A Review of Gasoline Compression Ignition: A Promising Technology Potentially Fueled with Mixtures of Gasoline and Biodiesel to Meet Future Engine Efficiency and Emission Targets

Abstract

:1. Introduction

2. Gasoline-Biodiesel Blends as Substitute Fuels for CI Engines

- -

- Biodiesel is more portable, available and renewable.

- -

- Emissions such as CO, CO2, PM, SO2, and HC from biodiesel are lower compared to petroleum- based diesel fuel.

- -

- It is easier and faster to produce biodiesel than diesel petroleum-based fuel.

- -

- The cetane value of biodiesel is higher than 100 that can results in better performance of CI engines than petroleum diesel fuel.

- -

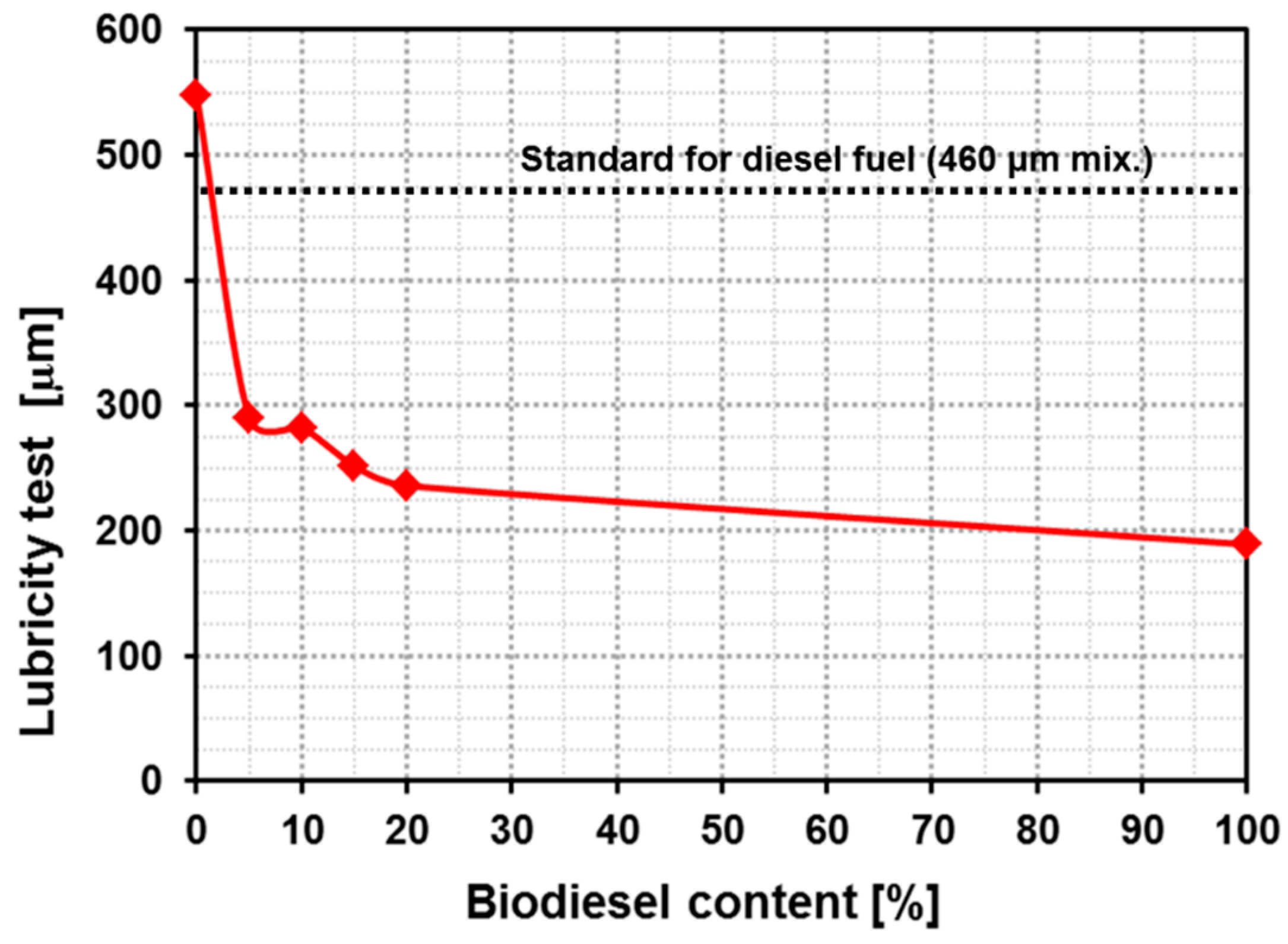

- Biodiesel’s lubricity is better compared to petroleum-based diesel fuel which can reduce engine maintenance and improve the engine lifetime.

- -

- Different from conventional diesel, biodiesel can be used without additional lubricants because of its purity and the clarity.

- -

- Biodiesel can be used to solve energy security problems and has great potential to stimulate rural development and sustainability.

- -

- Biodiesel can be obtained without mining, transporting, or refining activities like petroleum diesel fuel.

- -

- Biodiesel can be produced locally, thus being cheaper than petroleum diesel fuel.

- -

- The aromatic content, flash point, sulfur content, and biodegradability of biodiesel are better excellent than those of petroleum diesel fuel.

- -

- Biodiesel is safer, much more non-toxic, and more biodegradable compared to petroleum-based diesel fuel.

- -

- Biodiesel is non-flammable, however it has higher combustion efficiency because of its huge oxygen fraction if compared to petroleum diesel.

- -

- Biodiesel can produce low emissions, less visible smoke, and smalles amounts of noxious fumes and odors.

- -

- Blends of up to 20% biodiesel can be run without any modification of engines.

- -

- It produces higher emissions of NOx than petroleum diesel fuel.

- -

- Biodiesel has cold weather starting problems due to the higher cloud and pour point causing fuel freezing.

- -

- Biodiesel is naturally corrosive if exposed to brass and copper.

- -

- Biodiesel has around 11 to 17 times higher viscosity than diesel. Furthermore, pumping, atomization in the injector systems and combustion problems commonly happen in diesel engines due to the larger chemical structure and molecular mass of biodiesel than diesel.

- -

- The engine speed and power of the diesel engine is lower when utilizing biodiesel.

- -

- Biodiesel produces deposits in injectors, on the pistons, on the combustion chamber walls, and on the head of engines.

- -

- Deposit formation inside injector and on rings and filter and line plugging will happen due to the gumming and sticking which are promoted by its high viscosity in long term operation using biodiesel.

- -

- Biodiesel is incompatible with petroleum-based engine lubricating oils.

- -

- Excessive engine wear can be caused by biodiesel.

- -

- The cost-competitiveness of biodiesel cannot be compared with petroleum gasoline or diesel.

3. Challenges and Opportunities in GCI Engine Research

4. LTC Concept

5. GCI Engines and CI Engines with Gasoline Fuel

5.1. GCI Engines

5.2. CI Engines with Gasoline Fuel

5.3. Potential Methods to Obtain High Efficiency and Low Emission Targets of CI Engines in GCI Modes

5.4. Studies on GCI Engines Fueled Using Gasoline and Biodiesel Blends

5.4.1. Gasoline-Biodiesel Preparation and Properties during Storage

5.4.2. Spray Behaviors of Gasoline-Biodiesel Blending Fuel

5.4.3. Auto Burning Behaviors of a Blended of Gasoline-Biodiesel

5.4.4. Single Injection Mode of Gasoline-Biodiesel Blend

5.4.5. Double Injection Mode of Gasoline-Biodiesel Blends

5.4.6. EGR and Intake Boosting of Gasoline-Biodiesel Blend

6. Conclusions and Recommendations

6.1. Conclusions

- A literature study of GCI engines potentially fueled with biodiesel-gasoline blends.

- The study on the combustion process and exhaust emission behaviors of gasoline CI engines using various injection timings in a single injection mode fueled with biodiesel-gasoline blends.

- The study about the effects of 5 and 20% biodiesel-gasoline blends on the efficiency and exhaust emissions in gasoline compression ignition engines under single injection mode.

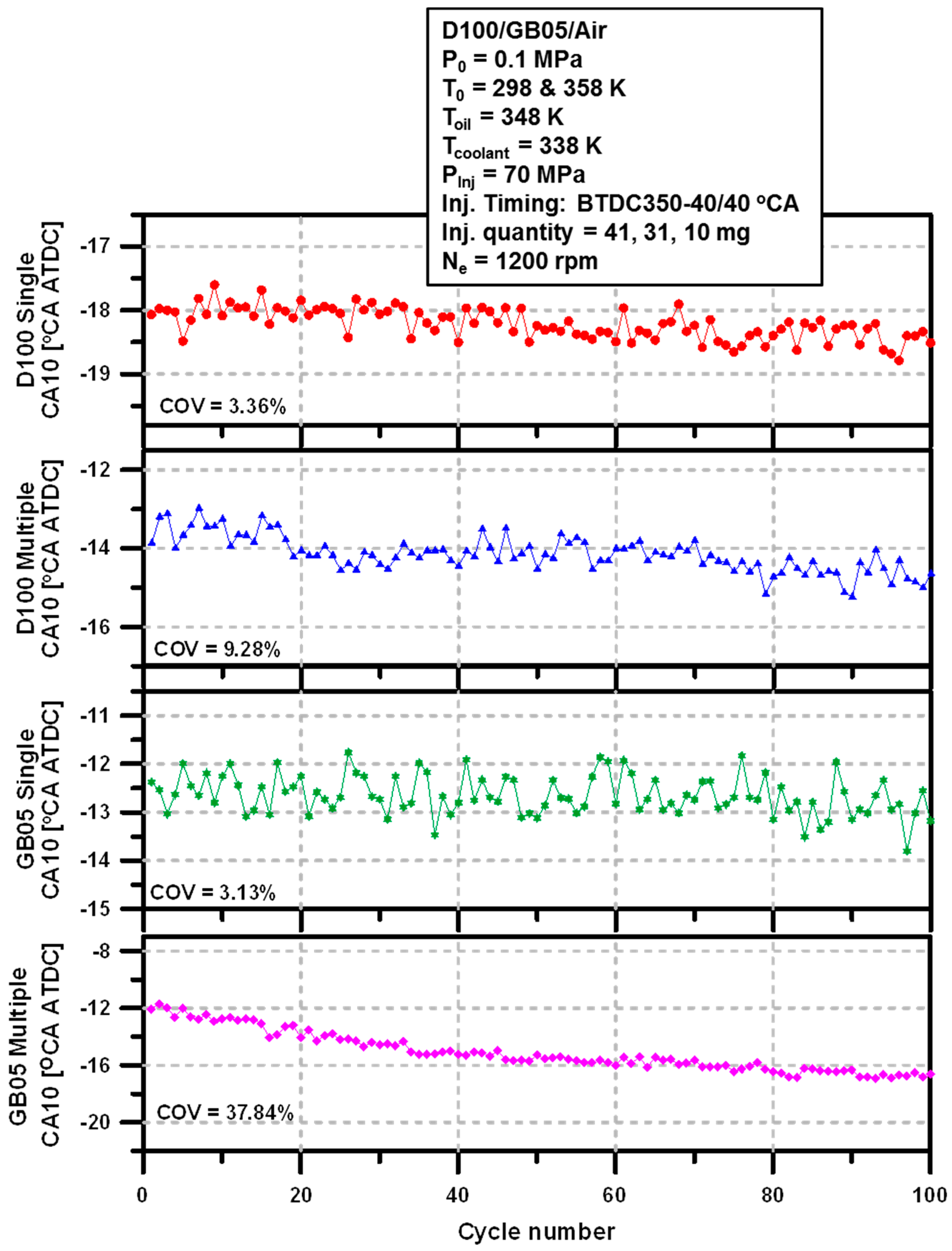

- A study of the combustion and exhaust emissions of a gasoline CI engine fueled with biodiesel-gasoline through a double injection method which comprises of pilot and main injection.

- Experimental investigation of the combustion process and emission behaviors of CI engines fueled with biodiesel-gasoline blends in the early injection HCCI mode.

- An investigation on the effect of EGR and inlet boosting on the process of combustion and emission behaviors of a GCI engine using gasoline-biodiesel-blends.

6.2. Recommendations

- Use of hot EGR to raise the inlet temperature and a smaller fuel injection pressure (to minimize too much mixing and cylinder wall-wet/impingement of fuel) is required for the GCI engine concept of volatile/vaporizable/less-reactivity and also low cetane-number fuels at smaller engine speeds or engine operating loads.

- Several issues related to the emission and combustion behaviors of gasoline CI engines using blends of biodiesel in gasoline need to be studied further, including stability under low and middle load conditions, cold start and idle conditions, operation in acceptable transient conditions, noise/engine sound quality and in-cylinder PRR at middle and big loads through injection of fuel methods, exhaust emissions (especially HC, carbon monoxide, NOx and smoke emissions control), LTO and diesel particulate filters (DPFs).

- Several issues related to hardware optimization of gasoline CI engines using a mixing of gasoline-biodiesel also need to be studied further. In this case they include: the combustion chamber/cylinder-head/piston-crown design, injectors holes and angles, injection arrangement and injection method systems, cooled and uncooled EGR, turbochargers combined with superchargers or boosting to obtain higher intake pressures at big EGR ratio, subsequent/exhaust treatment, and quality of fuel (lubrication behavior, viscosity, and detergent-like properties). Thus, advanced additive technology has to be implemented for the various conditions come upon in gasoline compression ignition engines.

- More significant experimental, simulation and development studies and work are required to push gasoline compression ignition engine technology to the step of real application.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tutak, W.; Lukacs, K.; Szwaja, S.; Bereczky, A. Alcohol-diesel fuel combustion in the compression ignition engine. Fuel 2015, 154, 196–206. [Google Scholar] [CrossRef]

- Dec, J.E. Advanced compression-ignition engines—Understanding the in-cylinder processes. Proc. Combust. Inst. 2009, 32, 2727–2742. [Google Scholar] [CrossRef]

- Lu, X.; Han, D.; Huang, Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog. Energy Combust. Sci. 2011, 37, 741–783. [Google Scholar] [CrossRef]

- Kalghatgi, G.T.; Risberg, P.; Ångström, H. Advantages of Fuels with High Resistance to Auto-Ignition in Late-Injection, Low-Temperature, Compression Ignition Combustion; SAE Technical Paper 2006-01-3385; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Won, H.W.; Peters, N.; Pitsch, H.; Tait, N.; Kalghatgi, G. Partially Premixed Combustion of Gasoline Type Fuels Using Larger Size Nozzle and Higher Compression Ratio in a Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013; Volume 11. [Google Scholar] [CrossRef]

- Ra, Y.; Yun, J.E.; Reitz, R.D. Numerical Parametric Study of Diesel Engine Operation with Gasoline. Combust. Sci. Technol. 2009, 181, 350–378. [Google Scholar] [CrossRef]

- Ra, Y.; Loeper, P.; Reitz, R.; Andrie, M.; Krieger, R.; Foster, D.; Durrett, R.; Gopalakrishnan, V.; Plazas, A.; Peterson, R.; et al. Study of High Speed Gasoline Direct Injection Compression Ignition (GDICI) Engine Operation in the LTC Regime. SAE Int. J. Engines 2011, 4, 1412–1430. [Google Scholar] [CrossRef]

- Ra, Y.; Loeper, P.; Andrie, M. Gasoline DICI Engine Operation in the LTC Regime Using Triple-Pulse Injection. SAE Int. J. Engines 2012, 1109–1132. [Google Scholar] [CrossRef]

- Sellnau, M.; Foster, M.; Hoyer, K.; Moore, W.; Sinnamon, J.; Husted, H. Development of a Gasoline Direct Injection Compression Ignition (GDCI) Engine. SAE Int. J. Engines 2014, 7, 835–851. [Google Scholar] [CrossRef]

- Han, D.; Duan, Y.; Wang, C.; Lin, H.; Huang, Z. Experimental study on the two stage injection of diesel and gasoline blends on a common rail injection system. Fuel 2015, 159, 470–475. [Google Scholar] [CrossRef]

- Benajes, J.; Broatch, A.; Garcia, A.; Monico Muñoz, L. An Experimental Investigation of Diesel-Gasoline Blends Effects in a Direct-Injection Compression-Ignition Engine Operating in PCCI Conditions; SAE Technical Paper 2013-01-1676; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Adams, C.A.; Loeper, P.; Krieger, R.; Andrie, M.J.; Foster, D.E. Effects of biodiesel-gasoline blends on gasoline direct-injection compression ignition (GCI) combustion. Fuel 2013, 111, 784–790. [Google Scholar] [CrossRef]

- Zelenyuk, A.; Reitz, P.; Stewart, M.; Imre, D.; Loeper, P.; Adams, C.; Andrie, M.; Rothamer, D.; Foster, D.; Narayanaswamy, K.; et al. Detailed characterization of particulates emitted by pre-commercial single-cylinder gasoline compression ignition engine. Combust. Flame 2014, 161, 2151–2164. [Google Scholar] [CrossRef]

- Zhang, F.; Rezaei, S.Z.; Xu, H.; Shuai, S.-J. Experimental Investigation of Different Blends of Diesel and Gasoline (Dieseline) in a CI Engine. SAE Int. J. Engines 2014, 7, 1920–1930. [Google Scholar] [CrossRef]

- Putrasari, Y.; Praptijanto, A.; Budi, W.; Lim, O. Resources, policy, and research activities of biofuel in Indonesia: A review. Energy Rep. 2016, 2, 237–245. [Google Scholar] [CrossRef] [Green Version]

- Salvi, B.L.; Panwar, N.L. Biodiesel resources and production technologies—A review. Renew. Sustain. Energy Rev. 2012, 16, 3680–3689. [Google Scholar] [CrossRef]

- Hassan, M.H.; Kalam, M.A. An overview of biofuel as a renewable energy source: Development and challenges. Procedia Eng. 2013, 56, 39–53. [Google Scholar] [CrossRef]

- Yang, B.; Li, S.; Zheng, Z.; Yao, M.; Cheng, W. A Comparative Study on Different Dual-Fuel Combustion Modes Fuelled with Gasoline and Diesel; SAE International: Warrendale, PA, USA, 2012; Volume 0694. [Google Scholar] [CrossRef]

- Shi, Y.; Reitz, R.D. Optimization of a heavy-duty compression-ignition engine fueled with diesel and gasoline-like fuels. Fuel 2010, 89, 3416–3430. [Google Scholar] [CrossRef]

- Rose, K.D.; Ariztegui, J.; Cracknell, R.F.; Dubois, T.; Hamje, H.D.C.; Pellegrini, L.; Rickeard, D.J.; Heuser, B.; Schnorbus, T.; Kolbeck, A.F. Exploring a Gasoline Compression Ignition (GCI) Engine Concept; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Misra, R.D.; Murthy, M.S. Blending of additives with biodiesels to improve the cold flow properties, combustion and emission performance in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2011, 15, 2413–2422. [Google Scholar] [CrossRef]

- Kweon, C.; Okada, S.; Foster, D.; Bae, M.; Schauer, J. Effect of engine operating conditions on particle-phase organic compounds in engine exhaust of a heavy-duty direct-injection (DI) diesel engine. SAE Trans. 2003, 112, 460–476. [Google Scholar]

- Kweon, C.; Okada, S.; Stetter, J.; Christenson, C.; Shafer, M.; Schauer, J.; Foster, D. Effects of Fuel Composition on Combustion and Detailed Chemical/Physical Characteristics of Diesel Exhaust; SAE International: Warrendale, PA, USA, 2003; Volume 22. [Google Scholar] [CrossRef]

- Bae, C.; Kim, J. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Tesfa, B.; Mishra, R.; Zhang, C.; Gu, F.; Ball, A.D. Combustion and performance characteristics of CI (compression ignition) engine running with biodiesel. Energy 2013, 51, 101–115. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Li, L.; Wang, J.; Reitz, R.D. Effect of biodiesel saturation on soot formation in diesel engines. Fuel 2016, 175, 240–248. [Google Scholar] [CrossRef]

- Cordiner, S.; Mulone, V.; Nobile, M.; Rocco, V. Impact of biodiesel fuel on engine emissions and Aftertreatment System operation. Appl. Energy 2016, 164, 972–983. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Hountalas, D.T.; Giakoumis, E.G.; Andritsakis, E.C. Performance and emissions of bus engine using blends of diesel fuel with bio-diesel of sunflower or cottonseed oils derived from Greek feedstock. Fuel 2008, 87, 147–157. [Google Scholar] [CrossRef]

- Pulkrabek Willard, W. Engineering Fundamentals of Internal Combustion Engine, 2nd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Kalghatgi, G. Fuel/Engine Interactions; Society of Automotive Engineers: Wallendale PA USA, 2014. [Google Scholar]

- Cracknell, R.; Ariztegui Cortijo, J.; Dubois, T.; Engelen, B.; Manuelli, P.; Pellegrini, L.; Williams, J.; Deppenkemper, K.; Graziano, B.; Heufer, K.A.; et al. Modelling a Gasoline Compression Ignition (GCI) Engine Concept; SAE Technical Paper 2014-01-1305; SAE International: Warrendale, PA, USA, 2014; pp. 1–54. [Google Scholar] [CrossRef]

- Lu, X.; Qian, Y.; Yang, Z.; Han, D.; Ji, J.; Zhou, X.; Huang, Z. Experimental study on compound HCCI (homogenous charge compression ignition) combustion fueled with gasoline and diesel blends. Energy 2014, 64, 707–718. [Google Scholar] [CrossRef]

- Han, D.; Ickes, A.M.; Bohac, S.V.; Huang, Z.; Assanis, D.N. HC and CO emissions of premixed low-temperature combustion fueled by blends of diesel and gasoline. Fuel 2012, 99, 13–19. [Google Scholar] [CrossRef]

- Feng, Z.; Zhan, C.; Tang, C.; Yang, K.; Huang, Z. Experimental investigation on spray and atomization characteristics of diesel/gasoline/ethanol blends in high pressure common rail injection system. Energy 2016, 112, 549–561. [Google Scholar] [CrossRef]

- Kodavasal, J.; Kolodziej, C.P.; Ciatti, S.A. Effects of injection parameters, boost, and swirl ratio on gasoline compression ignition operation at idle and low-load conditions. Int. J. Engine Res. 2016, 18, 824–836. [Google Scholar] [CrossRef]

- Sim, J.; Elwardany, A.; Jaasim, M. Numerical Simulations of Hollow-Cone Injection and Gasoline Compression Ignition Combustion With Naphtha Fuels. J. Energy Resour. Technol. 2017, 138, 052202. [Google Scholar] [CrossRef]

- Zhong, S.; Wyszynski, M.L.; Megaritis, A.; Yap, D.; Xu, H. Experimental Investigation into HCCI Combustion Using Gasoline and Diesel Blended Fuels. SAE Int. J. Engines 2005. [Google Scholar] [CrossRef]

- Leermakers, C.A.J.; Van den Berge, B.; Luijten, C.C.M.; Somers, L.M.T.; de Goey, L.P.H.; Albrecht, B.A. Gasoline-Diesel Dual Fuel: Effect of Injection Timing and Fuel Balance; SAE Technical Paper 2011-01-2437; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Prikhodko, V.Y.; Curran, S.J.; Barone, T.L.; Lewis, S.A.; Storey, J.M.; Cho, K.; Wagner, R.M.; Parks, J.E. Emission Characteristics of a Diesel Engine Operating with In-Cylinder Gasoline and Diesel Fuel Blending; SAE International: Warrendale, PA, USA, 2010; Volume 2266, pp. 946–955. [Google Scholar]

- Curran, S.; Prikhodko, V.; Cho, K.; Sluder, C.; Parks, J.; Wagner, R.; Kokjohn, S.; Reitz, R. In-Cylinder Fuel Blending of Gasoline/Diesel for Improved Efficiency and Lowest Possible Emissions on a Multi-Cylinder Light-Duty Diesel Engine; SAE Technical Paper 2010-01-2206; SAE International: Warrendale, PA, USA, 2010; pp. 1–20. [Google Scholar] [CrossRef]

- Lawler, B.; Splitter, D.; Szybist, J.; Kaul, B. Thermally Stratified Compression Ignition: A new advanced low temperature combustion mode with load flexibility. Appl. Energy 2017, 189, 122–132. [Google Scholar] [CrossRef]

- Loeper, P.; Ra, Y.; Foster, D.; Ghandhi, J. Experimental and computational assessment of inlet swirl effects on a gasoline compression ignition (GCI) light-duty diesel engine. In Proceedings of the SAE 2014 World Congress and Exhibition, Detroit, MI, USA, 8–10 April 2014; Volume 1. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K. Evolution, challenges and path forward for low temperature combustion engines. Prog. Energy Combust. Sci. 2017, 61, 1–56. [Google Scholar] [CrossRef]

- Krasselt, J.; Foster, D.; Ghandhi, J.; Herold, R.; Reuss, D.; Najt, P. Investigations into the Effects of Thermal and Compositional Stratification on HCCI Combustion—Part I: Metal Engine Results. SAE Int. J. Engines 2009, 2, 1034–1053. [Google Scholar] [CrossRef]

- Kalghatgi, G.T.; Risberg, P.; Angstrom, H.-E. Partially Pre-Mixed Auto-Ignition of Gasoline to Attain Low Smoke and Low NOx at High Load in a Compression Ignition Engine and Comparison with a Diesel Fuel; SAE Technical Paper 2007-01-0006; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Loeper, P.; Ra, Y.; Adams, C.; Foster, D.; Ghandhi, J.; Andrie, M.; Krieger, R.; Durrett, R. Experimental investigation of light-medium load operating sensitivity in a gasoline compression ignition (GCI) light-duty diesel engine. In Proceedings of the SAE 2013 World Congress and Exhibition, Detroit, MI, USA, 16–18 April 2013; Volume 2. [Google Scholar] [CrossRef]

- Kodavasal, J.; Kolodziej, C.P.; Ciatti, S.A.; Sibendu, S. Computational Fluid Dynamics Simulation of Gasoline Compression Ignition. J. Energy Resour. Technol. 2017, 137, 032212. [Google Scholar] [CrossRef]

- Yu, L.; Shuai, S.; Li, Y.; Li, B.; Liu, H.; He, X.; Wang, Z. An experimental investigation on thermal efficiency of a compression ignition engine fueled with five gasoline-like fuels. Fuel 2017, 207, 56–63. [Google Scholar] [CrossRef]

- Zhou, L.; Boot, M.D.; De Goey, L.P.H. Gasoline—Ignition Improver—Oxygenate Blends as Fuels for Advanced Compression Ignition Combustion; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013; Volume 2. [Google Scholar] [CrossRef]

- Doornbos, G.; Somhorst, J.; Boot, M. Literature Study and Feasibility Test Regarding a Gasoline/EHN Blend Consumed by Standard CI-Engine Using a Non-PCCI Combustion Strategy; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Weall, A.; Collings, N. Investigation into Partially Premixed Combustion in a Light-Duty Multi-Cylinder Diesel Engine Fuelled Gasoline and Diesel with a Mixture of Gasoline and Diesel; SAE Technical Paper 2007-01-4058; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Şahin, Z.; Durgun, O.; Bayram, C. Experimental investigation of gasoline fumigation in a single cylinder direct injection (DI) diesel engine. Energy 2008, 33, 1298–1310. [Google Scholar] [CrossRef]

- Manente, V.; Johansson, B.; Cannella, W. Gasoline partially premixed combustion, the future of internal combustion engines? Int. J. Engine Res. 2011, 12, 194–208. [Google Scholar] [CrossRef]

- Cnr, I.M.; Corcione, F.; Valentino, G.; Tornatore, C.; Merola, S.; Marchitto, L. Optical Investigation of Premixed Low-Temperature Combustion of Lighter Fuel Blends in Compression Ignition Engines; SAE Technical Paper 2011-24-0045; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, H.; Zhang, J.; Tian, G.; Kalghatgi, G. Investigation into Light Duty Dieseline Fuelled Partially-Premixed Compression Ignition Engine. SAE Int. J. Engines 2011, 4, 2124–2134. [Google Scholar] [CrossRef]

- Yang, H.; Shuai, S.; Wang, Z.; Wang, J. Fuel octane effects on gasoline multiple premixed compression ignition (MPCI) mode. Fuel 2013, 103, 373–379. [Google Scholar] [CrossRef]

- Kim, K.; Kim, D.; Jung, Y.; Bae, C. Spray and combustion characteristics of gasoline and diesel in a direct injection compression ignition engine. Fuel 2013, 109, 616–626. [Google Scholar] [CrossRef]

- Thoo, W.J.; Kevric, A.; Ng, H.K.; Gan, S.; Shayler, P.; La Rocca, A. Characterisation of ignition delay period for a compression ignition engine operating on blended mixtures of diesel and gasoline. Appl. Therm. Eng. 2014, 66, 55–64. [Google Scholar] [CrossRef]

- Kolodziej, C.; Kodavasal, J.; Ciatti, S.; Som, S.; Shidore, N.; Delhom, J. Achieving Stable Engine Operation of Gasoline Compression Ignition Using 87 AKI Gasoline Down to Idle; SAE Technical Paper 2015-01-0832; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Shuai, S.; Xu, H. Combustion and emission characteristics of Multiple Premixed Compression Ignition (MPCI) mode fuelled with different low octane gasolines. Appl. Energy 2015, 160, 769–776. [Google Scholar] [CrossRef]

- Du, J.; Sun, W.; Guo, L.; Xiao, S.; Tan, M.; Li, G.; Fan, L. Experimental study on fuel economies and emissions of direct-injection premixed combustion engine fueled with gasoline/diesel blends. Energy Convers. Manag. 2015, 100, 300–309. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.M.; An, H.; Chou, S.K. Modeling on blend gasoline/diesel fuel combustion in a direct injection diesel engine. Appl. Energy 2015, 160, 777–783. [Google Scholar] [CrossRef]

- Yang, B.; Yao, M.; Zheng, Z.; Yue, L. Experimental Investigation of Injection Strategies on Low Temperature Combustion Fuelled with Gasoline in a Compression Ignition Engine. J. Chem. 2015, 2015, 207248. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, C.; Liu, Q.; Wang, Q.; Wang, X. An experimental study on the combustion and emission characteristics of a diesel engine under low temperature combustion of diesel/gasoline/n-butanol blends. Appl. Energy 2016, 170, 219–231. [Google Scholar] [CrossRef]

- Lee, S.; Jeon, J.; Park, S. Optimization of combustion chamber geometry and operating conditions for compression ignition engine fueled with pre-blended gasoline-diesel fuel. Energy Convers. Manag. 2016, 126, 638–648. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Wang, J.; He, X. Improvement of emission characteristics and thermal ef fi ciency in diesel engines by fueling gasoline/diesel/PODEn blends. Energy 2016, 97, 105–112. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Shuai, S.; Wang, J. Investigations into Multiple Premixed Compression Ignition mode Fuelled with Different Mixtures of Gasoline and Diesel; SAE Technical Paper 2015-01-0833; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef] [Green Version]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Kalghatgi, G.T. Fuel effects in CAI gasoline engines. In HCCI and CAI Engines for the Automotive Industry; Zhao, H., Ed.; Woodhead Publishing: Cambridge, UK, 2007; pp. 206–237. [Google Scholar]

- Eng, J.A. Characterization of Pressure Waves in HCCI Combustion Reprinted From: Homogeneous Charge Compression Ignition Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2002; Volume 1, p. 15. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B.; Yao, C.; Liu, M.; Wu, T.; Wei, H.; Dou, Z. Study on cyclic variability of dual fuel combustion in a methanol fumigated diesel engine. Fuel 2016, 164, 99–109. [Google Scholar] [CrossRef]

- Maurya, R.K.; Agarwal, A.K. Experimental investigation of cyclic variations in HCCI combustion parameters for gasoline like fuels using statistical methods. Appl. Energy 2013, 111, 310–323. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, F.; Zhao, Y.; Li, D.; Lei, X. Study on cycle-by-cycle variations in a diesel engine with dimethyl ether as port premixing fuel. Appl. Energy 2015, 143, 58–70. [Google Scholar] [CrossRef]

- Christensen, M.; Johansson, B. Supercharged Homogeneous Charge Compression Ignition (HCCI) with Exhaust Gas Recirculation and Pilot Fuel; SAE Technical Paper 2000-01-1835; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Sjöberg, M.; Dec, J.E.; Hwang, W. Thermodynamic and Chemical Effects of EGR and Its Constituents on HCCI Autoignition; SAE Technical Paper 2007-01-0207; SAE International: Warrendale, PA, USA, 2007; pp. 776–790. [Google Scholar] [CrossRef]

- Iverson, R.J.; Herold, R.E.; Augusta, R.; Foster, D.E.; Ghandhi, J.B.; Eng, J.A.; Najt, P.M. The Effects of Intake Charge Preheating in a Gasoline-Fueled HCCI Engine; SAE Technical Paper 2005-01-3742; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Andreae, M.M.; Cheng, W.K.; Kenney, T.; Yang, J. Effect of Air Temperature and Humidity on Gasoline HCCI Operating in the Negative-Valve-Overlap Mode; SAE Technical Paper 2007-01-0221; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Iida, M.; Aroonsrisopon, T.; Hayashi, M.; Foster, D.; Martin, J. The Effect of Intake Air Temperature, Compression Ratio and Coolant Temperature on the Start of Heat Release in an HCCI (Homogeneous Charge Compression Ignition) Engine—Operation Ragin; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Qiu, T.; Song, X.; Lei, Y.; Dai, H.; Cao, C.; Xu, H.; Feng, X. Effect of back pressure on nozzle inner flow in fuel injector. Fuel 2016, 173, 79–89. [Google Scholar] [CrossRef]

- Desantes, J.M.; Payri, R.; Salvador, F.J.; Manin, J. Influence on Diesel Injection Characteristics and Behavior Using Biodiesel Fuels; SAE Technical Paper 2009-01-0851; SAE International: Warrendale, PA, USA, 2009; Volume 4970. [Google Scholar] [CrossRef]

- Wislocki, K.; Pielecha, I.; Czajka, J.; Stobnicki, P. Experimental and Numerical Investigations into Diesel High-Pressure Spray—Wall Interaction under Various Ambient Conditions; SAE International: Warrendale, PA, USA, 2012; Volume 1662. [Google Scholar] [CrossRef]

- Shehata, M.S.; Attia, A.M.A.; Abdel Razek, S.M. Corn and soybean biodiesel blends as alternative fuels for diesel engine at different injection pressures. Fuel 2015, 161, 49–58. [Google Scholar] [CrossRef]

- Tirabnpath, P.; Hespel, C.; Chanchaona, S.; Foucher, F. Influence of biodiesel and diesel fuel blends on the injection rate under cold conditions. Fuel 2015, 144, 80–89. [Google Scholar] [CrossRef]

- Anand, K.; Reitz, R.D. Exploring the benefits of multiple injections in low temperature combustion using a diesel surrogate model. Fuel 2016, 165, 341–350. [Google Scholar] [CrossRef]

- Kim, D.; Bae, C. Application of double-injection strategy on gasoline compression ignition engine under low load condition. Fuel 2017, 203, 792–801. [Google Scholar] [CrossRef]

- Jiang, X.; Deng, F.; Yang, F.; Zhang, Y.; Huang, Z. High temperature ignition delay time of DME/n -pentane mixture under fuel lean condition. Fuel 2017, 191, 77–86. [Google Scholar] [CrossRef]

- Ying, W.; Li, H.; Jie, Z.; Longbao, Z. Study of HCCI-DI combustion and emissions in a DME engine. Fuel 2009, 88, 2255–2261. [Google Scholar] [CrossRef]

- Dernotte, J.; Dec, J.E.; Ji, C. Investigation of the Sources of Combustion Noise in HCCI Engines. SAE Int. J. Engines 2014, 7. [Google Scholar] [CrossRef]

- Ogunkoya, D.; Fang, T. Engine performance, combustion, and emissions study of biomass to liquid fuel in a compression-ignition engine. Energy Convers. Manag. 2015, 95, 342–351. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodríguez-Fernández, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Cairns, A.; Blaxill, H. The Effects of Combined Internal and External Exhaust Gas Recirculation on Gasoline Controlled Auto-Ignition; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Zhao, H.; Peng, Z.; Williams, J.; Ladommatos, N. Understanding the Effects of Recycled Burnt Gases on the Controlled Autoignition (CAI) Combustion in Four-Stroke Gasoline Engines; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Olsson, J.-O.; Tunestål, P.; Ulfvik, J.; Johansson, B. The effect of cooled EGR on emissions and performance of a turbocharged HCCI engine. Soc. Autom. Eng. 2003, 2003, 21–38. [Google Scholar] [CrossRef]

- Yao, M.; Chen, Z.; Zheng, Z.; Zhang, B.; Xing, Y. Effect of EGR on HCCI Combustion fuelled with Dimethyl Ether (DME) and Methanol Dual-Fuels; SAE Technical Paper 2005-01-3730; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Sjöberg, M.; Dec, J.E. EGR and Intake Boost for Managing HCCI Low-Temperature Heat Release over Wide Ranges of Engine Speed; SAE International: Warrendale, PA, USA, 2007; pp. 776–790. [Google Scholar] [CrossRef]

- Saxena, S.; Bedoya, I.D. Fundamental phenomena affecting low temperature combustion and HCCI engines, high load limits and strategies for extending these limits. Prog. Energy Combust. Sci. 2013, 39, 457–488. [Google Scholar] [CrossRef]

- Suzuki, Y.; Harada, T.; Watanabe, H.; Shoji, M.; Matsushita, Y.; Aoki, H.; Miura, T. Visualization of aggregation process of dispersed water droplets and the effect of aggregation on secondary atomization of emulsified fuel droplets. Proc. Combust. Inst. 2011, 33, 2063–2070. [Google Scholar] [CrossRef]

- Califano, V.; Calabria, R.; Massoli, P. Experimental evaluation of the effect of emulsion stability on micro-explosion phenomena for water-in-oil emulsions. Fuel 2014, 117, 87–94. [Google Scholar] [CrossRef]

- Segawa, D.; Yamasaki, H.; Kadota, T.; Tanaka, H.; Enomoto, H.; Tsue, M. Water-coalescence in an oil-in-water emulsion droplet burning under microgravity. Proc. Combust. Inst. 2000, 28, 985–990. [Google Scholar] [CrossRef]

- Strizhak, P.A.; Piskunov, M.V.; Volkov, R.S.; Legros, J.C. Evaporation, boiling and explosive breakup of oil–water emulsion drops under intense radiant heating. Chem. Eng. Res. Des. 2017, 127, 72–80. [Google Scholar] [CrossRef]

- Kadota, T.; Yamasaki, H. Recent advances in the combustion of water fuel. Prog. Energy Combust. Sci. 2002, 28, 385–404. [Google Scholar] [CrossRef]

- Watanabe, H.; Okazaki, K. Visualization of secondary atomization in emulsified-fuel spray flow by shadow imaging. Proc. Combust. Inst. 2013, 34, 1651–1658. [Google Scholar] [CrossRef]

- Putrasari, Y.; Lim, O. A study on combustion and emission of GCI engines fueled with gasoline-biodiesel blends. Fuel 2017, 189, 141–154. [Google Scholar] [CrossRef]

- Thongchai, S.; Lim, O. The influence of biodiesel blended in gasoline-based fuels on macroscopic spray structure from a diesel injector. Int. J. Autom. Technol. 2019. accepted. [Google Scholar]

- Kanti, S.; Kim, K.; Lim, O. Experimental study on non-vaporizing spray characteristics of biodiesel-blended gasoline fuel in a constant volume chamber. Fuel Process. Technol. 2018, 178, 322–335. [Google Scholar] [CrossRef]

- Thongchai, S.; Lim, O. Investigation of the combustion characteristics of gasoline compression ignition engine fueled with gasoline-biodiesel blends. J. Mech. Sci. Technol. 2018, 32, 959–967. [Google Scholar] [CrossRef]

- Vu, D.N.; Das, S.K.; Jwa, K.; Lim, O. Characteristics of auto-ignition in gasoline—Biodiesel blended fuel under engine-like conditions. Proc. Inst. Mech. Eng. Part D J. Authomob. Eng. 2018, 1–13. [Google Scholar] [CrossRef]

- Putrasari, Y.; Lim, O. A study of a GCI engine fueled with gasoline-biodiesel blends under pilot and main injection strategies. Fuel 2018, 221, 269–282. [Google Scholar] [CrossRef]

| Properties (units) | Malaysia | Indonesia Republic of | Thailand | US | European Union | Brazil |

|---|---|---|---|---|---|---|

| SNI | E 14214 | ASTM D6751 | E 14214 | ANP 42 | ||

| Minimum flash point (°C) | 182 | 100 | 120 | 130 | 120 | 100 |

| Viscosity at 40 °C (cSt) | 4.415 | 2.3–6.0 | 3.5–5 | 1.9–6 | 3.5–5 | - |

| Maximum of sulphated ash (%-mass) | 0.01 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Minimum of sulphur (%-mass) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | - |

| Maximum of cloud point (°C) | 15.2 | 18 | - | - | - | - |

| Classification of copper corrosion (3 h, 50 °C) | 1 | 3 | 1 | 3 | 1 | 1 |

| Minimum of cetane number | - | 51 | 51 | 47 | 51 | - |

| Maximum of sediment and water content (volume %) | 0.05 | 0.05 | - | 0.05 | - | 0.05 |

| Maximum of CCR 100% (%-mass) | - | - | 0.3 | 0.05 | - | 0.1 |

| Neutralization value (mg, KOH/gm) | - | - | - | 0.05 | 0.05 | 0.08 |

| Maximum Free glycerin (%-mass) | 0.01 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Maximum Total glycerin (%-mass) | 0.01 | 0.24 | 0.25 | 0.24 | 0.25 | 0.38 |

| Maximum Phosphorus (%-mass) | - | 10 | 0.001 | 0.001 | 0.001 | - |

| Maximum distillation temperature (°C) | - | 360 | - | 360 | - | 360 |

| Oxidation stability (h) | - | - | 6 | 3 | 6 | 6 |

| Test Item | Unit | Test Method | Gasoline | GB05 | GB10 | GB15 | GB20 | B100 | Diesel |

|---|---|---|---|---|---|---|---|---|---|

| Heating value | MJ/kg | ASTM D240:2009 | 45.86 | 45.32 | 44.92 | 44.57 | 43.6 | 39.79 | 45.93 |

| Kinematic Viscosity (40 °C) | Mm2/s | ISO 3104:2008 | 0.735 | - | - | - | - | 4.229 | 2.798 |

| Lubricity | µm | ISO 12156-1:2012 | 548 | 290 | 282 | 252 | 236 | 189 | 238 |

| Cloud Point | °C | ISO 3015:2008 | −57 | −37 | −32 | −20 | −16 | 3 | −5 |

| Pour Point | °C | ASTM D6749:2002 | −57 | −57 | −57 | −57 | −57 | 1 | −9 |

| Density (15 °C) | kg/m3 | ISO 12185:2003 | 712.7 | 722.3 | 732.2 | 742.6 | 757.1 | 882.3 | 826.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Putrasari, Y.; Lim, O. A Review of Gasoline Compression Ignition: A Promising Technology Potentially Fueled with Mixtures of Gasoline and Biodiesel to Meet Future Engine Efficiency and Emission Targets. Energies 2019, 12, 238. https://doi.org/10.3390/en12020238

Putrasari Y, Lim O. A Review of Gasoline Compression Ignition: A Promising Technology Potentially Fueled with Mixtures of Gasoline and Biodiesel to Meet Future Engine Efficiency and Emission Targets. Energies. 2019; 12(2):238. https://doi.org/10.3390/en12020238

Chicago/Turabian StylePutrasari, Yanuandri, and Ocktaeck Lim. 2019. "A Review of Gasoline Compression Ignition: A Promising Technology Potentially Fueled with Mixtures of Gasoline and Biodiesel to Meet Future Engine Efficiency and Emission Targets" Energies 12, no. 2: 238. https://doi.org/10.3390/en12020238

APA StylePutrasari, Y., & Lim, O. (2019). A Review of Gasoline Compression Ignition: A Promising Technology Potentially Fueled with Mixtures of Gasoline and Biodiesel to Meet Future Engine Efficiency and Emission Targets. Energies, 12(2), 238. https://doi.org/10.3390/en12020238