Enhanced Thermoelectric Characteristics of Ag2Se Nanoparticle Thin Films by Embedding Silicon Nanowires

Abstract

:1. Introduction

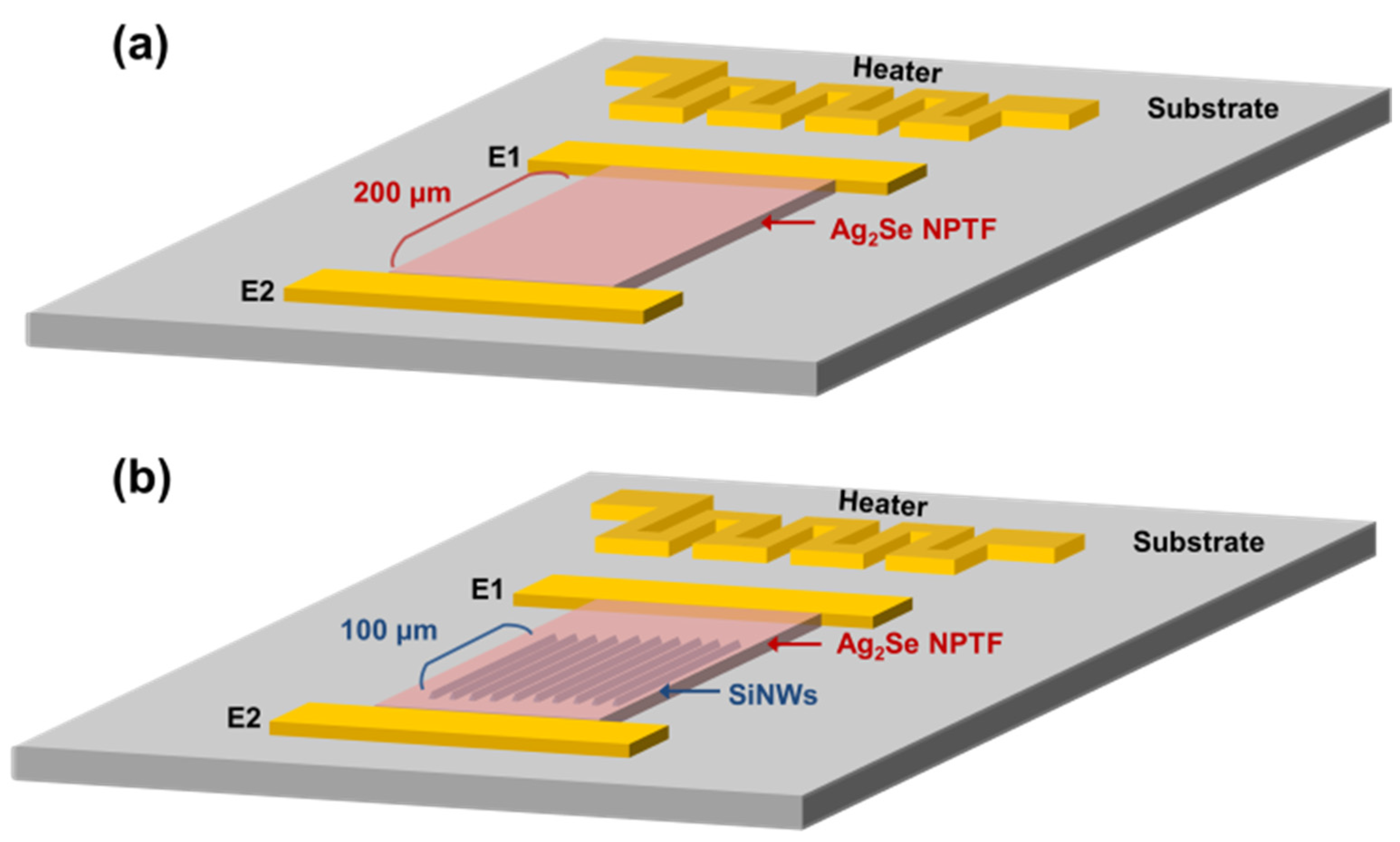

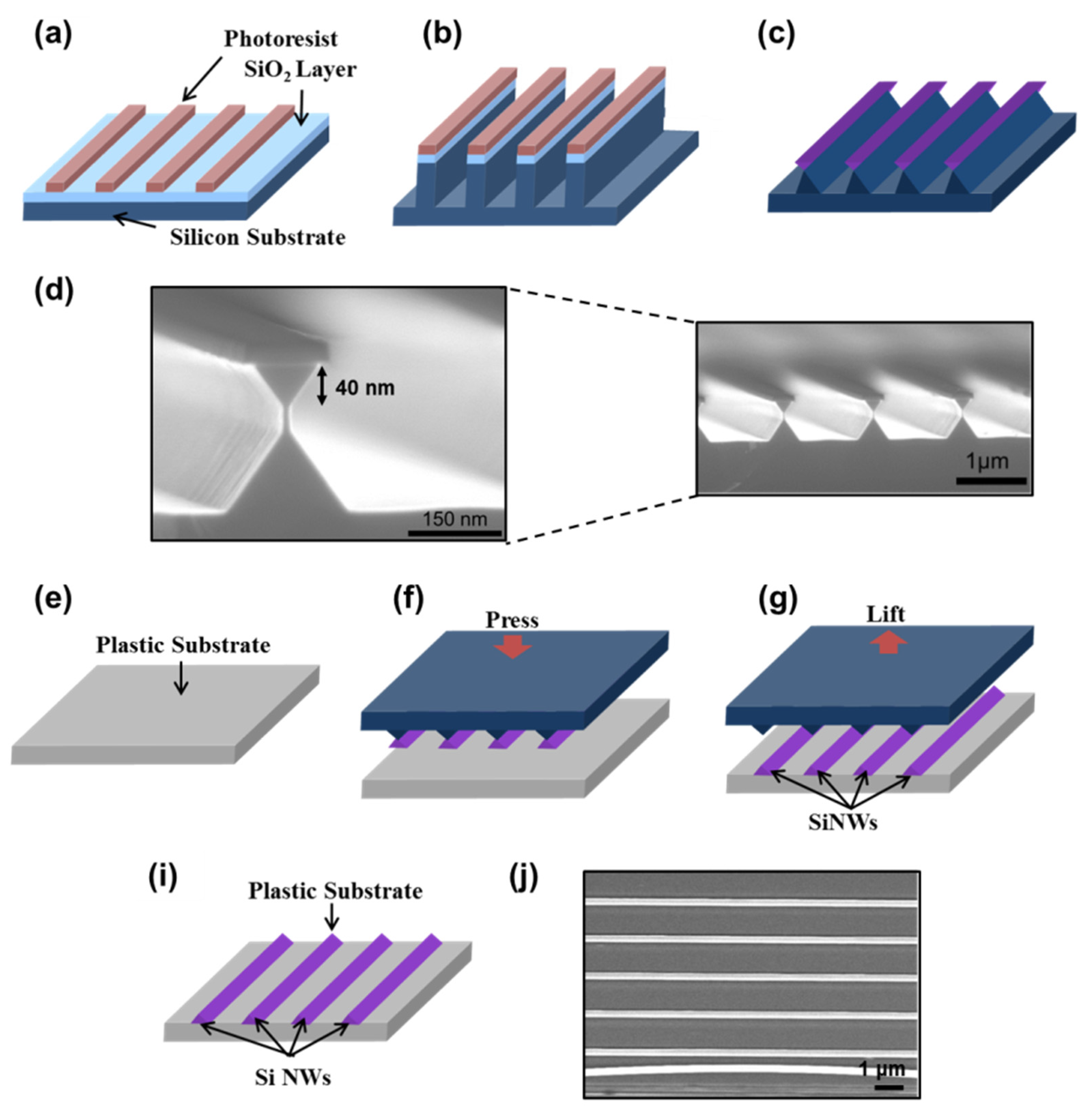

2. Materials and Methods

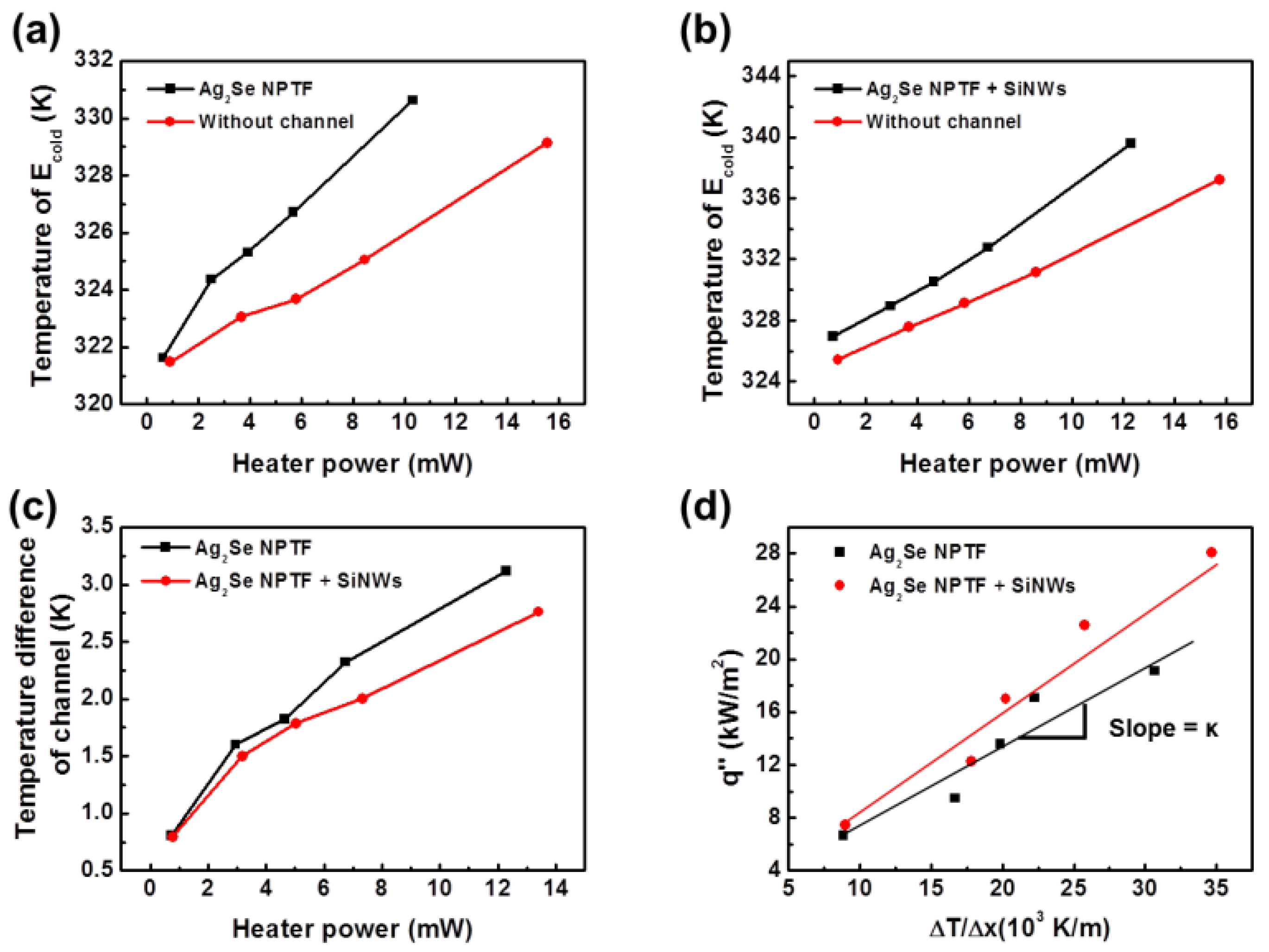

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Ai, X.; Wang, L.; Chang, Y.; Luo, W.; Jiang, W.; Chen, L. Improved thermoelectric performance of silver nanoparticles-dispersed Bi2Te3 composites deriving from hierarchical two-phased heterostructure. Adv. Funct. Mater. 2015, 25, 966–976. [Google Scholar] [CrossRef]

- Alam, H.; Ramakrishna, S. A review on the enhancement of figure of merit from bulk to nano-thermoelectric materials. Nano Energy 2013, 2, 190–212. [Google Scholar] [CrossRef]

- Yun, Y.; Cho, K.; Park, Y.; Yang, S.; Choi, J.; Kim, S. Thermoelectric characteristics of nanocomposites made of HgSe and Ag nanoparticles for flexible thermoelectric devices. Nano Res. 2017, 10, 683–689. [Google Scholar] [CrossRef]

- Choi, J.; Cho, K.; Yun, J.; Park, Y.; Yang, S.; Kim, S. Large voltage generation of flexible thermoelectric nanocrystal thin films by finger contact. Adv. Energy Mater. 2017, 7, 1700972. [Google Scholar] [CrossRef]

- Chen, Y.N.; Zhao, Y.; Liang, Z.Q. Solution processed organic thermoelectrics: Towards flexible thermoelectric modules. Energy Environ. Sci. 2015, 8, 401–422. [Google Scholar] [CrossRef]

- Suarez, F.; Nozariasbmarz, A.; Vashaee, D.; Ozturk, M.C. Designing thermoelectric generators for self-powered wearable electronics. Energy Environ. Sci. 2016, 9, 2099–2113. [Google Scholar] [CrossRef]

- Bahk, J.H.; Fang, H.Y.; Yazawa, K.; Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 2015, 3, 10362. [Google Scholar] [CrossRef]

- Wang, H.; Chu, W.; Wang, D.; Mao, W.; Pan, W.; Guo, Y.; Xiong, Y.; Jin, H. Low-Temperature Thermoelectric Properties of β-Ag2Se Synthesized by Hydrothermal Reaction. J. Electron. Mater. 2010, 40, 624–628. [Google Scholar] [CrossRef]

- Xiao, C.; Xu, J.; Li, K.; Feng, J.; Yang, J.; Xie, Y. Superionic phase transition in silver chalcogenide nanocrystals realizing optimized thermoelectric performance. J. Am. Chem. Soc. 2012, 134, 4287–4393. [Google Scholar] [CrossRef]

- Tsubota, T.; Ohtaki, M.; Eguchi, K.; Arai, H. Thermoelectric properties of Al-doped ZnO as a promising oxide material for high-temperature thermoelectric conversion. J. Mater. Chem. 1997, 7, 85–90. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.F.; Nan, C.W.; Zhou, M.; Liu, W.; Zhang, B.P.; Kit, T. High-performance Ag0.8Pb18+xSbTe20 thermoelectric bulk materials fabricated by mechanical alloying and spark plasma sintering. Appl. Phys. Lett. 2006, 88, 092104. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Jeon, Y.; Cho, K.; Kim, S. Field-effect modulation of the thermoelectric characteristics of silicon nanowires on plastic substrates. Nanotechnology 2016, 109, 485401. [Google Scholar] [CrossRef]

- Curtin, B.M.; Fang, E.W.; Bowers, J.E. Highly ordered vertical silicon nanowire array composite thin films for thermoelectric devices. J. Electron. Mater. 2012, 41, 887–894. [Google Scholar] [CrossRef]

- Hochbum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced thermoelectric performance of rough silicon nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.K.; Goddard III, W.A.; Heath, J.R. Silicon nanowires as efficient thermoelectric materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef]

- Zeng, X.; Yan, C.; Ren, L.; Zhang, T.; Zhou, F.; Liang, X.; Wang, N.; Sun, R.; Xu, J.B.; Wong, C.P. Silver Telluride Nanowire Assembly for High-Performance Flexible Thermoelectric Film and Its Application in Self-Powered Temperature Sensor. Adv. Electron. Mater. 2019, 5, 1800612. [Google Scholar] [CrossRef]

- Zhou, C.; Dun, C.; Wang, K.; Zhang, X.; Shi, Z.; Liu, G.; Hewitt, C.A.; Qiao, G.; Carroll, D.L. General method of synthesis ultrathin ternary metal chalcogenide nanowires for potential thermoelectric applications. Nano Energy 2016, 30, 709–716. [Google Scholar] [CrossRef]

- Xu, E.; Li, Z.; Acosta, J.A.; Li, N.; Swartzentruber, B.; Zheng, S.; Sinitsyn, N.; Htoon, H.; Wang, J.; Zhang, S. Enhanced thermoelectric properties of topological crystalline insulator PbSnTe nanowires grown by vapor. Nano Res. 2016, 9, 820–830. [Google Scholar] [CrossRef]

- Choi, J.; Cho, K.; Yoon, D.S.; Kim, S. Thermal conductivity of silicon nanowires embedded on thermoelectric platforms. Meas. Sci. Technol. 2016, 27, 105007. [Google Scholar] [CrossRef]

- Choi, J.; Cho, K.; Kim, S. Flexible thermoelectric generators composed of n-and p-type silicon nanowires fabricated by top-down method. Adv. Energy Mater. 2017, 7, 1602138. [Google Scholar] [CrossRef]

- Yang, S.; Cho, K.; Park, Y.; Kim, S. Bendable thermoelectric generators composed of p-and n-type silver chalcogenide nanoparticle thin films. Nano Energy 2018, 49, 333–337. [Google Scholar] [CrossRef]

- Seong, H.; Cho, K.; Kim, S. Photocurrent characteristics of solution-processed HgTe nanoparticle thin films under the illumination of 1.3 µm wavelength light. Semicond. Sci. Technol. 2008, 23, 075011. [Google Scholar] [CrossRef]

- Jang, W.; Bao, W.; Jing, L.; Lau, C.N.; Dames, C. Thermal conductivity of suspended few-layer graphene by a modified T-bridge method. Appl. Phys. Lett. 2013, 103, 133102. [Google Scholar] [CrossRef]

- Ghasemi, H.; Ni, G.; Marconnet, A.M.; Loomis, J.; Yerci, S.; Miljkovic, N.; Chen, G. Solar steam generation by heat localization. Nat. Commun. 2014, 5, 4449. [Google Scholar] [CrossRef] [Green Version]

- Khuu, V.; Osterman, M.; Bar-Cohen, A.; Pecht, M. Considerations in the use of the laser flash method for thermal measurements of thermal interface materials. IEEE Trans. Compon. Pack. Manuf. Technol. 2011, 1, 1015–1028. [Google Scholar] [CrossRef]

- Amirthan, G.; Udaya kumar, A.; Balasubramanian, M. Thermal conductivity studies on Si/SiC ceramic composites. Ceram. Int. 2011, 37, 423–426. [Google Scholar] [CrossRef]

- Rolan, R.B.; Anaya, J.; Kuball, M. Thermal conductivity of bulk GaN–Effects of oxygen magnesium doping and strain field compensation. Appl. Phys. Lett. 2014, 105, 202105. [Google Scholar]

- Sato, N.; Kuwabara, K.; Ono, K.; Sakata, T.; Morimura, H.; Terada, J.; Kudou, K.; Kamei, T.; Yano, M.; Machida, K.; et al. Monolithic integration fabrication process of thermoelectric and vibrational devices for microelectromechanical system power generator. Jpn. J. Appl. Phys. 2007, 46, 6062. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Cho, K.; Kim, S. Enhanced Thermoelectric Characteristics of Ag2Se Nanoparticle Thin Films by Embedding Silicon Nanowires. Energies 2020, 13, 3072. https://doi.org/10.3390/en13123072

Yang S, Cho K, Kim S. Enhanced Thermoelectric Characteristics of Ag2Se Nanoparticle Thin Films by Embedding Silicon Nanowires. Energies. 2020; 13(12):3072. https://doi.org/10.3390/en13123072

Chicago/Turabian StyleYang, Seunggen, Kyoungah Cho, and Sangsig Kim. 2020. "Enhanced Thermoelectric Characteristics of Ag2Se Nanoparticle Thin Films by Embedding Silicon Nanowires" Energies 13, no. 12: 3072. https://doi.org/10.3390/en13123072

APA StyleYang, S., Cho, K., & Kim, S. (2020). Enhanced Thermoelectric Characteristics of Ag2Se Nanoparticle Thin Films by Embedding Silicon Nanowires. Energies, 13(12), 3072. https://doi.org/10.3390/en13123072