1. Introduction

Climate change is one of the most pressing challenges addressed in modern times [

1,

2]. The European Union leads one of the first environmental coalitions in the world that targets decarbonization and the use of renewables [

3,

4]. In line with the above coalitions, the EU member states have adopted a specific directive to promote electricity from renewable energy resources (2001/77/EC), followed by the renewable energy directive 28/2009/EC for promoting the use of renewable energy resources with 20% of the total power production by 2020 [

5,

6]. The fishing industry is one of the most energy intensive industries in the world due to an escalating demand and enlarging supply of fishery and aquaculture products. Based on Food and Agriculture Organization (FAO) information, the total world fish production in 2016 was about 171 million tonnes as compared to 19.3 million tonnes in 1950 [

7]. The seafood trade is characterized by a diversity of products such as high value species shrimp, salmon, tuna, groundfish, flatfish, sea bass, and sea bream to low-value species such as small pelagic, which has been traded in high quantity and exported to low-income countries [

8]. The global investment in fish products has increased significantly during the last 40 years from (EUR 8 billion) to about (EUR 133 billion) in 2017 [

9]. A fish processing industrial site accommodates a set of operations required to prepare fish and other seafood in such a way that the created final product will have the quality to be delivered to the customer [

10].

Such fish processing operations are extremely complex with a significant impact on the environment in relation to air quality and carbon emissions. Based on the updated assessment report from the European Sea Ports Organization for the top ten environmental priorities, air quality and energy consumption were found to be the top two [

11].

The fish processing industry is an energy-intensive industry. The main sources of energy are electricity and liquid fuels, and their shares differ according to process operations from the fishing stage to the packaging of products [

12,

13]. Energy usage in fish processing industries can have two main operating modes: (i) direct use, such as lighting system, heating, and box washing machine, or (ii) indirect use through converting the power to another form of energy, such as cooling cycle, freezing, and equipment [

14]. The energy consumption also varies with factors, including the age of the production plant, level of automation, and level of maturity of processes for production. The other parameters that can influence the energy usage for fish industries are: (i) seasons when the amount of fishing can increase the demand for energy, (ii) weather that can have a significant effect on the total processed fish during a year, and (iii) the number of fisheries and boats that can also affect the total energy use. For example, the process equipment consumes a greater amount of energy in hot seasons, which might increase the amount of energy consumed [

15]. Cooling and freezing are found to be the biggest consumers of electricity due to refrigeration and air conditioning [

16]. Cooling systems also produce huge amounts of emissions, such as refrigerant gases containing ammonia and other harmful compounds [

17].

Furthermore, energy costs are found to be the largest overhead in the fishing industry. An estimation of fuel equivalent levels associated with direct consumption of fuel required by electrical energy used by various processes is estimated to be EUR 9.85 billion [

18]. In the UK, studies estimate the total energy consumption and costs of cold stores and blast freezers ranging from 10.9 to about 20.7 GWh with an equivalent cost of 1.7–3.2 mil. at USD 0.15/kWh, and about 45 GWh for cold stores with a total cost of 6.8 mil. at USD 0.15/kWh [

19].

Therefore, the overall increased demand for fishery ports and their energy intensive nature have led to an increased amount of energy consumption resulting in significant amounts of carbon emissions. Hence, there is a clear necessity to integrate renewables so as to make the fishing industry less dependent on the grid. However, the intermittency of renewable energy is the main challenge to manage power and control energy flows in fish processing industries that might disrupt the flow of power in critical times during operations [

20,

21]. This challenge can be avoided using intelligent energy management systems of a smart grid approach [

22,

23,

24]. Such smart grid technology can help to manage power flows using electricity storage while sharing power with a local community, or selling excess energy to the grid [

18,

25,

26].

The concept of smart grids was defined by the Energy Networks Association (ENA) as the generation through to home automation with a smart meter being an important element, with every piece of network equipment, communications technology, and processes in between contributing to an efficient and smart grid [

27]. The transmission of electricity from suppliers to consumers with the aid of computer systems (through control automation, continuous monitoring, and optimization of a distribution system) is known as smart grid technology. The objective of a smart grid is to save energy, reduce costs, and increase reliability [

28] with smart micro-grid-controlled distribution networks that act independently and can also operate in islanding mode [

28]. The benefit of using smart grids is to allow renewable energy sources to integrate with local energy sources to increase the reliability of power and quality across the system. Consumers play a vital role in a smart grid as they can use energy systems to prevent energy waste/ loss, reduce power consumption during peak times, and improve energy efficiency. Cost operations can also be reduced through the smart use of energy via smart grid strategies [

29,

30,

31].

This paper conducts energy analysis and modelling for fish industries by exploring energy transition from a building level to an energy community level. We adopt modelling principles to deliver a simulation analysis framework utilizing energy modelling software tools to increase energy efficiency for the industrial fish port in Milford Haven, South Wales. This is achieved by investigating the energy usage for fish processing and maximizing the use of renewable energy sources in energy clusters. Our modelling informs how to minimize carbon emissions and store the power surplus in energy storage systems. Next, a smart energy community model has been developed using multiple software applications, allowing the simulation of energy usage at the local site and integration of different consumer agents. We also develop a mathematical model for the integration of five industries with a local domestic community of 200 houses. This scenario investigates the capability of the local solar farm to meet the power demand of the local energy community. We look to find the optimum balance between the battery storage system and the number of photovoltaics (PVs) required to meet the community power demand, followed by a stand-alone, off-grid system.

Following this introduction,

Section 2 presents related work.

Section 3 then elaborates on the methodology used for this study, followed by

Section 4 which describes the case study used to demonstrate and validate the research.

Section 5 presents the proposed smart energy community model.

Section 6 discusses the results. The final section provides concluding remarks and directions for future research.

2. Related Work

The first approach in our research involved identifying scientific and authoritative publications related to the deployment of renewables and energy/carbon reduction in ports and the wider fish industries. As such, a set of keywords were identified that informed our search strategy using established academic search engines. The selected keywords are as follows: “renewable energy”, “seaports”, “fish industries”, “carbon reduction”, “smart grid”, “battery system”, and “microgrid”.

We have conducted searches in indexed educational engines, such as Scopus and Google scholar, based on which key concepts have been determined, and additional studies have been identified and included in the literature survey. The authors conducted a comprehensive critical review of the academic literature, regulations and industrial developments around fish ports energy systems and their management. The study corpus was then divided into chronological and thematic groupings. Following the observation of new challenges and opportunities that arise imminently from a mismatch in these projections, key concepts were identified from the related fields.

Buiza et al. [

32] analyzed Mediterranean ports with a view to assess the current situation in relation to energy, operation, and environmental aspects. The study demonstrates how smart energy management can play a vital role for ports activities by enabling integration with renewable energy resources to ensure self-consumption and to reduce carbon emission.

Hue at al. [

33] sought to reduce daily emissions from Taiwanese fishing vessels based on the efficiency analysis of historical data of energy use. Their study explores different ways to reduce carbon emissions and energy consumption via subsidizing fishing vessels to encourage fisheries to use clean energy and apply more informed energy practices for the appliances. Mishra et al. [

20] estimate carbon emissions for various activities in ports demonstrating that about 280,558 tones CO2e/year are produced from port activities. The authors propose several models for integrating renewable energy sources in order to reduce CO

2 emission.

Acciaro et al. [

34] demonstrate the necessity of port authorities to start applying smart energy management to tackle environmental impact by increasing energy efficiency to reduce both cost of energy and carbon emission. The study compares two port case studies that have adopted smart energy management strategies. A similar study [

35] suggests that smart grid and micro grid approaches can help to increase the power efficiency of the port energy management system. The authors also recommend port authorities and stakeholders to utilize more informed energy management strategies to gain a greater benefit for the port and the communities. Statistical techno-economic analysis is also used to investigate the impact of renewable energy and energy storage of boats to develop an energy network that can exchange power with the grid. The study provided by Lamberti et al. [

6] found that renewable energy generators can provide an optimum solution to sell energy to the grid while also covering capital and operation costs.

A study released by Prousalidis et al. [

36] discusses the ability to develop ports as energy hubs by implementing smart energy systems. Such analysis is based on the assumption that a local port can install cold ironing to meet power demand of berth vessels.

Ramos et al. [

37] investigate the application of a tidal farm to meet the local energy demand in ports using a 3D hydrodynamic model with 25 turbines that can meet the local energy demand. However, the drawbacks of the study are the difficulties of finding the appropriate places to install tidal turbines for ports. Another research study [

38] provides a techno-economic investigation of applying tidal energy to meet energy needs for ports and local communities. The study shows that using tidal energy is a viable option from a cost and sustainability perspective. The study also manages to investigate the design of a tidal turbine generator while assessing the feasibility of applying the system from an economical perspective.

Ramos et al. [

21] proposed a micro-grid model to meet the energy demand for ports. The study identifies that installing a 5 MW of PV and a 6.5 MW wind turbine, respectively, should provide an optimal renewable capability to meet power demand for ports in general. The authors also show that a renewable capability with 20,000 units of electricity at 72-volt and 630 amp would meet only 60% of total power demand in a port. Manolis, et al. [

31] demonstrates the impact of a distributed demand response strategy using multi-agent systems for improving voltage in energy distribution networks for ports. Similarly, other authors [

39] propose statistical methods for integrating solar farms and biomass energy to meet power demand in port sites. The impact of such integration identifies 50% of power demand optimization with the local power generation from renewable energy.

Based on the literature survey, we found that the existing studies, although exploring energy management strategies for ports are very limited in terms of the capability to provide a holistic energy analysis that can be scaled from a site level to a community level. Such limitations can also be identified for the three criteria used for conducting analysis which are as follows: applying renewable energy, minimizing carbon emission, and the proposed smart grid.

Table 1 presents a summary of the analysis reported in the related work section.

At a wider scale, the review of the literature has evidenced a research gap in that there is a lack of research that delivers a ‘’demand–response’’ capability within a fishery port, while optimizing the use of battery storage, and at the same time promoting the formation of sustainable energy communities. The novelty of the paper is the delivery of a co-simulation environment that leverages calibrated energy simulation models to deliver an optimization capability that (a) manages electrical storage within a district environment, and (b) promotes the formation of energy communities in a fishery port ecosystem.

3. Methodology

The authors have designed a methodology to address the above objectives that ensures that rigor and significance criteria are met. By rigor, the authors have ensured that the methodology is scalable, in that the techniques and methods used are independent in the context of the research as provided by the selected fishery port. Conversely, the significance criteria are met by ensuring that the proposed methodology generates an impact within the selected demonstration environment through substantial energy and carbon reductions, as well as energy autonomy through the concept of energy communities that rely on renewables.

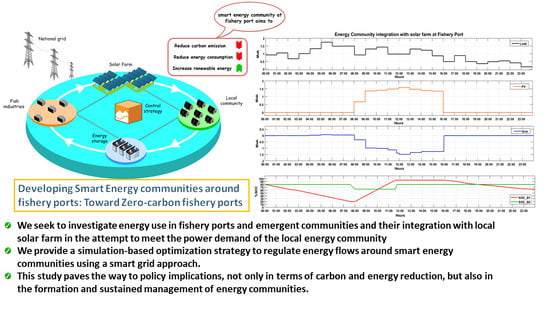

The research methodology is developed in the context of the Smart Cluster Energy System for the Fish Processing Industry (piSCES) project. The piSCES project aims to reduce the costs and carbon footprint for the fish processing industry by developing and testing a new “smart grid” electricity network for fish industries in Milford haven port as shown in

Figure 1. The smart cluster energy system for the fish processing industry operation will ultimately reduce the costs and carbon footprint of energy networks in the fish processing industry by implementing smart grid technologies [

26,

42]. This will be done through modelling the usage profile of their energy networks and optimizing that against the wholesale energy market and any available onsite generation. The methodology adopted in the paper is generic with an application for the Milford Haven port in South Wales. The Milford Haven port is considered the largest energy port in UK and considered the largest handler of oil and gas with the capability of meeting about 30% of the UK gas demand. One of the functions of the port is the responsibility for the safe movement of vessels on the Milford Haven Waterway, a deep-water site on the western coast of the UK. Furthermore, the port has a strategic plan to diversify functions, including transportation, energy, renewables, engineering, leisure and tourism fishing, food processing, and aquaculture [

43].

In this study, we aim to infer the extent to which the energy needs of fish industries, as well as the surrounding local community, can be met by developing a co-simulation capability that can inform the optimal management of energy in a fishery port ecosystem. This translates into the following objectives:

- -

Develop a simulation capability of energy demand and use in a fishery port setting.

- -

Promote the creation of smart energy communities within the local surrounding ecosystem, and beyond.

- -

Advise on the optimum capacity of the energy storage for the smart energy community

3.1. Simulation Based Analysis

To develop a simulation model for the building in each different aspect, three software packages are used, namely DesignBuilder, EnergyPlus, and Building Control Virtual Test Bed BCVTB. These simulation tools are based on a mathematical model of the process being investigated. The simulation tools allow a detailed analysis of the process before it is applied in a real application. For the mathematical model, different parameters can vary to test multiple aspects of the process. The settings can be adjusted, and repeated simulations increase the possibility of an accurate simulation result. The simulation could have an impact on the future result through predicting and optimizing the main parameters that will reflect the overall performance of the system. However, the more precise the mathematical model, the more realistic the simulation, and the more meaningful the result [

44].

The first element of the simulation model identifies the creation of the building geometry using DesignBuilder [

45]. Once the geometry is built, then we use the data collected from the site as input data for each geometry building, such as site location, weather data, operation time, equipment specification, etc. DesignBuilder interacts with a simulation engine, EnergyPlus, to calculate the annual energy consumption of the building while also reporting on the total operation cost and the amount of emission that has been produced during a one-year period [

46]. The next step after developing the simulation model of each building is to investigate the capability of the local solar farm to meet the power demand of five buildings cluster at the fishery port. The solar farm has been modelled using Simulink and EnergyPlus.

The next objective is to integrate the cluster of buildings with the solar farm through simulation. To achieve this, an investigation is conducted to identify the capability of the solar farm to meet the total power demand of the entire site of buildings with their associated operations. Also, we aim to find the optimum management of the energy system in the port by investigating power supply and demand as a first step in the overall optimization process within the port. To solve this question, we use BCVTB to connect different types of simulation engines for facilitating the exchange of data among various simulation instances [

47]. The power generation source identified by the solar farm has been modelled using EnergyPlus, which enables a simulation of the power generation during one year with the ability to test how the solar power generation can meet the local power demand. There are several parameters required for modelling the solar farm, such as PV modules’ properties, number of modules, inverters, the location of the farm, weather data, and the total number of panels based on the modelling and simulation. It is observed that the energy demand of the port is constant throughout the year, while energy production changes based on the seasons and weather.

3.2. Simulation-Based Optimization

The optimization process is based on the simulation of the smart energy cluster system. The optimization is based on the MATLAB/SIMULINK platform that facilitates the development of a smart energy community ecosystem. The smart energy community model consists of different multi-agent systems: load model, solar farm, grid integration, and battery energy systems as depicted in

Figure 2. The control algorithm works to manage power among agents with two proposed energy management scenarios for the smart energy community.

The first scenario will demonstrate the load model based on five industries at the fishery port, each with different functionalities. This will help to investigate the efficiency for the standalone system via the solar farm and to assess different demand scenarios to exchange power with the grid by finding the optimum storage size of the battery system at the site.

The second scenario will be implementing the smart energy community, including local domestic power demand involving 200 houses around the fishery port with the five processing industrial workflows. This experiment is a challenge due to the complexity of the model size. The charge controller will manage power flow among loads, solar farm, grid, and battery while allowing to run the model sufficiently without any disruption. The model will keep an activity interconnectivity with the grid in case the power from the battery system is not enough to meet the power demand from the community, especially at night.

The model is run several times to identify the optimum number of battery storage system when the model does not supply power from the grid. The model will present the behavior of the system in separate graph files in order to see how the entire industry system is run for 24 h. The model is running instantaneously (per second) with different scenarios and input parameters in the attempt to identify the optimum capacity of the battery storage system that can support the more optimal use of energy and reduce capital cost at the site.

4. Application Case Study

The analyses have been focused on the Milford Haven Port with five buildings and a solar farm based on which the entire fish processing workflow is conducted (see

Figure 3). The Packaway building is the main building in the port and contains several appliances consuming energy: a flake ice machine, ice store freezer, box washing machine, lighting systems, and smart meter. Also, there are four storage units in the Packaway building, and each storage has an installed LED lighting system. A 50-kW box-washing machine is another appliance used by the fisheries when they need to clean fish containers. The cold storage room is on for 24 h per day to store fish or other products before sending to the market. The Packaway has installed a solar panel system on the roof of the building, with 50 kW capacity, that is interconnected with local inverter to use it directly based on weather factors. The models have been created based on 2-D drawing, and the internal appliances have been modelled and calibrated based on data collected from the port.

M Shed building is currently occupied by different tenants and has an internal lighting system and several appliances. Units B & C of the building are used as storage facilities while Unit A is used as a boat repair workshop for an incident response provider. F shed is a new building divided into six units: unit one, unit two at ground floor, unit two at first floor, unit three is also on the ground floor. The ground floor units are used for fish processing, while first-floor units are used for storage such as fish containers. The building is still unoccupied, except for unit four, which is occupied with some appliances for fish food processing industries.

J Shed is considered the largest building in the port site and is currently occupied by different stakeholders. It is a complex building and has many electrical systems. The building is split into three occupied units: unit A contains a retail shop and an office space, fish processing appliances, and storage boxes used by individuals as fish deposits.

K shed is a warehouse. It contains a fridge/freezer used by a stakeholder, with a cold room fed mainly from solar PV panels on the roof, with a power capacity of 50 kW. There is a chiller storage room used to store fish, and the chiller is out of service due to technical issues. Also, the main hall has a 62-double-tube lighting system. The chiller storage consists of a lighting system and cooling system.

The solar farm is installed with about a 5-megawatt PV power capacity, containing about 20,000 panels. There are four main cabins in the site, which convert DC to AC (32,000 kV) and then link the solar farm to the national grid.

5. Proposed Smart Energy Community Model

A smart energy community provides the opportunity for the fishery port to become more sustainable. Introducing smart energy systems to the fish-processing industry will help to minimize the operation costs by reducing energy losses and efficiently by using locally generated power. Howell et al. [

48] suggests that applying a smart energy community model can be beneficial to an industry as a reliable strategy for reducing carbon emissions and can portray such industry in a positive light with the public and within the industrial sector.

For the Milford Haven site, we propose an integration between load model, PV model, battery, and grid in order to achieve a better understanding of the overall operation of the port. The signals generated during simulation are used to assess the load, power generation, grid, and the battery’s state of charge. The building has a rooftop PV system with a capacity of 50 kW, including a DC-DC converter and a DC-AC inverter. For the proposed smart grid model, the power generation is connected with the main appliances in the building and energy excess is configured to charge the battery system. The system has different priority levels whereby the energy produced is utilized for operating the appliances. When there is no demand from the building, the battery system is charged at a second priority level. When there is no demand and the battery is charged, the excess will be sent to the national grid. When there is no power generation from the PV system, the battery system is used to meet the power demand. Similarly, if the battery system discharges when there is power demand from a building, the model will be interconnected to the national grid to avoid disruption in the model. The system has been tested with different battery capacities as a means to identify the required number of battery systems that are required for the local power demand of the main building for 12 months. We have adopted a multi-stage approach with five iterations in order to develop the proposed smart energy community for the port, namely building simulation stage, energy generation model, energy storage model, grid model, and integration of agents.

5.1. Solar Farm

EnergyPlus software was used to simulate hourly power production for one year, considering a 50 kW solar plant and associated inverters. EnergyPlus also uses the weather data of the fish industry site based on the latitude and longitude of the location. The EnergyPlus engine gives an output of solar energy on an annual basis and shows the hourly power generation and solar radiation. The solar PV model has a capacity of 50 kW and the power output from PV is modelled as DC. However, this needs to be converted to AC, which can be used to run different equipment in the buildings. Therefore, a DC-DC converter regulates the output 3-phase voltages at 50 Hz to feed generated power to the grid at standard 3-phase voltages.

5.2. Grid Integration Model

The purpose of the grid is to balance the system and take care of spikes in the system. The grid supplies any excessive power demand to the property/building and accepts positive power. The infinite grid is used for the flexibility of feeding power demand and to ensure generation to the model. For the Packaway building, the grid is connected with the PV system, load model, and battery system with a frequency of 50 Hz based on the European standards. As grids are used for their flexibility of power flow, we have modelled the grid model at a frequency of 50 Hz.

5.3. Battery Model

Electrochemical batteries are the most common and efficient types of batteries from all the various storage services available. They store and emit energy via electrochemical reactions that are extremely stable through a variety of operating conditions. Such batteries can operate on short periods of time and have greater energy storage efficiency [

49]. New batteries, like Li-Io, are far more effective than previous generations, and therefore are widely used for electric cars [

50]. For each building, a Li-Io battery system has been used with 12 volts and 100 Ah for each battery. The battery model is controlled by an input P signal that is generated and sent to the model in the form of a command system. The signal represents the difference between power generation from PV and power demand from the building. The signal indicates the need to charge or discharge the storage system. A positive signal means that the battery system is in a charging state and the negative signal means that it is discharging. The total power is divided based on a battery voltage in order to find the current input for controlling current sources. Multiplying the voltage and the current will lead to determining the overall output power signal. The state of battery charge signal is generated and sent by a command to the main control block.

In this model, a Lithium ion (Li-Io) battery has been used with a nominal voltage of 12 volts, with an initial state of charge of 80%. Li-Io batteries are chosen based on their electrochemical potential to provide energy density for weight. Li-Io batteries are widely used for electrical energy storage due to their high specific energy per unit weight and energy density per unit volume. The Li-Io battery represents one of the most efficient solutions due to capability to pose hazard safety with its large capacity [

51]. Studies report [

52] that 12-volt Li-Io batteries are efficient for most of the analyzed storage parameters comparing to lead acid except maximum power capacity. The advantage of using Li-Io batteries with 12 volt-100 Ah is the superior ability to achieve auto-balance between the parallel connections which provides greater flexibility in various applications. Also, Li-Io batteries have benefits when dealing with increased storage capacities in charging and discharging operations [

53]. For this study, we use Li-Io 12-volt 100 Ah as a standard reference to identify the optimum number of battery systems within fish processing community.

Figure 4 presents the battery model for the smart energy community. The battery model consists of a battery charge controller that controls the charge and discharge based on the reference state of charge minimum and maximum level. The battery is integrated with the three-phase channels that interconnect with other agents to charge or discharge the system based on the different requirements in the model. The subsystem model is a DC/AC converter that converts stored power in the battery to AC, which can be used to respond to the load demand.

5.4. Load Model

5.4.1. Industries at Fishery Ports

There are five fish processing businesses in Milford Haven port. Each building houses a fish processing business and has its own energy consumption. Each building has been modelled as a separate load using DesignBuilder, that calculates energy consumption using the EnergyPlus simulation engine. The simulation result data will be used in MATLAB/SIMULINK for integration with different agents. Three-phase dynamic load models are connected by default to ensure integration of each building entity with the smart energy community model as a part of requirements. The process will be replicated for each building with the objective to achieve a community of individual industries, each running different fish processing businesses.

5.4.2. Local Community Houses

In Milford Haven port, there is a small community of houses around the marina as living areas for the staff working in the port. Adding domestic buildings is a key element in the overall modelling as it enables the formation of the smart energy community. We use 200 houses with different loads as a mean to establish the emerging fish port community. In the simulation, all buildings are simulated under one load to achieve integration with other community entities.

5.5. Charge Controller

5.5.1. Charge Controller Strategy for the Fish Processing Industries

The strategy of the charge/discharge controller is based upon a set of rules to distribute and manage the power among the four agents. The scenario has two different operation modes: when industries demand (ID) = farm production (FP), then all the power generation should feed the power consumption. If FP is greater than ID: check if the battery is full or not. If the battery is full, then send the power generation to the national grid. Otherwise, charge the battery system. If FP is less than ID, check the state of charge of the battery system. Is the SOC greater than 98% or less than 20%? If yes, then discharge ID from the battery system. Otherwise, the power demand is met by the national grid.

Figure 5a presents a flow chart describing the charge and discharge controller processes considering the main storage system.

5.5.2. Charge Controller Strategy for Industries and the Local Community

The strategy of the charge/discharge controller is based upon a set of rules to control and manage the power system among the four agents. The scenario has two operation modes:

When community demand (CD) = farm production (FP), then all the power generation should feed the power consumption. If FP is greater than CD: If no, then charge battery_1. If yes, check if battery storage_1 is full. If the battery is full, then check backup battery storage: If it is full, then sell the surplus power production to the national grid. Otherwise, charge the backup battery. If no, check the state of charge (SOC) of the battery system. Is the SOC is greater than 98% and less than 20%? If no, check the SOC of the backup battery system. Is the SOC greater than 98%? If yes, then discharge CD from the battery system. Otherwise, the power demand is met by the national grid.

Figure 5b is a flow chart describing the charge and discharge controller processes considering the main storage system.

5.6. Mathematical Model for Optimization

In the mathematical model, we measure the energy generation and energy consumption from a cost perspective. If the generated energy is greater than the load demand of industries at time

t, the excess energy will be stored in batteries. In this state, the stored energy in the battery at time

t is as follows:

where

and

are stored energy of the battery at time

t and

t−1,

is the round-trip efficiency of the batteries,

is the inverter efficiency, and

is load demand at

t.

If the load demand exceeds the produced energy at time

t, the deficiency of the load demand is offset by battery discharge. In a discharging state, the energy stored in the battery at time

t is found as follows [

54]:

The objective function is presented as cost.

where

C is the capital cost of the system, while

and

represent the cost of batteries and PVs.

and

are the numbers of batteries and PVs.

The calculation of the optimum number of PV modules and batteries is based upon a loss of power supply probability (

LPSP) concept [

55].

LPSP can be defined as the long-term average proportion of the load not supplied by the system. An

LPSP of 0 means the load will always be met, and the

LPSP of 1 means that the load will never be met [

54].

When the energy available in batteries is insufficient to meet the load demand for hour t, that deficit called loss of power supply for hour t is expressed:

The inverter efficiency is set to equal 95%. The

LPSP can be defined as:

Different permutations of the number of PV modules and the number of batteries could be calculated for the desired

LPSP. In order to consider the

LPSP, the following is considered during optimization:

where

is the maximum allowable

LPSP and is considered to be 2%.

For the energy system, at any time, we have:

This means that the batteries should not be discharged or charged outside of the set range at any time.

takes the value of nominal capacity of battery

and

obtained by the maximum depth of discharge

such as:

The maximum depth of discharge is considered to be 80%. Further constraints are follows:

The optimization was done using the SLSQP algorithm available through the SciPy optimization package for Python, and the results are validated using IBM CPLEX. We suppose that the capacity of the nominated batteries is 1.2 kWh each. As the optimal number of the PVs is much smaller than our current capacity of generating power by PVs, we assume that we don’t need additional PV modules. The optimal number of the batteries at to meet demands for five industries and 200 houses is .

6. Results and Discussion

This section presents simulation analysis based on the integration of the solar farm unit using BCVTB. Based on the simulation, we present results for optimizing energy consumption using scheduling appliances techniques at the building level. We expand our analysis to a community level by presenting results obtained from the simulation of a smart energy community model. For the community evaluation, the first scenario will present simulation results of a smart energy community with five industries with the objective to find the optimum battery capacity for storage. The second scenario will show results from a simulation of a smart energy community considering local domestic community power demands.

6.1. Result of Energy Simulation for the Industrial Site

The main objective of the evaluation is to demonstrate integration of the cluster of buildings with the solar farm through simulation by investigating the capability of the solar farm to meet the total power demand of the entire site of buildings with their associated operations. Also, we aim to find the optimum management of the energy system in the port by investigating power supply and demand as a first step in the overall optimization process in the port. Co-simulation software has been used, such as BCVTB software, to connect different types of simulation engines for facilitating the exchange of data among various simulations. The solar farm has been modelled using Simulink and EnergyPlus linked together with BCVTB.

Figure 6 presents the BCVTB models and the main components for the integrations. The model shown in

Figure 6 highlights the conceptual integration between power demand and supply within the energy cluster. To analyze the power supply and demand, we have used two different simulation engines to (i) evaluate total power demand in the fish industry and (ii) simulate solar farm energy generation.

Figure 7 illustrates the energy simulation results across five buildings at Milford Haven port. As shown, there are seasonal variations in energy consumption across the selected buildings, which can be attributed to fishing seasons. Cold rooms in fishery ports are one of the most crucial appliances which consume in excess of 60 percent of the total energy. This is reflected in the energy consumption of the K Shed building over a 12 months period. The building involves the fish food production line, with several energy consuming pieces of equipment and appliances.

Figure 8 presents the simulation results of the five buildings integrated with the local solar farm, using the BCVTB co-simulation platform. The figure illustrates that the solar farm power production is higher than the local energy demand, which means that the local energy demand can be met by the local energy supply from the solar farm. Also, the production reaches its peak in the summer period, due to longer day times when more energy can be produced compared to winter seasons.

There are several parameters required for modelling the solar farm, such as PV modules properties, number of modules, inverters, location of the farm, weather data, and the total number of panels.

Based on the modelling and simulation,

Figure 8 illustrates simulated energy production and consumption in the port over a year, whereas

Figure 9 presents the energy consumption of the buildings with solar farm generation. It is observed that the energy demand of the port is constant throughout the year while energy production evolves based on the seasons and weather specificities.

Optimizing Schedules in the Packaway Building

Scheduling appliances are the core of optimization as a flexible approach to manage the energy consumption and production in the port. However, to understand the impact of energy consumption, we first apply our analysis on the Packaway building and propose an energy-based scheduling method for smarter energy management.

Table 2 shows the trends of the energy consumption per appliance at four intervals in the Packaway building, as identified during the simulation.

Table 3 presents the input constraints of the appliances which must be considered for the energy optimization process for achieving integration with renewable energy sources. It considers power capacity, the minimum running time of each appliance, the ability to interrupt appliance, and the required start time.

Table 4 presents the optimized time of operation per appliance as resulted from the optimization. It presents the total amount of energy that must be consumed, and the total amount of energy needed either from the local power generation or the national grid. The results presented below are obtained based on the simulation-based optimization process and show the optimized time of operation of appliances by considering different parameters that impact the total power consumption and operation time of each appliance. Such optimized schedules can orchestrate energy management at the port level and provide a more efficient use of resources within the port.

6.2. Results of the Community Simulation

In this section, we provide the results of analysis of the community simulation. In this scenario, we investigated the capability to meet the local power demand of a community using a local solar farm by developing a smart grid model to understand how local power generation can satisfy the load demand for a 24-h period.

6.2.1. Results of the Local Community Evaluation

As explained in

Section 5, we simulated power management of the energy supply and demand for five fish processing industries and their associated operation at Milford Haven port. The simulation results showed that a stand-alone smart grid model can meet the local power demand for 24 h without the need of power from the grid. The power produced from 5 MW solar from 6 AM to 4 PM can charge a 600 kW Li-Io battery storage to meet the power demand at night. The simulation result from

Figure 9 shows that a 50 kAh battery storage is the optimum capacity to meet the local power demand of five industries during the night. However, the power load of industries will be met directly from the solar farm in the daytime period which will also recharge the battery system to meet the local power demand at night. Also, the simulation results show that the system will dump the surplus power from the solar farm to the grid. The battery charge state shows that the battery system discharges from 12 AM until 8 AM.

As presented in

Figure 9, more power supply is needed from 5 AM to 8 AM because at this time, fish industries run ice making machines required to store fish before sending it to market. Most of the power demand in the night is used for lighting, cleaning, and for the cold storage system. Each industry has installed a cold room to store fish, which is considered the most consumed appliances in the industry. The proposed storage integration will help to reduce a considerable amount of carbon emission and also to reduce energy cost with the local energy grid. In addition, the installed solar farm can have a significant impact on the port by increasing income and reducing energy cost as provides a cost-efficient alternative to the main grid.

Figure 9 presents the simulation results when integrating the fish processing industries with the solar farm. The results proved that a smart energy community for fishery ports can not only reduce carbon emissions, but can also help to reduce energy consumption, thus facilitating a transition towards clean and sustainable energy. In addition, such community models are dumping greener energy to the national grid by using renewables resources available at the site. Furthermore, the solar farm can have a significant impact on the port by increasing the income by selling power to the grid as well as minimizing the impact on the energy cost when buying from the national grid.

6.2.2. Results of the Larger Community Evaluation

In this experiment, we developed a smart energy community around port using the multi-model simulation platform. The aim of this scenario is to investigate the capability of the solar farm to meet the power demand of the port and the local 200 houses community. The current load is identified by the five buildings at Milford Haven port. In this experiment, we incorporate a load consumption of 200 community houses around the port for 24 h. Also, we propose a charge controller strategy containing two battery storage systems. The main battery storage system and a backup battery system are adopted due to variant loads in the community. To conduct the simulation, we have used an Intel® Core i7TM @ 4.00 GHz with 16 GB RAM, a computational environment that supported the complexity of running an optimization problem to identify to required amount of battery storage for the energy community. The proposed smart control strategy contains two battery systems: (i) one battery as a main battery for the whole model and, (ii) a backup battery system to meet the variation of energy demand from the local energy community in the night as well as to avoid buying power from the grid. During the experiments, we repeated the simulation several times with the same input parameters while changing the battery system capacity in order to get the optimum number of batteries as shown in

Table 5.

Table 5 shows the simulation trials with an optimum amount of battery storage. The simulation results show that about 1.2 MW capacity of Li-Io battery storage is the optimum capacity for the main battery and about 250 kW is the optimum capacity of back-up battery storage.

Figure 10 presents the simulation result of developing a smart energy community at the fishery port. The simulation results show that a 1000 battery storage is the optimum amount of battery storage for a community of five industries and 200 community houses.

The simulation results presented in

Figure 10, show that smart energy communities can identify high fluctuations in power demand from both fishery port buildings and the local surrounding community. The results also demonstrate that battery storage can avoid/delay the process of purchasing power from the grid as the state of charge of the main battery reacts adequately to meet the power demand during the night. When the battery system capability is finished, the back-up battery can be used to satisfy the power demand in the buildings. As a consequence of the complexity of the community simulation, we identify a slight use of power from the grid between 4 and 6 AM, as an expected fault in the model which is determined by the increased number of energy models included in the simulation.

7. Conclusions

Actionable knowledge can play a determinant role in reducing the carbon footprint of our building [

56,

57]. Due to increased carbon emission and energy consumption in fish processing industries, it has become necessary to find a smarter way to manage energy and reduce energy consumption. Renewable energy sources and optimized energy strategies are important enablers that play a vital role in the overall energy management landscape. Applying smart energy management tools can prove to be an efficient and feasible method from an economic perspective, but such solutions can present associated modelling complexity.

This paper primarily focuses on the delivery of a co-simulation environment that leverages calibrated energy simulation models to deliver an optimization capability that (a) manages electrical storage within a district an environment, and (b) promotes the formation of energy communities in a fishery port ecosystem.

This research paves the way for policy implications in that the research evidences the carbon and energy reduction potential, as well as promotes low carbon fishery ports and the formation of energy communities in the surrounding ecosystem. Such strategies constitute the aim of future research for the authors with the local authority within the Milford Heaven Council and beyond. It is important to note that the Milford Haven port authority is a national strategic industrial site where the authors were limited in terms of energy audit procedures and optimization strategies. The latter required acceptance by the authority. We have explored different types of optimization strategies based on the energy audit and consultations with fishery port stakeholders and port authorities. As informed by the requirement capture process, the optimization strategy was to minimize the deployment of equipment and investments while observing benefits and efficiency in terms of energy management at the site and community level. The proposed model was developed based on a trade-off criterion related to the cost of implementation and efficiency with a view to: (a) reduce to a minimum investment in the implementation of the proposed model, and (b) demonstrate clear benefits in terms of costs and energy savings.

Future work will explore energy sharing models as a means for optimizing energy and resources at the community level. We will focus on the formation and use of a community energy sharing market with corresponding discovery mechanisms whereby energy agents such as prosumers can satisfy individual demands from consumers [

58]. Such sharing models will assess the level of trust that can be placed in an energy provider with regards to an advertised energy capability. This approach will unlock energy exchanges within a community [

59] and will allow prosumers to monetize their energy excess in a more secured and flexible local market environment.