1. Introduction

Lithium-ion batteries are currently considered some of the most efficient devices for energy storage in the medium power capacity range, such as that used in electric vehicles and stationary applications. This is due to their favorable advantages, such as its high power density, long lifetimes, and moderate discharge rate [

1]. Nevertheless, the temperature of lithium-ion batteries varies depending on the context in which they are, either increasing or decreasing, thus affecting the performance of the battery. Indeed, the temperature increases during the battery charging and discharging processes.

From the electrical aspect of the batteries it is important to know the state of the battery, which normally includes the state of charge (SoC), state of health (SoH), state of power (SoP) and state of energy (SoE). In general, these states are not observable (i.e., cannot be measured), but need to be estimated from measurements of physical parameters such as voltage, current, temperature or battery usage time.

As future vehicular technologies aim to incorporate high performance batteries, they therefore require an intelligent system to control and monitor the state of the batteries. The current methods used to estimate the states of a battery require a model that represents the physical behavior of the battery. To obtain a good estimate, the model must be accurate, but at the same time simple and cheap.

Electric models vary according to their complexity. In some applications, a simple model that captures the basic electrical behavior of a cell can be used. Electrochemical models are very precise, but are difficult to parametrize and require a high computational capacity [

2]. In most applications, equivalent electrical circuits (EECs) are used because they offer a balance between precision and simplicity, and are also useful to obtain an idea of how a cell responds to different usage scenarios. The electrochemical impedance spectroscopy (EIS) method [

3] is used to determine the parameters of an equivalent circuit of a battery. The method has a reasonable accuracy when compared to a model with the real-time measurements of the charge/discharge of a battery. However, it does not consider a constant phase element (CPE) to represent the Nyquist diagram of the battery at low frequency.

Considerable efforts have been made by researchers to find more accurate and reliable methods to predict the SoC of a battery. One of the most widely used methods has been the Kalman filter (KF) [

4]. The KF estimates the SoC with very low errors and it is easy to implement in real applications. The purpose of the KF is to estimate the state of a system from measurements that contain errors. The original KF is a linear estimation method. To expand its application in non-linear systems, the extended Kalman filter (EKF) [

5,

6,

7,

8] and the unscented Kalman filter (UKF) [

9,

10] have been developed. Both the EKF and UKF methods can estimate the SOC with great accuracy if the battery model is sufficiently accurate and the system is not highly non-linear.

Other methods combine different types of KF. Andre [

11], proposed an advanced mathematical method to estimate the SoC and SoH in a lithium-ion battery by combining a standard Kalman filter (KF) and an unscented Kalman filter (UKF). The first filter estimated the polarization overvoltage, the diffusion overvoltage and the ohmic resistance of the equivalent electrical circuit model of the lithium-ion battery. The outputs of the first filter were the inputs for the second filter, which estimated the SoC and the polarization and diffusion resistance. This method was implemented in a code in MATLAB and the simulations indicated an error in the SoC and SoH estimation below 1%. Fengchun et al., in [

12] proposed a method to estimate the SoC by considering different health conditions in lithium-ion batteries. The concentrated parameter model was used to model the battery, and was estimated using the square minimum method. A discretization method of the battery model was also proposed, which had the advantage of calibrating the parameters in real time. Subsequently, the parameters were incorporated into the algorithm of the adaptive extended Kalman filter (FKEA) to estimate the SoC. The simulations indicated that the parameters of the battery model degraded as the battery aged, therefore the parameters have to be updated to achieve an optimal performance in the estimation of the battery voltage and the estimation of the SoC. For different levels of battery aging, the error in the SoC estimation was less than 2.5%. Li et al. [

13] developed a comparative study of algorithms to estimate the SoC in a LiFePO

4 (LFP) battery used in an electric vehicle. The algorithms that were investigated included the Luenberger observer, extended Kalman filter (EKF) and the sigma Kalman filters or unscented (UKF), which are designed to estimate the SoC in a lithium-ion LFP battery. To evaluate these algorithms, they were verified with two driving profiles typical of an electric vehicle, the new European driving cycle (NECD) and the Artemis cycle. Based on the results of the experimental tests, they concluded that the accuracy of the Luenberger observer was mainly based on the accuracy of the battery model, since it did not take into account the uncertainty of the model and the noise of the measurement. The EKF is comparatively more accurate than the Luenberger observer. Finally, in terms of tracking accuracy, convergence and the robustness of the estimate against the temperature uncertainty and drift current of the sensor, the UKF provided the best results in the SoC estimation unlike the other algorithms.

In recent years, the particle filter (PF) [

14,

15,

16,

17,

18] has been used to estimate the SoC. Additionally, the PF algorithm is very useful in applications that are considered a non-Gaussian source of uncertainty. The PF requires a considerable number of initial particles and the calculation capacity is very high. In [

19], the dependence of the computational load of the PF was solved using a hybrid method to estimate the SoC of a battery based on an adaptive extended Kalman particle filter (AEKPF). Five experimental tests were carried out to evaluate the performance of the algorithm and showed that the average of the absolute error was less than 1%.

The abovementioned methods to estimate the SoC were developed with the model at room temperature, therefore the operation of the method for different temperature conditions of the batteries has not been disclosed, which is important to identify the model parameters for each temperature. The objective of this research was to identify an EEC whose parameters were dependent on the SoC and temperature. In addition, the EEC identification was used to estimate the SoC of a Li-ion cell. The rest of the article is organized as follows:

Section 2 presents the electric model of a Li-ion cell, showing that it is necessary to include a constant phase element in the model in relation to the measured data.

Section 3 carries out a parametric identification of the EEC for different values of SoC and temperature. For this, an optimization problem was solved by means of a genetic algorithm. In

Section 4 a multivariable model was constructed for each EEC parameter based on the SoC and temperature. Two models were tested; in the first, empirical equations were adjusted, while in the second, an ANN was used. In

Section 5, the SoC was estimated using the extended Kalman filter algorithm. Finally in

Section 6, the conclusions of this research are presented.

4. Multivariable Model of the Cell

In this section, a multivariable model of each EEC parameter was constructed where the independent variables were the surface temperature of the cell and the SoC. Two methodologies were tested. In the first, empirical equations are used [

31], while the second used an Artificial Neural Network (ANN).

4.1. Adjustment with Empirical Equations

In the literature different equations have been reported to model the parameters of a battery [

31]. In this section, we tried to find the empirical equations that best fit the parameters obtained in

Section 3.2 of

Section 3. The mathematical models chosen were based on polynomial and exponential functions, in terms of SoC and temperature variables.

As can be seen in

Figure 5, each parameter was strongly dependent on the SoC and to a lesser degree on the temperature. In this way, it was necessary to analyze each parameter separately. To estimate the coefficients of the equations that represented each parameter, the GA was used. In this case, the optimization model to solve this is shown in Equation (13):

where X

kest is the sample k of one of the parameters (R

s, R

1, C

1, W) estimated in the impedance spectrum adjustment, while X

kcal (u) is the parameter obtained by the empirical equation for the sample k, where u is the design variable, which in our case corresponded to the SoC and surface temperature of the cell. An adjustment was made for each parameter.

Finding an equation for the R

s parameter is very difficult due to the high variations it has for different SoC and temperature. Equation (14) shows the best equation we found to model parameter R

s:

For this parameter, all of the coefficient limits were defined between −10 and 10 as shown in

Table 1.

Like parameter R

1, in this case, there was less difficulty in finding the equation that represented it. Equation (15) shows the best equation found to model parameter R

1:

For this parameter, all of the coefficient limits were established between −1 and 1, with the exception of parameter b

3 whose upper limit was 30 shown in

Table 2.

Parameter C

1 shows an exponential type pattern of temperature dependence throughout the measurements. The slope of the exponential function decreased slowly with the SoC, while the rise of the exponential function began at a low SoC. Furthermore, there was the additional complexity that at high temperature (>50 °C) the behavior of the capacitor changed with respect to other temperatures, which can be seen in

Figure 5. The best equation found to model parameter C

1 is defined in Equation (16):

For this parameter, the coefficient limits were as follows: −10 ≤ d

1 ≤ 10; −1 ≤ d

2 ≤ 1; −1 ≤ d

3 ≤ 1; −1 ≤ d

4 ≤ 1; −10 ≤ d

5 ≤ 10; and −1 ≤ d

6 ≤ 1, thus obtaining the values shown in

Table 3.

Parameter W had a similar behavior at different temperatures. The best equation found to model parameter W is defined in Equation (17):

For this parameter, the coefficient limits were as follows: −50 ≤ g

1 ≤ 10; −10 ≤ g

2 ≤ 60; −1 ≤ g

3 ≤ 1; −30 ≤ g

4 ≤ 10; −10 ≤ g

5 ≤ 50; −20 ≤ g

6 ≤ 10; −1 ≤ g

7 ≤ 700; and −1 ≤ g

8 ≤ 1, thus obtaining the values that are shown in

Table 4.

Finally, for the different adjusted models, it was determined that the RMSRE varied in a range between 7% and 34%, which was high for the purposes of this study. Considering this fact, it was decided to try other methodologies in the hope of reducing the adjustment error. For this, the use of an Artificial Neural Network (ANN) was proposed.

Section 4.2 details this type of models and the results obtained.

4.2. Adjustment with Artificial Neuronal Networks

Consider a problem where, after an experiment has been carried out, information is available that relates a variable to other nv independent variables, that is: y = f(x), where f(x) is a function that relations nv input variables x with an output variable y.

Let the ANN be that as shown in

Figure 6, with inputs x

1, x

2; output y, and two hidden layers with three neurons each. w

ij is the weighting factors that connect the neuron i with the j [

32]:

The output of the first layer is given by Equation (18):

The output of each neuron can be affected by an activation function, so that yC1 = f (HC1), where f(x) can be any function, for example f(x) = x, f(x) = x2, f(x) = 1/(1 + e−x) (sigmoid), etc.

By analogy, the output of layer 2 is expressed in Equation (19):

Finally, the output in the last layer is given by Equation (20):

From Equation (20) it can be observed that the output of a neural network is numerically speaking a sequential product of vectors by matrices. The network is completely characterized when the values of the input variables and the weighting coefficients are known. For the above-mentioned network there is the n

coeff = n

v × n

C1 + n

C1 × n

C2 + n

C2 coefficient, where n

v is the number of input variables, n

C1 and n

C2 are the number of neurons in layers 1 and 2, these parameters being the unknowns of the problem. The structure defined in Equations (18)–(20) can be used to find a model for the parameters of the Li-ion cell. For this, it is necessary to formulate the optimization problem. In this sense, the objective function can be defined as the mean square error between the parameters obtained in the frequency spectrum adjustment defined in

Section 3 and the output delivered by the ANN. The optimization problem that needs to be solved is as shown in Equation (21):

In Equation (21) the design variables are the w

ij weighting factors of the network and y

itag corresponds to some of the parameters (Rs, R

1, C

1, W) that were estimated in

Section 3, where training is required for each of them. It should be remembered that the n

d = 88 values are available for each parameter, each of which is linked to a SoC and temperature value. y

itrain is obtained by the network defined in Equations (18)–(20).

Equations (18)–(20) were programmed in MATLAB (R2014a, The MatWorks Inc., Torrance, CA, USA), obtaining an algorithm that allowed us to train a network under the supervised learning scheme. The genetic algorithm was used as an optimization technique as delivered the best results in the simulations. The program allows for the use of up to two layers of a neural network and an arbitrary number of neurons per layer. It can be used as an activation function, that can be; linear, quadratic or sigmoid, the latter being the one that delivered the best results.

Table 5 shows a summary of the structure of the neural network used for the estimation of each parameter (R

s, R

1, C

1, W) by using the sigmoid as an activation function.

4.3. Results

Table 6 shows the values of the modeled parameters at SoC = 90% and 25 °C room temperature.

Table 7 shows the results of the RMSRE for each parameter estimated using the empirical equation methodology and the ANN.

As seen in

Table 7, the estimation model with neural networks presented a better performance with respect to the estimation model using empirical equations, since it reduced the estimation error by almost half.

For example,

Figure 7 show the estimated data of Rs in the parametric identification in

Section 3, in the modeling with equations and in the modeling with the ANN as a function of temperature and SoC, respectively.

Up until now, great effort has been made to obtain a model as accurate as possible of the cell. The reason for this is that the SoC estimation algorithms of Li-ion cells require models as accurate as possible, as this allow for good quality estimations of SoC to be made.

Section 5 explains the methodology chosen to estimate the SoC, known as the extended Kalman filter.

5. Estimation of the SoC

In this section, the extended Kalman filter (EKF) algorithm was used to estimate the SoC of a Li-ion cell. The EKF algorithm has been widely used for SoC estimation [

21]. This algorithm deals with the general problem of estimating a state x

R

n of a process controlled in discrete time that is modeled by a non-linear stochastic difference equation. The EKF is a recursive prediction filter that is based on the use of state-space techniques and recursive algorithms. The non-linear dynamic system is disturbed, and by some noise, mostly corresponds to white noise. To improve the state estimated by the EKF, measurements that relate to the state are used. Therefore, the EKF is divided into a prediction stage and a correction stage [

33].

Based on the general model of a non-linear discrete stochastic system in state-space, which is shown in Equation (22), the stages and the equations of the EKF algorithm are shown in

Figure 8:

where Q = E[ww

T] and R = E[rr

T].

In discrete time, if we consider that the current is constant in the interval ∆t, the SoC can be expressed by Equation (23):

In the SoC estimation a Randles model is considered to be as that of

Figure 1 but considers β = 1, that is, the constant phase element is considered as a capacitance capacitor C

2.

The ratio of the open circuit voltage (V

OCV) to the SoC is non-linear. Using the V

OCV measured in the laboratory, the V

OCV and SoC ratio can be represented by Equation (24). This model was adjusted using the methodology presented in

Section 4.1:

The expressions in Equations (6) and (8) can be written in the form of state-space in continuous time, which is shown in Equation (25):

The discrete-time solution of a continuous-state state space model is given by Equation (26):

Taking the V

OCV expressed by Equation (24) in combination with Equation (26) and in addition to Equation (7), which corresponds to the output voltage ratio of the circuit of

Figure 1, will produce a discrete model in state-space to estimate the SoC using the EKF algorithm. This model is shown in Equation (27):

where

The state variable is defined as x = [V1 V2 SOC]T, the input is uk = ik, and the output is yk = V0 − 2.0659. The values of P0, Qk and Rk are difficult to determine, therefore, these parameters were selected by trial and error. The following values were obtained: the initial covariance was P0= 2 × 10−8, noise process covariance and measurements are Qk = 5 × 10−8 and Rk = 2, respectively.

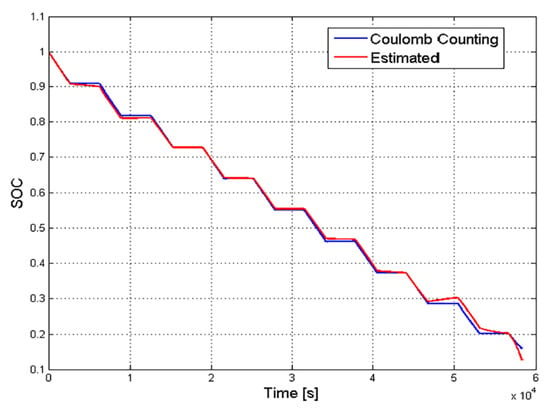

To adjust the algorithm, experimental data from the Li-ion cell discharge process were used. In this process, a pulse of current is applied to the cell every 45 min until the cell is completely discharged. The experiment starts with the cell fully charged, then the voltage and the current are measured at the terminals of the cell, and the current integration method is used to calculate the SoC as a reference. In this way, the initial SoC in the experiment is known and in this investigation the reference obtained by the Coulomb-counting method was considered as the true SoC.

To estimate the SoC, the discharge current and voltage data of the experimental procedure described above were used. To avoid the temperature of the cell increasing due to the current, the cell discharged with current pulses at a rate of 0.13 C. The temperature of the cell is kept constant at 25 °C and the initial SoC was 100%.

Figure 9 shows the results obtained in the estimation of the SoC. The RMSRE obtained was 1.19%, which is similar or less than those found in the literature [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

21]. This error is acceptable and it was observed that the prediction of the SoC using EKF, in each instant managed to follow the reference SoC. In each iteration the EKF obtained the output voltage of the model based on the measured current and the state variables. This allowed us to compare the response of the model to the dynamics of voltage measured experimentally.

Figure 10 shows the comparison of the output voltage estimated by the algorithm and the experimental voltage. The voltage behavior was due to the discharge current profile, where the current was greater than zero for 45 min and was zero for 75 min. When the current was zero the cell voltage increased until the open circuit voltage was reached, as seen in more detail near the cutoff voltage. Then when the current was greater than zero the cell voltage decreased [

14].

In

Figure 10, it can be seen that the estimated voltage followed the dynamics of the voltage measured in the laboratory. This is due to the fact that an accurate model was used to represent the relationship between V

OCV and SoC.

6. Conclusions

In this research, a method was developed to identify an equivalent electrical circuit of a Li-ion cell. The results obtained showed that the behavior of the cell depends on its SoC and temperature. From the impedance spectrum, a model of a Li-ion cell was derived, where it was verified that the cell had fractional properties. The adjustment by the genetic algorithm allowed the accurate identification of an electrical model of the cell. The uncertainty of the adjustment was 4%, therefore the adjustment provided good accuracy to predict the dynamic effects of the battery. With regard to modeling the parameters based on the SoC and the temperature, the models with neural networks provided better results with a RMSRE of 5% for both the Rs and W. The RMSRE for the parameters R1 and C1 were to be 13% and 10%, respectively. Therefore, the characterization of the cell was carried out under different conditions allowing us to understand the behavior of a Li-ion cylindrical cell more precisely. This is important for monitoring the charge/discharge process in order to know the state of charge or state of health of the battery precisely.

While the parameterization of the model was carried out for different SoC and temperature conditions, in the SoC estimation, each parameter of the model was considered as constant and calculated as the average of the measured values at different SoCs and a fixed temperature of 25 °C. For the SoC estimation, the extended Kalman filter based on a Randles model was used. The maximum error of estimation of the SoC was 1.19%.

This algorithm can be very useful since the battery is a critical component, which makes the precision of measuring the SoC more and more important. Future research can improve the estimation by considering the variation of the SoC and temperature.