Adaptive Droop Based Virtual Slack Control of Multiple DGs in Practical DC Distribution System to Improve Voltage Profile

Abstract

:1. Introduction

2. Control Issues in DC Power System

2.1. Voltage Control of DG

2.2. Power Control of DG

3. DC Distribution System Operations

- The system estimation block estimates the conductance matrix of the distribution system, G, and generates the current sensitivity matrix, ∂Igen,ref/∂IL between DGs and loads. G is estimated on-line, and supports decision making of the operator person.

- The optimal current flow block determines the offset current reference vector of the DGs, Igen,o. Also, it checks if the current reference vector, Igen,ref exceeds the current limits of the DGs. If so, it adjusts Igen,o to modify Igen,ref.

- The virtual slack control block generates Igen,ref based on Igen,o and ∂Igen,ref/∂IL.

3.1. Optimal Current Flow

3.1.1. Current Flow Analysis

3.1.2. Optimal Current Flow with Constraints

3.2. Virtual Slack Control Based on Adaptive Droop

3.3. On-Line Conductance Matrix Estimation Using Kalman-Filter Algorithm

- Measurement update: Acquire the measurements, z(t) and compute a posteriori quantities.where k (∈Rn×1) is the Kalman gain, P (∈Rn×n) is a positive-definite symmetric matrix, and r is a positive number selected to avoid a singular matrix. Typically, P−(0) is given as P−(0) = λI (λ > 0), where I is an identity matrix.

- Time update:where Q (∈Rm×m) is a positive-definite covariance matrix, which is zero in this study because the stationary process and measurement noises are mutually independent.

- Time increment: Increment t and repeat.

4. Case Studies

4.1. Optimal Current Flow

4.1.1. Current Flow Analysis

4.1.2. Optimal Current Flow with Constraints

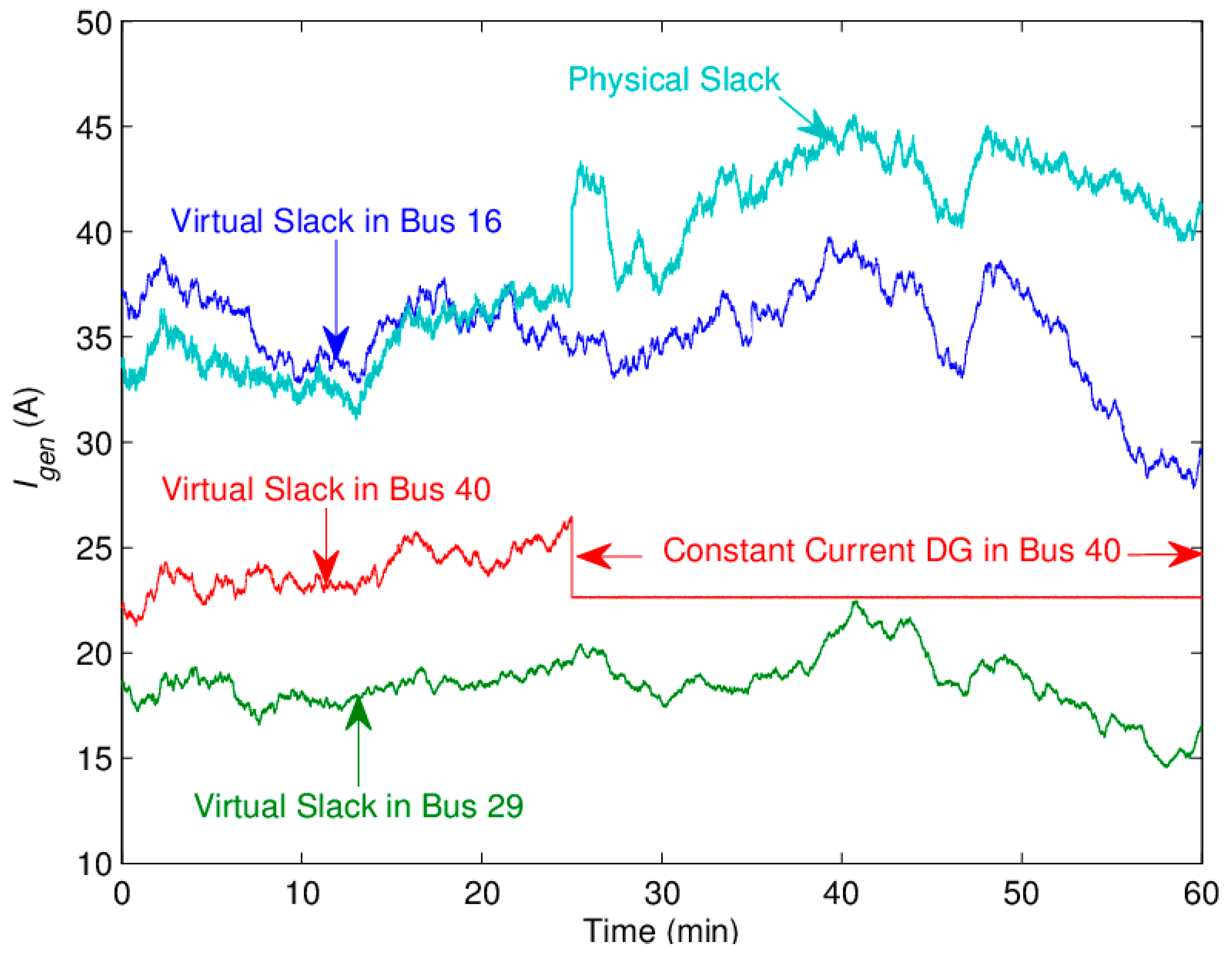

4.2. Virtual Slack Control Based on Current Sensitivity

4.2.1. Sensitivity to Errors Caused by Biased Measurement

4.2.2. Performance of Virtual Slack Control

4.2.3. Operation by OCF and Virtual Slack Control

4.3. On-Line Estimation

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, L.; Chen, D. Control and Operation of a DC Microgrid with Variable Generation and Energy Storage. IEEE Trans. Power Deliv. 2011, 26, 2513–2522. [Google Scholar] [CrossRef]

- Chang, Y.C.; Liaw, C.M. Establishment of a Switched-Reluctance Generator-Based Common DC Microgrid System. IEEE Trans. Power Electron. 2011, 26, 2512–2527. [Google Scholar] [CrossRef]

- Baran, M.E.; Mahajan, N.R. DC Distribution for Industrial Systems: Opportunities and Challenges. IEEE Trans. Ind. Appl. 2003, 39, 1596–1601. [Google Scholar] [CrossRef]

- Li, Y.; Luo, L.; Rehtanz, C.; Ruberg, S.; Yang, D.; Xu, J. An Industrial DC Power Supply System Based on an Inductive Filtering Method. IEEE Trans. Ind. Electron. 2012, 59, 714–722. [Google Scholar] [CrossRef]

- She, X.; Huang, A.Q.; Lukic, S.; Baran, M.E. On Integration of Solid-State Transformer with Zonal DC Microgrid. IEEE Trans. Smart Grid 2012, 3, 975–985. [Google Scholar] [CrossRef]

- Albu, M.; Kyriakides, E.; Chicco, G.; Popa, M.; Nechifor, A. Online Monitoring of the Power Transfer in a DC Test Grid. IEEE Trans. Instrum. Meas. 2010, 59, 1104–1118. [Google Scholar] [CrossRef]

- Liu, B.; Liang, C.; Duan, S. Design Considerations and Topology Selection for DC-Module-Based Building Integrated Photovoltaic System. In Proceedings of the IEEE Conference on Industrial Electronics and Applications, Singapore, 3–5 June 2008; pp. 1066–1070. [Google Scholar]

- Wu, T.F.; Chang, C.H.; Lin, L.C.; Yu, G.R.; Chang, Y.R. DC-Bus Voltage Control with a Three-Phase Bidirectional Inverter for DC Distribution Systems. IEEE Trans. Power Electron. 2013, 28, 1890–1899. [Google Scholar] [CrossRef]

- Hayashi, Y. Approach for highly efficient and ultra compact converters in next generation 380 V DC distribution system. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Raleigh, NC, USA, 15–20 September 2012; pp. 3803–3810. [Google Scholar]

- Rodriguez, M.; Stahl, G.; Corradini, L.; Maksimovic, D. Smart DC Power Management System Based on Software-Configurable Power Modules. IEEE Trans. Power Electron. 2013, 28, 1571–1586. [Google Scholar] [CrossRef]

- Majumder, R.; Ghosh, A.; Ledwich, G.; Zare, F. Power Management and Power Flow Control with Back-to-Back Converters in a Utility Connected Microgrid. IEEE Trans. Power Syst. 2010, 25, 821–834. [Google Scholar] [CrossRef]

- Byeon, G.; Yoon, T.; Oh, S.; Jang, G. Energy Management Strategy of the DC Distribution System in Buildings Using the EV Service Model. IEEE Trans. Power Electron. 2012, 28, 1544–1554. [Google Scholar] [CrossRef]

- Lu, D.D.C.; Agelidis, V.G. Photovoltaic-Battery-Powered DC Bus System for Common Portable Electronic Devices. IEEE Trans. Power Electron. 2012, 24, 849–855. [Google Scholar] [CrossRef]

- Wang, C.M.; Lin, C.H.; Yang, T.C. High-Power-Factor Soft-Switched DC Power Supply System. IEEE Trans. Power Electron. 2011, 26, 647–654. [Google Scholar] [CrossRef]

- Stupar, A.; Friedli, T.; Minibock, J.; Kolar, J.W. Towards a 99% Efficient Three-Phase Buck-Type PFC Rectifier for 400-V DC Distribution Systems. IEEE Trans. Power Electron. 2012, 27, 1732–1744. [Google Scholar] [CrossRef]

- Kim, J.G.; Kim, S.K.; Park, M.; Yu, I.K.; Lee, H.; Kim, Y.G.; Kim, H.M.; Won, Y.J.; Jeong, K.W.; Yang, B. Loss Characteristic Analysis of HTS DC Power Cable Using LCC Based DC Transmission System. IEEE Trans. Appl. Super Conduct. 2012, 22, 5801304. [Google Scholar]

- Marnay, C.; Lanzisera, S.; Stadler, M.; Lai, J. Building Scale DC Microgrids. In Proceedings of the IEEE Energytech, Cleveland, OH, USA, 29–31 May 2012; pp. 1–5. [Google Scholar]

- Cvetkovic, I.; Dong, D.; Zhang, W.; Jiang, L.; Boroyevich, D.; Lee, F.C.; Mattavelli, P. A Testbed for Experimental Validation of a Low-voltage DC Nanogrid for Buildings. In Proceedings of the IEEE Power Electronics and Motion Control Conference, Novi Sad, Serbia, 4–6 September 2012; pp. LS7c.5-1–LS7c.5-8. [Google Scholar]

- Willis, H.L. Analytical Methods and Rules of Thumb for Modeling DG-Distribution Interaction. In Proceedings of the IEEE PES Summer Meeting, Seattle, WA, USA, 16–20 July 2000; pp. 1643–1644. [Google Scholar]

- Ochoa, L.F.; Feltrin, A.P.; Harrison, G.P. Time-Series-Based Maximization of Distributed Wind Power Generation Integration. IEEE Trans. Energy Convers. 2008, 23, 968–974. [Google Scholar] [CrossRef] [Green Version]

- Falaghi, H.; Haghifam, M.R. ACO Based Algorithm for Distributed Generation Sources Allocation and Sizing in Distribution Systems. In Proceedings of the IEEE Lausanne Power Tech, Lausanne, Switzerland, 1–5 July 2007; pp. 555–560. [Google Scholar]

- Shaaban, M.F.; Saadany, E.F.E. Optimal allocation of renewable DG for reliability improvement and losses reduction. In Proceedings of the IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–8. [Google Scholar]

- Hadian, A.; Haghifam, M.R.; Zohrevand, J.; Rezai, E.A. Probabilistic Approach for Renewable DG Placement in Distribution Systems with Uncertain and Time Varying Loads. In Proceedings of the IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009; pp. 1–8. [Google Scholar]

- Lee, S.H.; Kang, Y.C.; Park, J.-W. Optimal Operation of Multiple DGs in DC Distribution System to Improve System Efficiency. IEEE Trans. Ind. Appl. 2016, 52, 3673–3681. [Google Scholar] [CrossRef]

- Saadat, H. Power System Analysis; McGraw Hill: Singapore, 2004; pp. 233–234. [Google Scholar]

- Wilamowski, B.M.; Yu, H. Improved Computation for Levenberg- Marquardt Training. IEEE Trans. Neural Netw. 2010, 21, 930–937. [Google Scholar] [CrossRef] [PubMed]

- Kamen, E.W.; Su, J.K. Introduction to Optimal Estimation; Springer: London, UK, 1999; pp. 149–183. [Google Scholar]

- Lee, S.H.; Park, J.W. Selection of Optimal Location and Size of Multiple Distributed Generations by Using Kalman Filter Algorithm. IEEE Trans. Power Syst. 2009, 24, 1393–1400. [Google Scholar]

| AC | DC | |||

|---|---|---|---|---|

| Device | System | Device | System | |

| Slack | V, f | P, Q | V | P |

| Generator | V, P | f, Q | P | V |

| Load | P, Q | V, δ | P | V |

| Ideal | Voltage Control | Current Control | ||||

|---|---|---|---|---|---|---|

| Value (kV, A) | Value (kV, A) | Error (%) | Value (kV, A) | Error (%) | ||

| Bus 16 | V | 22.876 | 22.651 | −0.98 | 22.872 | −0.02 |

| I | 37.286 | 17.882 | −52.04 | 36.916 | −0.99 | |

| Bus 29 | V | 23.042 | 23.037 | −0.02 | 23.033 | −0.04 |

| I | 18.660 | 18.671 | 0.06 | 18.660 | 0 | |

| Bus 40 | V | 22.982 | 23.224 | 1.05 | 22.993 | 0.05 |

| I | 22.648 | 35.938 | 58.68 | 22.877 | 1.01 | |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.H. Adaptive Droop Based Virtual Slack Control of Multiple DGs in Practical DC Distribution System to Improve Voltage Profile. Energies 2019, 12, 1541. https://doi.org/10.3390/en12081541

Lee SH. Adaptive Droop Based Virtual Slack Control of Multiple DGs in Practical DC Distribution System to Improve Voltage Profile. Energies. 2019; 12(8):1541. https://doi.org/10.3390/en12081541

Chicago/Turabian StyleLee, Soo Hyoung. 2019. "Adaptive Droop Based Virtual Slack Control of Multiple DGs in Practical DC Distribution System to Improve Voltage Profile" Energies 12, no. 8: 1541. https://doi.org/10.3390/en12081541