Evaluation of a Modified Equivalent Fuel-Consumption Minimization Strategy Considering Engine Start Frequency and Battery Parameters for a Plugin Hybrid Two-Wheeler

Abstract

:1. Introduction

- (1)

- The conventional Basic rule-based Energy Management Strategy (BEMS);

- (2)

- The Modified rule-based Energy Management Strategy (MEMS);

- (3)

- The conventional Equivalent fuel Consumption Minimization Strategy (ECMS);

- (4)

- The Modified ECMS named as ECMS_LL.

- To design and develop a novel modified ECMS for a plugin hybrid concept two-wheeler, which enhances the fuel optimality further when compared to traditional ECMS.

- Evaluation and assessment of modified ECMS with traditional ECMS and other rule-based strategies.

- To perform an all-inclusive study and evaluation of energy management strategies considering battery parameters influencing battery ageing (battery temperature, battery Ah throughput, SOC and charge/discharge C rate), engine switching events and charge sustenance along with fuel economy.

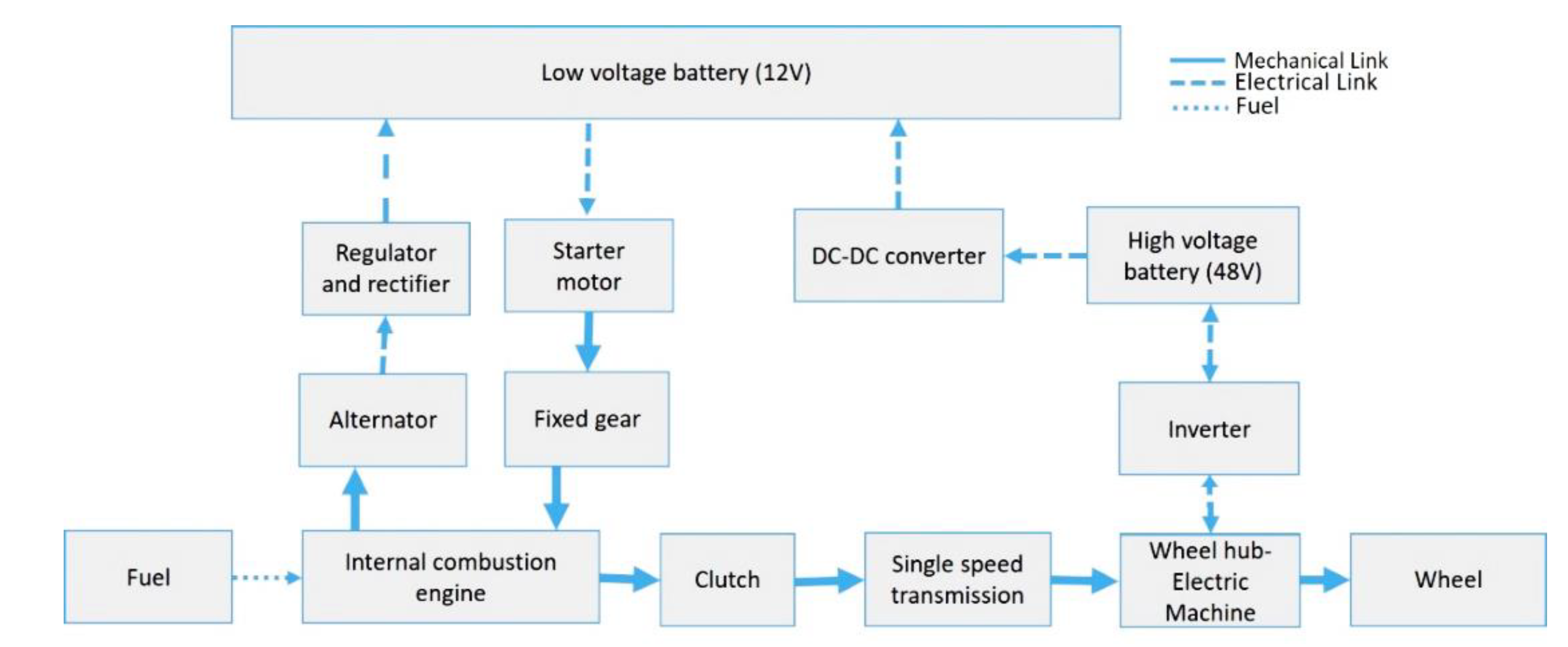

2. Vehicle Model and System Configuration

2.1. System Configuration

2.1.1. Vehicle Model

2.1.2. Engine

2.1.3. Electric Machine

2.1.4. Transmission

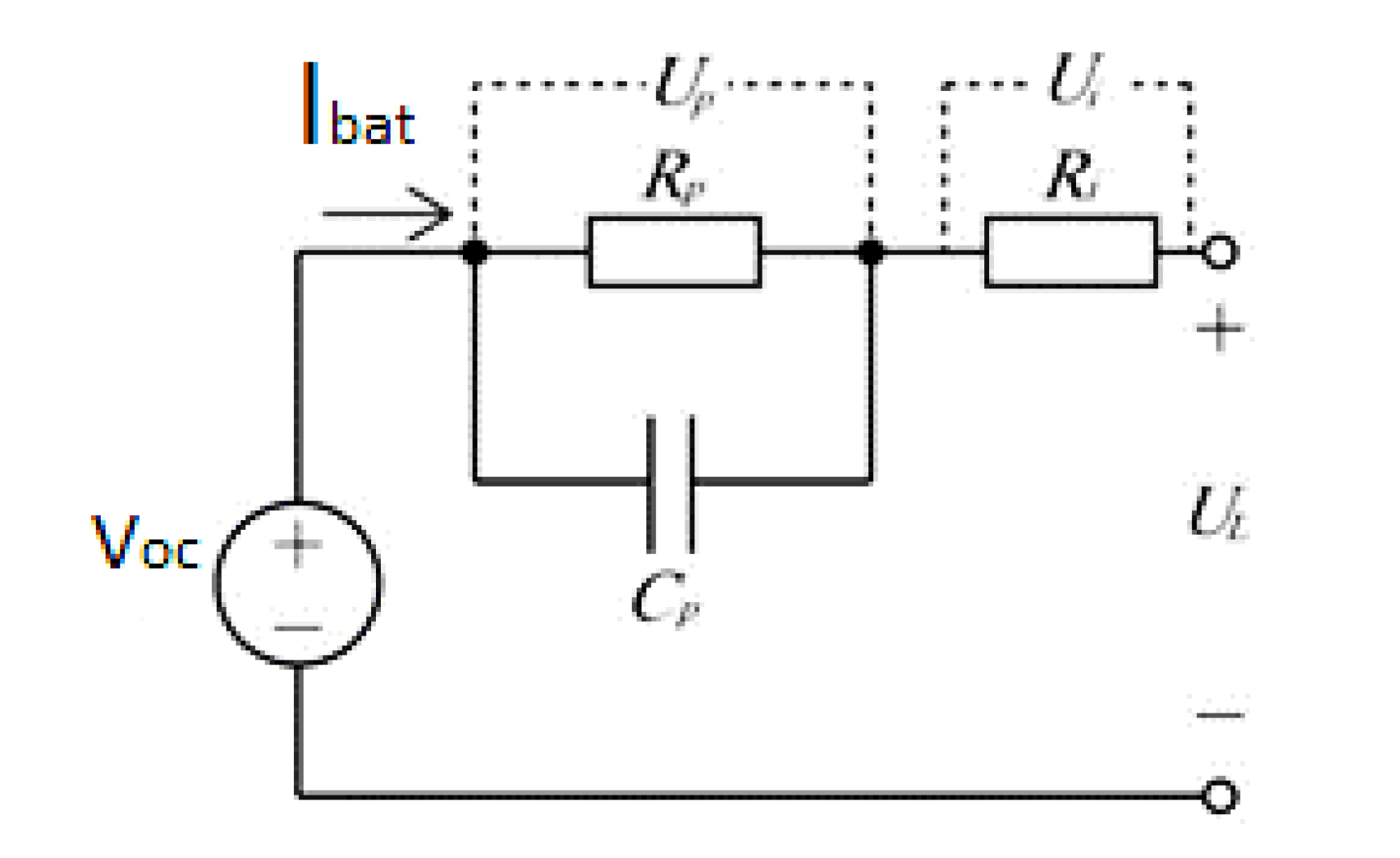

2.1.5. Battery Model

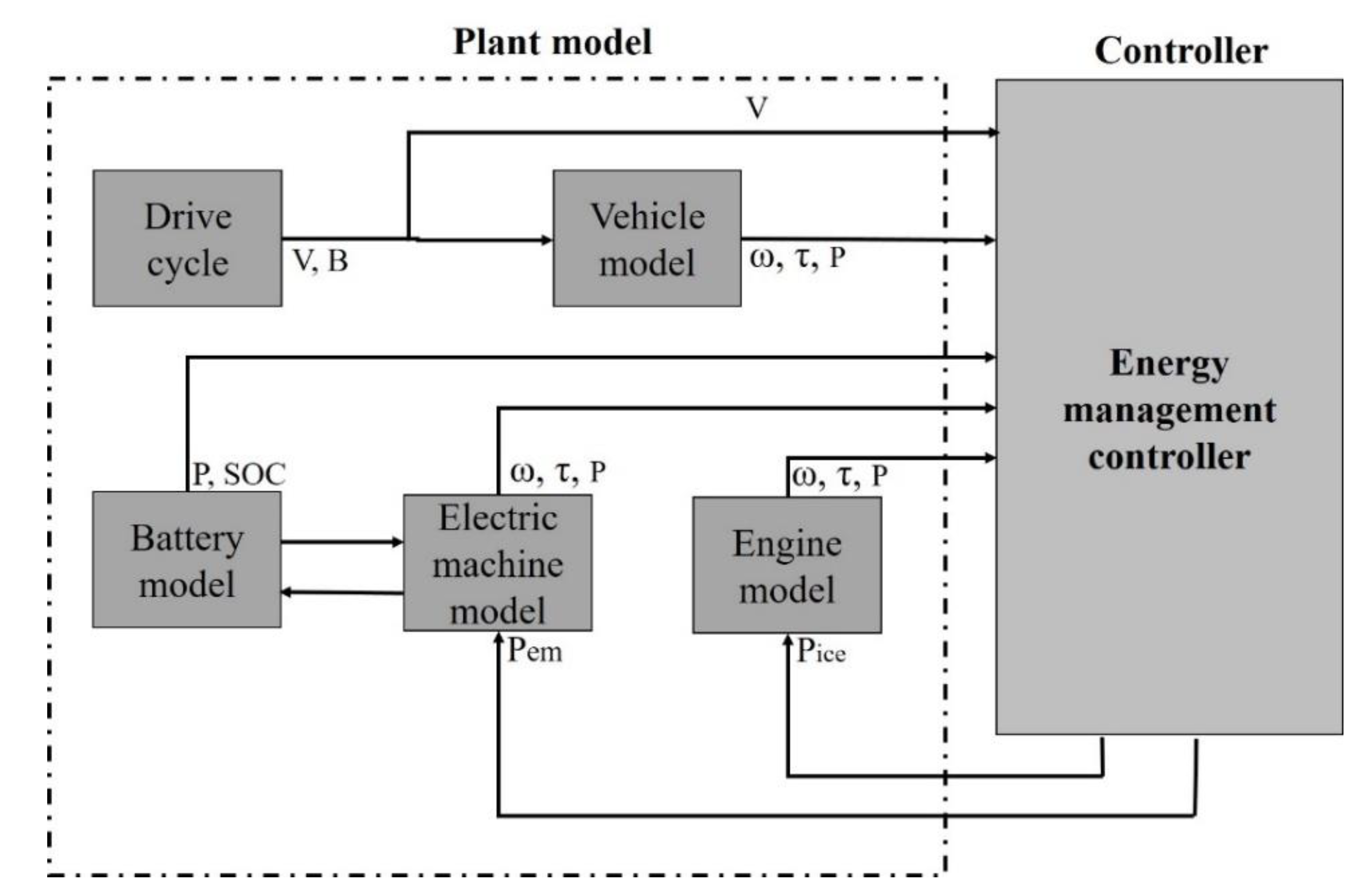

3. HEV Energy Management Control Formulation

4. Energy Management Strategy Development

4.1. Energy Management Overview

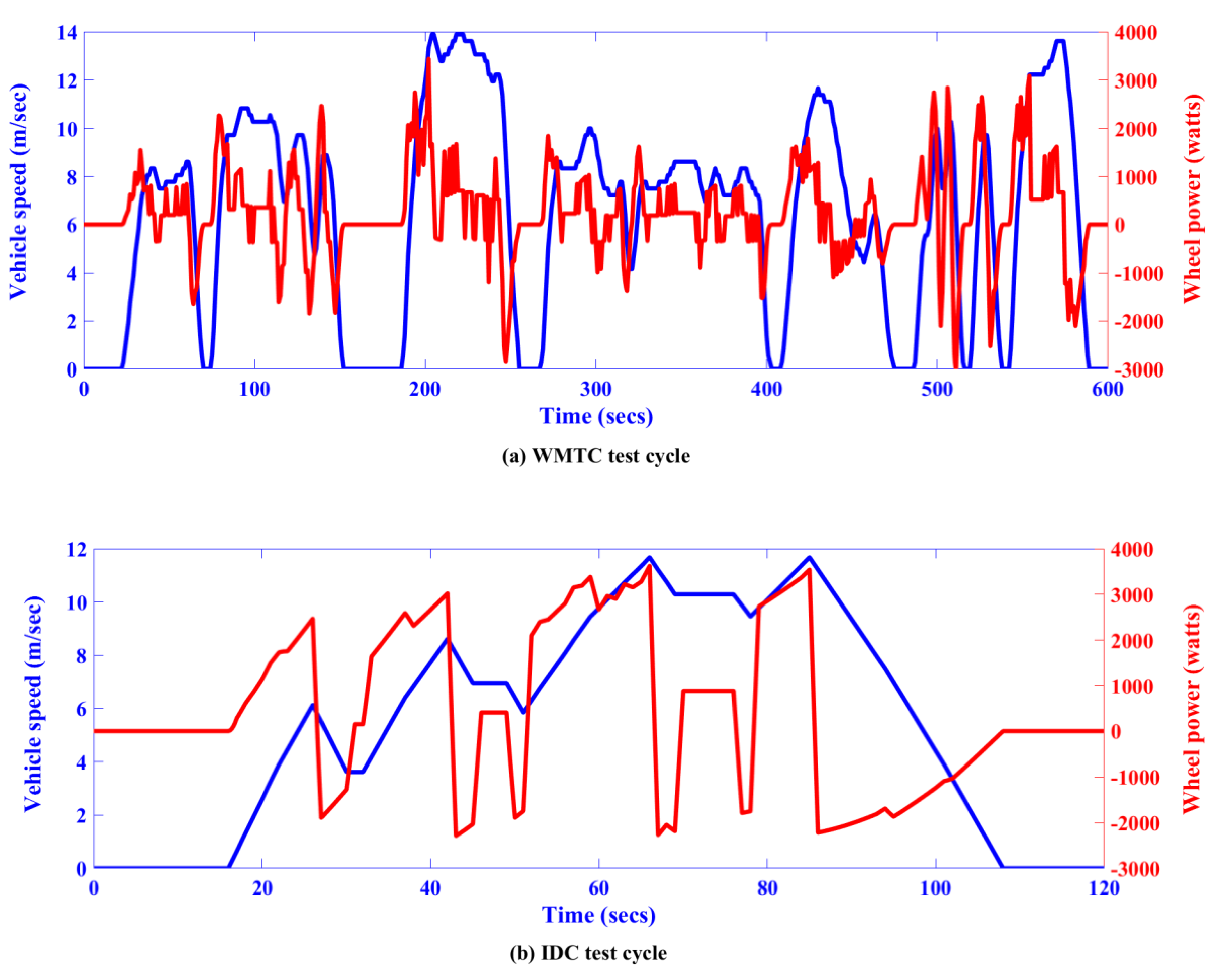

4.2. Drive Cycles

4.3. Engine Switching Event

4.4. Energy Management Objectives

- (1)

- Charge sustainability: the battery SOC should remain at the defined SOC target reference at the end of the trip.

- (2)

- The satisfaction of driver demand: at each instant, the total torque output of the powertrain should be equal to the driver’s demand.

- (3)

- Actuator limitations: at each instant, the output of each powertrain component (engine and electric machine) is within its maximum torque/power rating; similarly, the total battery power is within acceptable limits in both charge and discharge operation.

4.5. Basic Rule-Based Energy Management Strategy (BEMS)

4.6. Modified Rule-Based Energy Management Strategy (MEMS)

4.7. Optimal Control Solution

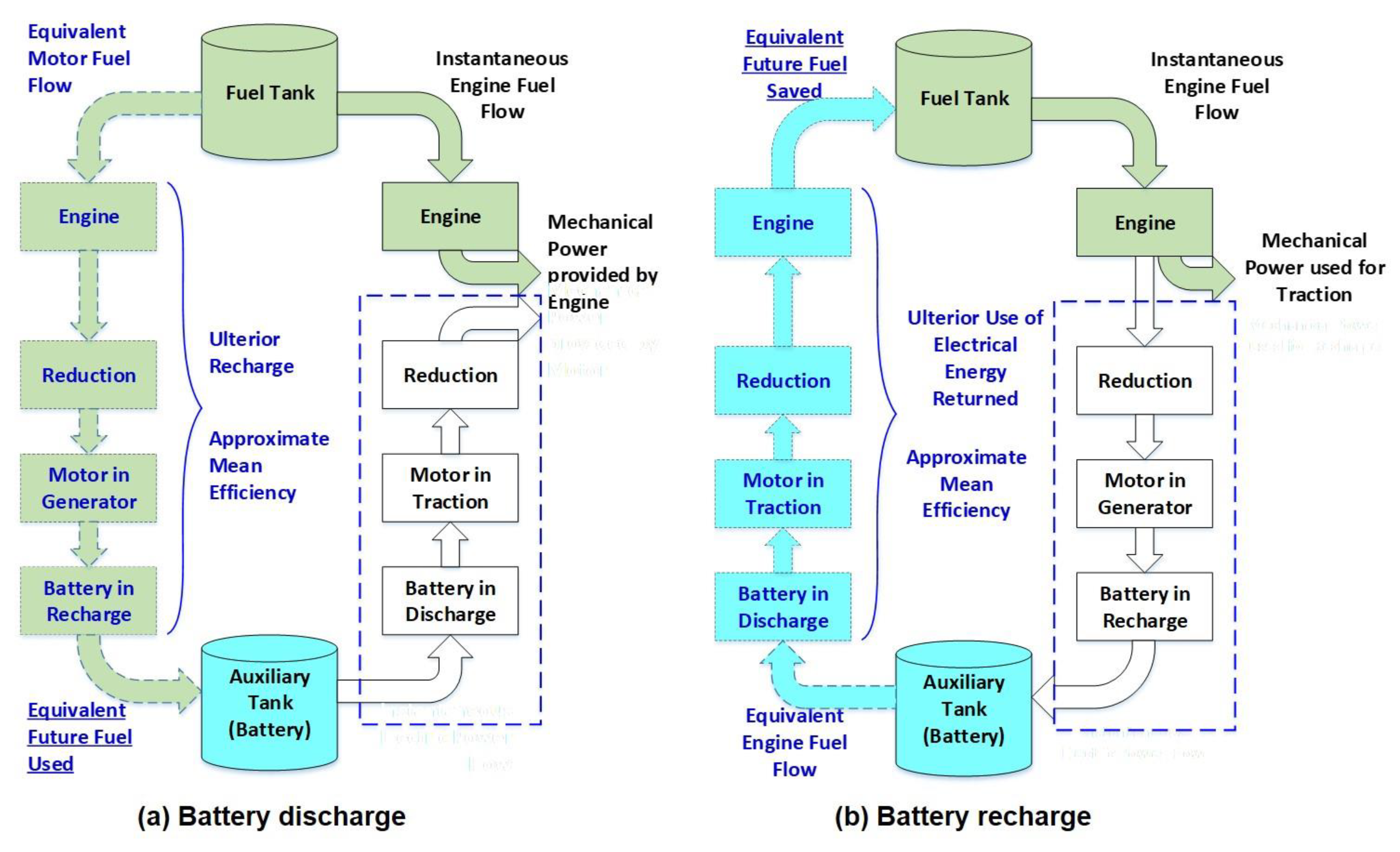

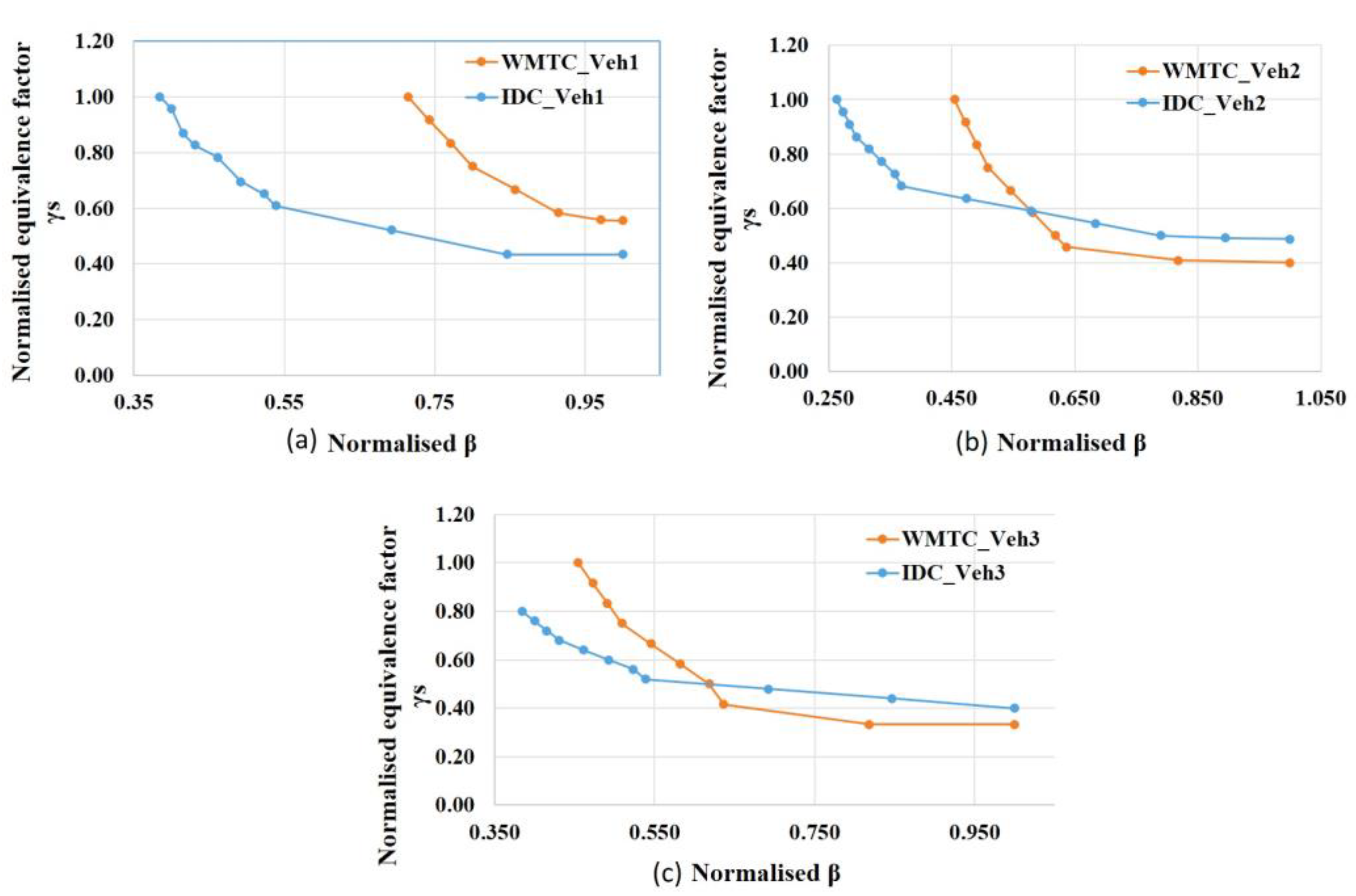

4.7.1. Equivalent Fuel-Consumption Minimization Strategy (ECMS)

4.7.2. Proposed Equivalent Fuel Consumption Minimization Strategy (ECMS_LL)

5. Simulation Results and Discussion

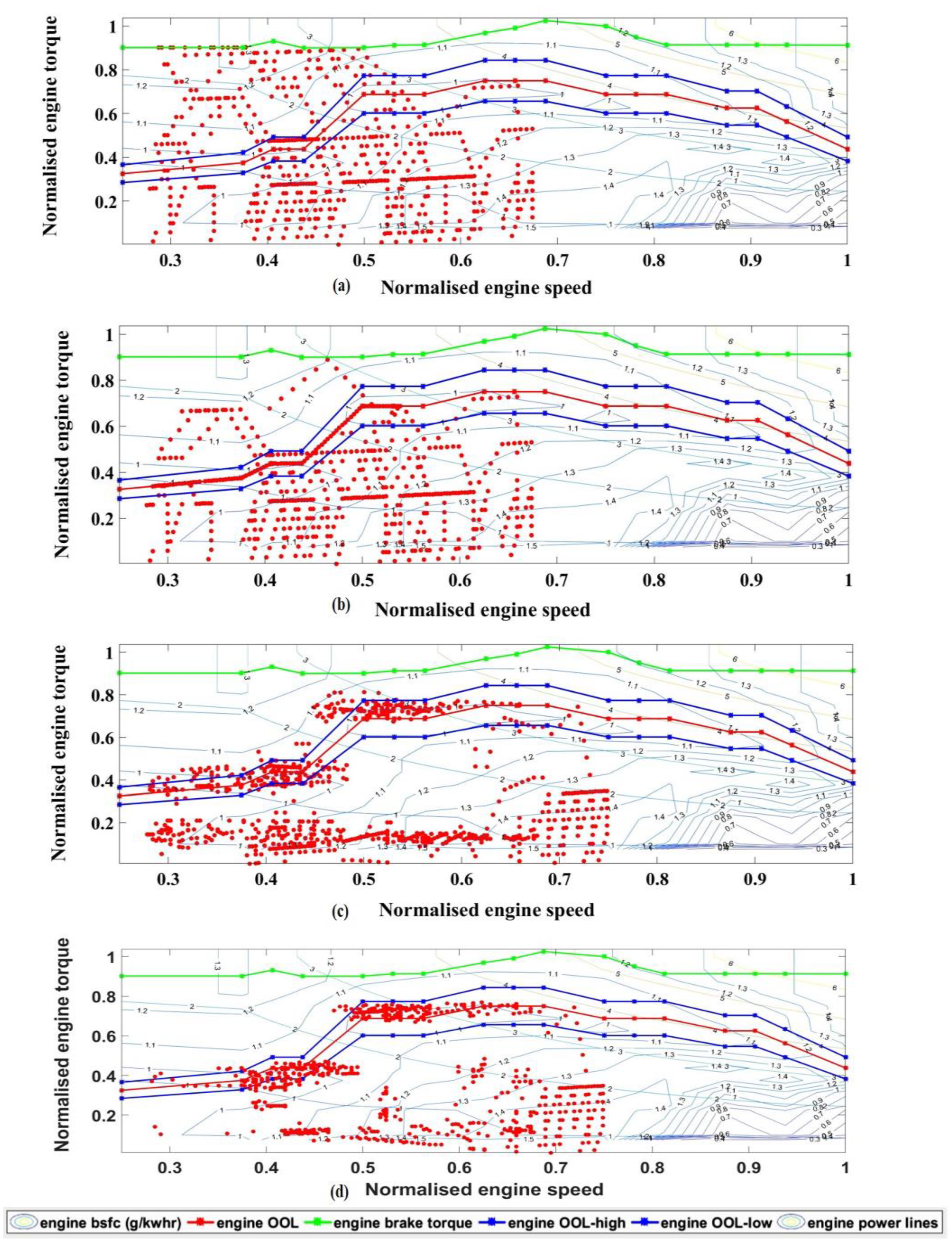

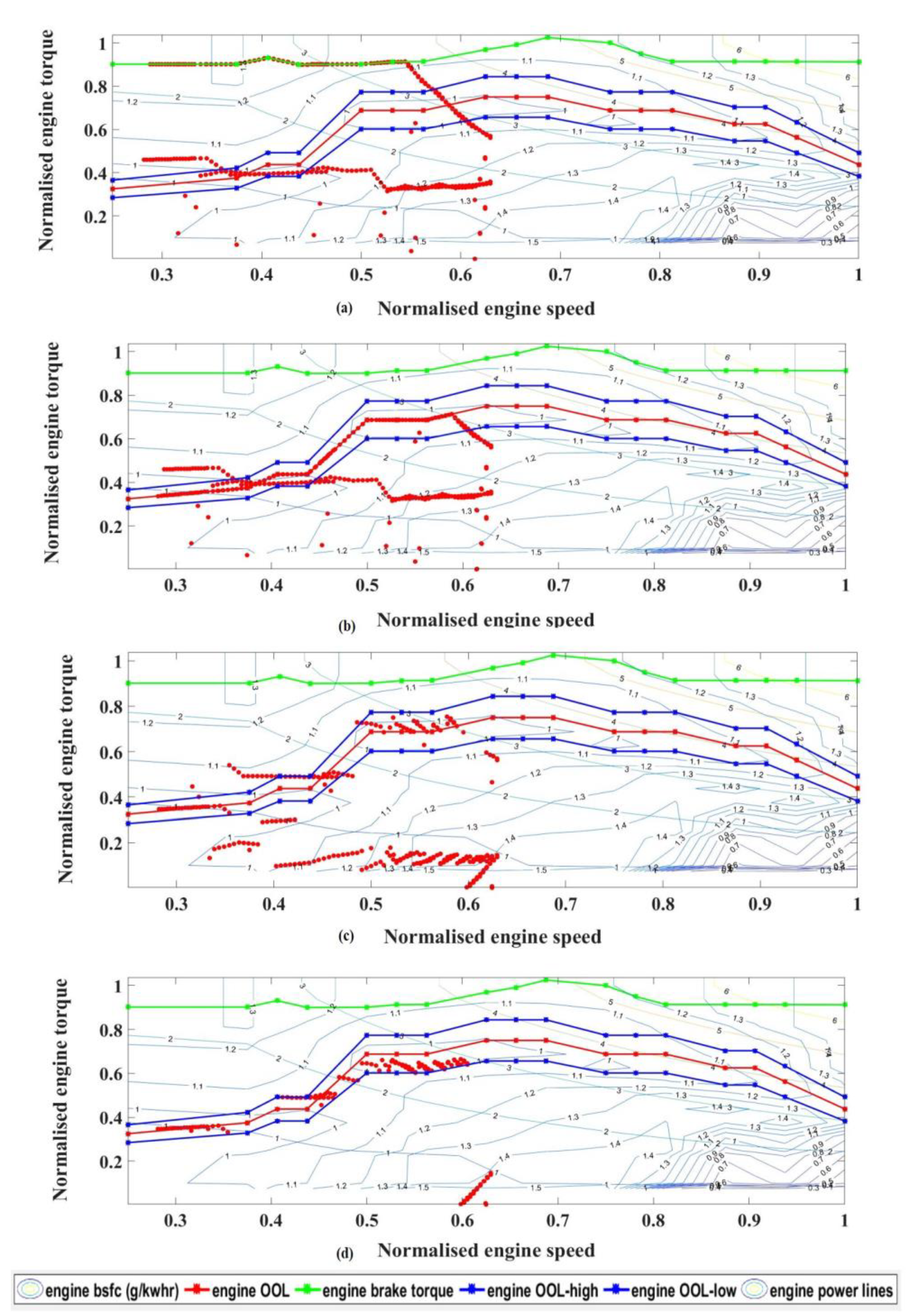

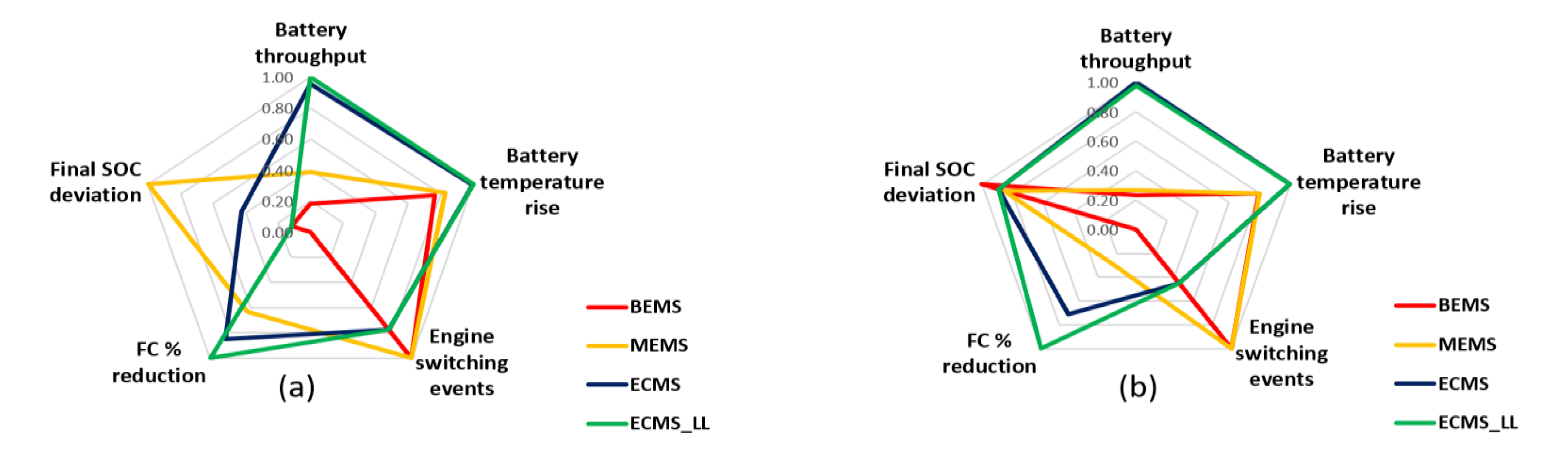

5.1. Engine Operating Points and Fuel Economy

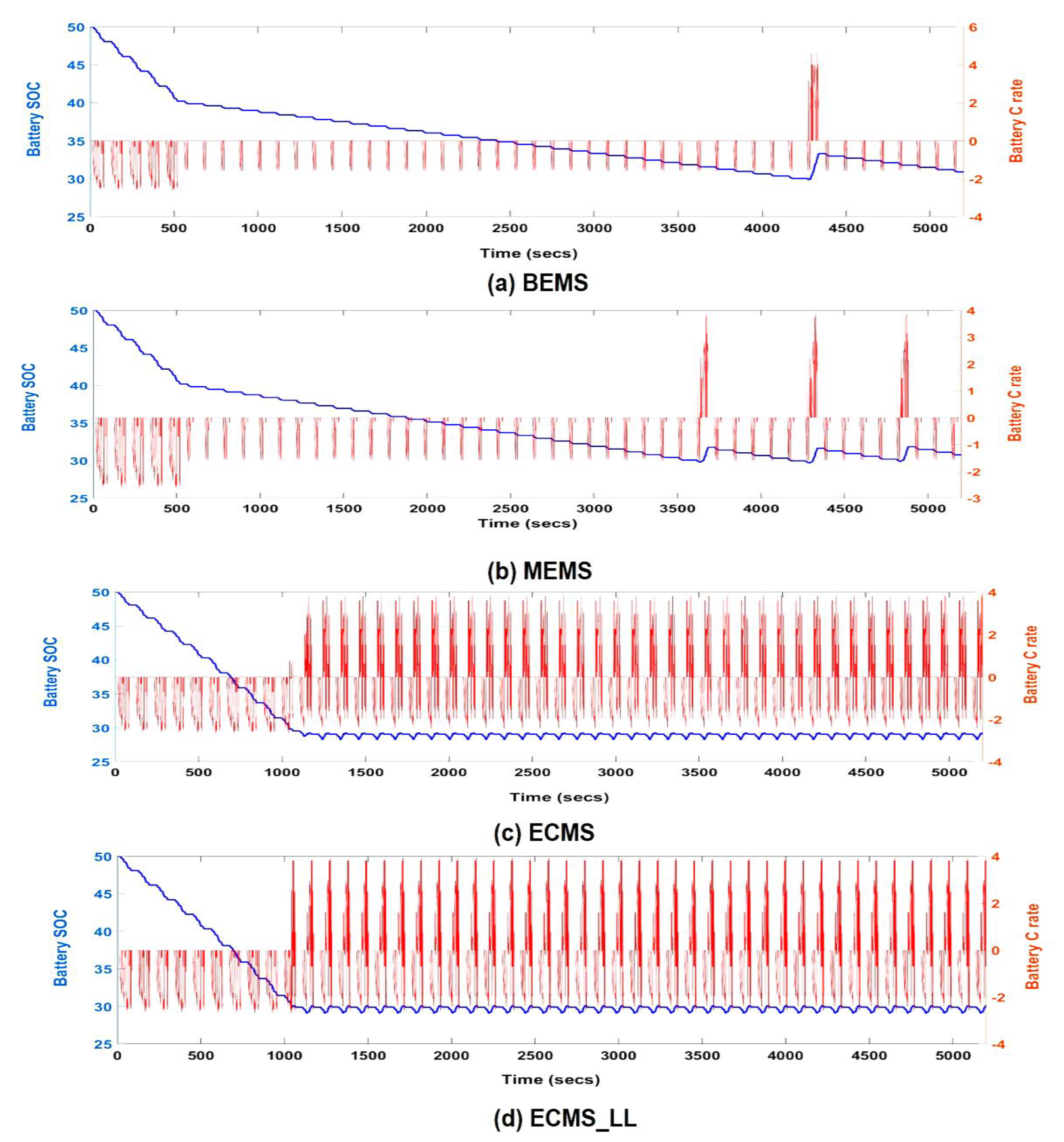

5.2. Charge Sustainability

5.3. Engine Switching Events

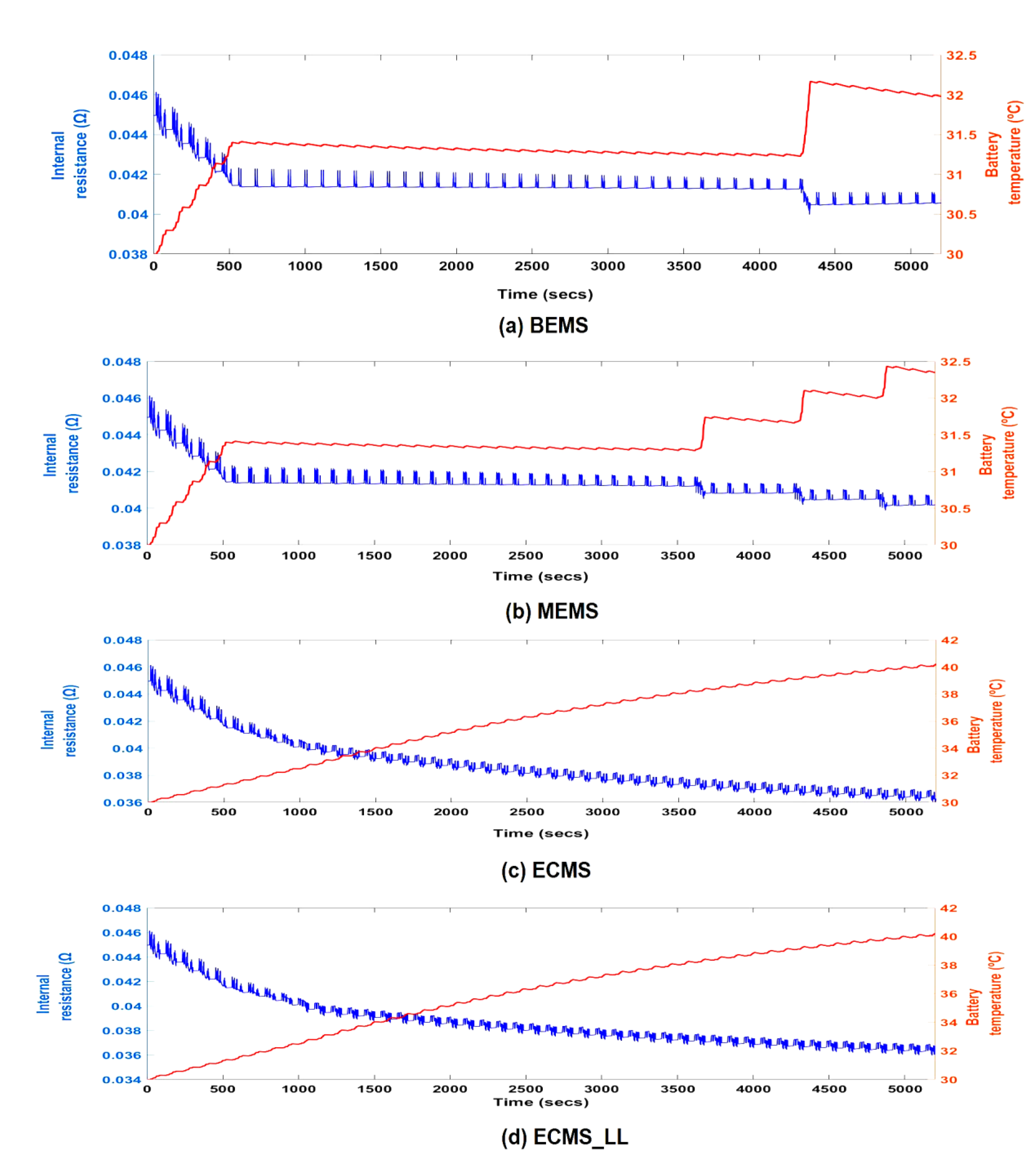

5.4. Battery Temperature

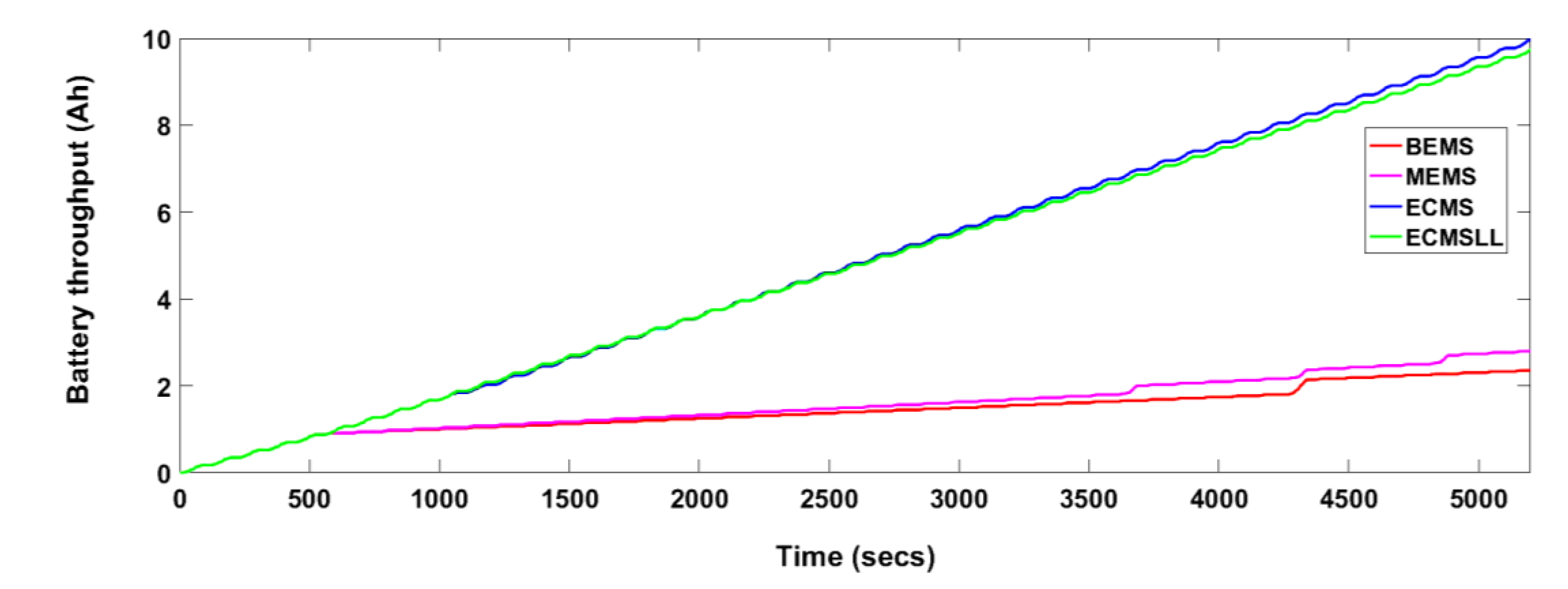

5.5. Battery Throughput

5.6. Battery Charge and Dis-Charge C Rates

5.7. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Chan, C.C. The State of the Art of Electric and Hybrid Vehicles; IEEE: Piscataway, NJ, USA, 2002; Volume 90, pp. 247–275. [Google Scholar]

- Markel, T.; Simpson, A. Cost-benefit analysis of plug-in hybrid electric vehicle technology. World Electr. Veh. J. 2007, 1, 294–301. [Google Scholar] [CrossRef] [Green Version]

- Wirasingha, S.G.; Emadi, A. Classification and review of control strategies for plug-in hybrid electric vehicles. Trans. Veh. Technol. 2010, 60, 111–122. [Google Scholar] [CrossRef]

- Salmasi, F.R. Control strategies for hybrid electric vehicles: Evolution, classification, comparison, and future trends. Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Zeng, Y.; Cai, Y.; Kou, G.; Gao, W.; Qin, D. Energy management for plug-in hybrid electric vehicle based on adaptive simplified-ECMS. Sustainability 2018, 10, 2060. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.J.; Yin, C.L.; Zhang, J.W. Design of an energy management strategy for parallel hybrid electric vehicles using a logic threshold and instantaneous optimization method. Int. J. Automot. Technol. 2009, 10, 513–521. [Google Scholar] [CrossRef]

- Škugor, B.; Deur, J.; Cipek, M.; Pavković, D. Design of a power-split hybrid electric vehicle control system utilizing a rule-based controller and an equivalent consumption minimization strategy. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2014, 228, 631–648. [Google Scholar]

- Chen, B.C.; Wu, Y.Y.; Wu, Y.L.; Lin, C.C. Adaptive power split control for a hybrid electric two-wheeler. IEEE Trans. Veh. Technol. 2011, 60, 1430–1437. [Google Scholar] [CrossRef]

- Tang, L.; Rizzoni, G.; Onori, S. Energy management strategy for HEVs including battery life optimization. Trans. Transp. Electrif. 2015, 1, 211–222. [Google Scholar] [CrossRef]

- Sun, C.; He, H.; Sun, F. The role of velocity forecasting in adaptive-ECMS for hybrid electric vehicles. Energy Procedia 2015, 75, 1907–1912. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Kum, D.; Park, Y. Synthesis of predictive equivalent consumption minimization strategy for hybrid electric vehicles based on closed-form solution of optimal equivalence factor. Trans. Veh. Technol. 2017, 66, 5604–5616. [Google Scholar] [CrossRef]

- Paganelli, G.; Delprat, S.; Guerra, T.M.; Rimaux, J.; Santin, J.J. Equivalent consumption minimization strategy for parallel hybrid powertrains. In Proceedings of the Vehicular Technology Conference. IEEE 55th Vehicular Technology Conference, Birmingham, AL, USA, 6–9 May 2002; Volume 4, pp. 2076–2081. [Google Scholar]

- Musardo, C.; Rizzoni, G.; Guezennec, Y.; Staccia, B. A-ECMS: An adaptive algorithm for hybrid electric vehicle energy management. Eur. J. Control 2005, 11, 509–524. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Rizzoni, G. ECMS as a realization of Pontryagin’s minimum principle for HEV control. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 3964–3969. [Google Scholar]

- Kim, N.; Cha, S.; Peng, H. Optimal control of hybrid electric vehicles based on Pontryagin’s minimum principle. Trans. Control Syst. Technol. 2010, 19, 1279–1287. [Google Scholar]

- Choi, S.S.; Lim, H.S. Factors that affect cycle-life and possible degradation mechanisms of a Li-ion cell based on LiCoO2. J. Power Sources 2002, 111, 130–136. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Broussely, M.; Biensan, P.; Bonhomme, F.; Blanchard, P.; Herreyre, S.; Nechev, K.; Staniewicz, R.J. Main aging mechanisms in Li ion batteries. J. Power Sources 2005, 146, 90–96. [Google Scholar] [CrossRef]

- Belt, J.R.; Ho, C.D.; Miller, T.J.; Habib, M.A.; Duong, T.Q. The effect of temperature on capacity and power in cycled lithium ion batteries. J. Power Sources 2005, 142, 354–360. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Sciarretta, A.; Guezennec, Y.; Rizzoni, G. Optimal energy management of hybrid electric vehicles including battery aging. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; pp. 2125–2130. [Google Scholar]

- Kum, D.; Peng, H.; Bucknor, N.K. Control of engine-starts for optimal drivability of parallel hybrid electric vehicles. J. Dyn. Syst. Meas. Control 2013, 2, 135. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Lee, H. Mode transition control using disturbance compensation for a parallel hybrid electric vehicle. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2011, 225, 150–166. [Google Scholar] [CrossRef]

- Babu, D.S.; Raj, S.S.; Malsoor, B. Stability Enhancement of A Powered Two Wheeler Vehicle Under Curve Negotiation. Int. Refereed. J. Eng. Sci. 2016, 5, 62–71. [Google Scholar]

- Delavaux, M.; Lhomme, W.; McGordon, A. Comparison between forward and backward approaches for the simulation of an electric vehicle. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC2010), Lille, France, 3–5 September 2010. [Google Scholar]

- Dixon, G.; Stobart, R.; Steffen, T. Unified Backwards Facing and Forwards Facing Simulation of a Hybrid Electric Vehicle using MATLAB Simscape. SAE Tech. Paper 2015. [Google Scholar] [CrossRef] [Green Version]

- Paganelli, G.; Guerra, T.M.; Delprat, S.; Santin, J.J.; Delhom, M.; Combes, E. Simulation and assessment of power control strategies for a parallel hybrid car. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2000, 214, 705–717. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.A. Experimental validation of a battery dynamic model for EV applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Tremblay, O.; Dessaint, L.A.; Dekkiche, A.I. A generic battery model for the dynamic simulation of hybrid electric vehicles. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 284–289. [Google Scholar]

- Hussein, A.A.H.; Batarseh, I. An overview of generic battery models. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, At Detroit, Michigan, USA, 24–29 July 2011; pp. 1–6. [Google Scholar]

- Wang, D.; Bao, Y.; Shi, J. Online lithium-ion battery internal resistance measurement application in state-of-charge estimation using the extended Kalman filter. Energies 2017, 10, 1284. [Google Scholar] [CrossRef] [Green Version]

- Vignesh, B.R.; Grandjean, T.; McGordon, A.; Greenwood, D. Thermal modeling of lithium ion batteries for temperature rise predictions in hybrid vehicle application. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monacco, 10–12 April 2018; pp. 1–7. [Google Scholar]

- Onori, S.; Serrao, L.; Rizzoni, G. Adaptive equivalent consumption minimization strategy for hybrid electric vehicles. In Proceedings of the ASME 2010 dynamic systems and control conference, Cambridge, MA, USA, 13–15 September 2010; pp. 499–505. [Google Scholar]

- Vignesh, B.R. Parametric Modelling, Simulation and Validation of Lithium Ion Batteries for Temperature Rise Prediction in Hybrid Two-Wheelers. Ph.D. Thesis, University of Warwick, Coventry, UK, 2016. [Google Scholar]

- Srinivasan, R.; Baisden, A.C.; Carkhuff, B.G.; Butler, M.H. The five modes of heat generation in a Li-ion cell under discharge. J. Power Sources 2014, 262, 93–103. [Google Scholar] [CrossRef]

- Onori, S.; Serrao, L. On Adaptive-ECMS strategies for hybrid electric vehicles. In Proceedings of the International Scientific Conference on Hybrid and Electric Vehicles, RHEVE 2011, Malmaison, France, 6–7 December 2011; Volume 67. [Google Scholar]

- Urdhwaresh, R. Limits, Regulations, Measurement of Exhaust Emissions and Calculation of Fuel Consumption. In Indian Emissions Regulations; Automotive Research Association of India: Pune, India, 2017. [Google Scholar]

- Windover, P.R.; Owens, R.J.; Levinson, T.M.; Laughlin, M.; Gaines, L. Stop and Restart Effects on Modern Vehicle Starting System Components; Argonne National Lab. (ANL): Argonne, IL, USA, 2015. [Google Scholar]

- Sciarretta, A.; Guzzella, L. Control of hybrid electric vehicles. Ieee Control Syst. Mag. 2007, 27, 60–70. [Google Scholar]

- Paganelli, G.; Ercole, G.; Brahma, A.; Guezennec, Y.; Rizzoni, G. General supervisory control policy for the energy optimization of charge-sustaining hybrid electric vehicles. JSAE Rev. 2010, 22, 511–518. [Google Scholar] [CrossRef]

- Warner, J.T. The Handbook of Lithium-ion Battery Pack Design: Chemistry, Components, Types and Terminology; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Leng, F.; Tan, C.M.; Pecht, M. Effect of temperature on the aging rate of Li ion battery operating above room temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef] [Green Version]

| Vehicle Configuration | Engine Sizing | Battery Charge C Rate |

|---|---|---|

| Veh 1 | 80% | 5 C |

| Veh 2 | 100% | 3 C |

| Veh 3 | 70% | 1 C |

| Mode | State | Battery | Vehicle Conditions | Eng | Mot | Gen | Descriptions |

|---|---|---|---|---|---|---|---|

| Launch mode | Vehicle launch | SOC > SOCLowlimit | V > 0, DT < Mmt | Off | On | Off | Vehicle start condition with motor alone providing the drive torque |

| Vehicle launch | SOC > SOCLowlimit | V > 0, DT > Mmt | On | On | Off | Vehicle start condition with motor and ICE providing the drive torque | |

| Vehicle launch | SOC < SOCLowlimit | V > 0 | On | Off | Off | Vehicle start condition with engine alone providing the drive torque | |

| Pure EV-mode | EV state | SOC > SOCLowlimit | Mmn > V > 0 and DT < Mmt | Off | On | Off | Vehicle run condition with motor providing the drive torque |

| ICE-mode | Charging state | SOC < SOCLowlimit | 0 < V < Mmn, DT < Met | On | Off | On | Drive torque provided by ICE alone and battery charged by engine |

| ICE only state | SOC < SOCLowlimit | V > Mmn or DT > Met | On | Off | Off | Drive torque provided by ICE alone | |

| Combined mode | High power demand | SOC > SOCLowlimit | V < Mmn, DT > Mmt | On | On | Off | Drive torque provided by both motor and ICE |

| Regeneration mode | Braking state | SOC < SOCHighlimit | DT < 0, V > Mgn | Off | Off | Off | No regenerative braking |

| Braking state | SOC < SOCHighlimit | DT < 0, V < Mgn | Off | Off | On | Regenerative braking | |

| Braking state | SOC > SOCHighlimit | DT < 0 | Off | Off | Off | No regenerative braking |

| Controllers | Veh 1 | Veh 2 | Veh 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WMTC | IDC | WMTC | IDC | WMTC | IDC | |||||||

| Abs FC (gms) | FC Red (%) | Abs FC (gms) | FC Red (%) | Abs FC (gms) | FC Red (%) | Abs FC (gms) | FC Red (%) | Abs FC (gms) | FC Red (%) | Abs FC (gms) | FC Red (%) | |

| BEMS | 146.7 | 0.0 | 142.8 | 0.0 | 148.1 | 0.0 | 148.0 | 0.0 | 145.7 | 0.0 | 141.1 | 0.0 |

| MEMS | 138.1 | 5.9 | 139.1 | 2.6 | 146.3 | 1.3 | 145.3 | 1.8 | 144.1 | 1.1 | 138.1 | 2.1 |

| ECMS | 137.1 | 6.5 | 129.3 | 9.4 | 144.0 | 2.8 | 139.0 | 6.0 | 143.2 | 1.7 | 133.0 | 5.7 |

| ECMS_LL | 130.0 | 11.4 | 112.6 | 21.2 | 136.5 | 7.9 | 121.8 | 17.7 | 140.0 | 3.9 | 128.2 | 9.1 |

| Controllers | Veh 1 | Veh 2 | Veh 3 | |||

|---|---|---|---|---|---|---|

| WMTC | IDC | WMTC | IDC | WMTC | IDC | |

| BEMS | 0.30 | 0.31 | 0.31 | 0.31 | 0.31 | 0.32 |

| MEMS | 0.33 | 0.31 | 0.32 | 0.31 | 0.31 | 0.31 |

| ECMS | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| ECMS_LL | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Controllers | Veh 1 | Veh 2 | Veh 3 | |||

|---|---|---|---|---|---|---|

| WMTC | IDC | WMTC | IDC | WMTC | IDC | |

| BEMS | 89 | 96 | 89 | 96 | 89 | 96 |

| MEMS | 89 | 96 | 89 | 96 | 89 | 96 |

| ECMS | 69 | 43 | 69 | 43 | 69 | 43 |

| ECMS_LL | 69 | 43 | 69 | 43 | 69 | 43 |

| Controllers | Absolute Battery Temperature (°C) | Battery Temperature Rise (°C) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Veh 1 | Veh 2 | Veh 3 | Veh 1 | Veh 2 | Veh 3 | |||||||

| W | I | W | I | W | I | W | I | W | I | W | I | |

| BEMS | 31.4 | 32.0 | 31.4 | 31.9 | 31.7 | 31.8 | 1.4 | 2.0 | 1.4 | 1.9 | 1.7 | 1.8 |

| MEMS | 33.9 | 32.3 | 33.2 | 32.1 | 33.3 | 32.3 | 3.9 | 2.3 | 3.2 | 2.1 | 3.3 | 2.3 |

| ECMS | 41.7 | 41.2 | 41.0 | 41.4 | 39.3 | 38.4 | 11.7 | 11.2 | 11.0 | 11.4 | 9.3 | 8.4 |

| ECMS_LL | 43.8 | 41.9 | 44.3 | 42.0 | 42.7 | 38.4 | 13.8 | 11.9 | 14.3 | 12.0 | 12.7 | 8.4 |

| Controllers | Battery throughput in Ah | Battery throughput Rise in % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Veh 1 | Veh 2 | Veh 3 | Veh 1 | Veh 2 | Veh 3 | |||||||

| W | I | W | I | W | I | W | I | W | I | W | I | |

| BEMS | 1.8 | 2.3 | 1.7 | 2.3 | 2.0 | 2.4 | 0 | 0 | 0 | 0 | 0 | 0 |

| MEMS | 3.7 | 2.7 | 3.0 | 2.5 | 3.7 | 3.1 | 52 | 13 | 74 | 6 | 84 | 29 |

| ECMS | 9.5 | 10.5 | 9.4 | 10.7 | 9.0 | 9.5 | 437 | 350 | 446 | 357 | 349 | 290 |

| ECMS_LL | 10.9 | 11.2 | 11.5 | 11.2 | 11.0 | 9.5 | 516 | 378 | 566 | 381 | 451 | 291 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kommuri, N.K.; McGordon, A.; Allen, A.; Quang Truong, D. Evaluation of a Modified Equivalent Fuel-Consumption Minimization Strategy Considering Engine Start Frequency and Battery Parameters for a Plugin Hybrid Two-Wheeler. Energies 2020, 13, 3122. https://doi.org/10.3390/en13123122

Kommuri NK, McGordon A, Allen A, Quang Truong D. Evaluation of a Modified Equivalent Fuel-Consumption Minimization Strategy Considering Engine Start Frequency and Battery Parameters for a Plugin Hybrid Two-Wheeler. Energies. 2020; 13(12):3122. https://doi.org/10.3390/en13123122

Chicago/Turabian StyleKommuri, Naga Kavitha, Andrew McGordon, Antony Allen, and Dinh Quang Truong. 2020. "Evaluation of a Modified Equivalent Fuel-Consumption Minimization Strategy Considering Engine Start Frequency and Battery Parameters for a Plugin Hybrid Two-Wheeler" Energies 13, no. 12: 3122. https://doi.org/10.3390/en13123122