Regular and Irregular Performance Variation of Module String and Occurred Conditions for Potential Induced Degradation-Affected Crystalline Silicon Photovoltaic Power Plants

Abstract

:1. Introduction

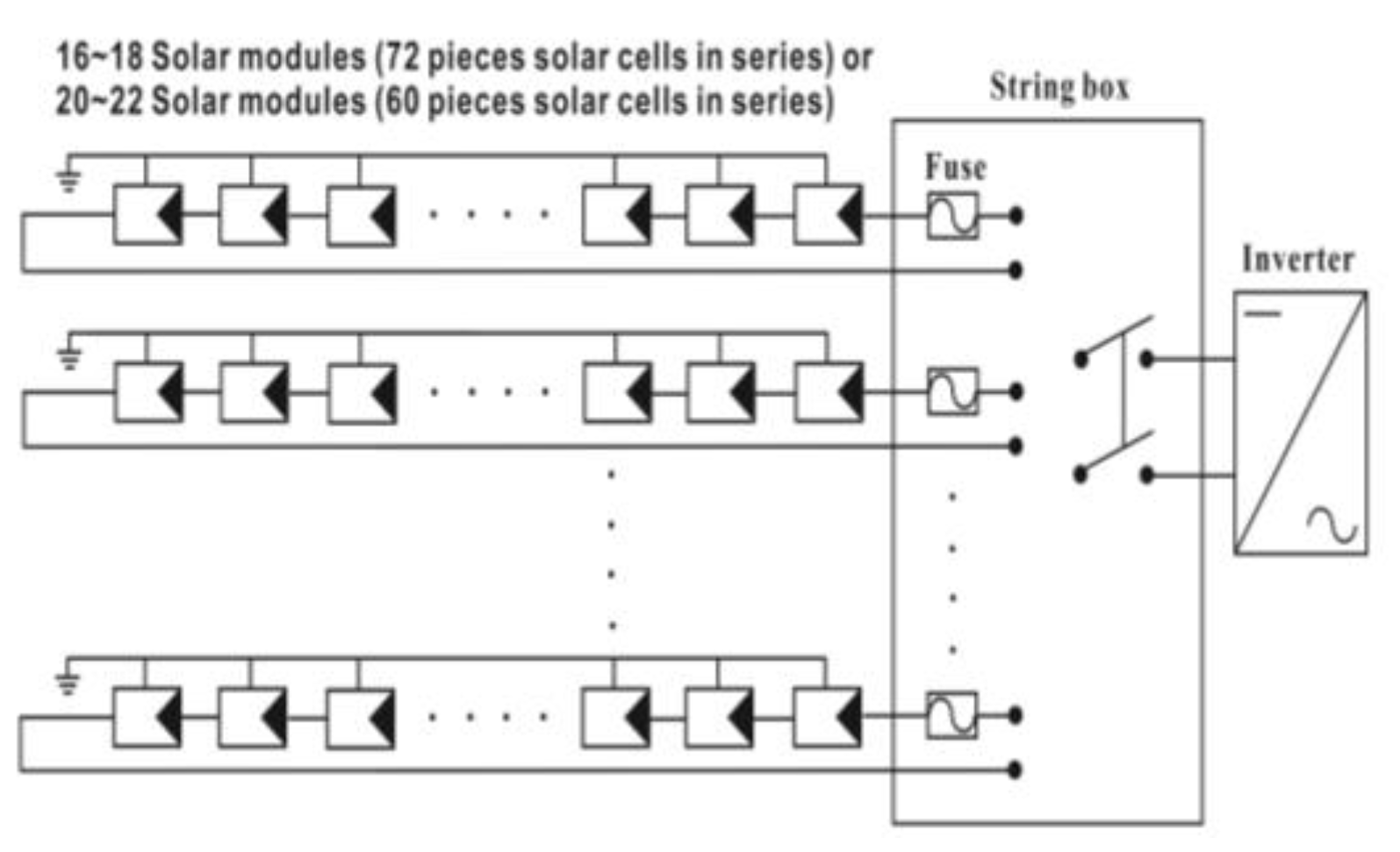

2. Materials and Methods

3. Results

3.1. Probability of PID for Crystalline Silicon Photovoltaic Power Plants Distributed in Various Climate Conditions

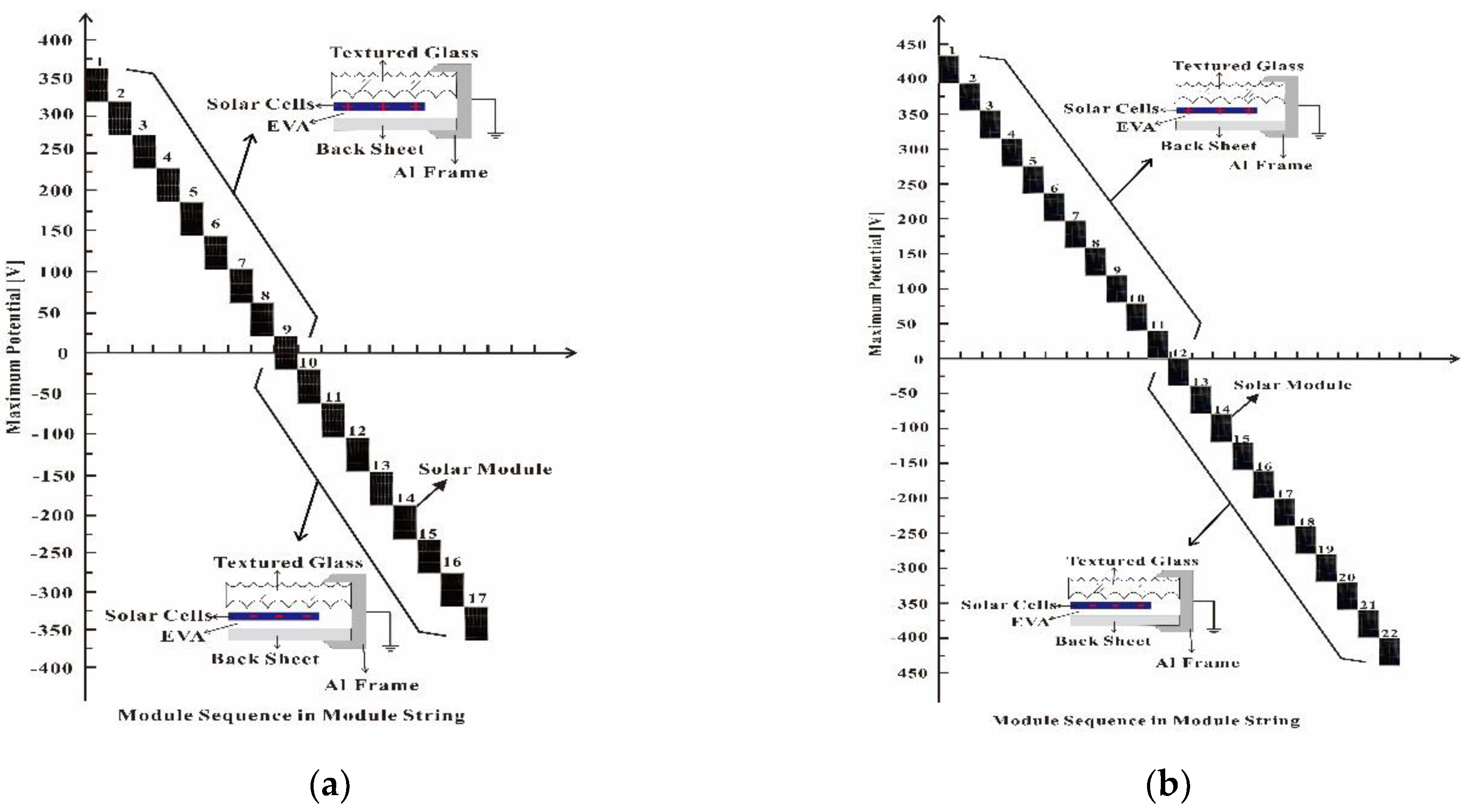

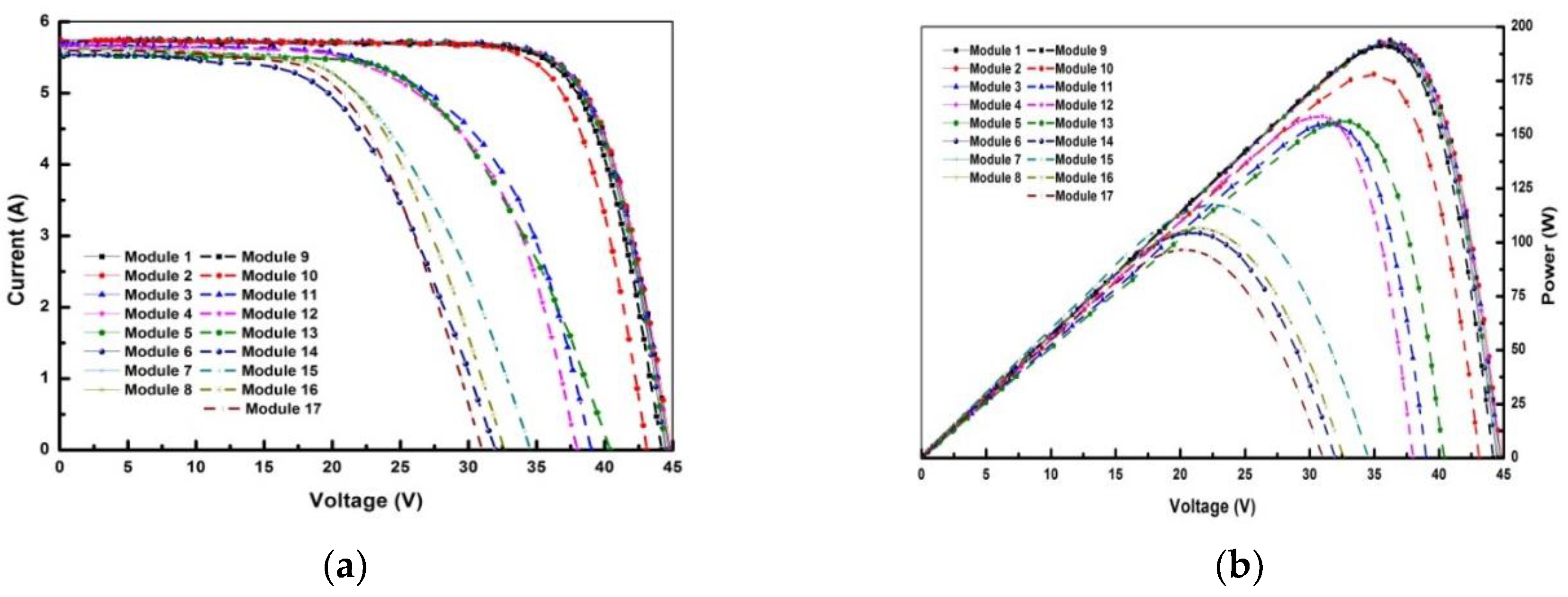

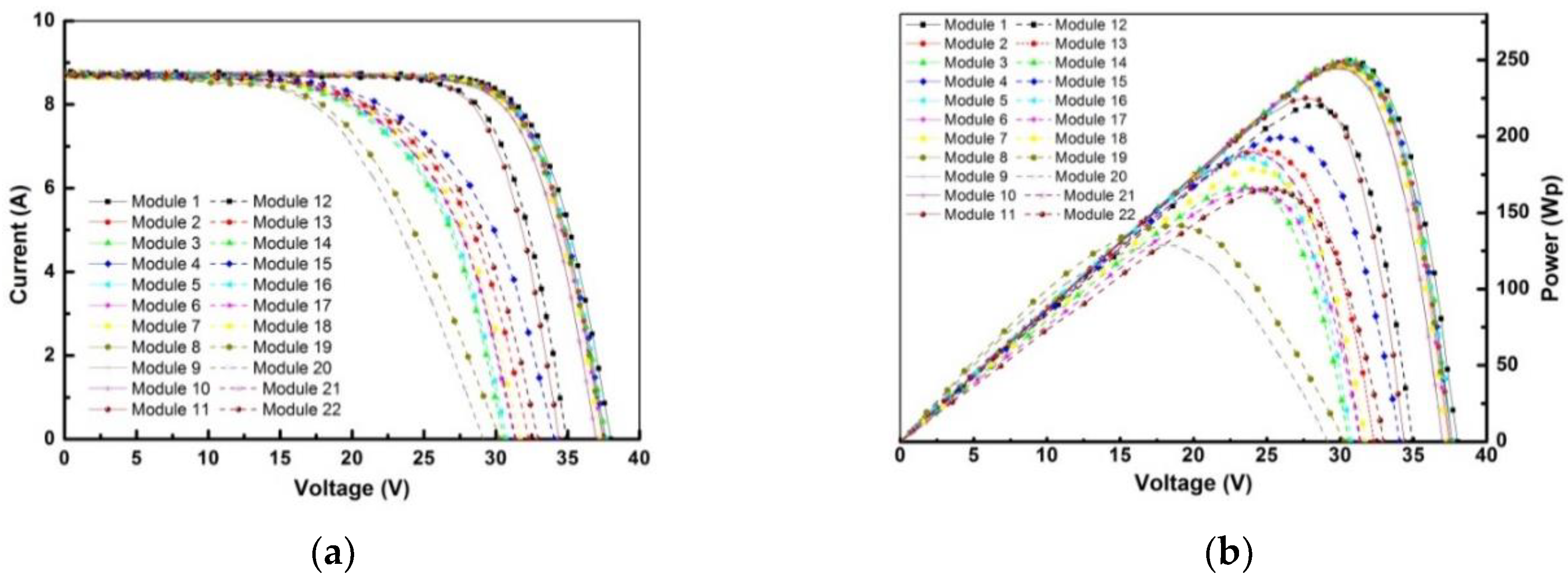

3.2. Regular and Irregular Performance Deterioration of Module Strings from PID-Affected Power Plants

3.2.1. Regular and Irregular Degradation of Open Circuit Voltage of Module Strings under Field Conditions

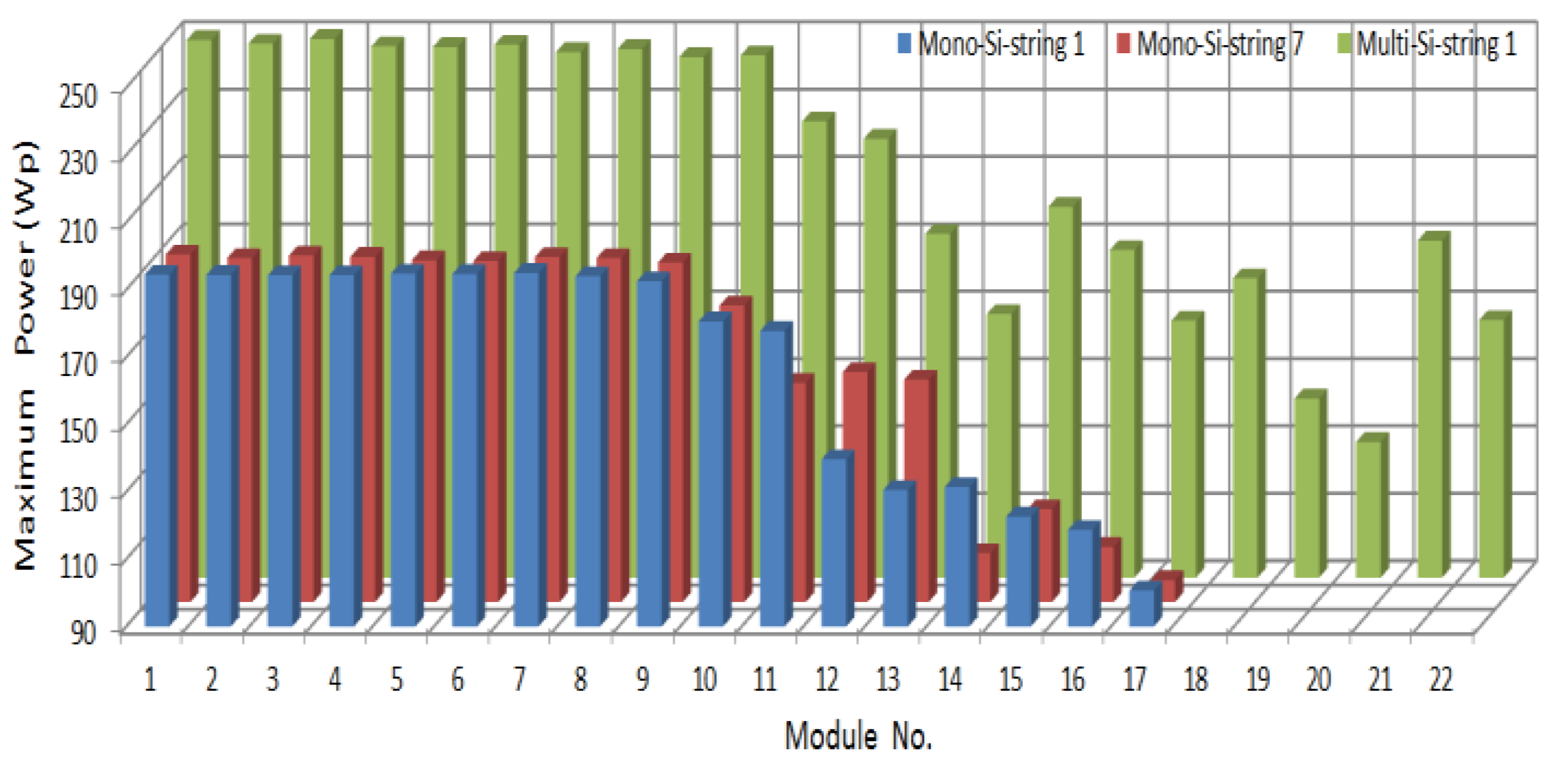

3.2.2. Parametric Analysis of Solar Modules Dismounted from PID-Affected Power Plants under STC

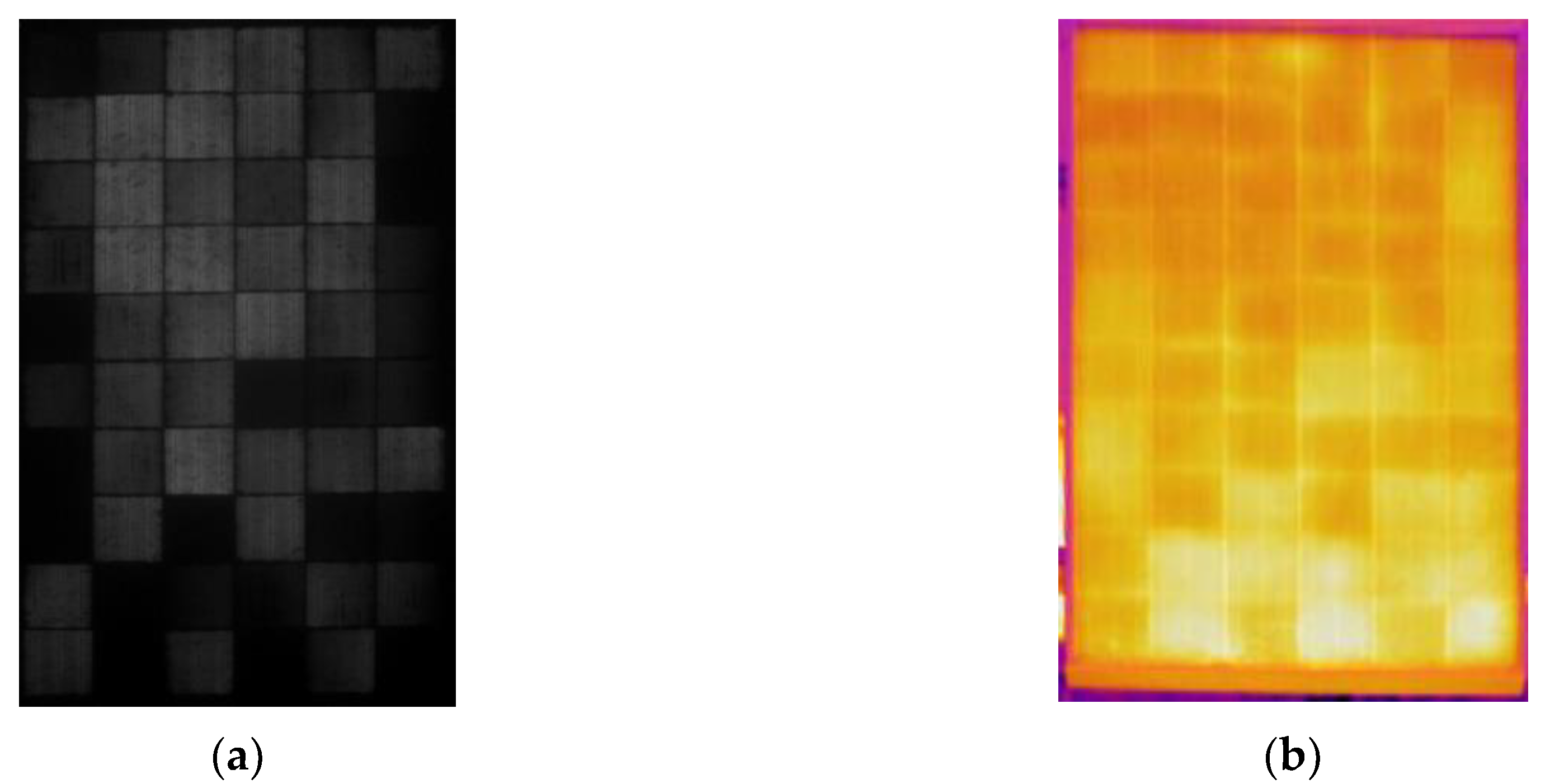

3.2.3. Electroluminescence Images and Thermography Images for Monocrystalline and Multicrystalline Silicon Solar Modules Suffered from PID

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Osterwald, C.R.; McMahon, T.J. History of accelerated and qualification testing of terrestrial photovoltaic modules: A literature review. Prog. Photovolt. Res. Appl. 2009, 17, 11–33. [Google Scholar] [CrossRef]

- Munoz, M.A.; Alonso-Garcia, M.C.; Vela, N.; Chenlo, F. Early degradation of silicon PV modules and guaranty conditions. Sol. Energy 2011, 85, 2264–2274. [Google Scholar] [CrossRef]

- Ishii, T.; Takashima, T.; Otani, K. Long-term performance degradation of various kinds of photovoltaic modules under moderate climatic. Prog. Photovolt. Res. Appl. 2011, 19, 170–179. [Google Scholar] [CrossRef]

- Kahoul, N.; Chenni, R.; Cheghib, H.; Mekhilef, S. Evaluating the reliability of crystalline silicon photovoltaic modules in harsh environment. Renew. Energy 2017, 109, 66–72. [Google Scholar] [CrossRef]

- Schneller, E.J.; Brooker, R.P.; Shiradkar, N.S.; Rodgers, M.P.; Dhere, N.G.; Davis, K.O.; Seigneur, H.P.; Mohajeri, N.; Wohlgemuth, J.; Scardera, G.; et al. Manufacturing metrology for c-Si module reliability and durability Part Ⅲ: Module manufacturing. Renew. Sustain. Energy Rev. 2016, 59, 992–1016. [Google Scholar] [CrossRef]

- Luo, W.; Khoo, Y.S.; Hacke, P.; Naumann, V.; Lausch, D.; Harvey, S.P.; Singh, J.P.; Chai, J.; Wang, Y.; Aberle, A.G.; et al. Potential-induced degradation in photovoltaic modules: A critical review. Energy Environ. Sci. 2017, 10, 43–68. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Masuda, A.; Ohdaira, K. Changes in the current density-voltage and external quantum efficiency characteristics of n-type single-crystalline silicon photovoltaic modules with a rear-side emitter undergoing potential-induced degradation. Sol. Energy Mater. Sol. Cells 2016, 151, 113–119. [Google Scholar] [CrossRef]

- Hacke, P.; Terwilliger, K.; Glick, S.; Tamizhmani, G.; Tatapudi, S.; Stark, C.; Koch, S.; Weber, T.; Berghold, J.; Hoffmann, S.; et al. Interlaboratory Study to Determine Repeatability of the Damp-Heat Test Method for Potential-Induced Degradation and Polarization in Crystalline Silicon Photovoltaic Modules. IEEE J. Photovolt. 2015, 5, 94–101. [Google Scholar] [CrossRef]

- Swanson, R.; Cudzinovic, M.; Deceuster, D.; Desai, V.; Jurgens, J.; Kaminar, N.; Mulligan, W.; Rodrigues-Barbosa, L.; Rose, D.; Smith, D.; et al. The surface polarization effect in high efficiency silicon solar cells. In Proceedings of the 15th International Photovoltaic Science & Engineering Conference, Shanghai, China, 10–15 October 2005; pp. 410–413. [Google Scholar]

- Hacke, P.; Smith, R.; Terwilliger, K.; Perrin, G.; Sekulic, B.; Kurtz, S. Development of an IEC test for crystalline silicon modules to qualify their resistance to system voltage stress. Prog. Photovolt. Res. Appl. 2014, 22, 775–783. [Google Scholar] [CrossRef]

- Oh, J.; Bowden, S.; Tamizhmani, G. Potential-induced degradation (PID): Incomplete recovery of shunt resistance and quantum efficiency losses. IEEE J. Photovolt. 2015, 6, 1540–1548. [Google Scholar]

- Koentopp, M.B.; Krober, M.; Taubitz, C. Toward a PID standard: Understanding and modeling of laboratory tests and field progression. IEEE J. Photovolt. 2016, 6, 252–257. [Google Scholar] [CrossRef]

- Koehl, M.; Hoffmann, S. Impact of rain and soiling on potential induced degradation. Prog. Photovolt. Res. Appl. 2016, 24, 1304–1309. [Google Scholar] [CrossRef]

- Kaden, T.; Lammers, K.; Moller, H.J. Power loss prognosis from thermographic images of PID affected silicon solar modules. Sol. Energy Mater. Sol. Cells 2015, 142, 24–28. [Google Scholar] [CrossRef]

- Naumann, V.; Lausch, D.; Hahnel, A.; Bauer, J.; Breitenstein, O.; Graff, A.; Werner, M.; Swatek, S.; Großer, S.; Bagdahn, J.; et al. Explanation of potential-induced degradation of the shunting type by Na decoration of stacking faults in Si solar cells. Sol. Energy Mater. Sol. Cells 2013, 120, 383–389. [Google Scholar]

- Ziebarth, B.; Mrovec, M.; Elsasser, C.; Gumbsch, P. Potential-induced degradation in solar cells: Electronic structure and diffusion mechanism of sodium in stacking faults of silicon. J. Appl. Phys. 2014, 116, 093510–093517. [Google Scholar] [CrossRef]

- Harvey, S.P.; Aguiar, J.A.; Hacke, P.; Guthrey, H.; Johnston, S.; AI-Jassim, M. Sodium accumulation at potential-induced degradation shunted areas in polycrystalline silicon modules. IEEE J. Photovolt. 2016, 6, 1440–1445. [Google Scholar] [CrossRef]

- Dong, N.C.; Islam, M.A.; Ishikawa, Y.; Uraoka, Y. The influence of sodium ions decorated micro-cracks on the evolution of potential induced degradation in p-type crystalline silicon solar cells. Sol. Energy 2018, 174, 1–6. [Google Scholar] [CrossRef]

- Koch, S.; Nieschalk, D.; Berghold, J.; Wendlandt, S.; Krauter, S.; Grunow, P. Potential induced degradation effects on crystalline silicon cells with various antireflective coatings. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt, Germany, 24–28 September 2012; pp. 1985–1990. [Google Scholar]

- Mishina, K.; Ogishi, A.; Ueno, K.; Jonai, S.; Ikeno, N.; Saruwatari, T.; Hara, K.; Ogura, A.; Yamazaki, T.; Doi, T.; et al. Plasma-enhanced chemical-vapor deposition of silicon nitride film for high resistance to potential-induced degradation. Jpn.J. Appl. Phys. 2015, 54. [Google Scholar] [CrossRef]

- Zhou, C.; Zhu, J.; Zhou, S.; Tang, Y.; Foss, S.E.; Haug, H.; Nordseth, O.; Marstein, E.S.; Wang, W. SiOyNx/SiNx stack: A promising surface passivation layer for high-efficiency and potential-induced degradation resistant mc-silicon solar cells. Prog. Photovolt. Res. Appl. 2017, 25, 23–32. [Google Scholar] [CrossRef]

- Hylsky, J.; Strachala, D.; Hladik, J.; Cudek, P.; Kazda, T.; Vanek, J.; Vyroubal, P.; Stary, J. Design of P-type photovoltaic cells resistant to potential-induced degradation. IEEE J. Photovolt. 2018, 8, 1215–1221. [Google Scholar] [CrossRef]

- Kapur, J.; Stika, K.M.; Westphal, C.S.; Norwood, J.L.; Hamzavytehrany, B. Prevention of potential-induced degradation with thin ionomer film. IEEE J. Photovolt. 2015, 5, 219–223. [Google Scholar] [CrossRef]

- Virtuani, A.; Annigoni, E.; Ballif, C. One-type-fits-all-systems: Strategies for preventing potential-induced degradation in crystalline silicon solar photovoltaic modules. Prog. Photovolt. Res. Appl. 2019, 27, 13–21. [Google Scholar] [CrossRef]

- Hoffmann, S.; Koehl, M. Effect of humidity and temperature on the potential-induced degradation. Prog. Photovolt. Res. Appl. 2014, 22, 173–179. [Google Scholar] [CrossRef]

- Suzuki, S.; Nishiyama, N.; Yoshino, S.; Ujiro, T.; Watanabe, S.; Doi, T.; Masuda, A.; Tanahashi, T. Acceleration of potential-induced degradation by salt-mist preconditioning in crystalline silicon photovoltaic modules. Jpn. J. Appl. Phys. 2015, 54, KG08–KG12. [Google Scholar] [CrossRef]

- Lausch, D.; Naumann, V.; Breitenstein, O.; Bauer, J.; Graff, A.; Bagdahn, J.; Hagendorf, C. Potential-Induced Degradation (PID): Introduction of a Novel Test Approach and Explanation of Increased Depletion Region Recombination. IEEE J. Photovolt. 2014, 4, 834–840. [Google Scholar] [CrossRef]

- Pingel, S.; Frank, O.; Winkler, M.; Daryan, S.; Geipel, T.; Hoehne, H.; Berghold, J. Potential induced degradation of solar cells and panels. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 2817–2822. [Google Scholar]

- Jaeckel, B.; Cosic, M.; Arp, J. Investigation of c-Si modules degradation and recovery effect under high potentials: CV-PID. In Proceedings of the 40th Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 0937–0942. [Google Scholar]

- Wang, H.; Cheng, X.; Yang, H.; He, W.; Chen, Z.; Xu, L.; Song, D. Potential-induced degradation: Recombination behavior, temperature coefficients and mismatch losses in crystalline silicon photovoltaic power plant. Sol. Energy 2019, 188, 258–264. [Google Scholar] [CrossRef]

- Hylsky, J.; Strachala, D.; Vyroubal, P.; Gudek, P.; Vanek, J.; Vanysek, P. Effect of negative potential on the extent of PID degradation in photovoltaic power plant in a real operation mode. Microelectron. Reliab. 2018, 85, 12–18. [Google Scholar] [CrossRef]

- Yang, H.; Wang, F.; Wang, H.; Chang, J.; Song, D.; Su, C. Performance deterioration of p-type single crystalline silicon solar modules affected by potential induced degradation in photovoltaic power plant. Microelectron. Reliab. 2017, 72, 18–23. [Google Scholar] [CrossRef]

- Islam, M.A.; Hasanuzzaman, M.; Rahim, N.A. A comparative investigation on in-situ and laboratory standard test of the potential induced degradation of crystalline silicon photovoltaic modules. Renew. Energy 2018, 127, 102–113. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, P.; Yang, H.; Chang, J.; Song, D.; Sang, S. Performance variation of dark current density-voltage characteristics for PID-affected monocrystalline silicon solar modules from the field. Microelectron. Reliab. 2018, 81, 320–327. [Google Scholar] [CrossRef]

- Chang, J.; Wang, H.; Yang, H.; Zhang, J.; Huang, J. The Real Situation of Potential-Induced Degradation in Multicrystalline Silicon Photovoltaic Power Plant. In Proceedings of the 43rd IEEE Photovoltaic Specialist Conference, Portland, OR, USA, 5–10 June 2016; pp. 1682–1685. [Google Scholar]

- Huang, J.; Li, H.; Sun, Y.; Wang, H.; Yang, H. Investigation on potential-induced degradation in a 50 MWp crystalline silicon photovoltaic power plant. Int. J. Photoenergy 2018, 1–7. [Google Scholar] [CrossRef]

- Masuda, A.; Akitomi, M.; Inoue, M.; Okuwaki, K.; Okugawa, A.; Ueno, K.; Yamazaki, T.; Hara, K. Microscopic aspects of potential-induced degradation phenomena and their recovery process for p-type crystalline Si photovoltaic modules. Curr. Appl. Phys. 2016, 16, 1659–1665. [Google Scholar] [CrossRef]

- Martinez-Moreno, F.; Figueiredo, G.; Lorenzo, E. In-the-field PID related experiences. Sol. Energy Mater. Sol. Cells 2018, 174, 485–493. [Google Scholar] [CrossRef] [Green Version]

- Oh, W.; Kim, J.; Kang, B.; Bae, S.; Lee, K.D.; Lee, H.S.; Kim, D.; Chan, S. Evaluation of potential-induced degradation in crystalline Si solar cells using Na fault injection. Microelectron. Reliab. 2016, 64, 646–649. [Google Scholar] [CrossRef]

- Gou, X.; Li, X.; Yu, J.; Wang, S.; Zhang, X.; Zhou, S.; Fan, W.; Huang, Q. Influence of crystal defect density of silicon wafers on potential-induced degradation (PID) in solar cells and modules. Phys. Status Solidi A 2017, 214, 1700006. [Google Scholar] [CrossRef]

- Hacke, P.; Spataru, S.; Terwilliger, K.; Perrin, G.; Glick, S.; Kurtz, S.; Wohlgemuth, J. Accelerated testing and modeling of potential-induced degradation as a function of temperature and relative humidity. IEEE J. Photovolt. 2015, 5, 1549–1553. [Google Scholar] [CrossRef]

- Bauer, J.; Naumann, V.; Grober, S.; Hagendorf, C.; Schutze, M.; Breitenstein, O. On the mechanism of potential-induced degradation in crystalline silicon solar cells. Phys. Status Solidi–Rapid Res. Lett. 2012, 6, 331–333. [Google Scholar] [CrossRef]

- Masuda, A.; Hara, Y.; Jonai, S. Consideration on Na diffusion and recovery phenomena in potential-induced degradation for crystalline Si photovoltaic modules. Jpn. J. Appl. Phys. 2016, 55, BF10–BF15. [Google Scholar] [CrossRef]

- Park, J.; Chan, M.K.Y. Mechanism of Na accumulation at extended defects in Si from first-principles. J. Appl. Phys. 2018, 123. [Google Scholar] [CrossRef]

- Spataru, S.; Hacke, P.; Sera, D.; Packard, C.; Kerekes, T.; Teodorescu, R. Temperature-dependency analysis and correction methods of in situ power-loss estimation for crystalline silicon modules undergoing potential-induced degradation stress testing. Prog. Photovolt. Res. Appl. 2015, 23, 1536–1549. [Google Scholar] [CrossRef]

| Location | Latitude (N) | Longitude (E) | Installed Capacity (MWp) | ModuleTechnology | PID or PID-Free |

|---|---|---|---|---|---|

| Yining | 44°01′ | 81°17′ | 50 | Multi-Si | PID-free |

| Aksu | 40°21′ | 81°09′ | 100 | Multi-Si | PID-free |

| Jiayuguan | 39°48′ | 98°17′ | 50 | Multi-Si | PID-free |

| Quyang | 38°42′ | 114°40′ | 100 | Multi-Si | PID |

| Jinchang | 38°31′ | 102°12′ | 150 | Multi-Si | PID-free |

| Golmud | 35°35′ | 92°42′ | 590 | Multi-Si& Mono-Si | PID-free |

| Dingbian | 37°23′ | 107°45′ | 100 | Multi-Si& Mono-Si | PID (Mono-Si) |

| Xi’an | 34°17′ | 108°57′ | 1 | Multi-Si | PID-free |

| Shanghai | 31°15′ | 121°29′ | 1 | Multi-Si& Mono-Si | PID-free |

| Shigatse | 29°16′ | 88°57′ | 20 | Mono-Si | PID-free |

| Taizhou | 28°40′ | 121°26′ | 2 | Mono-Si | PID-free |

| Zhanjiang | 21°15′ | 110°22′ | 0.1 | Mono-Si | PID |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Sun, Y.; Wang, H.; Zhang, J. Regular and Irregular Performance Variation of Module String and Occurred Conditions for Potential Induced Degradation-Affected Crystalline Silicon Photovoltaic Power Plants. Energies 2019, 12, 4230. https://doi.org/10.3390/en12224230

Huang J, Sun Y, Wang H, Zhang J. Regular and Irregular Performance Variation of Module String and Occurred Conditions for Potential Induced Degradation-Affected Crystalline Silicon Photovoltaic Power Plants. Energies. 2019; 12(22):4230. https://doi.org/10.3390/en12224230

Chicago/Turabian StyleHuang, Jingsheng, Yaojie Sun, He Wang, and Junjun Zhang. 2019. "Regular and Irregular Performance Variation of Module String and Occurred Conditions for Potential Induced Degradation-Affected Crystalline Silicon Photovoltaic Power Plants" Energies 12, no. 22: 4230. https://doi.org/10.3390/en12224230

APA StyleHuang, J., Sun, Y., Wang, H., & Zhang, J. (2019). Regular and Irregular Performance Variation of Module String and Occurred Conditions for Potential Induced Degradation-Affected Crystalline Silicon Photovoltaic Power Plants. Energies, 12(22), 4230. https://doi.org/10.3390/en12224230