Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines

Abstract

1. Introduction

2. Materials and Methods

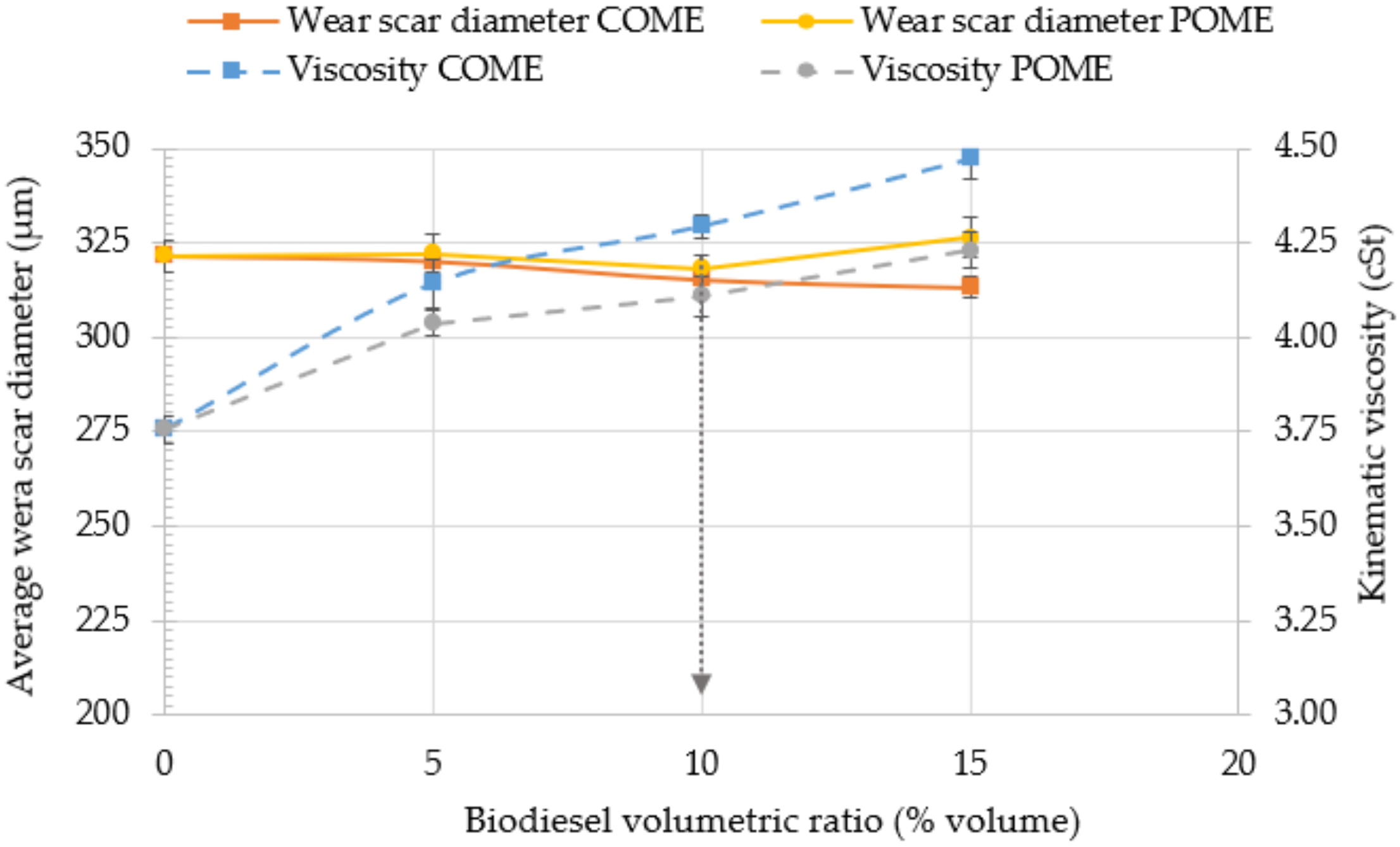

- To find a suitable ratio of the fuel blend by mainly considering fuel lubricity and viscosity; the fuel blends were prepared at various ratios, i.e., 0%, 5%, 10%, and 15% (by volume) of the biodiesel to the waste plastic oil.

- To test the suitable fuel blends with a single-cylinder diesel engine without any engine modifications. The objective of this test was to evaluate engine performance, combustion characteristics, and exhaust emissions.

2.1. Materials

2.1.1. Waste Plastic Oil

2.1.2. Production of Castor Oil Biodiesel and Palm Oil Biodiesel

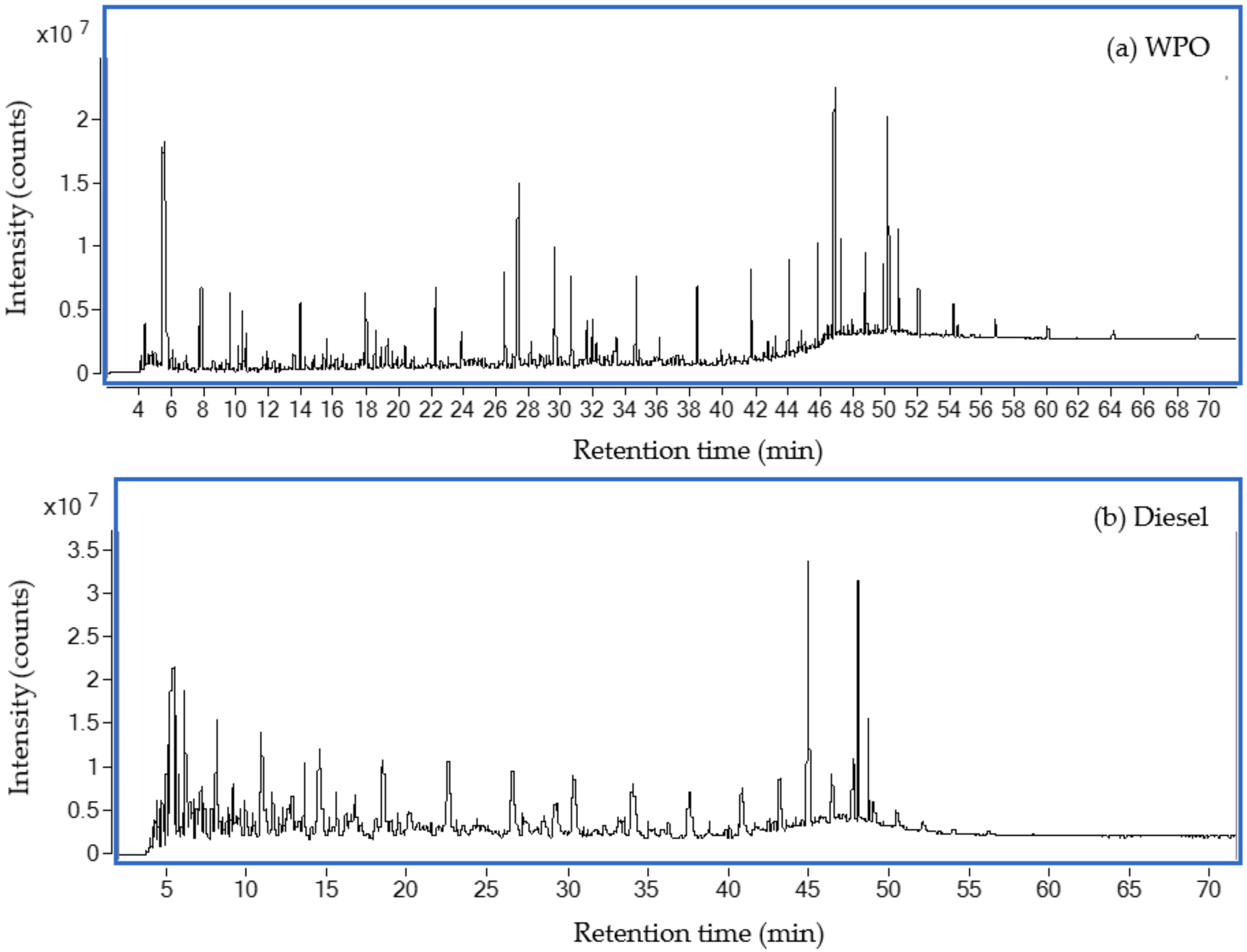

2.2. Gas Chromatography Analysis

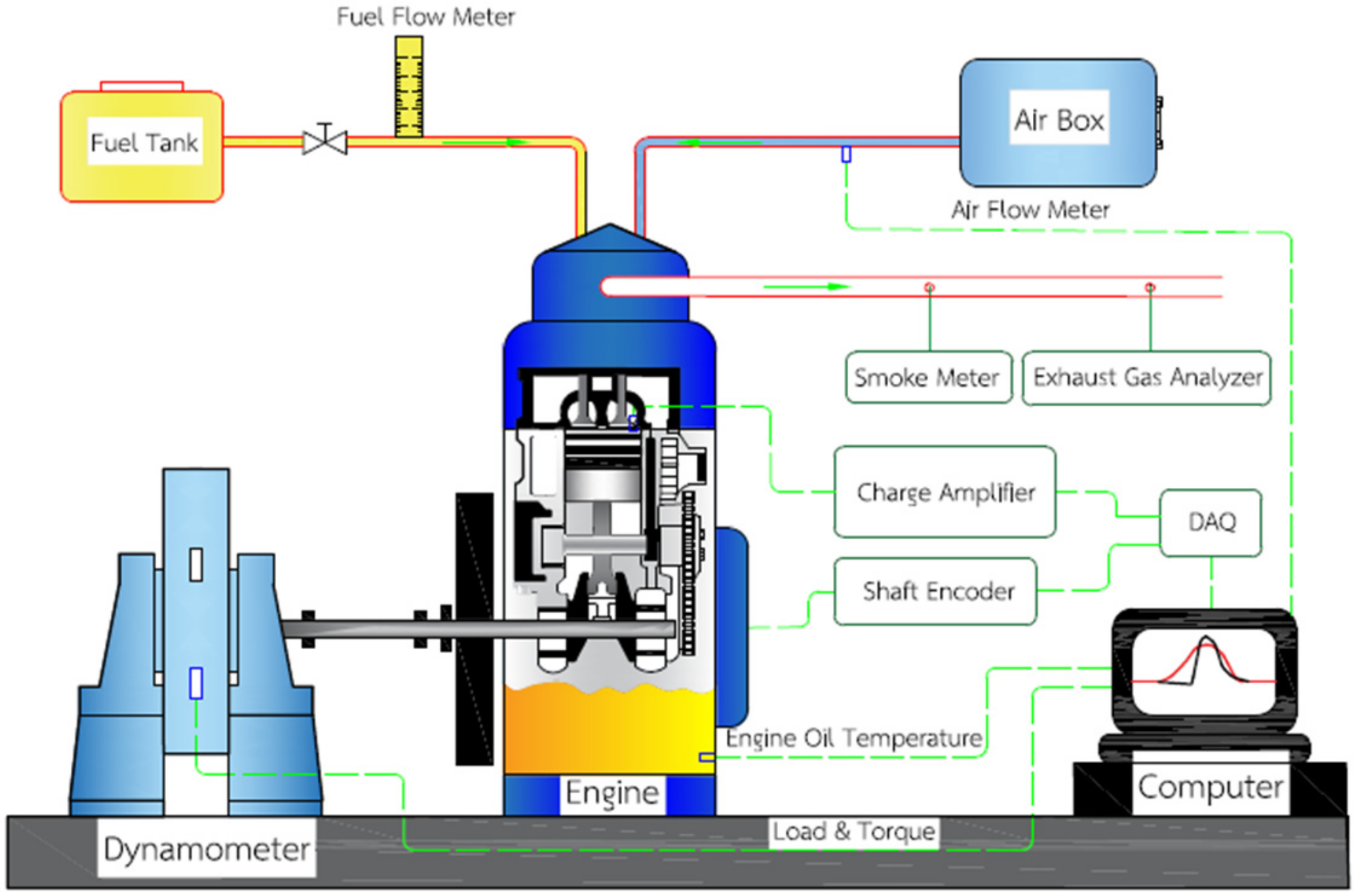

2.3. Experimental Setup

2.3.1. Testing by Adjusting Engine Load

2.3.2. Emission Testing

3. Results and Discussions

3.1. Test Fuels

Characterization of Waste Plastic Oil

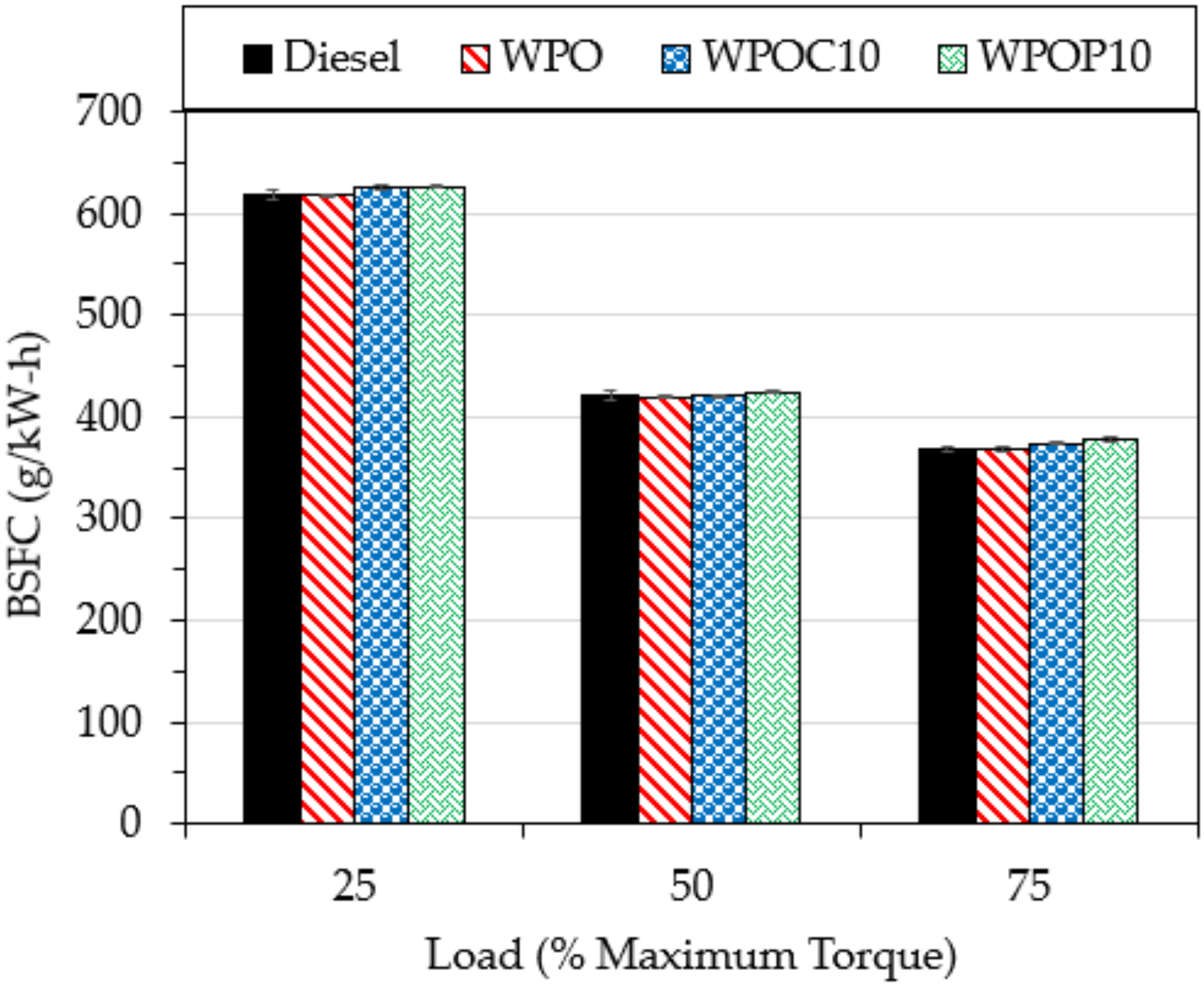

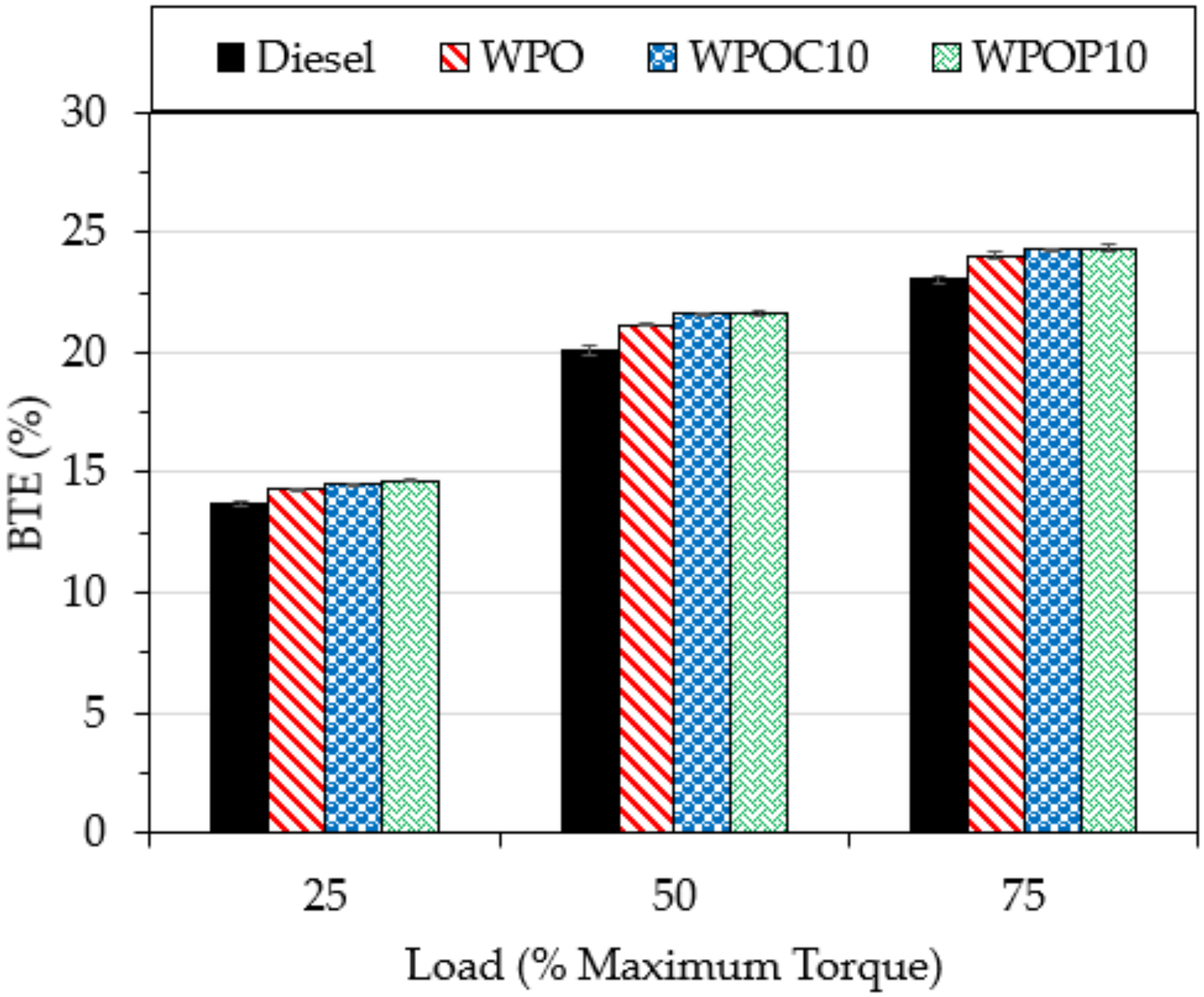

3.2. Engine Performance

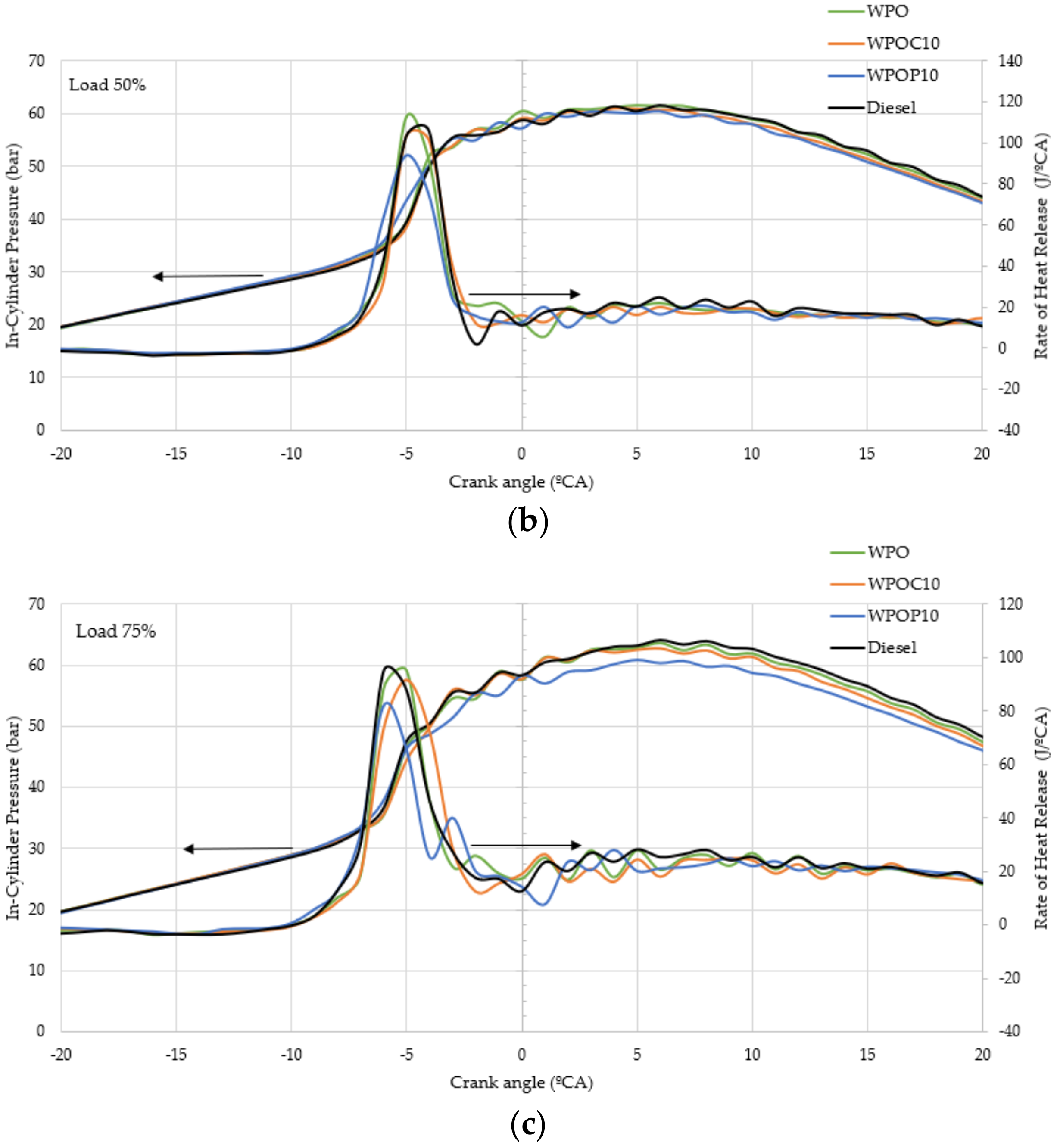

3.3. Combustion Characteristics

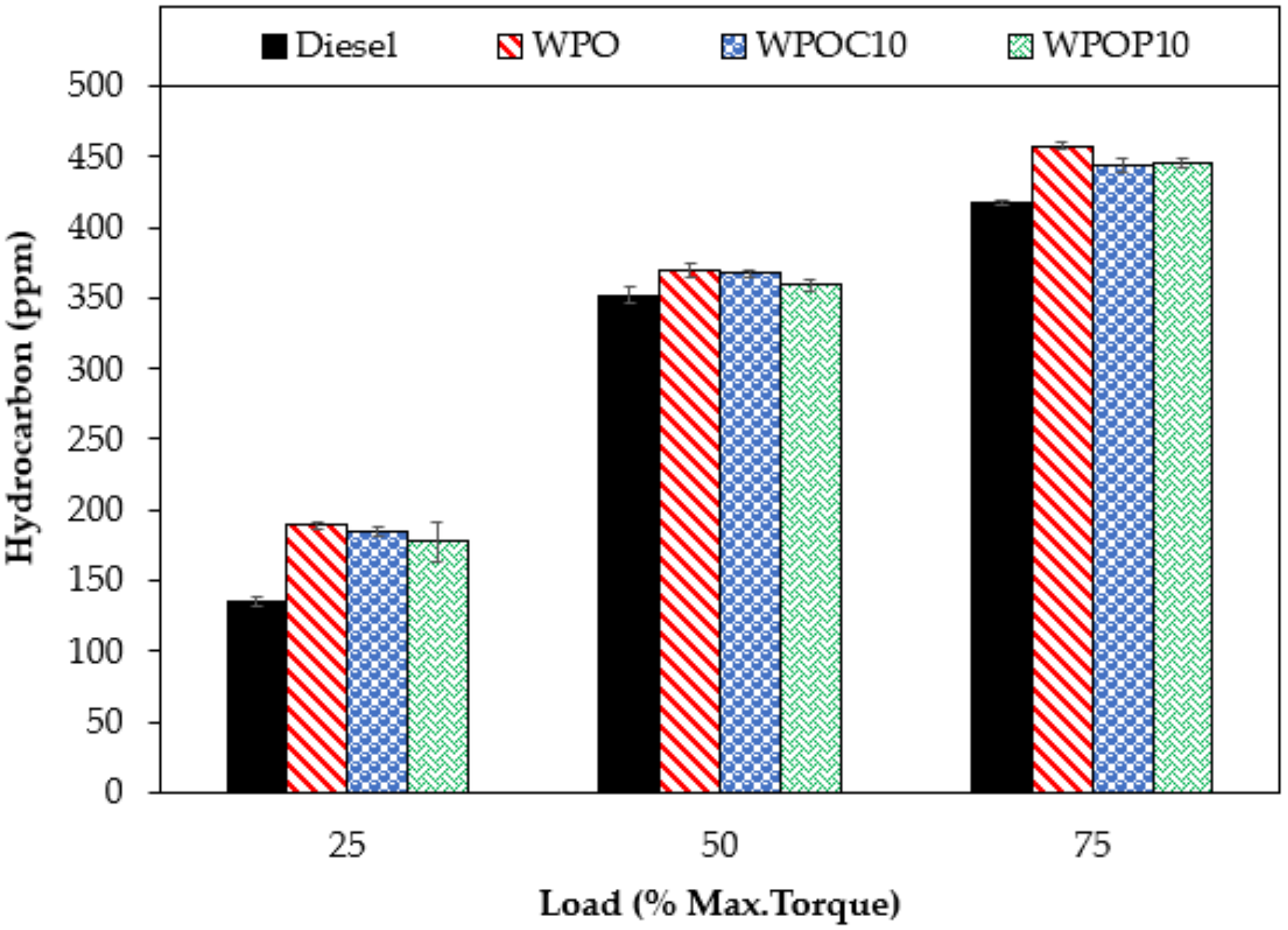

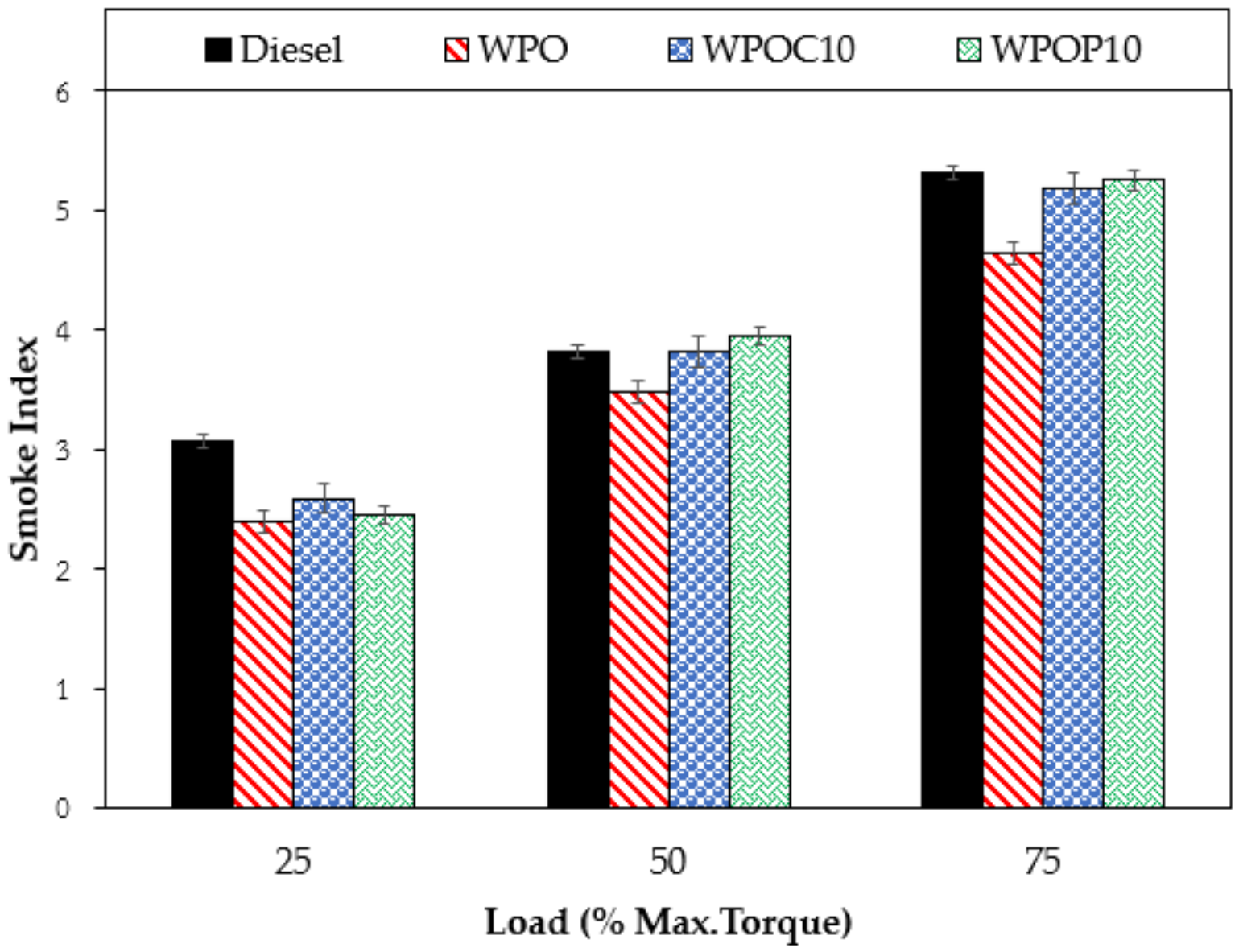

3.4. Emissions

4. Conclusions

- Considering fuel lubricity and viscosity, the presence of 10% (v/v) biodiesel was the optimal ratio for improving the waste plastic oil.

- The brake thermal efficiency of the engine was slightly improved with the addition of biodiesel to waste plastic oil.

- The addition of castor oil as compared to palm oil biodiesel caused a delay in the start of the combustion, resulting in a higher peak of heat release rate.

- The reduction in the level of hydrocarbon- and oxide-containing nitrogen emissions was found with the addition of biodiesel, while carbon monoxide and the smoke emissions were increased.

- Comparing the two tested biodiesels, the presence of castor oil in waste plastic oil showed lower carbon monoxide and smoke emissions without any penalty regarding the levels of hydrocarbon- and oxide-containing nitrogen emissions when the engine was operated at a high load.

- Future studies on engine modification, such as to the piston, injection timing, and injection pressure, can be considered for further improvements through the reduction of exhaust emissions by the use of biodiesel as a blend component in waste plastic oil.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| BSFC | brake-specific fuel consumption |

| BTE | brake thermal efficiency |

| CO | carbon monoxide |

| COME | castor oil methyl ester |

| HC | hydrocarbon |

| HDPE | high-density polyethylene |

| HFRR | high-frequency reciprocating rig |

| KOH | potassium hydroxide |

| LDPE | low-density polyethylene |

| MBT | mechanical biological treatment |

| NOX | nitrogen oxides |

| PE | polyethylene |

| POME | palm oil methyl ester |

| PP | polypropylene |

| PS | polystyrene |

| WPO | waste plastic oil |

| WPOC10 | fuel blend of 10% castor oil biodiesel and 90% waste plastic oil |

| WPOP10 | fuel blend of 10% palm oil biodiesel and 90% waste plastic oil |

| GC-MS | gas chromatography–mass spectrometry |

References

- Energy Policy and Planning Office, Ministry of Energy, Thailand. Energy Statistics of Thailand. Available online: http://www.eppo.go.th/index.php/th/informationservices/ct-menu-item-56?orders[publishUp]=publishUp&issearch=1 (accessed on 28 July 2019).

- Gabbar, H.A.; Aboughaly, M.; Stoute, C.A. DC thermal plasma design and utilization for the low density polyethylene to diesel oil pyrolysis reaction. Energies 2017, 10, 784. [Google Scholar] [CrossRef]

- Damodharan, D.; Sathiyagnanam, A.P.; Rana, D.; Kumar, B.R.; Saravanan, S. Extraction and characterization of waste plastic oil (WPO) with the effect of n-butanol addition on the performance and emissions of a DI diesel engine fueled with WPO/diesel blends. Energy Convers. Manag. 2016, 131, 117–126. [Google Scholar] [CrossRef]

- Kaimal, V.K.; Vijayabalan, P. A detailed study of combustion characteristics of a DI diesel engine using waste plastic oil and its blends. Energy Convers. Manag. 2015, 105, 951–956. [Google Scholar] [CrossRef]

- Areeprasert, C.; Asingsamanunt, J.; Srisawat, S.; Kaharn, J.; Inseemeesak, B.; Phasee, P.; Khaobang, C.; Siwakosit, W.; Chiemchaisri, C. Municipal plastic waste composition study at transfer station of Bangkok and possibility of its energy recovery by pyrolysis. Energy Procedia 2017, 107, 222–226. [Google Scholar] [CrossRef]

- Baskaran, R.; Sathish Kumar, P. Evaluation on performance of CI engine with waste plastic oil-diesel blends as alternative fuel. Int. J. Res. Appl. Sci. Eng. Technol. 2015, 3, 642–646. [Google Scholar]

- Syamsiro, M.; Saptoadi, H.; Kismurtono, M.; Mufrodi, Z.; Yoshikawa, K. Utilization of waste polyethylene pyrolysis oil as partial substitute for diesel fuel in a DI diesel engine. Int. J. Smart Grid Clean Energy 2018, 8, 38–47. [Google Scholar] [CrossRef]

- Sachuthananthan, B.; Reddy, D.R.; Mahesh, C. Production of diesel like fuel from municipal solid waste plastics for using in CI Engine to study the combustion, performance and emission characteristics. Int. J. Pure Appl. Math. 2018, 119, 85–98. [Google Scholar]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef]

- Mani, M.; Nagarajan, G.; Sampath, S. Characterisation and effect of using waste plastic oil and diesel fuel blends in compression ignition engine. Energy 2011, 36, 212–219. [Google Scholar] [CrossRef]

- Ramesha, D.K.; Kumara, G.P.; Lalsaheb; Mohammed, A.V.T.; Mohammad, H.A.; Kasma, M.A. An experimental study on usage of plastic oil and B20 algae biodiesel blend as substitute fuel to diesel engine. Environ. Sci. Pollut. Res. 2015, 23, 9432–9439. [Google Scholar] [CrossRef]

- Senthilkumar, P.; Sankaranarayanan, G. Effect of Jatropha methyl ester on waste plastic oil fueled DI diesel engine. J. Energy Inst. 2016, 89, 504–512. [Google Scholar] [CrossRef]

- Keera, S.T.; El Sabagh, S.M.; Taman, A.R. Castor oil biodiesel production and optimization. Egypt. J. Pet. 2018, 27, 979–984. [Google Scholar] [CrossRef]

- ISO12156-1: Diesel Fuel—Assessment of Lubricity Using the High Frequency Reciprocating Rig. 2016. Available online: https://www.iso.org/standard/65227.html (accessed on 1 June 2020).

- Wathakit, K.; Sukjit, E.; Maithomklang, S.; Srisertpol, J. Fuel properties, performance and emission of alternative fuel from pyrolysis of waste plastics. In Proceedings of the 2019 the 6th International Conference on Mechatronics and Mechanical Engineering, Wuhan, China, 9–11 November 2019; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar]

- Shirneshan, A.; Almassi, M.; Ghobadian, B.; Borghei, A.M.; Najafi, G. Brake specific fuel consumption of diesel engine by using biodiesel from waste cooking oil. World Sci. J. 2013, 1, 45–52. [Google Scholar]

- Kumar, S.; Prakash, R.; Murugan, S.; Singh, R.K. Performance and emission analysis of blends of waste plastic oil obtained by catalytic pyrolysis of waste HDPE with diesel in a CI engine. Energy Convers. Manag. 2013, 74, 323–331. [Google Scholar] [CrossRef]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Hanchi, S.; Tazerout, M. Experimental evaluation of performance and emissions of DI diesel engine fueled with eucalyptus biodiesel. In Proceedings of the Internal Combustion Engines: Performance, Fuel Economy and Emissions, London, UK, 29–30 November 2011; pp. 167–176. [Google Scholar]

- Adaileh, W.M.; Alqdah, K.S. Performance of diesel engine fuelled by a biodiesel extracted from a waste cocking oil. Energy Procedia 2012, 18, 1317–1334. [Google Scholar] [CrossRef]

- Yusop, A.F.; Mamat, R.; Yusaf, T.; Najafi, G.; Yasin, M.H.M.; Khathri, A. Analysis of particulate matter (PM) emissions in diesel engines using palm oil biodiesel blended with diesel fuel. Energies 2018, 11, 1039. [Google Scholar] [CrossRef]

- Arato, K.; Takashima, T. A study on reduction of heat loss by optimizing combustion chamber shape. SAE Int. J. Engines 2015, 8, 596–608. [Google Scholar] [CrossRef]

- Pumpuang, A.; Maithomklang, S.; Sukjit, E.; Dejvajara, D.; Samaiklang, P.; Sanluecha, S. Utilization of Castor Oil-Based Ethyl Ester Biodiesel in a Diesel Engine; No. 2019-32-0606; SAE Technical Paper: 2019; SAE International: Pennsylvania, PA, USA, 2019. [Google Scholar]

- Kaimal, V.K.; Vijayabalan, P. A study on synthesis of energy fuel from waste plastic and assessment of its potential as an alternative fuel for diesel engines. Waste Manag. 2016, 51, 91–96. [Google Scholar] [CrossRef]

- Mrityunjaya, S.K.M.; Ramesha, D.K.; Premkumara, G.; Ranaprapareddy, N. Performance and emission characteristics of a compression ignition engine using blends of bio-oil as a fuel. J. Middle Eur. Constr. Des. Cars 2011, 9, 40–44. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. An experimental study on the combustion, performance and emission characteristics of a diesel engine fuelled with diesel-castor oil biodiesel blends. Renew. Energy 2018, 119, 174–184. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Muraleedharan, C.; Jayaraj, S. Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew. Energy 2005, 30, 1789–1800. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Dearn, K.; Tsolakis, A. Improving Ethanol-Diesel Blend through the Use of Hydroxylated Biodiesel; No. 2014-01-2776; SAE Technical Paper: 2014; SAE International: Pennsylvania, PA, USA, 2014. [Google Scholar]

- Panwar, N.L.; Shrirame, H.Y.; Rathore, N.S.; Jindal, S.; Kurchania, A.K. Performance evaluation of a diesel engine fueled with methyl ester of castor seed oil. Appl. Therm. Eng. 2010, 30, 245–249. [Google Scholar] [CrossRef]

- Sukjit, E.; Liplap, P.; Maithomklang, S.; Arjharn, W. Experimental Investigation on a DI Diesel Engine Using Waste Plastic Oil Blended with Oxygenated Fuels; No. 2017-24-0116; SAE Technical Paper: 2017; SAE International: Pennsylvania, PA, USA, 2017. [Google Scholar]

- Azad, A.K.; Rasul, M.G.; Khan, M.M.K.; Sharma, S.C.; Bhuiya, M.M.K. Recent development of biodiesel combustion strategies and modelling for compression ignition engines. Renew. Sustain. Energy Rev. 2016, 56, 1068–1086. [Google Scholar] [CrossRef]

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the use of diesel-biodiesel-alcohol blends in compression ignition engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef]

- Sukjit, E.; Maithomklang, S.; Trirak, N.; Klinkaew, N. Emission benefits from the use of castor oil in a compression ignition engine fuelled with diesel-ethanol blends. Int. J. Electr. Energy 2018, 6, 57–63. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Piaszyk, J.; Dearn, K.D.; Tsolakis, A. Finding synergies in fuels properties for the design of renewable fuels-hydroxylated biodiesel effects on butanol-diesel blends. Environ. Sci. Technol. 2013, 47, 3535–3542. [Google Scholar] [CrossRef]

| Engine | Specification |

|---|---|

| Model | Kirloskar TV1 |

| Engine type | Single cylinder, 4 stroke, Water cooler, Direct injection |

| Bore | 87.5 mm |

| Stroke | 110 mm |

| Connecting rod length | 234 mm |

| Swept volume | 661 cc |

| Rate output | 3.5 kW at 1500 rpm |

| Compression ratio | 12–18 |

| Dynamometer | Eddy current, Water cooler |

| Fatty Acid | % wt. | ||

|---|---|---|---|

| POME | COME | ||

| Lauric | C12:0 | 0.92 | 0.02 |

| Myristic | C14:0 | 1.28 | 0.06 |

| Palmitic | C16:0 | 46.29 | 1.63 |

| Stearic | C18:0 | 4.63 | 1.66 |

| Oleic | C18:1 | 37.07 | 3.85 |

| Ricinoleic | C18:1 OH | - | 85.6 |

| Linoleic | C18:2 | 8.67 | 6.04 |

| Linolenic | C18:3 | 0.03 | 0.43 |

| Arachidic | C20:0 | 0.36 | 0.08 |

| Other | 0.75 | 0.63 | |

| Properties | Test Method | Diesel | WPO | POME | COME | WPOP10 | WPOC10 |

|---|---|---|---|---|---|---|---|

| Kinematic viscosity at 40 °C (cSt) | ASTM D445 | 4.19 | 3.76 | 6.46 | 18.61 | 4.11 | 4.29 |

| Specific gravity at 15.6 °C | ASTM D1298 | 0.828 | 0.825 | 0.875 | 0.910 | 0.830 | 0.845 |

| Density at 15.6 °C (kg/m3) | ASTM D1298 | 827 | 824 | 874 | 909 | 829 | 844 |

| Flash point (°C) | ASTM D93 | 68 | 41 | 96 | 108 | 45 | 48 |

| Gross calorific value (MJ/kg) | ASTM D240 | 42.45 | 40.58 | 36.79 | 37.95 | 39.18 | 39.64 |

| Cetane index | ASTM D976 | 60.2 | 60.0 | 48.7 | 39.4 | 59.6 | 54.5 |

| Carbon Content | % Area | |

|---|---|---|

| WPO | Diesel | |

| C4–C11 | 12.85 | 17.56 |

| C12–C20 | 74.39 | 73.28 |

| >C20 | 12.76 | 9.16 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaewbuddee, C.; Sukjit, E.; Srisertpol, J.; Maithomklang, S.; Wathakit, K.; Klinkaew, N.; Liplap, P.; Arjharn, W. Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines. Energies 2020, 13, 2823. https://doi.org/10.3390/en13112823

Kaewbuddee C, Sukjit E, Srisertpol J, Maithomklang S, Wathakit K, Klinkaew N, Liplap P, Arjharn W. Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines. Energies. 2020; 13(11):2823. https://doi.org/10.3390/en13112823

Chicago/Turabian StyleKaewbuddee, Chalita, Ekarong Sukjit, Jiraphon Srisertpol, Somkiat Maithomklang, Khatha Wathakit, Niti Klinkaew, Pansa Liplap, and Weerachai Arjharn. 2020. "Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines" Energies 13, no. 11: 2823. https://doi.org/10.3390/en13112823

APA StyleKaewbuddee, C., Sukjit, E., Srisertpol, J., Maithomklang, S., Wathakit, K., Klinkaew, N., Liplap, P., & Arjharn, W. (2020). Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines. Energies, 13(11), 2823. https://doi.org/10.3390/en13112823