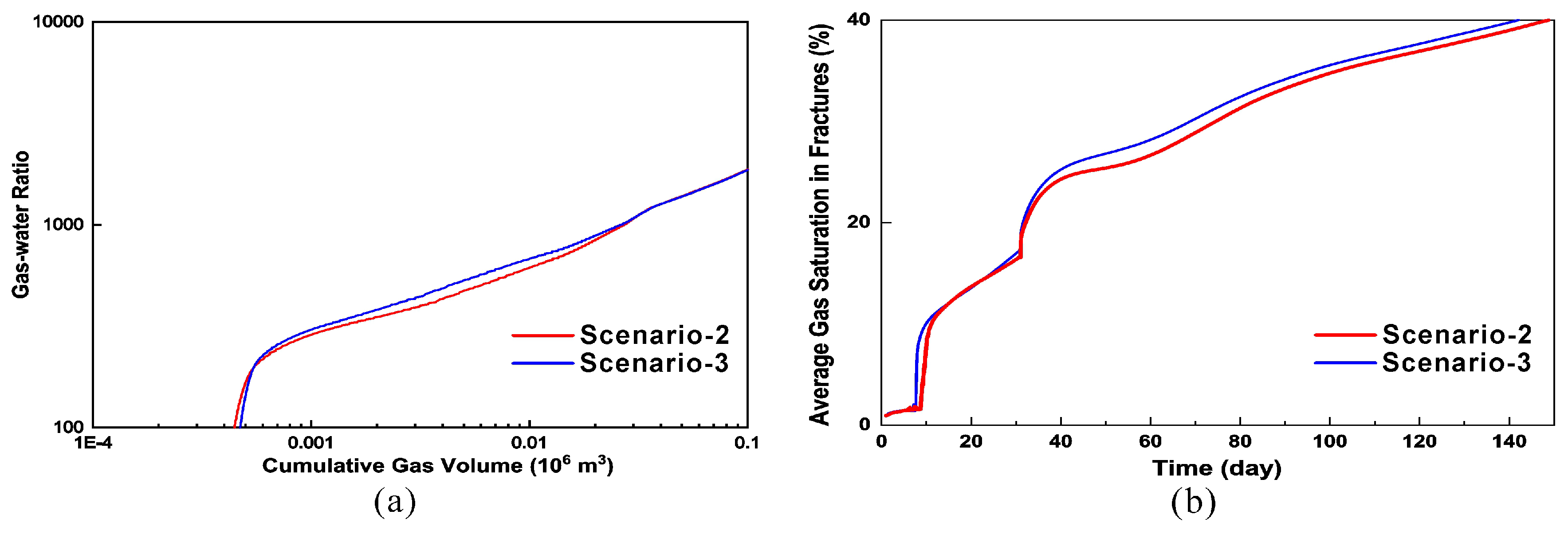

4.2. Fracture Cleanup

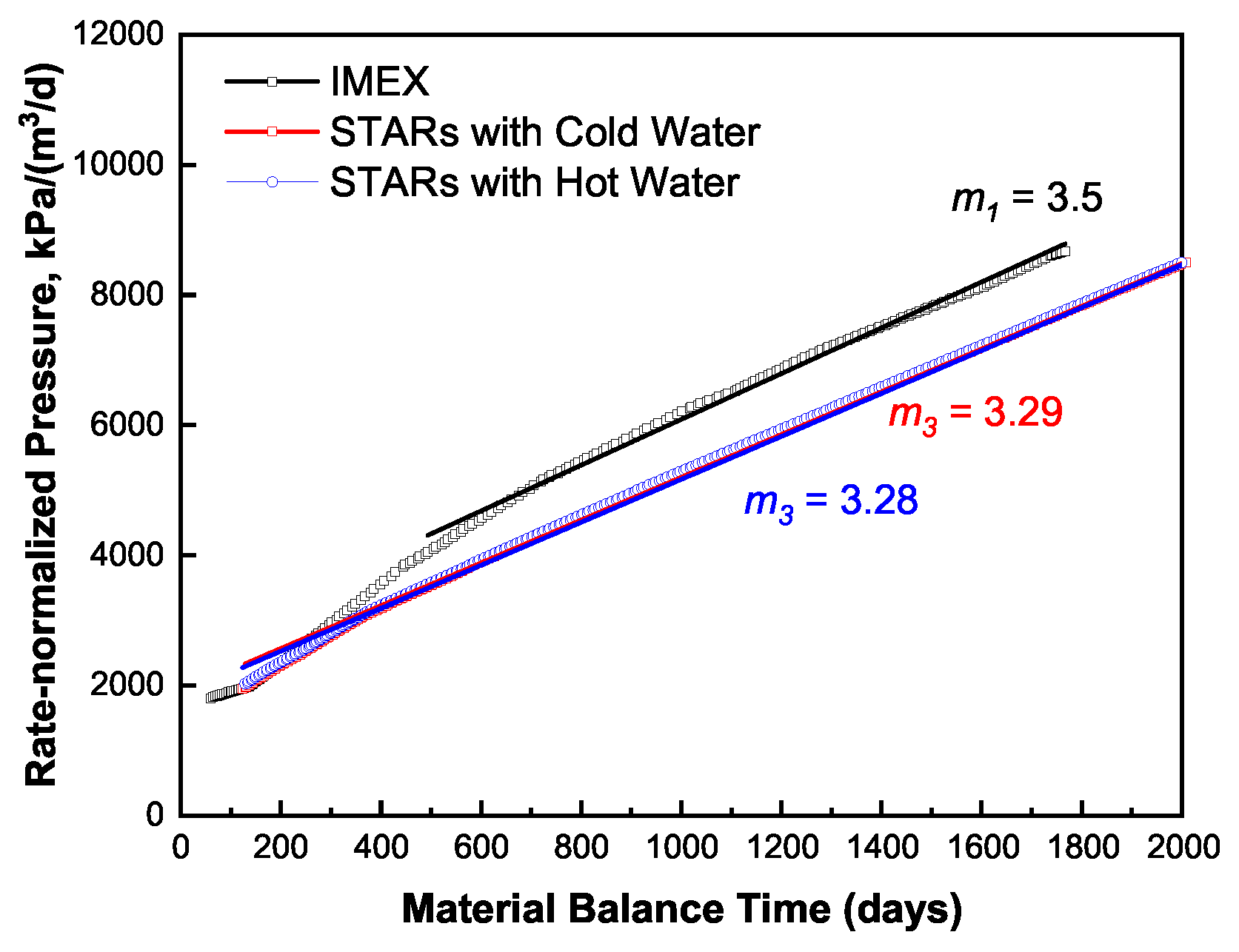

4.3. On Fracture-Volume Estimation

5. Implications

5.1. On Flowback Chemical Analysis

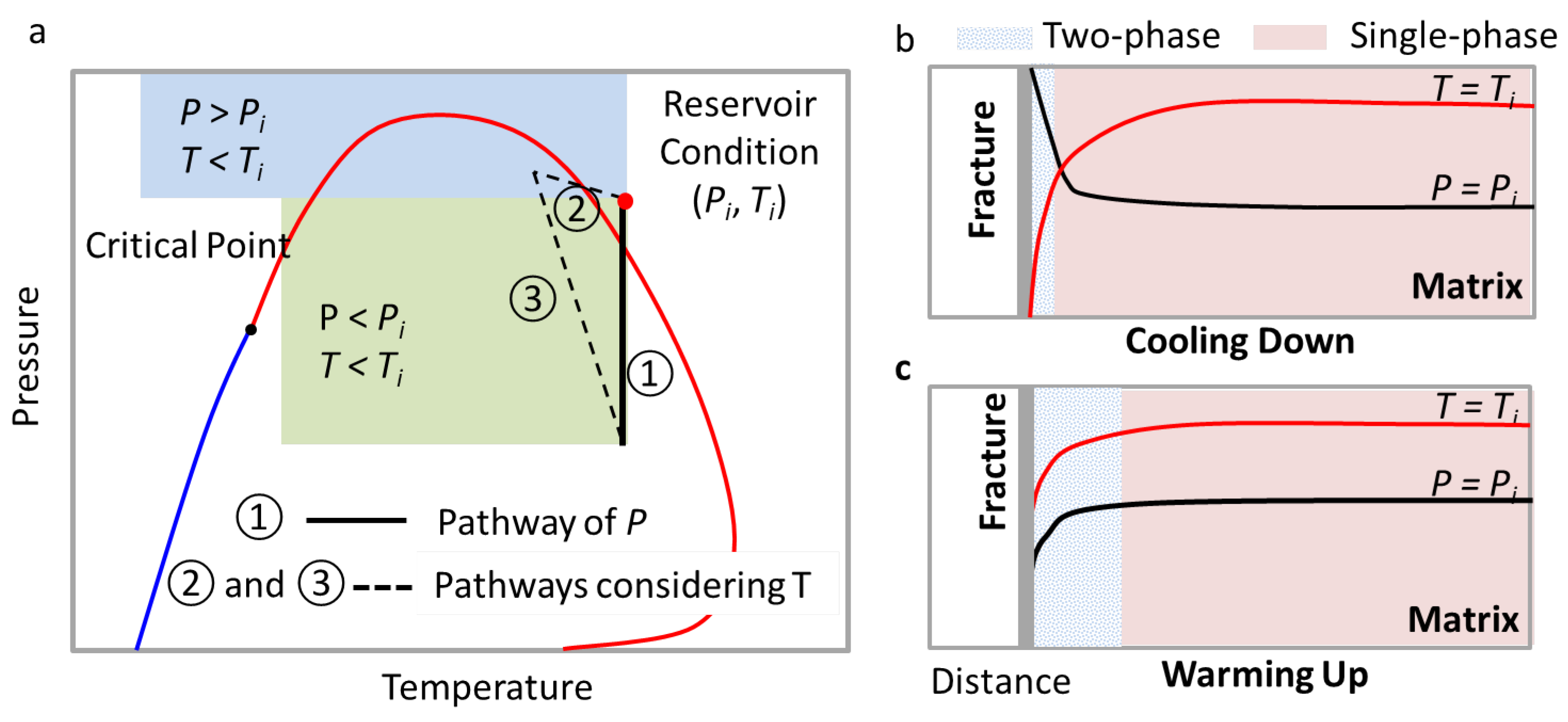

5.2. On Phase Behaviors of Gas-Condensate Wells

6. Limitations and Recommendation for Future Studies

7. Conclusions

- Formation is cooled down during the fracturing period. The cool-down region in formation expands with time. However, the change in formation temperature is constrained within the area near the matrix–fracture interface during the shut-in and flowback periods. Fractures are warmed up after the fracturing treatment. The warm-up process mainly occurs during the early shut-in period. Wells without any extended shut-in days can experience a significant increase in fracture temperature during the flowback period.

- Gas flow from matrix into fracture plays a key role in the fracture-temperature change during the shut-in and flowback periods. Sensitivity analysis indicates that fractures with a smaller width and larger length generally contribute to an accelerated warm-up process, whereas increasing matrix permeability contributes to a slower warm-up process. In addition, the change in fracture temperature is highly related to thermal conductivity of formation rock and initial reservoir temperature.

- Without considering the temperature change, flowback simulation may yield an overestimated gas production and underestimated water production. The change in fracture temperature also affects the gas saturation in fractures during shut-in, which further affects the process of fracture cleanup during flowback. Flowback data analysis without considering the temperature change may yield an overestimated fracture volume. In addition, it is recommended to consider the thermal effect for flowback chemical analysis and flowback drawdown management.

Author Contributions

Acknowledgments

Conflicts of Interest

Data Availability

Abbreviations

| A | Fracture surface area |

| Water formation factor | |

| Total compressibility of water, gas, and fracture | |

| Effective fracture volume | |

| Initial formation temperature | |

| Fracture temperature at the end of fracturing operation | |

| Rate-normalized pressure | |

| Material balance time | |

| Flowing pressure at bottomhole | |

| Initial reservoir pressure | |

| Water rate | |

| Gas rate | |

| Cumulative water volume | |

| Cumulative gas volume | |

| Thermal conductivity |

Appendix A. Gas-Saturation Profiles for Varying km

Appendix B. Alkouh et al. (2014)’s Method

References

- Estrada, J.M.; Bhamidimarri, R. A review of the issues and treatment options for wastewater from shale gas extraction by hydraulic fracturing. Fuel 2016, 182, 292–303. [Google Scholar] [CrossRef]

- Bahr, H.A.; Weiss, H.J.; Bahr, U.; Hofmann, M.; Fischer, G.; Lampenscherf, S.; Balke, H. Scaling behavior of thermal shock crack patterns and tunneling cracks driven by cooling or drying. J. Mech. Phys. Solids 2010, 58, 1411–1421. [Google Scholar] [CrossRef]

- Tarasovs, S.; Ghassemi, A. Self-similarity and scaling of thermal shock fractures. Phys. Rev. E 2014, 90, 012403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Enayatpour, S.; van Oort, E.; Patzek, T. Thermal cooling to improve hydraulic fracturing efficiency and hydrocarbon production in shales. J. Nat. Gas Sci. Eng. 2019, 62, 184–201. [Google Scholar] [CrossRef]

- Gao, Q.; Tao, J.; Hu, J.; Yu, X.B. Laboratory study on the mechanical behaviors of an anisotropic shale rock. J. Rock Mech. Geotech. Eng. 2015, 7, 213–219. [Google Scholar] [CrossRef] [Green Version]

- Qiu, P.; Hu, R.; Hu, L.; Liu, Q.; Xing, Y.; Yang, H.; Qi, J.; Ptak, T. A Numerical Study on Travel Time Based Hydraulic Tomography Using the SIRT Algorithm with Cimmino Iteration. Water 2019, 11, 909. [Google Scholar] [CrossRef]

- Sookprasong, P.; Gill, C.C.; Hurt, R.S. Lessons learned from das and dts in multicluster, multistage horizontal well fracturing: Interpretation of hydraulic fracture initiation and propagation through diagnostics. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Bangkok, Thailand, 25–27 August 2014. [Google Scholar]

- Ugueto, G.A.; Huckabee, P.T.; Molenaar, M.M. Challenging Assumptions About Fracture Stimulation Placement Effectiveness Using Fiber Optic Distributed Sensing Diagnostics: Diversion, Stage Isolation and Overflushing. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015. [Google Scholar]

- Ugueto, C.; Gustavo, A.; Huckabee, P.T.; Molenaar, M.M.; Wyker, B.; Somanchi, K. Perforation cluster efficiency of cemented plug and perf limited entry completions; Insights from fiber optics diagnostics. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 9–11 February 2016. [Google Scholar]

- Sierra, J.R.; Kaura, J.D.; Gualtieri, D.; Glasbergen, G.; Sarker, D.; Johnson, D. DTS monitoring of hydraulic fracturing: Experiences and lessons learned. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Holley, E.H.; Molenaar, M.M.; Fidan, E.; Banack, B. Interpreting uncemented multistage hydraulic-fracturing completion effectiveness by use of fiber-optic DTS injection data. SPE Drill. Complet. 2013, 28, 243–253. [Google Scholar] [CrossRef]

- Beck, G.; Verma, S. Development and Field Testing Novel Natural Gas (NG) Surface Process Equipment for Replacement of Water as Primary Hydraulic Fracturing Fluid. In Proceedings of the Carbon Storage and Oil and Natural Gas Technologies Review Meeting, Pittsburgh, PA, USA, 16–18 August 2016. [Google Scholar]

- Cheng, Y. Impact of water dynamics in fractures on the performance of hydraulically fractured wells in gas shale reservoirs. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10–12 February 2010. [Google Scholar]

- Cheng, Y. Impact of Water Dynamics in Fractures on the Performance of Hydraulically Fractured Wells in Gas-Shale Reservoirs. J. Can. Pet. Technol. 2012, 51, 143–151. [Google Scholar] [CrossRef]

- Alkouh, A.; McKetta, S.; Wattenbarger, R.A. Estimation of Effective-Fracture Volume Using Water-Flowback and Production Data for Shale-Gas Wells. J. Can. Pet. Technol. 2014, 53, 290–303. [Google Scholar] [CrossRef]

- Ghanbari, E.; Dehghanpour, H. The fate of fracturing water: A field and simulation study. Fuel 2016, 163, 282–294. [Google Scholar] [CrossRef]

- Noe, S.; Crafton, J. Factors Affecting Early Well Productivity in Six Shale Plays. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Edwards, R.W.; Celia, M.A. Shale gas well, hydraulic fracturing, and formation data to support modeling of gas and water flow in shale formations. Water Resour. Res. 2018, 54, 3196–3206. [Google Scholar] [CrossRef]

- Bertoncello, A.; Wallace, J.; Blyton, C.; Honarpour, M.M.; Kabir, S. Imbibition and Water Blockage in Unconventional Reservoirs: Well-Management Implications During Flowback and Early Production. SPE Reserv. Eval. Eng. 2014, 17, 497–506. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, B.; Gao, D. Is Formation Damage an Issue in Shale Gas Development? In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15–17 February 2012. [Google Scholar]

- Cao, P.; Liu, J.; Leong, Y.K. A multiscale-multiphase simulation model for the evaluation of shale gas recovery coupled the effect of water flowback. Fuel 2017, 199, 191–205. [Google Scholar] [CrossRef]

- Wijaya, N.; Sheng, J.J. Effect of desiccation on shut-in benefits in removing water blockage in tight water-wet cores. Fuel 2019, 244, 314–323. [Google Scholar] [CrossRef]

- Lai, F.; Li, Z.; Wang, Y. Impact of water blocking in fractures on the performance of hydraulically fractured horizontal wells in tight gas reservoir. J. Pet. Sci. Eng. 2017, 156, 134–141. [Google Scholar] [CrossRef]

- Fakcharoenphol, P.; Torcuk, M.; Kazemi, H.; Wu, Y.S. Effect of shut-in time on gas flow rate in hydraulic fractured shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 32, 109–121. [Google Scholar] [CrossRef] [Green Version]

- Edwards, R.W.; Doster, F.; Celia, M.A.; Bandilla, K.W. Numerical modeling of gas and water flow in shale gas formations with a focus on the fate of hydraulic fracturing fluid. Environ. Sci. Technol. 2017, 51, 13779–13787. [Google Scholar] [CrossRef]

- Birdsell, D.T.; Rajaram, H.; Dempsey, D.; Viswanathan, H.S. Hydraulic fracturing fluid migration in the subsurface: A review and expanded modeling results. Water Resour. Res. 2015, 51, 7159–7188. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Tatomir, A.; Taylor, R.; Sauter, M. Numerical investigations of upward migration of fracking fluid along a fault zone during and after stimulation. Energy Procedia 2017, 125, 126–135. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Tatomir, A.; Anighoro, T.; Sauter, M. Modeling fate and transport of hydraulic fracturing fluid in the presence of abandoned wells. J. Contam. Hydrol. 2019, 221, 58–68. [Google Scholar] [CrossRef]

- Lan, Q.; Ghanbari, E.; Dehghanpour, H. Water loss versus soaking time: Spontaneous imbibition in tight rocks. In Proceedings of the SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 25–27 February 2014. [Google Scholar]

- Makhanov, K.; Habibi, A.; Dehghanpour, H.; Kuru, E. Liquid uptake of gas shales: A workflow to estimate water loss during shut-in periods after fracturing operations. J. Unconv. Oil Gas Resour. 2014, 7, 22–32. [Google Scholar] [CrossRef]

- Crafton, J.W. Modeling Flowback Behavior or Flowback Equals “Slowback”. In Proceedings of the SPE Shale Gas Production Conference, Fort Worth, TX, USA, 16–18 November 2008. [Google Scholar]

- Ilk, D.; Currie, S.M.; Symmons, D.; Broussard, N.J.; Blasingame, T.A. A Comprehensive Workflow for Early Analysis and Interpretation of Flowback Data from wells in Tight Gas/Shale Reservoir Systems. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 20–22 September 2010. [Google Scholar]

- Ezulike, D.O.; Dehghanpour, H. A model for simultaneous matrix depletion into natural and hydraulic fracture networks. J. Nat. Gas Sci. Eng. 2014, 16, 57–69. [Google Scholar] [CrossRef]

- Abbasi, M.A.; Dehghanpour, H.; Hawkes, R.V. Flowback Analysis for Fracture Characterization. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar]

- Clarkson, C.R. Modeling 2-Phase Flowback of Multi-Fractured Horizontal Wells Completed in Shale. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar]

- Williams-Kovacs, J.; Clarkson, C. Stochastic Modeling of Multi-Phase Flowback From Multi-Fractured Horizontal Tight Oil Wells. In Proceedings of the SPE Unconventional Resources Conference-Canada, Calgary, AB, Canada, 5–7 November 2013. [Google Scholar]

- Abbasi, M.A.; Ezulike, D.O.; Dehghanpour, H.; Hawkes, R.V. A Comparative Study of Flowback Rate and Pressure Transient Behavior in Multifractured Horizontal Wells Completed in Tight Gas and Oil Reservoirs. J. Nat. Gas Sci. Eng. 2014, 17, 82–93. [Google Scholar] [CrossRef]

- Xu, M.; Dehghanpour, H. Advances in Understanding Wettability of Gas Shales. Energy Fuels 2014, 28, 4362–4375. [Google Scholar] [CrossRef]

- Bearinger, D. Message in a Bottle. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. [Google Scholar]

- Zolfaghari, A.; Dehghanpour, H.; Ghanbari, E.; Bearinger, D. Fracture characterization using flowback salt-concentration transient. SPE J. 2016, 21, 233–244. [Google Scholar] [CrossRef]

- Balashov, V.N.; Engelder, T.; Gu, X.; Fantle, M.S.; Brantley, S.L. A model describing flowback chemistry changes with time after Marcellus Shale hydraulic fracturing. AAPG Bull. 2015, 99, 143–154. [Google Scholar] [CrossRef]

- Merry, H.; Ehlig-Economides, C.; Wei, P. Model for a Shale Gas Formation with Salt-Sealed Natural Fractures. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Carpenter, C. Model for a Shale-Gas Formation with Salt-Sealed Natural Fractures. J. Pet. Technol. 2016, 68, 62–64. [Google Scholar] [CrossRef]

- Wang, J.Y.; Holditch, S.; McVay, D. Modeling fracture-fluid cleanup in tight-gas wells. SPE J. 2010, 15, 783–793. [Google Scholar] [CrossRef]

- Wang, T.; Tian, S.; Li, G.; Sheng, M.; Ren, W.; Liu, Q.; Tan, Y.; Zhang, P. Experimental study of water vapor adsorption behaviors on shale. Fuel 2019, 248, 168–177. [Google Scholar] [CrossRef]

- Mullen, J. Petrophysical characterization of the Eagle Ford Shale in south Texas. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Agrawal, S.; Sharma, M.M. Practical insights into liquid loading within hydraulic fractures and potential unconventional gas reservoir optimization strategies. J. Unconv. Oil Gas Resour. 2015, 11, 60–74. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, S.; Sharma, M.M. Impact of Liquid Loading in Hydraulic Fractures on Well Productivity. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2013. [Google Scholar]

- Korson, L.; Drost-Hansen, W.; Millero, F.J. Viscosity of water at various temperatures. J. Phys. Chem. 1969, 73, 34–39. [Google Scholar] [CrossRef]

- Korosi, A.; Fabuss, B.M. Viscosity of liquid water from 25 to 150. degree. measurements in pressurized glass capillary viscometer. Anal. Chem. 1968, 40, 157–162. [Google Scholar] [CrossRef]

- Carmichael, L.; Berry, V.; Sage, B. Viscosity of Hydrocarbons. Methane. J. Chem. Eng. Data 1965, 10, 57–61. [Google Scholar] [CrossRef]

- Zhao, J.; Peng, Y.; Li, Y.; Tian, Z.; Fu, D. A semi-analytic model of wellbore temperature field based on double-layer unsteady heat conducting process. Nat. Gas Ind. 2016, 36, 68–75. [Google Scholar]

- Ramires, M.L.; Nieto de Castro, C.A.; Nagasaka, Y.; Nagashima, A.; Assael, M.J.; Wakeham, W.A. Standard reference data for the thermal conductivity of water. J. Phys. Chem. Ref. Data 1995, 24, 1377–1381. [Google Scholar] [CrossRef]

- Golubev, I. A bicalorimeter for determining the thermal conductivity of gases and liquids at high pressures and different temperatures. Teploenergetika 1963, 12, 78–82. [Google Scholar]

- Fontanilla, J.P.; Aziz, K. Prediction of bottom-hole conditions for wet steam injection wells. J. Can. Pet. Technol. 1982, 21. [Google Scholar] [CrossRef]

- Beggs, D.H.; Brill, J.P. A study of two-phase flow in inclined pipes. J. Pet. Technol. 1973, 25, 607–617. [Google Scholar] [CrossRef]

- Fontanilla, J.P. A Mathematical Model for the Prediction of Wellbore Heat Loss and Pressure Drop in Steam Injection Wells. Master’s Thesis, University of Calgary, Calgary, AB, Canada, 1980. [Google Scholar]

- Zhang, S.; Zhu, D. Efficient Flow Rate Profiling for Multiphase Flow in Horizontal Wells Using Downhole Temperature Measurement. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar]

- Cui, J.; Yang, C.; Zhu, D.; Datta-Gupta, A. Fracture diagnosis in multiple-stage-stimulated horizontal well by temperature measurements with fast marching method. SPE J. 2016, 21, 2–289. [Google Scholar] [CrossRef]

- Yoshida, N. Modeling and Interpretation of Downhole Temperature in a Horizontal Well with Multiple Fractures. Ph.D. Thesis, Texas A & M University, College Station, TX, USA, 2016. [Google Scholar]

- Yoshida, N.; Hill, A.D.; Zhu, D. Comprehensive Modeling of Downhole Temperature in a Horizontal Well with Multiple Fractures. SPE J. 2018, 23. [Google Scholar] [CrossRef]

- Barree, R.D.; Cox, S.A.; Gilbert, J.V.; Dobson, M.L. Closing the gap: Fracture half length from design, buildup, and production analysis. SPE Prod. Facil. 2005, 20, 274–285. [Google Scholar] [CrossRef]

- Bybee, K. Resolving Created, Propped, and Effective Hydraulic-Fracture Length. J. Pet. Technol. 2009, 61, 58–60. [Google Scholar] [CrossRef]

- Čermák, V.; Rybach, L. Thermal conductivity and specific heat of minerals and rocks. In Landolt-Börnstein: Numerical Data and Functional Relationships in Science and Technology; New Series, Group V (Geophysics and Space Research), Physical Properties of Rocks; Angenheister, G., Ed.; Springer: Berlin/Heidelberg, Germany, 1982; Volume Ia, pp. 305–343. [Google Scholar]

- Brigaud, F.; Vasseur, G. Mineralogy, porosity and fluid control on thermal conductivity of sedimentary rocks. Geophys. J. Int. 1989, 98, 525–542. [Google Scholar] [CrossRef] [Green Version]

- Ghanbari, E.; Dehghanpour, H. Impact of Rock Fabric on Water Imbibition and Salt Diffusion in Gas Shales. Int. J. Coal Geol. 2015, 138, 55–67. [Google Scholar] [CrossRef]

- Jennings, H.Y., Jr.; Newman, G.H. The effect of temperature and pressure on the interfacial tension of water against methane-normal decane mixtures. Soc. Pet. Eng. J. 1971, 11, 171–175. [Google Scholar] [CrossRef]

- Rushing, J.A.; Newsham, K.E.; Van Fraassen, K.C.; Mehta, S.A.; Moore, G.R. Laboratory measurements of gas-water interfacial tension at HP/HT reservoir conditions. In Proceedings of the CIPC/SPE Gas Technology Symposium 2008 Joint Conference, Calgary, AB, Canada, 16–19 June 2008. [Google Scholar]

- Shariat, A. Measurement and Modeling Gas-Water Interfacial Tension at High Pressure/High Temperature Conditions. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2014. [Google Scholar]

- Babadagli, T.; Hatiboglu, C.U. Analysis of counter-current gas–water capillary imbibition transfer at different temperatures. J. Pet. Sci. Eng. 2007, 55, 277–293. [Google Scholar] [CrossRef]

- Zhang, Y.; Ehlig-Economides, C. Accounting for remaining injected fracturing fluid in shale gas wells. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014; pp. 2365–2377. [Google Scholar]

- Mahadevan, J.; Sharma, M.M.; Yortsos, Y.C. Evaporative cleanup of water blocks in gas wells. SPE J. 2007, 12, 209–216. [Google Scholar] [CrossRef]

- Blauch, M.E.; Myers, R.R.; Moore, T.; Lipinski, B.A.; Houston, N.A. Marcellus shale post-frac flowback waters—Where is all the salt coming from and what are the implications? In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 23–25 September 2009. [Google Scholar]

- Haluszczak, L.O.; Rose, A.W.; Kump, L.R. Geochemical evaluation of flowback brine from Marcellus gas wells in Pennsylvania, USA. Appl. Geochem. 2013, 28, 55–61. [Google Scholar] [CrossRef]

- Hayes, T.D. Sampling and Analysis of Water Streams Associated with the Development of Marcellus Shale Gas; Gas Technology Institute: Des Plaines, IL, USA, 2009. [Google Scholar]

- Phan, T.T.; Vankeuren, A.N.P.; Hakala, J.A. Role of water- rock interaction in the geochemical evolution of Marcellus Shale produced waters. Int. J. Coal Geol. 2018, 191, 95–111. [Google Scholar] [CrossRef]

- Vazquez, O.; McCartney, R.A.; Mackay, E. Produced-Water-Chemistry History Matching Using a 1D Reactive Injector/Producer Reservoir Model. SPE Prod. Oper. 2013, 28, 369–375. [Google Scholar]

- Zolfaghari, A.; Dehghanpour, H.; Bearinger, D. Produced Flowback Salts vs. Induced-Fracture Interface: A Field and Laboratory Study. SPE J. 2019. [Google Scholar] [CrossRef]

- Tian, Y.; Ayers, W.B.; McCain, D., Jr. The Eagle Ford Shale play, south Texas: Regional variations in fluid types, hydrocarbon production and reservoir properties. In Proceedings of the IPTC 2013: International Petroleum Technology Conference, Beijing, China, 26–28 March 2013. [Google Scholar]

- Jones, R.; Pownall, B.; Franke, J. Estimating reservoir pressure from early flowback data. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014; pp. 2140–2155. [Google Scholar]

- Rodriguez, A.; Maldonado, F. Evaluating Pressure Drawdown Strategy for Hydraulically Fracture Shale Gas Condensate Producers. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, OK, USA, 9–10 April 2019. [Google Scholar]

- Reynolds, M.; Bachman, R.; Buendia, J.; Peters, W. The full montney—A critical review of well performance by production analysis of over 2000 montney multi-stage fractured horizontal gas wells. In Proceedings of the SPE/CSUR Unconventional Resources Conference, Calgary, AB, Canada, 20–22 October 2015. [Google Scholar]

- Fu, Y.; Dehghanpour, H.; Motealleh, S.; Lopez, C.M.; Hawkes, R. Evaluating Fracture Volume Loss During Flowback and Its Relationship to Choke Size: Fastback vs. Slowback. SPE Prod. Oper. 2019, 34, 615–624. [Google Scholar] [CrossRef]

- Fan, L.; Harris, B.W.; Jamaluddin, A.; Kamath, J.; Mott, R.; Pope, G.A.; Shandrygin, A.; Whitson, C.H. Understanding gas-condensate reservoirs. Oilfield Rev. 2005, 17, 14–27. [Google Scholar]

- Amini, K.; Soliman, M.Y.; House, W.V. A Three-Dimensional Thermal Model for Hydraulic Fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Olson, J.E.; Laubach, S.E.; Lander, R.H. Natural fracture characterization in tight gas sandstones: Integrating mechanics and diagenesis. AAPG Bull. 2009, 93, 1535–1549. [Google Scholar] [CrossRef]

- Fu, Y.; Dehghanpour, H.; Ezulike, D.O.; Jones, R.S., Jr. Estimating effective fracture pore volume from flowback data and evaluating its relationship to design parameters of multistage-fracture completion. SPE Prod. Oper. 2017, 32, 423–439. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Grid Number | 46 × 16 × 20 | Fracture Height, m | 55 |

| Dimensions, m | 400 × 400 × 100 | Fracture Half-length, m | 175 |

| Matrix Porosity, % | 5 | Fracture Width, m | 0.01 |

| Fracture Porosity, % | 60 | Initial Water Saturation, 1 | 0.2 |

| Matrix Permeability, mD | 0.001 | Residual Water Saturation, 1 | 0.2 |

| Fracture Permeability, mD | 2000 | Pressure Gradient, kPa/m | 6.6 |

| Temperature | Water Viscosity | Gas Viscosity | Temperature | Water Viscosity | Gas Viscosity |

|---|---|---|---|---|---|

| °C | mPa·s | mPa·s | °C | mPa·s | mPa·s |

| 0 | 1.7865 | 0.01024 | 80 | 0.3546 | 0.01279 |

| 10 | 1.3061 | 0.01058 | 90 | 0.3143 | 0.01310 |

| 20 | 1.0020 | 0.01090 | 100 | 0.2820 | 0.01340 |

| 30 | 0.7975 | 0.01123 | 110 | 0.2548 | 0.01369 |

| 40 | 0.6527 | 0.01155 | 120 | 0.2317 | 0.01398 |

| 50 | 0.5467 | 0.01186 | 130 | 0.2125 | 0.01427 |

| 60 | 0.4665 | 0.01218 | 140 | 0.1961 | 0.01456 |

| 70 | 0.4045 | 0.01249 | 150 | 0.1815 | 0.01484 |

| Thermodynamic Parameters | Values | Reference |

|---|---|---|

| Volumetric Heat Capacity, J/(m°C) | 1840,000 | [52] |

| Thermal Conductivity of Rock, J/(m·day·°C) | 148,608 | [52] |

| Thermal Conductivity of Water, J/(m·day·°C) | 51,840 | [53] |

| Thermal Conductivity of Gas, J/(m·day·°C) | 2592 | [54] |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Wellbore Depth, m | 975 | Radius of Inner Tubing, m | 0.0635 |

| Wellbore Length, m | 1000 | Radius of Outer Tubing, m | 0.08 |

| Casing Length, m | 1000 | Radius of Inner Casing, m | 0.14 |

| Radius of Hole, m | 0.3 | Radius of Outer Casing, m | 0.16 |

| Conductivity of Tubing Wall, J/(m·day·°C) | 3,738,387 | Conductivity of Casing Wall, J/(m·day·°C) | 3,738,387 |

| Conductivity of Cement, J/(m·day·°C) | 123,120 | Conductivity of Formation, J/(m·day·°C) | 148,608 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Lai, F.; Li, Z.; Fu, Y.; Wang, K.; Zhang, L.; Liang, Y. The Effect of Temperature on Flowback Data Analysis in Shale Gas Reservoirs: A Simulation-Based Study. Energies 2019, 12, 3751. https://doi.org/10.3390/en12193751

Yang S, Lai F, Li Z, Fu Y, Wang K, Zhang L, Liang Y. The Effect of Temperature on Flowback Data Analysis in Shale Gas Reservoirs: A Simulation-Based Study. Energies. 2019; 12(19):3751. https://doi.org/10.3390/en12193751

Chicago/Turabian StyleYang, Sen, Fengpeng Lai, Zhiping Li, Yingkun Fu, Kongjie Wang, Liang Zhang, and Yutao Liang. 2019. "The Effect of Temperature on Flowback Data Analysis in Shale Gas Reservoirs: A Simulation-Based Study" Energies 12, no. 19: 3751. https://doi.org/10.3390/en12193751

APA StyleYang, S., Lai, F., Li, Z., Fu, Y., Wang, K., Zhang, L., & Liang, Y. (2019). The Effect of Temperature on Flowback Data Analysis in Shale Gas Reservoirs: A Simulation-Based Study. Energies, 12(19), 3751. https://doi.org/10.3390/en12193751