Sustainable Utilization of Low Enthalpy Geothermal Resources to Electricity Generation through a Cascade System

Abstract

1. Introduction

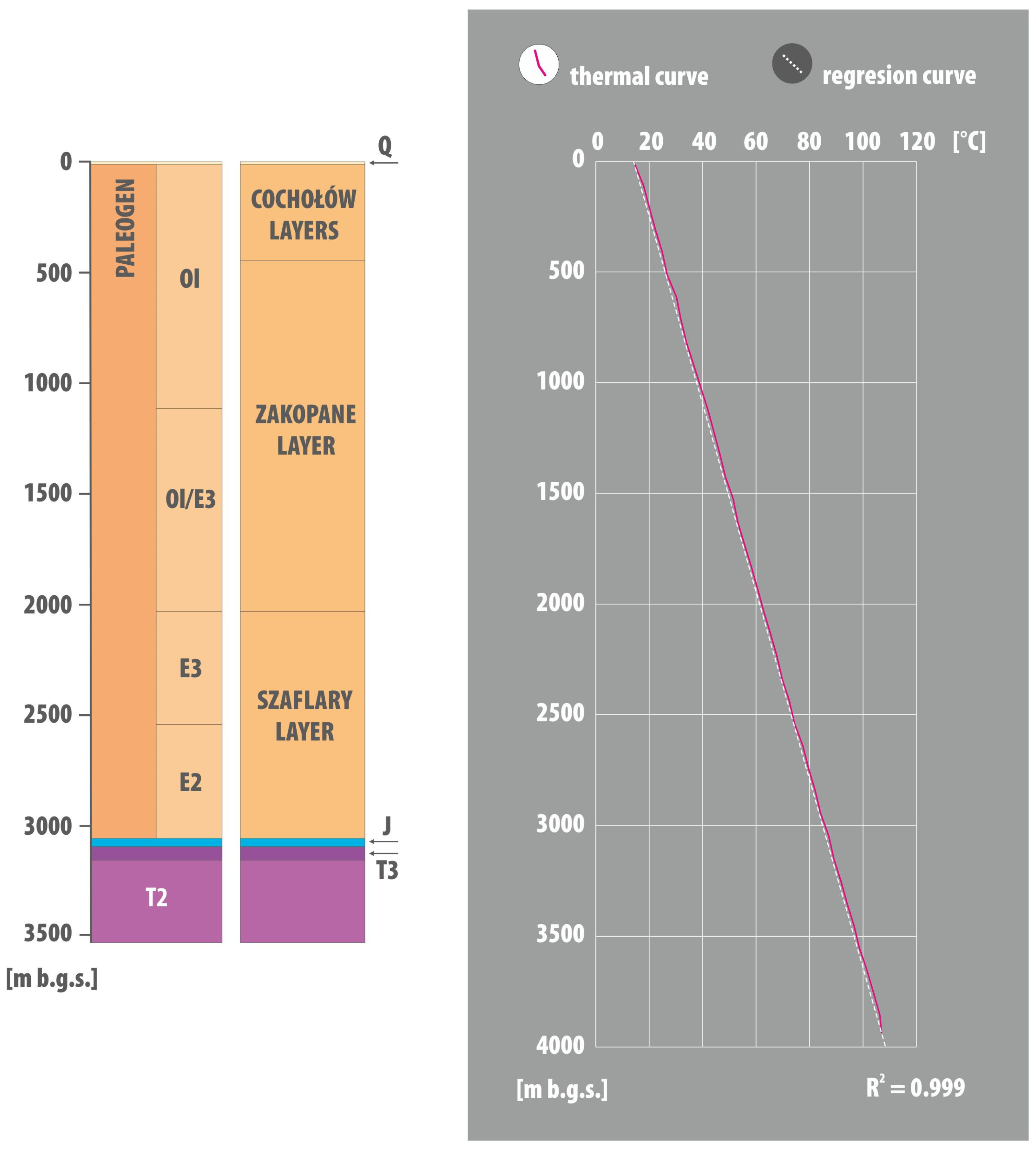

2. Characteristic of the Studied Area

3. Materials and Methods

- gross power of the ORC [W];

- —heat flux supplied to the superheater, evaporator, and preheater [W];

- —thermal efficiency of the ORC [-];

- —mass flow of the working fluid [kg/s];

- hwf1-hwf4—difference between specific enthalpy of the evaporation process [kJ/kg];

- hwf2-hwf3—difference between specific enthalpy of the condensing process [kJ/kg].

- gross power of the Kalina Cycle [W];

- —heat flux supplied to the evaporator [W];

- —thermal efficiency of the Kalina Cycle [-];

- —mass flow of the working fluid [kg/s];

- hwf1-hwf8—difference between the specific enthalpy of evaporation and separation process [kJ/kg];

- hwf4-hwf5—difference between the specific enthalpy of condensing process [kJ/kg];

- hwf9-hwf8—difference between the specific enthalpy of evaporation process [kJ/kg].

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gudmundsson, J.; Freeston, D.; Lienau, P. The lindal diagram. GRC Trans. 1985, 9, 15–17. [Google Scholar]

- Operacz, A.; Chowaniec, J. Prospective of geothermal water use in the Podhale Basin according to geothermal step distribution. Geol. Geophys. Environ. 2018, 44, 379–389. [Google Scholar] [CrossRef]

- Bloomberg New Energy Finance. New Energy Outlook 2019, Executive Summary; Bloomberg New Energy Finance: New York, NY, USA, 2019. [Google Scholar]

- Dumas, P.; Garabetian, T.; Serrano, C.; Pinzuti, V. EGEC Geothermal Market Report 2018 Key Findings, 8th ed.; European Geothermal Energy Council: Brussel, Belgium, 2019. [Google Scholar]

- Bertani, R. Geothermal power generation in the world 2010–2014 update report. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Xia, L.; Zhang, Y. An overview of world geothermal power generation and a case study on China—The resource and market perspective. Renew. Sustain. Energy Rev. 2019, 112, 411–423. [Google Scholar] [CrossRef]

- Hettiarachchi, H.M.; Golubovic, M.; Worek, W.M.; Ikegami, Y. The performance of the Kalina cycle system 11 (KCS-11) with low-temperature heat sources. J. Energy Resour. Technol. 2007, 129, 243–247. [Google Scholar] [CrossRef]

- Guzovic, Z.; Loncar, D.; Ferdelji, N. Possibilities of electricity generation in the Republic of Croatia by means of geothermal energy. Energy 2010, 35, 3429–3440. [Google Scholar] [CrossRef]

- Fallah, M.; Mohammad, S.; Mahmoudi, S.; Yari, M.; Akbarpour Ghiasi, R. Advanced exergy analysis of the Kalina cycle applied for low temperature enhanced geothermal system. Energy Convers. Manag. 2016, 108, 190–201. [Google Scholar] [CrossRef]

- Rodríguez, C.E.C.; Palacio, J.C.E.; Venturini, O.J.; Lora, E.E.S.; Cobas, V.M.; Santos, D.M.; Dotto, F.R.L.; Gialluca, V. Exergetic and economic comparison of ORC and Kalina cycle for low temperature enhanced geothermal system in Brazil. Appl. Therm. Eng. 2013, 52, 109–119. [Google Scholar] [CrossRef]

- Wang, E.; Yu, Z. A numerical analysis of a composition-adjustable Kalina cycle power plant for power generation from low-temperature geothermal sources. Appl. Energy 2016, 180, 834–848. [Google Scholar] [CrossRef]

- Arslan, O. Power generation from medium temperature geothermal resources: ANN-based optimization of Kalina cycle system-34. Energy 2011, 36, 2528–2534. [Google Scholar] [CrossRef]

- Shokati, N.; Ranjbar, F.; Yari, M. Exergoeconomic analysis and optimization of basic, dual-pressure and dual-fluid ORCs and Kalina geothermal power plants: A comparative study. Renew. Energy 2015, 83, 527–542. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Rogai, E.; Talluri, L. Exergoeconomic analysis and comparison between ORC and Kalina cycles to exploit low and medium-high temperature heat from two different geothermal sites. Energy Convers. Manag. 2017, 154, 503–516. [Google Scholar] [CrossRef]

- Karimi, S.; Mansouri, S. A comparative profitability study of geothermal electricity production in developed and developing countries: Exergoeconomic analysis and optimization of different ORC configurations. Renew. Energy 2018, 115, 600–619. [Google Scholar] [CrossRef]

- Altun, A.F.; Kilic, M. Thermodynamic performance evaluation of a geothermal ORC power plant. Renew. Energy 2020, 148, 261–274. [Google Scholar] [CrossRef]

- Liu, X.; Wei, M.; Yang, L.; Wang, X. Thermo-economic analysis and optimization selection of ORC system configurations for low temperature binary-cycle geothermal plant. Appl. Therm. Eng. 2017, 125, 153–164. [Google Scholar] [CrossRef]

- Liu, Q.; Duan, Y.; Yang, Z. Performance analyses of geothermal organic Rankine cycles with selected hydrocarbon working fluids. Energy 2013, 63, 123–132. [Google Scholar] [CrossRef]

- Basaran, A.; Ozgener, L. Investigation of the effect of different refrigerants on performances of binary geothermal power plants. Energy Convers. Manag. 2013, 76, 483–498. [Google Scholar] [CrossRef]

- Nemati, A.; Nami, H.; Ranjbar, F.; Yari, M. A comparative thermodynamic analysis of ORC and Kalina cycles for waste heat recovery: A case study for CGAM cogeneration system. Case Stud. Therm. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Walraven, D.; Laenen, B.; D’haeseleer, W. Comparison of thermodynamic cycles for power production from low-temperature geothermal heat sources. Energy Convers. Manag. 2013, 66, 220–233. [Google Scholar] [CrossRef]

- Tyszer, M.; Tomaszewska, B. The impact of geothermal water RO concentrate volume minimization on the possibility of comprehensive further use. Preliminary results. Desalin. Water Treat. 2019, 157, 250–258. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Szczepański, A. Possibilities for the efficient utilisation of spent geothermal waters. Environ. Sci. Pollut. Res. 2014, 21, 11409–11417. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Dendys, M. Zero-waste initiatives—Waste geothermal water as a source of medicinal raw material and drinking water. Desalin. Water Treat. 2018, 112, 12–18. [Google Scholar] [CrossRef]

- Rajchel, L. Zastosowanie wód geotermalnych w balneoterapii i rekreacji. In Atlas Zasobów Geotermalnych Formacji Mezozoicznej Na Niżu Polskim; Górecki, W., Ed.; Akademia Górniczo-Hutnicza im. S. Staszica: Kraków, Poland, 2006. [Google Scholar]

- Kaczmarczyk, M.; Tomaszewska, B.; Pająk, L. Geological and thermodynamic analysis of low enthalpy geothermal resources to electricity generation using ORC and kalina cycle technology. Energies 2020, 13, 1335. [Google Scholar] [CrossRef]

- Bujakowski, W.; Tomaszewska, B. (Eds.) Atlas Wykorzystania Wód Termalnych do Skojarzonej Produkcji Energii Elektrycznej i Cieplnej Przy Zastosowaniu Układów Binarnych w Polsce; Instytut Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk: Kraków, Poland, 2014. [Google Scholar]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact; Library of Congress Cataloging-in-Publication Data; Elsevier Ltd.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Akbari, M.; Mahmoudi, S.; Yari, M.; Rosen, A. Energy and exergy analyses of a new combined cycle for producing electricity and desalinated water using geothermal energy. Sustainability 2014, 6, 1796–1820. [Google Scholar] [CrossRef]

- Kaczmarczyk, M. Impact of rock mass temperature on potential power and electricity generation in the ORC installation. E3S Web Conf. 2017, 24, 02007. [Google Scholar] [CrossRef]

- Mirolli, M.; Hjartarson, H.; Mlcak, H.A.; Ralph, M. Testing and operating experience of the 2 MW kalina cycle geothermal power plant in Húsavík, Iceland. Power plant: Operation, maintenance and materials. Issue OMMI Internet J. 2002, 1, 2. [Google Scholar]

- Bielec, B.; Operacz, A. Najnowsze rozpoznanie parametrów eksploatacyjnych wód termalnych w ujęciu Chochołów PIG-1 w aspekcie efektu wygrzewania się otworu. Inżynieria Ekol. 2019, 19, 145–152. [Google Scholar] [CrossRef]

- Sikora, W.; Borysławski, A.; Cieszkowski, M.; Gucik, S. Geological Crosssection Cracow-Zakopane; Wydawnictwo Geologiczne: Warszawa, Poland, 1980. [Google Scholar]

- Chowaniec, J.; Długosz, P.; Drozdowski, B.; Nagy, J.; Witczak, W.; Witek, K. Dokumentacja Hydrogeologiczna Wód Termalnych Niecki Podhalańskiej, Inw. 594/98; Arch. CAG PIG: Warszawa, Poland, 1997. [Google Scholar]

- Kępińska, B. Warunki Termiczne i Hydrotermalne Podhalańskiego Systemu Geotermalnego; Studia, Rozprawy, Monografie, Zeszyt 135; Wydawnictwo IGSMiE PAN: Kraków, Poland, 2006. [Google Scholar]

- Oszczypko, N. Charakterystyka tektoniczna i geologiczna polskich Karpat Zachodnich. In Atlas Zasobów Geotermalnych Polskich Karpat Zachodnich; Górecki, W., Ed.; Akademia Górniczo-Hutnicza im. S. Staszica: Kraków, Poland, 2011. [Google Scholar]

- Barbacki, A.P.; Bujakowski, W.; Pająk, L. Atlas Zbiorników Wód Geotermalnych Małopolski; Wydawnictwo Instytutu Gospodarki Surowcami Mineralnymi i Energią PAN: Kraków, Poland, 2006. [Google Scholar]

- Cieszkowski, M.; Uchman, A.; Chowaniec, J. Litostratygrafia sukcesji osadowej niecki podhalańskiej. In Budowa Geologiczna Tatr i Podhala ze Szczególnym Uwzględnieniem Zjawisk Geotermalnych na Podhalu; Uchman, A., Chowaniec, J., Eds.; Państwowy Instytut Geologiczny: Bukowina Tatrzańska, Poland, 2009. [Google Scholar]

- Gołąb, J. Zarys stosunków geologicznych fliszu zachodniego Podhala. Biul. Inst. Geol. 1959, 149, 225–237. [Google Scholar]

- Watycha, L. Uwagi o geologii fliszu podhalańskiego we wschodniej części Podhala. Przegląd Geol. 1959, 5, 350–356. [Google Scholar]

- Halicki, B. Z badań nad fliszem podhalańskim i magurskim na Podhalu. Acta Geol. Pol. 1961, 8, 411–450. [Google Scholar]

- Halicki, B. Tektonika podhala. Rocz. PTG 1963, 33, 349–363. [Google Scholar]

- Garecka, M. Calacareous nanoplankton from the Podhale flysch (Oligocene-Miocene, Inner Carpathians, Poland). Stud. Geol. Pol. 2005, 124, 353–369. [Google Scholar]

- Chowaniec, J.; Poprawa, D.; Olszewska, B.; Skulich, J.; Smagowicz, M. Dokumentacja Hydrogeologiczna Zasobów Wód Podziemnych—Wody Termalne Otwór Chochołów Pig-1, Miejsc. Chochołów, gm. Czarny Dunajec, Woj. Nowosądeckie, 1364/93; CAG PIG: Warszawa, Poland, 1992. [Google Scholar]

- Józefko, I.; Bielec, B. Dokumentacja Hydrogeologiczna Ustalająca Zasoby Eksploatacyjne Ujęcia Wód Termalnych “Chochołów Pig-1”, MIEJSC. Witów, gm. Kościelisko, pow. Tatrzański, woj. Małopolskie, 5638/2009; CAG PIG: Warszawa, Poland, 2009. [Google Scholar]

- Kępińska, B.; Ciągło, J. Możliwości zagospodarowania wód geotermalnych Podhala do celów balneoterapeutycznych i rekreacyjnych. Geologia 2008, 34, 541–559. [Google Scholar]

- Pastor-Martinez, E.; Rubio-Maya, C.; Ambriz-Diaz, V.M.; Belman-Flores, J.M.; Pacheco-Ibarra, J.J. Energetic and exergetic performance comparison of different polygeneration arrangements utilizing geothermal energy in cascade. Energy Convers. Manag. 2018, 168, 252–269. [Google Scholar] [CrossRef]

- Yari, M.; Mehr, A.S.; Zare, V.; Mahmoudi, S.M.; Rosen, M.A. Exergoeconomic comparison of TLC (trilateral Rankine cycle), ORC (organic Rankine cycle) and Kalina cycle using a low grade heat source. Energy 2015, 83, 712–722. [Google Scholar] [CrossRef]

- Yari, M. Exergetic analysis of various types of geothermal power plants. Renew. Energy 2010, 35, 112–121. [Google Scholar] [CrossRef]

- Li, J.; Pei, G.; Li, Y.; Wang, D.; Ji, J. Energetic and exergetic investigation of an organic Rankine cycle at different heat source temperatures. Energy 2012, 38, 85–95. [Google Scholar] [CrossRef]

- Heberle, F.; Brüggemann, D. Exergy based fluid selection for a geothermal Organic Rankine Cycle for combined heat and power generation. Appl. Therm. Eng. 2010, 30, 1326–1332. [Google Scholar] [CrossRef]

- Rubio-Maya, C.; Amrbiz Diaz, V.M.; Pastor-Martinez, E.; Belman-Flores, J.M. Cascade utilization flow and medium enthalpy geothermal resources—A review. Renew. Sustain. Energy Rev. 2015, 52, 689–716. [Google Scholar] [CrossRef]

- Sadurski, A.; Nowicki, Z.; Sokołowski, A. Zagrożenia i Ochrona Wód Leczniczych i Termalnych; Państwowy Instytut Geologiczny: Warszawa, Poland, 2007. [Google Scholar]

- Kaczmarczyk, M. Potential of existing and newly designed geothermal heating plants in limiting of low emissions in Poland. E3S Web Conf. 2018, 44, 00062. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Sowiżdżał, A.; Tomaszewska, B. Energetic and environmental aspects of individual heat generation for sustainable development at a local scale—A case study from poland. Energies 2020, 13, 454. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkelerd, D.; Norrise, G.; Rydbergf, T.; Schmidtg, W.P.; Suhh, S.; Weidemai, B.P.; Penningtonf, D.W. Life cycle assessment. Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarczyk, M. Methodology and impact categories of environmental life cycle assessment in geothermal energy sector. E3S Web Conf. 2019, 100, 00032. [Google Scholar] [CrossRef]

- Bayer, P.; Rybach, L.; Blum, P.; Brauchler, R. Review on life cycle environmental effects of geothermal power generation. Renew. Sustain. Energy Rev. 2013, 26, 446–463. [Google Scholar] [CrossRef]

- Pająk, L.; Tomaszewska, B.; Bujakowski, W.; Bielec, B.; Dendys, M. Review of the low-enthalpy lower cretaceous geothermal energy resources in Poland as an environmentally friendly source of heat for urban district heating systems. Energies 2020, 13, 1302. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Tyszer, M.; Bodzek, M.; Rajca, M. The concept of multivariant use of geothermal water concentrates. Desalin. Water Treat. 2018, 128, 179–186. [Google Scholar] [CrossRef]

- Tomaszewska, B. New approach to the utilisation of concentrates obtained during geothermal water desalination. Desalin. Water Treat. 2018, 128, 407–413. [Google Scholar]

- Tomaszewska, B.; Bundschuh, J.; Pająk, L.; Dendys, M.; Delgado Quezada, V.; Bodzek, M.; Armienta, A.A.; Ormachea Munioz, M.; Kasztelewicz, A. Use of low-enthalpy and waste geothermal energy sources to solve arsenic problems in freshwater production in selected regions of Latin America using a process membrane distillation-research into model solutions. Sci. Total Environ. 2020, 714, 136853. [Google Scholar] [CrossRef]

| Geothermal Water Parameter | Unit | Value | |

|---|---|---|---|

| - | Variant AI, AII | Variant BI, BII | |

| Temperature of geothermal water before power plant | °C | 82 | 82 |

| Temperature of geothermal water after power plant | °C | 60 | 70 |

| Mineralisation | g/dm3 | 1.2440 | 1.2440 |

| Density | kg/m3 | 970.5046 | 970.5046 |

| Specific heat | kJ/kgK | 4.1895 | 4.1895 |

| Flow rate of geothermal water | kg/s | 20–51.22 | 20–51.22 |

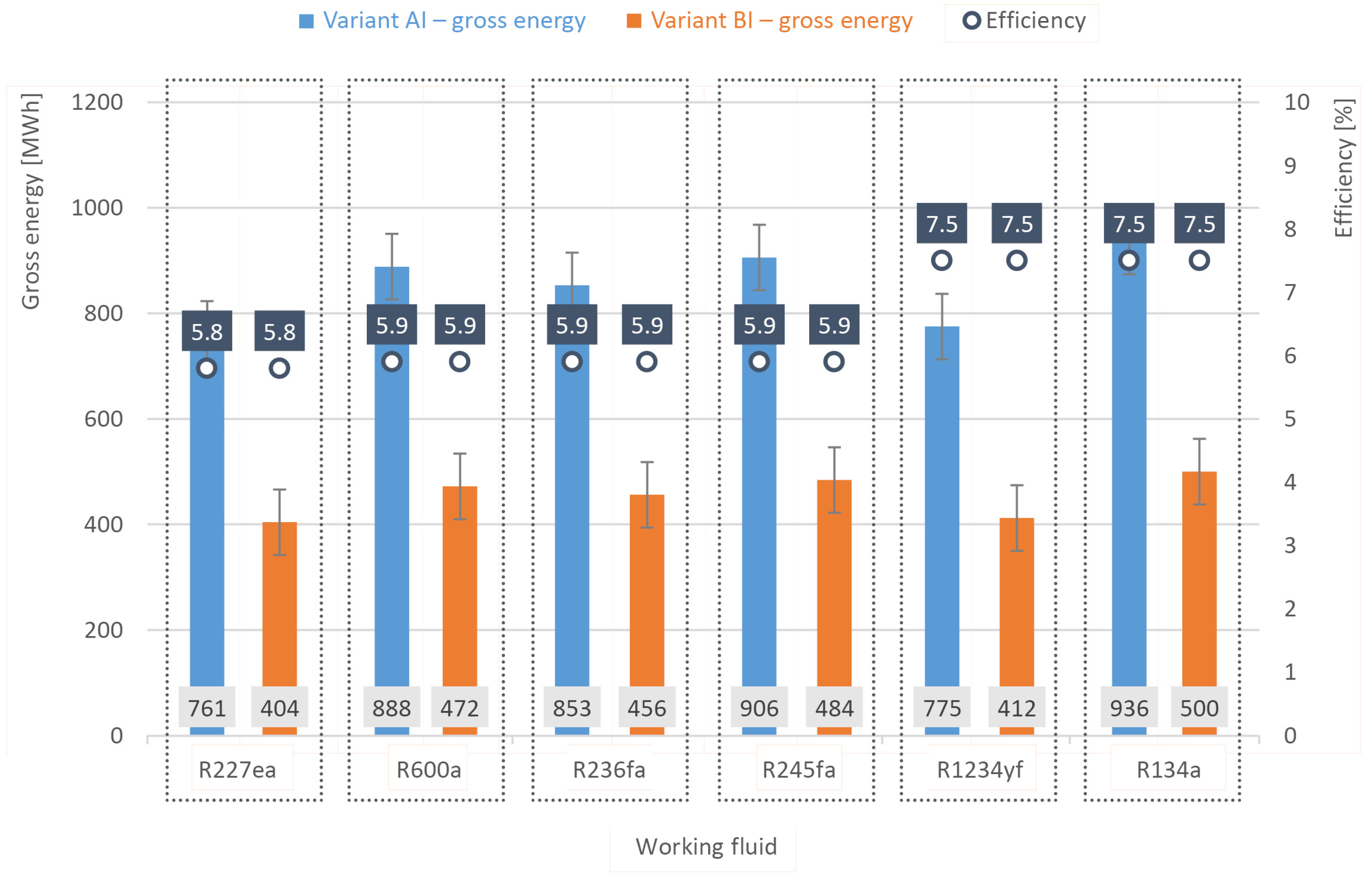

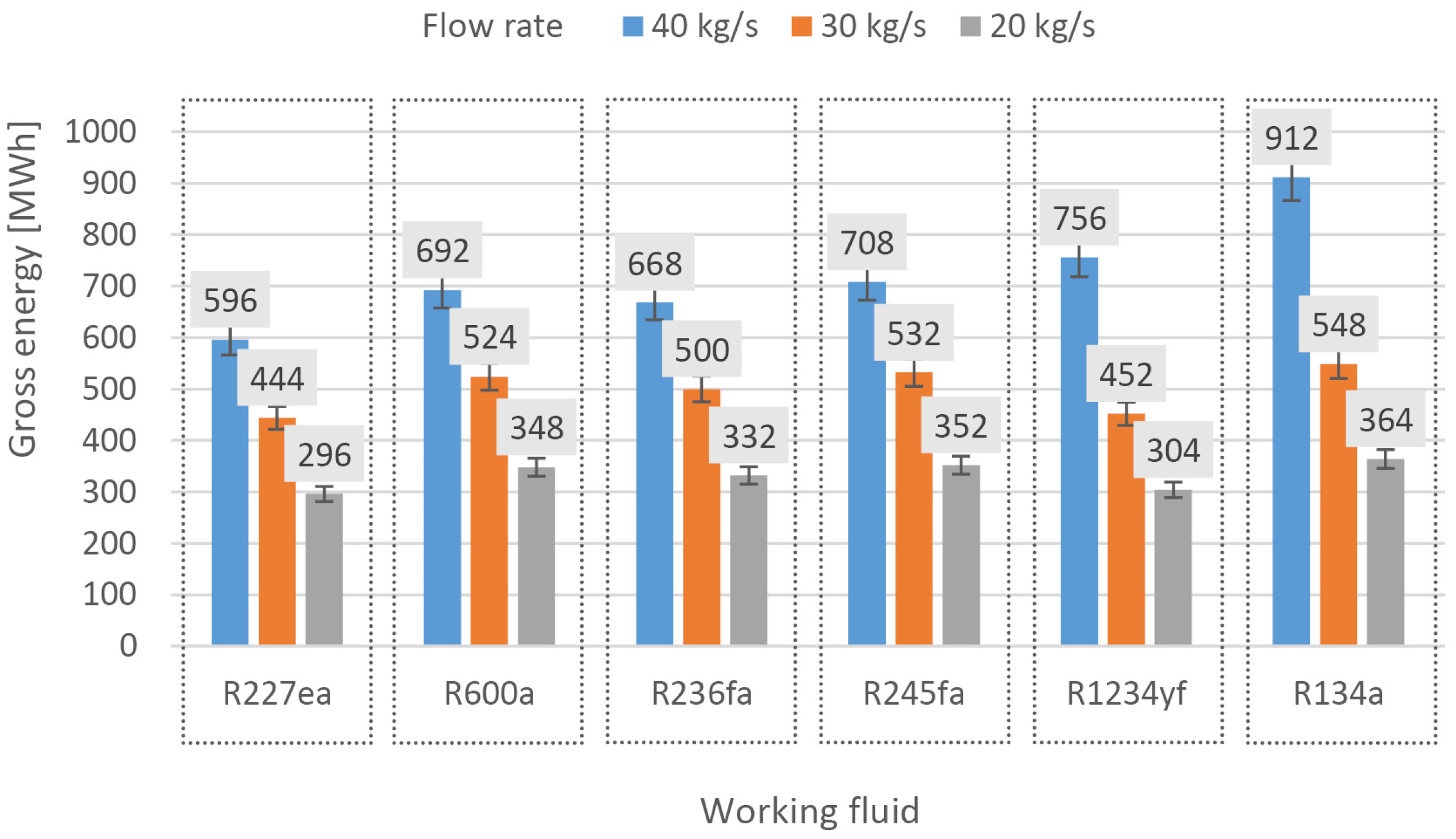

| Working Fluid | Efficiency [%] | Gross Power [kW]/Gross Energy [MWh] (Temperature of Geothermal Water after the Evaporator 60 °C) | Gross Power [kW]/Gross Energy [MWh] (Temperature of Geothermal Water after the Evaporator 70 °C) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AI | AII | BI | BII | ||||||

| Flow rate of geothermal water [kg/s] | 51.22 | 40 | 30 | 20 | 51.22 | 40 | 30 | 20 | |

| R227ea | 5.8 | 190/ 761 | 149/ 594 | 111/ 446 | 74/ 297 | 101/ 405 | 81/ 324 | 61/ 243 | 41/ 162 |

| R600a | 5.9 | 222/ 888 | 173/ 694 | 131/ 520 | 87/ 347 | 118/ 473 | 95/ 378 | 71/ 284 | 47/ 189 |

| R236fa | 5.9 | 213/ 853 | 167/ 666 | 125/ 500 | 83/ 333 | 114/ 454 | 91/ 363 | 68/ 272 | 45/ 182 |

| R245fa | 5.9 | 226/ 906 | 177/ 707 | 133/ 531 | 88/ 354 | 121/ 482 | 96/ 386 | 72/ 289 | 48/ 193 |

| R1234yf | 7.5 | 193/ 775 | 189/ 605 | 113/ 454 | 76/ 303 | 103/ 413 | 83/ 330 | 62/ 248 | 41/ 165 |

| R134a | 7.5 | 234/ 936 | 228/ 731 | 137/ 548 | 91/ 366 | 125/ 499 | 100/ 399 | 75/ 299 | 50/ 199 |

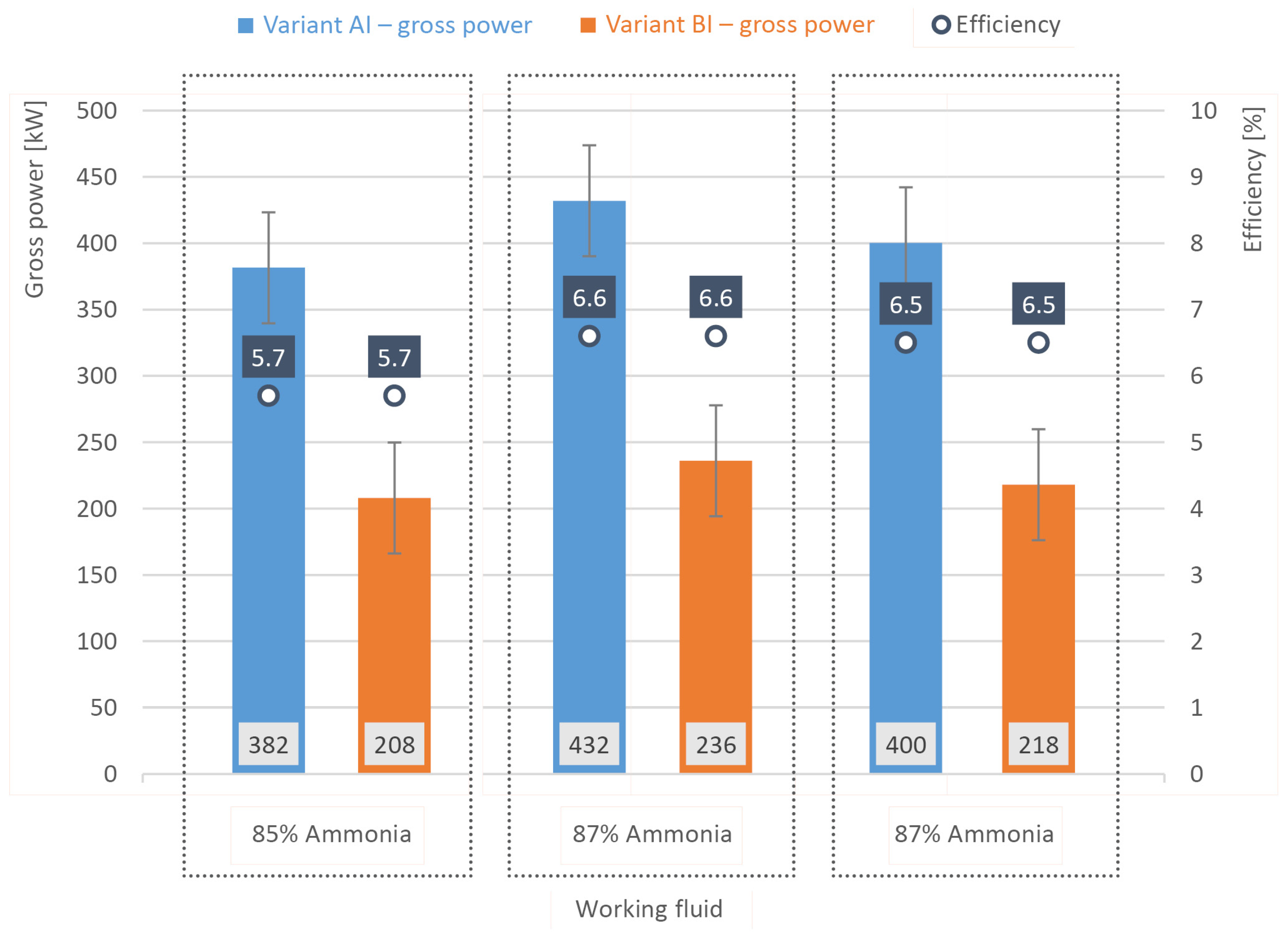

| Working Fluid | Efficiency [%] | Gross Power [kW]/Gross Energy [MWh] (Temperature of Geothermal Water after the Evaporator 60 °C) | Gross Power [kW]/Gross Energy [MWh] (Temperature of Geothermal Water after the Evaporator 70 °C) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AI | AII | BI | BII | ||||||

| Flow rate of geothermal water [kg/s] | 51.22 | 40 | 30 | 20 | 51.22 | 40 | 30 | 20 | |

| 85% Ammonia | 5.7 | 382/ 1526 | 298/ 1192 | 223/ 894 | 149/ 596 | 208/ 833 | 163/ 650 | 122/ 488 | 81/ 325 |

| 87% Ammonia | 6.6 | 432/ 1728 | 337/ 1350 | 253/ 1012 | 169/ 675 | 236/ 943 | 184/ 736 | 138/ 552 | 92/ 368 |

| 89% Ammonia | 6.5 | 400/ 1601 | 313/ 1251 | 234/ 938 | 156/ 625 | 218/ 874 | 171/ 682 | 128/ 512 | 85/ 341 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczmarczyk, M.; Tomaszewska, B.; Operacz, A. Sustainable Utilization of Low Enthalpy Geothermal Resources to Electricity Generation through a Cascade System. Energies 2020, 13, 2495. https://doi.org/10.3390/en13102495

Kaczmarczyk M, Tomaszewska B, Operacz A. Sustainable Utilization of Low Enthalpy Geothermal Resources to Electricity Generation through a Cascade System. Energies. 2020; 13(10):2495. https://doi.org/10.3390/en13102495

Chicago/Turabian StyleKaczmarczyk, Michał, Barbara Tomaszewska, and Agnieszka Operacz. 2020. "Sustainable Utilization of Low Enthalpy Geothermal Resources to Electricity Generation through a Cascade System" Energies 13, no. 10: 2495. https://doi.org/10.3390/en13102495

APA StyleKaczmarczyk, M., Tomaszewska, B., & Operacz, A. (2020). Sustainable Utilization of Low Enthalpy Geothermal Resources to Electricity Generation through a Cascade System. Energies, 13(10), 2495. https://doi.org/10.3390/en13102495