Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables

Abstract

:1. Introduction

2. Research Problem

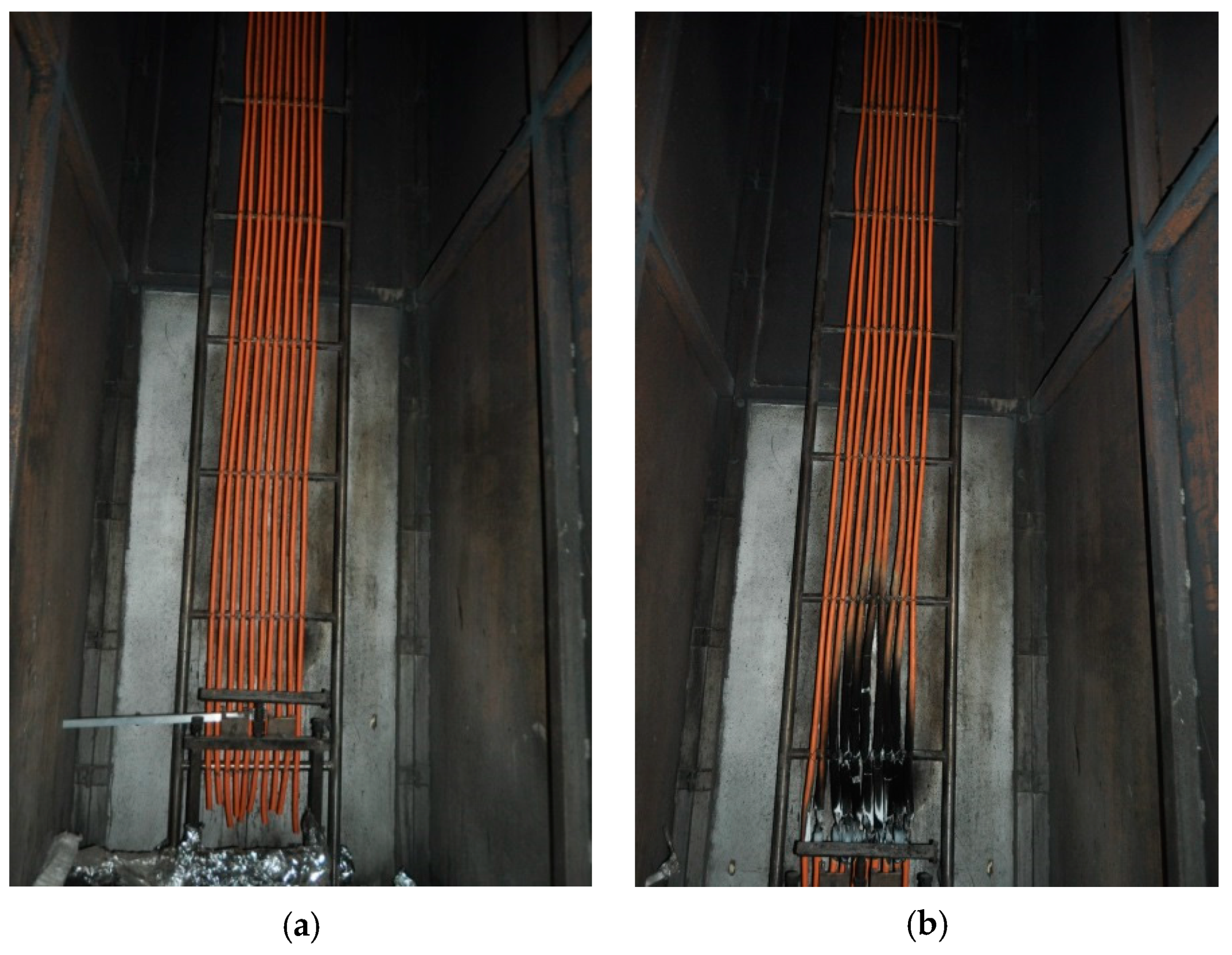

3. Materials and Methods

- Construction materials of conductors (specimens No 1, 2, 3, and 4);

- Conductor cross-section (specimens No 12, 13, 14, and 15);

- Non-metallic materials of cables (specimens No 5, 6, 7, and 8); and

- Armor and concentric conductors’ occurrence (specimens No 8, 9, 10, and 11).

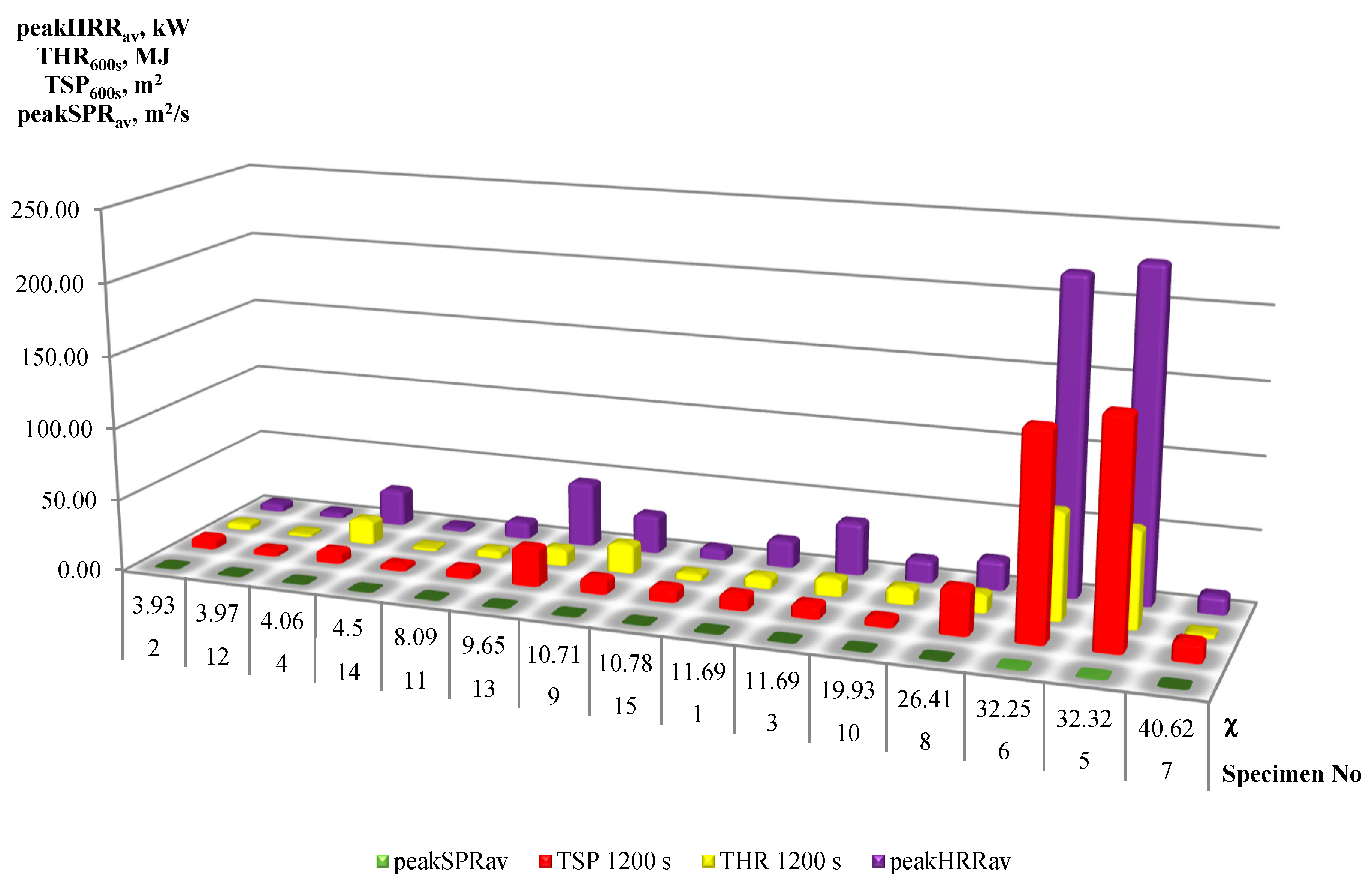

4. Results and Discussion

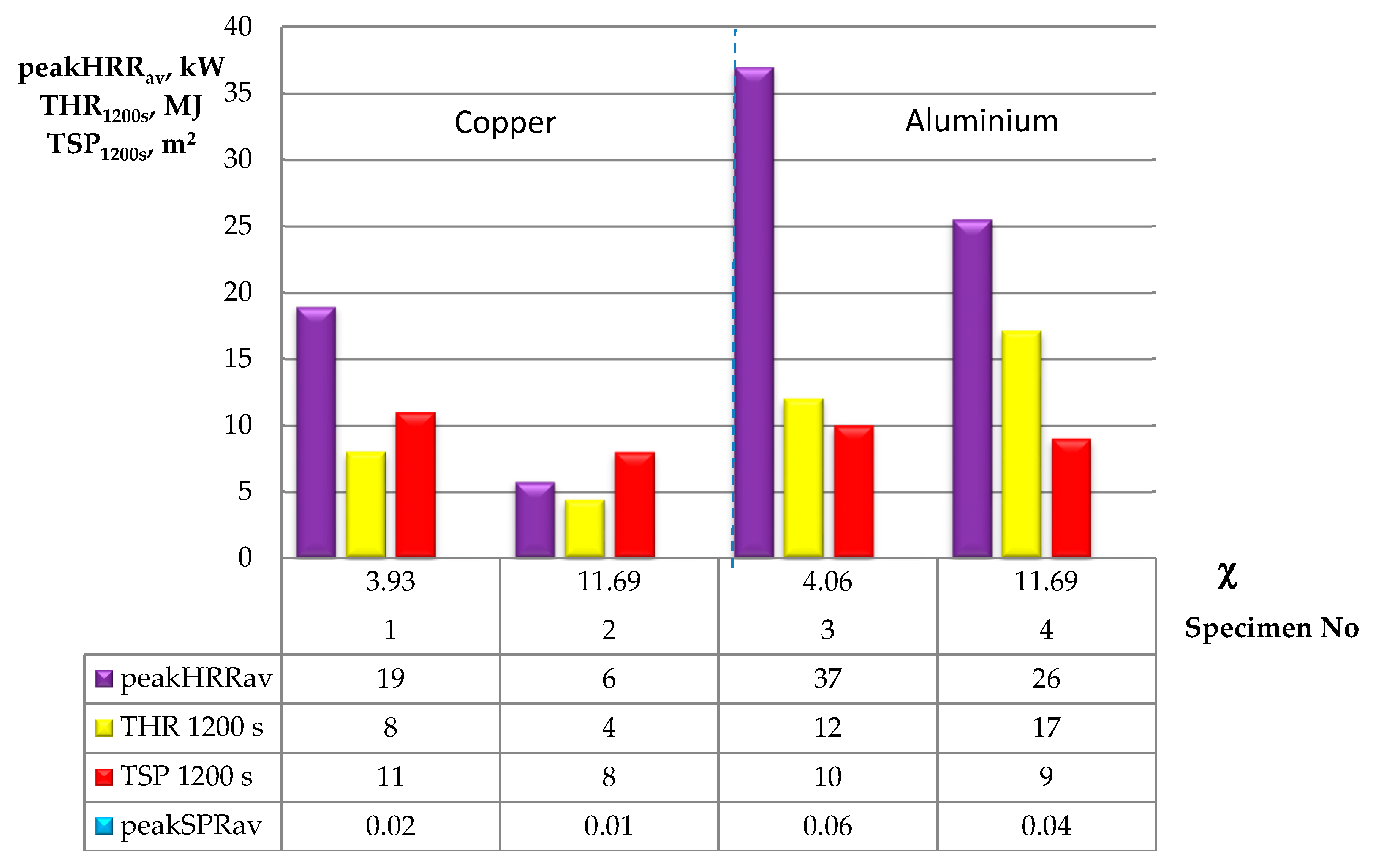

4.1. Material Used for the Conductor Construction

4.2. Conductor Cross-Section Shape

4.3. Number of Conductors

4.4. Materials Used for the Formulation of Non-Metallic Elements

4.5. Concentric Barrier

5. Conclusions

- The construction, number of conductors, and presence of armor or concentric metallic conductors improves fire properties by forming a barrier against flame penetration in the cable.

- The use of copper conductors resulted in a decrease of the fire parameters studied in comparison with cables including aluminum conductors (peakHRRav parameter was even four times lower for the copper cable)

- Construction materials based on non-plasticized poly(vinyl chloride) (PVC) significantly reduce fire properties of cables than halogen-free materials (LS0H), such as silane cross-linked polyolefin (XLPO), ethylene-acrylic copolymers (EVA), non-vulcanized rubber (EPDM), polyethylene (PE), and cross-linked polyethylene (XLPE) (peakHRRav parameter more than 17 times higher for the fully halogenated cable), which is due to the decomposition process of PVC material.

- There is no clear relationship shown between the fire parameters and the cable parameter, χ.

Author Contributions

Funding

Conflicts of Interest

References

- Kaczorek-Chrobak, K.; Fangrat, J. Relationship between Non-Metallic Material Content and Fire Properties of Electric Cables. Fire Mater. under review.

- Kaczorek-Chrobak, K.; Fangrat, J.; Papis, B.K. Instalacje Elektryczne a Bezpieczeństwo Pożarowe Budynków (Evaluation of Electrical Installations in terms of Fire Safety of Buildings). In Proceedings of the 65th Scientific Conference, Krynica-Zdrój, Poland, 15–20 September 2019. (In Polish). [Google Scholar]

- Huang, X.; Nakamura, Y. A Review of Fundamental Combustion Phenomena in Wire Fires. Fire Technol. 2019, 1–46. [Google Scholar] [CrossRef]

- Lenartowicz, R.; Fangrat, J. Electrical installations supplying fire safety equipment. In Instalacje zasilające Urządzenia Bezpieczeństwa Pożarowego; Monografia ITB: Warszawa, Poland, 2016; Volume 1. (In Polish) [Google Scholar]

- Delichatsios, M.A.; Delichatsios, M.M. Upward Flame Spread and Critical Conditions for PE/PVC Cables in a Tray Configuration. In Proceedings of the Fourth International Symposium on Fire Safety Science, Ottawa, ON, Canada, 13–17 July 1994; pp. 433–444. [Google Scholar]

- Fernandez-Pello, A.C.; Hasegawa, H.K.; Staggs, K.; Lipska-Quinn, A.E.; Alvares, N.J. A Study of the Fire Performance of Electrical Cables. In Proceedings of the Third International Symposium on Fire Safety Science, Bristol, UK, 13–15 February 2007; pp. 237–247. [Google Scholar]

- Yanga, H.; Fua, Q.; Chenga, X.; Yuenc, R.K.K.; Zhanga, H. Investigation of the flammability of different cables using pyrolysis combustion flow calorimeter. Procedia Eng. 2013, 62, 778–785. [Google Scholar] [CrossRef]

- Carcillo, M.; Caro, A.-S.; Sonnier, R.; Ferry, L.; Gesta, E.; Lagreve, C. Fire behaviour of electrical cables in cone calorimeter: Influence of cables structure and layout. Fire Saf. J. 2018, 99, 12–21. [Google Scholar]

- Braun, E.; Shields, J.R.; Harris, R.H.F. Fammability Characteristics of Electrical Cables Using the Cone Calorimeter; NIST Report NISTIR 88 4003; National Institute of Standards and Technology, Center for Fire Research: Gaithersburg, MD, USA, 1989.

- Hirshler, M.M. Survey of fire testing of electrical cables. Fire Mater. 1992, 16, 107–118. [Google Scholar] [CrossRef]

- Journeaux, T.; Sundström, B.; Johansson, P.; Försth, M.; Grayson, S.; Gregory, S.; Breulet, H.; Messa, S.; Lehrer, R.; Kobilsek, M. CEMAC—CE-MArking of Cables; SP Rapport NV-2010:27; SP Technical Research Institute of Sweden: Boräs, Sweden, 2010. [Google Scholar]

- Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC. Off. J. Eur. Union 2011, L88, 5–43.

- Wiatr, J.; Lenartowicz, R.; Orzechowski, M. Podstawy Projektowania i Budowy Elektroenergetycznych Linii Kablowych SN. Zeszyty dla Elektryków; Dom Wydawniczy Medium: Warszawa, Poland, 2009. [Google Scholar]

- Kaczorek-Chrobak, K. Reakcja na ogień kabli bezhalogenowych oraz kabli na bazie PVC (Reaction to fire of PVC based halogen-free electric cables). Elektroinfo 2015, 10, 25–27. (In Polish) [Google Scholar]

- Kaczorek-Chrobak, K. Toksyczne produkty spalania izolacji i powłok kabli elektroenergetycznych (Toxic combustion products of insulations and outer sheaths of cables). Elektroinfo 2015, 5, 24–27. (In Polish) [Google Scholar]

- Kaczorek, K. Bench-Scale Fire Toxicity Measurements of Polymers and Cables. Master’s Thesis, University of Central Lancashire, Preston, UK, February 2009. [Google Scholar]

- Kaczorek-Chrobak, K.; Kolbrecki, A. Reakcja na ogień kabli elektroenergetycznych (Reaction to Fire of Electric Cables). Materiały Budowlane 2015, 7, 40–43. (In Polish) [Google Scholar]

- CLC/TS 50576:2016 Electric Cables—Extended Application of Test Results for Reaction to Fire; CEN/CENELEC: Brussels, Belgium, 2017.

- Sundström, B.; Försth, M.; Johansson, P.; Grayson, S.; Journeaux, T. Prediction of Fire Classification of Cables. Extended Application of Test Data. In Extended Application of Test Data. In Proceedings of the 12th International Fire Science & Engineering Conference Interflam, Nottingham, UK, 5–7 July 2010. [Google Scholar]

- EN 50399:2011+A1:2016 Common test methods for cables under fire conditions—Heat release and smoke production measurement on cables during flame spread test—Test apparatus, procedures, results. bsi 2011. [CrossRef]

- Grayson, S.J.; Van Hees, P.; Green, A.M.; Vercellotti, U. Assessing the Fire Performance of Electric Cables (FIPEC). Fire Mater. 2001, 25, 49–60. [Google Scholar] [CrossRef]

- Foesth, M.; Sjostrom, J.; Wickstrom, U.; Andersson, P.; Girardin, B. Characterization of the thermal exposure in the EN 50399 cable test apparatus. In Proceedings of the 14th International Conference and Exhibition on Fire and Materials 2015, San Francisco, CA, USA, 2–4 February 2015; pp. 23–37. [Google Scholar]

- Grayson, S.J.; Van Hees, P.; Vercellotti, U.; Breulet, H.; Green, A.M. Fire Performance of Electric Cables—New Test Methods and Measurement Techniques (FIPEC); Final Report of European Commission; Interscience Communications Ltd: Hampshire, UK, 2010. [Google Scholar]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 85th ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Holley, C.E., Jr.; Huber, E.J., Jr. The Heat of Combustion of Magnesium and Aluminum; Los Alamos Scientific Laboratory: New Mexico, NW, USA, 1951. [Google Scholar]

- Gupta, B.L.; Varma, M. Ignition and combustion studies on metallized UDMH-RFNA bipropellant system. Indian J. Eng. Mater. Sci. 1999, 6, 13–21. [Google Scholar]

- Abbud-Madrid, A.; Fiechtner, G.J.; Branch, M.C.; Daily, J.W. Ignition and Combustion Characteristics of Pure Bulk Metals: Normal-Gravity Test Results. In Proceedings of the 32nd Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 10–13 January 1994. [Google Scholar]

- Kaczorek-Chrobak, K.; Fangrat, J. Combustion Products Dependence on Ventilation Conditions for PVC-Insulated Electric Wire. In Proceedings of the 11th Mediterranean Combustion Symposium, Adeje, Spain, 16–20 June 2019. [Google Scholar]

- Cullis, C.F.; Hirschler, M.M. The Combustion of Organic Polymers; Oxford University Press: New York, NY, USA, 1982. [Google Scholar]

- Babrauskas, V. Heat Release Rates. In SFPE Handbook of Fire Protection Engineering, 5th ed.; Hurley, M.J., Gottuk, D.T., Hall, J.R., Jr., Harada, K., Kuligowski, E.D., Puchovsky, M., Torero, J.L., Watts, J.M., Jr., Wieczorek, C.J., Eds.; Springer: Berlin, Germany, 2016. [Google Scholar]

- Kaczorek-Chrobak, K.; Fangrat, J. Fire Effluent Toxicity of PVC-Insulated Electric Wire in Ventilation-Controlled Fires. J. Hazard. Mater. submitted.

- McCarthy, S. Environmentally Benign Resins and Additives, for Use in the Wire and Cable Industry; Technical Report; The Massachusetts Toxics Use Reduction Institute, University of Massachusetts Lowell: Lowell, MA, USA, 2003; Available online: https://www.turi.org/TURI_Publications/Toxics_Use_Reduction_for_Industrial_Sectors/Wire_Cable/Environmentally_Benign_Resins_and_Additives_for_Use_in_the_Wire_and_Cable_Industry (accessed on 1 October 2019).

- Barnes, M.A.; Briggs, P.J.; Hirschler, M.M.; Matheson, A.F.; O’Neill, T.J. A Comparative Study of the Fire Performance of Halogenated and Non-Halogenated Materials for Cable Applications. Part I Tests on Materials and Insulated Wires. Fire Mater. 1996, 20, 1–16. [Google Scholar] [CrossRef]

| Specimen No | Conductor Size | χ | Conductor Material/Shape | Outer Sheath | Armor or Concentric Conductor | Bedding | Insulation |

|---|---|---|---|---|---|---|---|

| 1 | 4 × 35 mm2 | 3.93 | Cu/sector | LS0H compound | Cu tape and wires | LS0H tape | XLPE |

| 2 | 3 × 300 mm2 | 11.69 | Cu/sector | LS0H compound | Cu tape and wires | LS0H tape | XLPE |

| 3 | 4 × 35 mm2 | 4.06 | Al/sector | LS0H compound | Cu tape and wires | LS0H tape | XLPE |

| 4 | 3 × 300 mm2 | 11.69 | Al/sector | LS0H compound | Cu tape and wires | LS0H tape | XLPE |

| 5 | 3 × 1.5 mm2 | 32.32 | Cu/round | PVC compound | – | EPDM | PVC |

| 6 | 3 × 1.5 mm2 | 32.25 | Cu/round | PVC compound | – | EPDM | XLPE |

| 7 | 3 × 1.5 mm2 | 40.62 | Cu/round | LS0H compound | – | EPDM | XLPE |

| 8 | 3 × 1.5 mm2 | 26.41 | Cu/round | EVA/ATH/ZnB | – | XLPE | silane XLPO |

| 9 | 2 × 16 mm2 | 10.71 | Cu/round | thermoplastic LS0H | – | LS0H compound | XLPE |

| 10 | 3 × 1.5 mm2 | 19.93 | Cu/round | EVA/ATH/ZnB | Cu tape and wires | XLPE | silane XLPO |

| 11 | 2 × 16 mm2 | 8.09 | Cu/round | thermoplastic LS0H | Galvanized steel wires | LS0H compound | XLPE |

| 12 | 3 × 300 mm2 | 3.97 | Cu/round | LS0H compound | Cu tape and wires | LS0H compound | XLPE |

| 13 | 4 × 25 mm2 | 9.65 | Cu/round | thermoplastic LS0H | Galvanized steel wires | LS0H compound | XLPE |

| 14 | 3 × 300 mm2 | 4.5 | Cu/sector | LS0H compound | Cu tape and wires | LS0H compound | XLPE |

| 15 | 4 × 25 mm2 | 10.78 | Cu/sector | thermoplastic LS0H | Galvanized steel wires | LS0H compound | XLPE |

| Specimen No. | peakHRRav, kW | THR1200s, MJ | TSP1200s, m2 | peakSPRav, m2/s |

|---|---|---|---|---|

| 1 | 355 | 125 | 204 | 1.06 |

| 2 | 322 | 117 | 228 | 1.04 |

| 3 | 327 | 117 | 203 | 0.91 |

| Coefficient of variation, % | 4.3 | 3.0 | 6.6 | 5.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczorek-Chrobak, K.; Fangrat, J. Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables. Energies 2019, 12, 4569. https://doi.org/10.3390/en12234569

Kaczorek-Chrobak K, Fangrat J. Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables. Energies. 2019; 12(23):4569. https://doi.org/10.3390/en12234569

Chicago/Turabian StyleKaczorek-Chrobak, Katarzyna, and Jadwiga Fangrat. 2019. "Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables" Energies 12, no. 23: 4569. https://doi.org/10.3390/en12234569

APA StyleKaczorek-Chrobak, K., & Fangrat, J. (2019). Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables. Energies, 12(23), 4569. https://doi.org/10.3390/en12234569