Effect of Vertical Metal Plate on Transfer Efficiency of the Wireless Power Transfer System

Abstract

1. Introduction

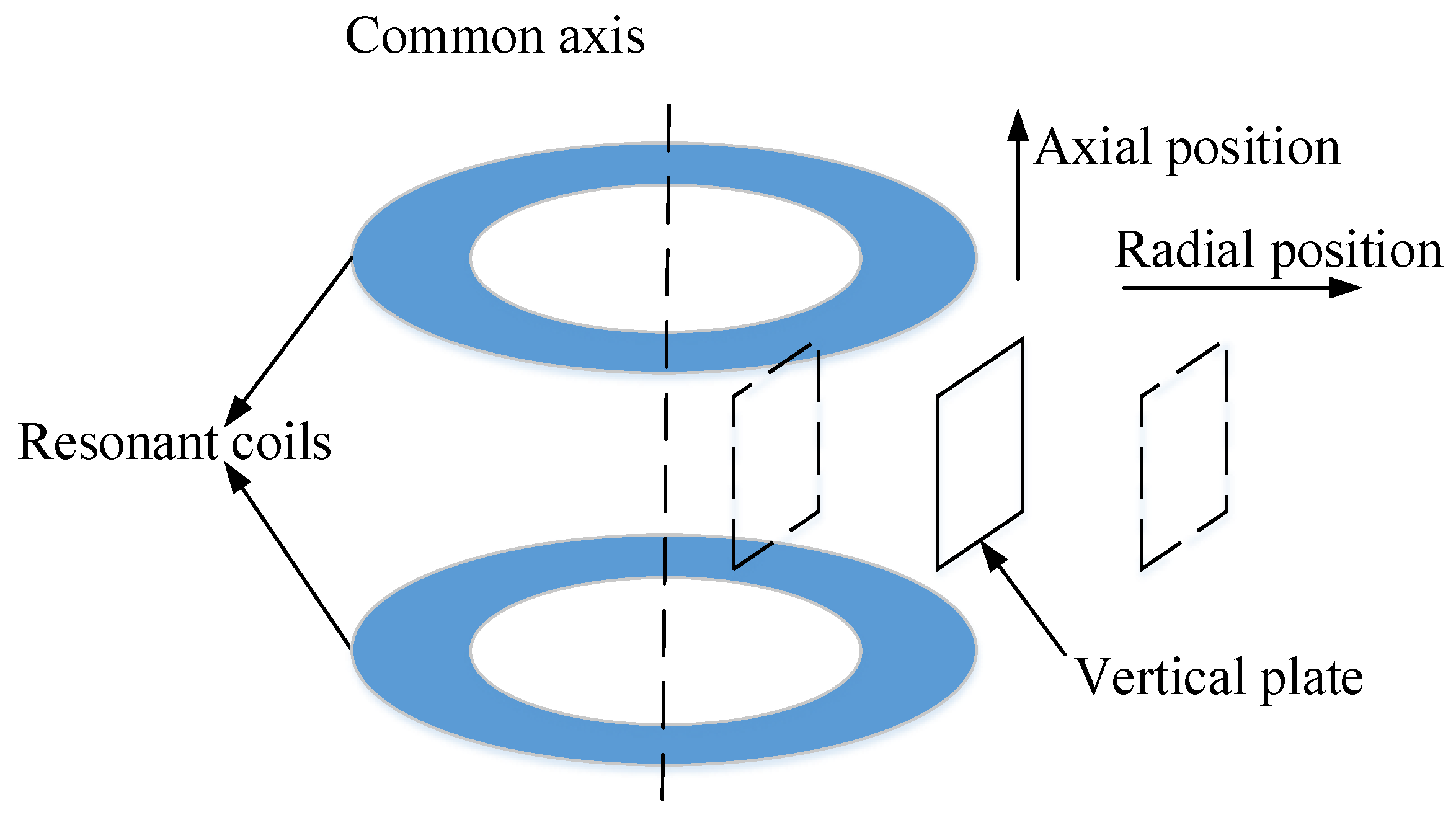

2. Basic Principle and Simulation

2.1. Basic Principle

2.2. Simulation

3. Effect of Metallic Plates

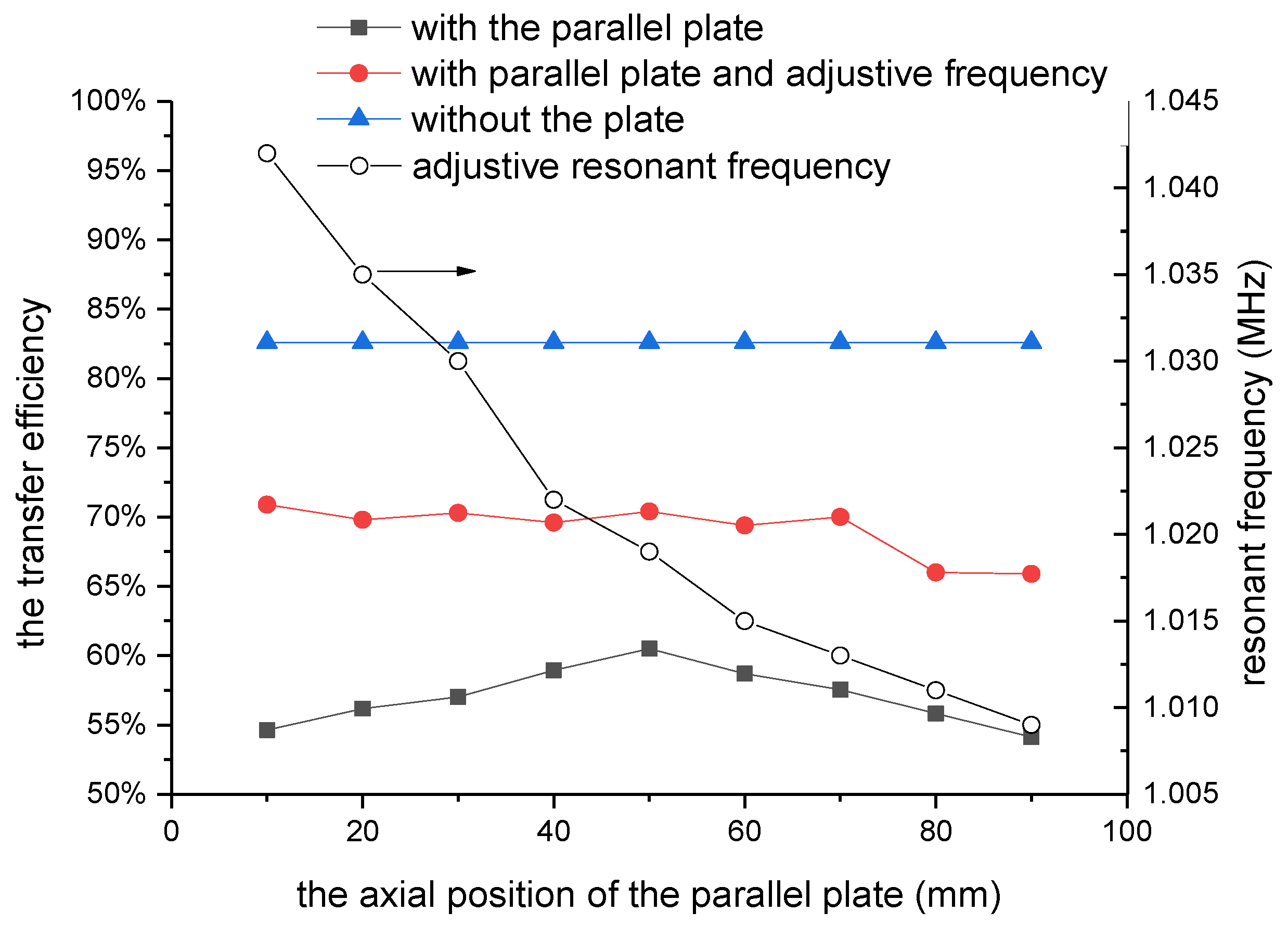

3.1. Impact of Parallel Metal Plates

3.2. The Impact of Vertical Metal Obstacles

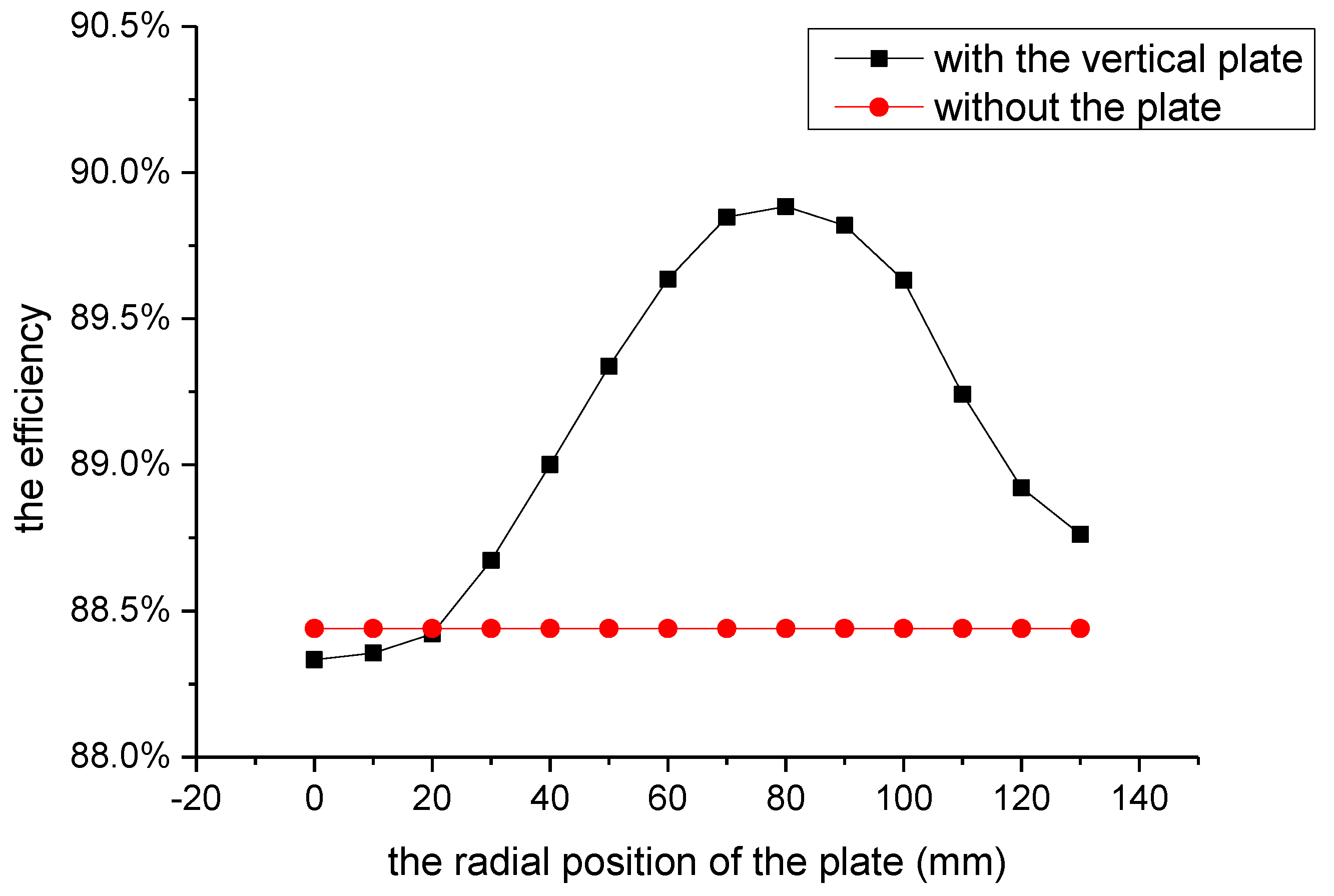

3.3. Effect of the Radial Position

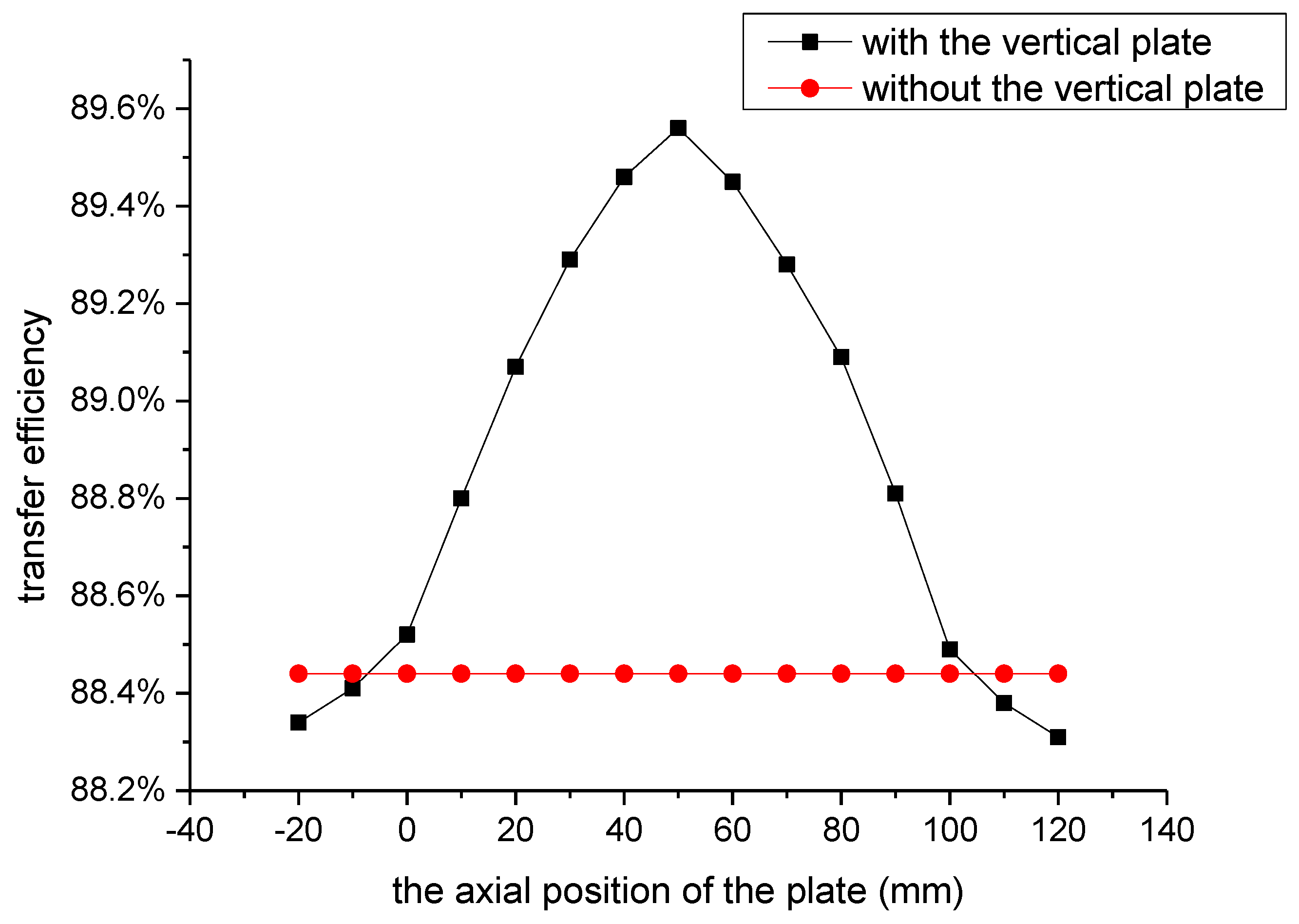

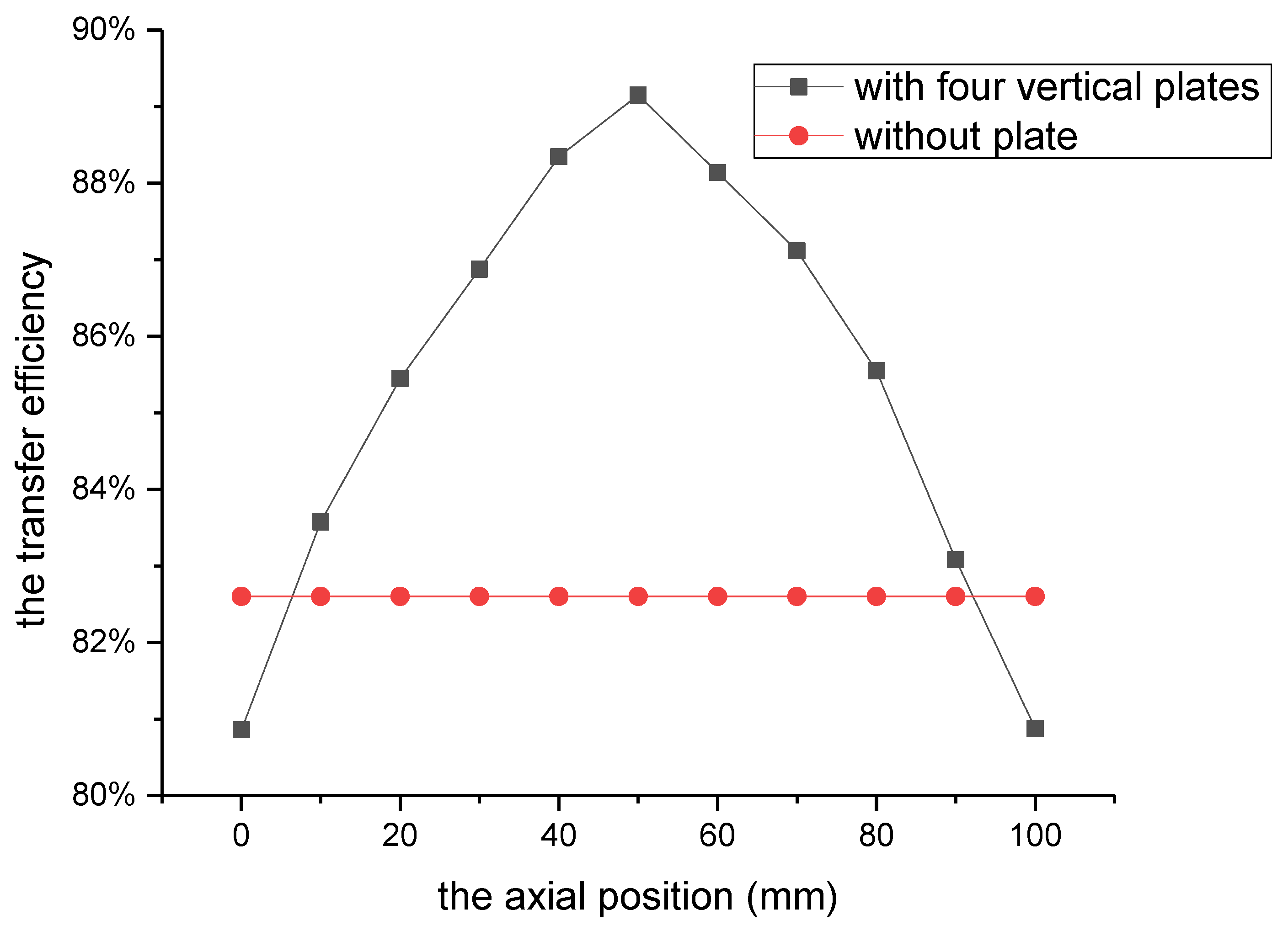

3.4. Effect of the Axial Position

3.5. Effect of Size

4. Experiment Results

4.1. Experimental Setup

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuipers, J.; Bruning, H.; Bakker, S.; Rijnaarts, H. Near field resonant inductive coupling to power electronic devices dispersed in water. Sens. Actuators A Phys. 2012, 178, 217–222. [Google Scholar] [CrossRef]

- Kim, J.; Son, H.; Kim, D.; Park, Y. Optimal design of a wireless power transfer system with multiple self-resonators for an LED TV. IEEE Trans. Consum. Electron. 2012, 58, 775–780. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Z.; Dai, H. A critical review of wireless power transfer via strongly coupled magnetic resonances. Energies 2014, 7, 4316–4341. [Google Scholar] [CrossRef]

- RamRakhyani, A.; Mirabbasi, S.; Chiao, M. Design and optimization of resonance-based efficient wireless power delivery systems for biomedical implants. IEEE Trans. Biomed. Circuits Syst. 2010, 5, 48–63. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ho, J.; Chen, L.; Poon, A. Wireless power transfer to a cardiac implant. Appl. Phys. Lett. 2012, 101, 073701. [Google Scholar] [CrossRef]

- Agarwal, K.; Jegadeesan, R.; Guo, Y.; Thakor, N. Wireless power transfer strategies for implantable bioelectronics. IEEE Rev. Biomed. Eng. 2017, 10, 136–161. [Google Scholar] [CrossRef] [PubMed]

- Kalwar, K.; Aamir, M.; Mekhilef, S. Inductively coupled power transfer (ICPT) for electric vehicle charging—A review. Renew. Sustain. Energy Rev. 2015, 47, 462–475. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, C.; Jiang, J.; Song, K.; Wei, G. A 3-kW wireless power transfer system for sightseeing car supercapacitor charge. IEEE T Power Electr. 2017, 32, 3301–3316. [Google Scholar] [CrossRef]

- Bi, Z.; Kan, T.; Mi, C.; Zhang, C.; Zhao, Z.; Keoleian, G. A review of wireless power transfer for electric vehicles: Prospects to enhance sustainable mobility. Appl. Energy 2016, 179, 413–425. [Google Scholar] [CrossRef]

- Choi, S.; Gu, B.; Jeong, S.; Chun, T. Advances in wireless power transfer systems for roadway-powered electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 3, 18–36. [Google Scholar] [CrossRef]

- Tesla, N. Apparatus for Transmission of Electrical Energy. U.S. Patent 649,621, 15 May 1990. [Google Scholar]

- Tesla, N. Apparatus for Transmitting Electrical Energy. U.S. Patent 1,119,732, 1 December 1914. [Google Scholar]

- Kim, H.; Song, C.; Kim, D.H.; Jung, D.H.; Kim, I.M.; Kim, Y.I.; Kim, J.; Ahn, S.; Kim, J. Coil design and measurements of automotive magnetic resonant wireless charging system for high-efficiency and low magnetic field leakage. Trans. Microw. Theory Tech. 2016, 64, 383–400. [Google Scholar] [CrossRef]

- Kang, M.; Noh, E.; Kim, K. NFC transmitter coil placement to minimise degradation of A4WP wireless power transfer efficiency. Electron. Lett. 2017, 53, 616–618. [Google Scholar] [CrossRef]

- Wang, S.; Chen, J.; Hu, Z.; Rong, C.; Liu, M. Optimisation design for series–series dynamic WPT system maintaining stable transfer power. IET Power Electron. 2017, 10, 987–995. [Google Scholar] [CrossRef]

- Feng, H.; Cai, T.; Duan, S.; Zhao, J.; Zhang, X.; Chen, C. An LCC-compensated resonant converter optimized for robust reaction to large coupling variation in dynamic wireless power transfer. IEEE T Ind. Electron. 2016, 63, 6591–6601. [Google Scholar] [CrossRef]

- Park, J.; Tak, Y.; Kim, Y.; Kim, Y.; Nam, S. Investigation of adaptive matching methods for near-field wireless power transfer. IEEE Trans. Antennas Propag. 2011, 59, 1769–1773. [Google Scholar] [CrossRef]

- Lim, Y.; Tang, H.; Lim, S.; Park, J. An adaptive impedance-matching network based on a novel capacitor matrix for wireless power transfer. IEEE Trans. Power Electron. 2014, 29, 4403–4413. [Google Scholar] [CrossRef]

- Fu, M.; Ma, C.; Zhu, X. A cascaded boost-buck converter for high efficiency wireless power transfer systems. IEEE Trans. Ind. Inf. 2014, 10, 1972–1980. [Google Scholar] [CrossRef]

- Fei, Z.; Hackworth, S.A.; Weinong, F.; Chengliu, L.; Zhihong, M.; Mingui, S. Relay effect of wireless power transfer using strongly coupled magnetic resonances. IEEE Trans. Magn. 2011, 47, 1478–1481. [Google Scholar] [CrossRef]

- Ye, Z.; Sun, Y.; Dai, X.; Tang, C.; Wang, Z.; Su, Y. Energy efficiency analysis of U-coil wireless power transfer system. IEEE Trans. Power Electr. 2015, 31, 4809–4817. [Google Scholar] [CrossRef]

- Sampath, J.; Vilathgamuwa, D.; Alphones, A. Efficiency enhancement for dynamic wireless power transfer system with segmented transmitter array. IEEE Tran. Transp. Electr. 2015, 2, 76–85. [Google Scholar] [CrossRef]

- Dai, H.; Liu, Y.; Chen, G.; Wu, X.; He, T.; Liu, A.; Ma, H. Safe charging for wireless power transfer. IEEEACM Trans. Netw. 2017, 25, 3531–3544. [Google Scholar] [CrossRef]

- Jawad, A.; Nordin, R.; Gharghan, S.; Jawad, H.; Ismail, M. Opportunities and challenges for near-field wireless power transfer: A review. Energies 2017, 10, 1022. [Google Scholar] [CrossRef]

- Hui, S.; Zhong, W.; Lee, C. A critical review of recent progress in mid-range wireless power transfer. IEEE Trans. Power Electr. 2013, 29, 4500–4511. [Google Scholar] [CrossRef]

- Sun, L.; Ma, D.; Tang, H. A review of recent trends in wireless power transfer technology and its applications in electric vehicle wireless charging. Renew Sustain. Energy Rev. 2018, 91, 490–503. [Google Scholar] [CrossRef]

- Feliziani, M.; Cruciani, S. Mitigation of the magnetic field generated by a wireless power transfer (WPT) system without reducing the WPT efficiency. In Proceedings of the 2013 International Symposium on Electromagnetic Compatibility, Brugge, Belgium, 2–6 September 2013; pp. 610–615. [Google Scholar]

- Kim, J.; Kim, J.; Kong, S.; Kim, H.; Suh, I.; Suh, N.; Cho, D.; Kim, J.; Ahn, S. Coil design and shielding methods for a magnetic resonant wireless power transfer system. Proc. IEEE 2013, 101, 1332–1342. [Google Scholar] [CrossRef]

- Strauch, L.; Pavlin, M.; Bregar, V.B. Optimization, design, and modeling of ferrite core geometry for inductive wireless power transfer. Int. J. Appl. Electrom. 2015, 49, 145–155. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Y.; Wang, Z.; Tang, C.; Xiong, Q. Design of magnetic coupler for EVs’ wireless charging. Int. J. Appl. Electrom. 2013, 43, 195–205. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.; Kim, D.; Jeong, Y.; Park, H.; Ahn, S. A three-phase wireless-power-transfer system for online electric vehicles with reduction of leakage magnetic fields. IEEE Trans. Microw. Theory Tech. 2015, 63, 3806–3813. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, Q.; Zhang, X.; Li, Y. Comparative study of metal obstacle variations in disturbing wireless power transmission system. IEEE Trans. Mag. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Krishnan, S.; Bhuyan, S.; Kyaw, O.; Kumar, V.P.; Wang, W.J. Effect of proximal metallic objects on the performance of wireless charging systems for electric vehicles. In Proceedings of the 2012 IEEE International Symposium on Radio-Frequency Integration Technology, Singapore, 21–23 November 2012; pp. 128–130. [Google Scholar] [CrossRef]

- Wen, F.; Huang, X. Optimal magnetic field shielding method by metallic sheets in wireless power transfer system. Energies 2016, 9, 733. [Google Scholar] [CrossRef]

- Ogawa, K.; Oodachi, N.; Obayashi, S.; Shoki, H. A study of efficiency improvement of wireless power transfer by impedance matching. In Proceedings of the 2012 IEEE MTT-S International Microwave Workshop Series on Innovative Wireless Power Transmission: Technologies, Systems, and Applications, Kyoto, Japan, 10–11 May 2012; pp. 155–157. [Google Scholar] [CrossRef]

- Liu, G.; Mrad, N.; Xiao, G.; Li, Z.; Ban, D. Metallic environmental effect on RF-based energy transmission. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 925–928. [Google Scholar] [CrossRef]

- Yu, X.; Sandhu, S.; Beiker, S.; Sassoon, R.; Fan, S. Wireless energy transfer with the presence of metallic planes. Appl. Phys. Lett. 2011, 99, 214102. [Google Scholar] [CrossRef]

- Yu, X.; Skauli, T.; Skauli, B.; Sandhu, S.; Catrysse, P.B.; Fan, S. Wireless power transfer in the presence of metallic plates: Experimental results. AIP Adv. 2013, 3, 062102. [Google Scholar] [CrossRef]

| Parameter | Description | Value |

|---|---|---|

| N | Turns of coils | 12 |

| R0 | Inner radius of coils | 60 mm |

| R1 | Outer radius of coils | 100 mm |

| D | Distance between the coils | 100 mm |

| S | Cross-section area of wire | 0.14 mm2 |

| RL | Load resistance | 100 Ω |

| L | Inductance of coil | 32.19 μH |

| C | Compensation capacitor | 0.787 nF |

| U | Voltage amplitude of alternating current source | 40 V |

| f | Frequency of AC source | 1 MHz |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Zou, J.; Zhou, Y.; Hong, Y.; Zhang, J.; Ding, Z. Effect of Vertical Metal Plate on Transfer Efficiency of the Wireless Power Transfer System. Energies 2019, 12, 3790. https://doi.org/10.3390/en12193790

Huang L, Zou J, Zhou Y, Hong Y, Zhang J, Ding Z. Effect of Vertical Metal Plate on Transfer Efficiency of the Wireless Power Transfer System. Energies. 2019; 12(19):3790. https://doi.org/10.3390/en12193790

Chicago/Turabian StyleHuang, Lantao, Jiahao Zou, Yihan Zhou, Yan Hong, Jing Zhang, and Zinan Ding. 2019. "Effect of Vertical Metal Plate on Transfer Efficiency of the Wireless Power Transfer System" Energies 12, no. 19: 3790. https://doi.org/10.3390/en12193790

APA StyleHuang, L., Zou, J., Zhou, Y., Hong, Y., Zhang, J., & Ding, Z. (2019). Effect of Vertical Metal Plate on Transfer Efficiency of the Wireless Power Transfer System. Energies, 12(19), 3790. https://doi.org/10.3390/en12193790