A Comprehensive Review of Strategies and Approaches for Enhancing the Performance of Thermoelectric Module

Abstract

:1. Introduction

2. Basic Principle of Thermoelectrics

3. Development of High-Efficiency Thermoelectric Modules

3.1. Thermoelectric Material

3.1.1. Doping/Alloying

3.1.2. Superlattices

3.1.3. Nanostructures

3.2. Structure/Geometry

3.3. Summary

4. Optimization of Thermal Management System of Thermoelectric Modules

4.1. Finned Heat Sink

4.2. Fluid–Air

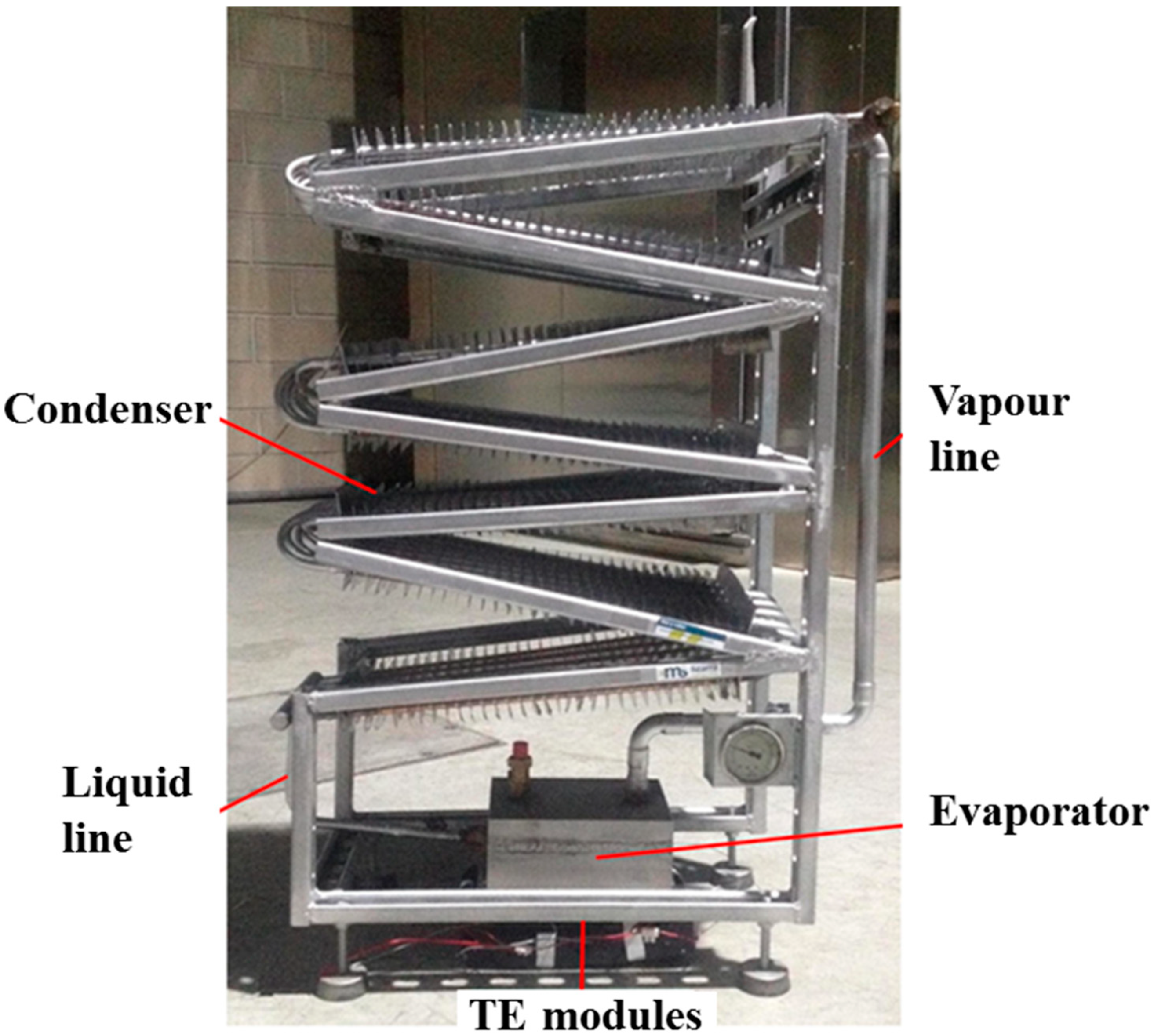

4.3. Heat Exchangers with Phase Change

4.4. Summary

5. Extrinsic Factors: Contact Resistance

6. Conclusions and Further Research Direction

- (1)

- The performance of thermoelectric devices is determined by two main factors: the thermoelectric material performance and the thermal structure, which corresponds to Z and temperature T. Thus, there are two corresponding ways to achieve high-performance thermoelectrics: one is for materials, and another is thermal design and optimization.

- (2)

- Although a high ZT has been obtained in some low dimensional thermoelectric materials such as superlattices, nanostructures, quantum dots, nanowires, and carbon nanotubes, the highest ZT of thermoelectric materials ever found at ambient temperature is 2.4 or even higher in the lab. However, many of them are not viable for large-scale commercial use at present due to their expensive materials and complex processes. Hence, developing the novel thermoelectric module shapes to order or a flexible thermoelectric module is a good way to address this issue. The polymer-based materials and screen-printed technology whose ZT value are generally in the range of 0.1–0.4 are flexible. It is noteworthy that the shape-engineerable painted materials are geometrically compatible to any shape. Although they do not have such a high ZT value, they are still very promising in TE applications and they also afford a new study direction for them.

- (3)

- Compared to improving materials to enhance the figure of merit Z through complex technical means and expensive instruments, controlling temperature T by the heat sinks or heat exchangers is much easier and has a high performance–price ratio. By optimizing the structure of the heat exchanger or using appropriate heat exchangers, the performance of the TEG will be increased from 20% to 150%, and the TEC will be upgraded from 20% to 600%, compared to the original heat exchanger.

- (4)

- In addition, thermal resistance is also an important factor affecting performance. According to the existing analytical model, when the TE working temperature approached the peak ZT temperature, the corresponding efficiency of different thermoelectric material without contact resistance was ranging from 6.88% to 14.32%. The experiment results show that using the TIM to reduce contact thermal resistance leads to 15% of temperature rises. We are not looking for ways to obtain higher values of Z, rather, the thermal structure design is another research direction in the future to achieve greater performance gains.

Author Contributions

Funding

Conflicts of Interest

References

- Khanmohammadi, S.; Saadat-Targhi, M.; Ahmed, F.W.; Afrand, M. Potential of thermoelectric waste heat recovery in a combined geothermal, fuel cell and organic Rankine flash cycle (thermodynamic and economic evaluation). Int. J. Hydrogen Energy 2020, 45, 6934–6948. [Google Scholar] [CrossRef]

- Selvan, K.V.; Hasan, N.; Ali, M.S.M. Methodological reviews and analyses on the emerging research trends and progresses of thermoelectric generators. Int. J. Energy Res. 2019, 43, 113–140. [Google Scholar] [CrossRef] [Green Version]

- He, R.; Schierning, G.; Nielsch, K. Thermoelectric Devices: Thermoelectric Devices: A Review of Devices, Architectures, and Contact Optimization (Adv. Mater. Technol. 4/2018). Adv. Mater. Technol. 2018, 3, 1700256. [Google Scholar] [CrossRef] [Green Version]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.; Pour Yazdi, M.A.; Kumar, R. Thermoelectric cooler and thermoelectric generator devices: A review of present and potential applications, modeling and materials. Energy 2019, 186, 115849. [Google Scholar] [CrossRef]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Harvesting Waste Heat to Save the Climate. Available online: http://www.i-sis.org.uk/harvestingWasteHeat.php (accessed on 3 June 2020).

- Zhao, L.-D.; Dravid, V.P.; Kanatzidis, M.G. The panoscopic approach to high performance thermoelectrics. Energy Environ. Sci. 2014, 7, 251–268. [Google Scholar] [CrossRef]

- Majumdar, A. Enhanced: Thermoelectricity in Semiconductor Nanostructures. Science 2004, 303, 777–778. [Google Scholar] [CrossRef]

- Cowen, L.M.; Atoyo, J.; Carnie, M.; Baran, D.; Schroeder, B.C. Review—Organic Materials for Thermoelectric Energy Generation. ECS J. Solid State Sci. Technol. 2017, 6, N3080–N3088. [Google Scholar] [CrossRef] [Green Version]

- Rojas, J.; Singh, D.; Inayat, S.B.; Sevilla, G.A.T.; Fahad, H.M.; Hussain, M.M. Review—Micro and Nano-Engineering Enabled New Generation of Thermoelectric Generator Devices and Applications. ECS J. Solid State Sci. Technol. 2017, 6, N3036–N3044. [Google Scholar] [CrossRef] [Green Version]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A review of the state of the science on wearable thermoelectric power generators (TEGs) and their existing challenges. Renew. Sustain. Energy Rev. 2017, 73, 730–744. [Google Scholar] [CrossRef]

- Hasaka, M.; Aki, T.; Morimura, T.; Kondo, S.-I. Thermoelectric properties of Cu-Sn-S. Energy Convers. Manag. 1997, 38, 855–859. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, L.-D.; Zheng, F.; Wu, D.; Pei, Y.L.; Tong, X.; Kanatzidis, M.G.; He, J. Broad temperature plateau for thermoelectric figure of merit ZT>2 in phase-separated PbTe0.7S0.3. Nat. Commun. 2014, 5, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Sakamoto, J. The microstructural stability and thermoelectric properties of Mm0.9Fe3.5Co0.5Sb12-based skutterudites. Mater. Chem. Phys. 2013, 138, 601–607. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Tan, M.; Deng, Y.; Wang, Y. Ordered structure and high thermoelectric properties of Bi2(Te,Se)3 nanowire array. Nano Energy 2014, 3, 144–151. [Google Scholar] [CrossRef]

- Pei, Y.; Shi, X.; LaLonde, A.; Wang, H.; Chen, L.; Snyder, G.J. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 2011, 473, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.-H.; Shao, L.; Zhang, K.; Pipe, K.P. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat. Mater. 2013, 12, 719–723. [Google Scholar] [CrossRef]

- Min, G.; Rowe, D. Cooling performance of integrated thermoelectric microcooler. Solid-state Electron. 1999, 43, 923–929. [Google Scholar] [CrossRef]

- Bulman, G.; Barletta, P.; Lewis, J.; Baldasaro, N.; Manno, M.; Bar-Cohen, A.; Yang, B. Superlattice-based thin-film thermoelectric modules with high cooling fluxes. Nat. Commun. 2016, 7, 10302. [Google Scholar] [CrossRef]

- Chowdhury, I.; Prasher, R.; Lofgreen, K.; Chrysler, G.; Narasimhan, S.; Mahajan, R.; Koester, D.; Alley, R.; Venkatasubramanian, R. On-chip cooling by superlattice-based thin-film thermoelectrics. Nat. Nanotechnol. 2009, 4, 235–238. [Google Scholar] [CrossRef]

- Mu, S.; Zhou, H.; Zhao, W.; He, D.; Zhu, W.; Nie, X.; Sun, Z.; Zhang, Q. High-performance YbAl3/Bi0.5Sb1.5Te3 artificially tilted multilayer thermoelectric devices via material genome engineering method. J. Power Sources 2019, 430, 193–200. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, X.; Pan, C.; Wang, L. A facile method to intimately contacted nanocomposites as thermoelectric materials: Noncovalent heterojunctions. J. Power Sources 2019, 412, 153–159. [Google Scholar] [CrossRef]

- Cai, S.; Hao, S.; Luo, Z.-Z.; Li, X.; Hadar, I.; Bailey, T.P.; Hu, X.; Uher, C.; Hu, Y.-Y.; Wolverton, C.; et al. Discordant nature of Cd in PbSe: Off-centering and core–shell nanoscale CdSe precipitates lead to high thermoelectric performance. Energy Environ. Sci. 2020, 13, 200–211. [Google Scholar] [CrossRef]

- Nie, G.; Li, W.; Guo, J.; Yamamoto, A.; Kimura, K.; Zhang, X.; Isaacs, E.B.; Dravid, V.; Wolverton, C.; Kanatzidis, M.G.; et al. High performance thermoelectric module through isotype bulk heterojunction engineering of skutterudite materials. Nano Energy 2019, 66, 104193. [Google Scholar] [CrossRef]

- Queen Mary Research Online. Available online: https://qmro.qmul.ac.uk (accessed on 3 June 2020).

- Rosi, F. Thermoelectricity and thermoelectric power generation. Solid-State Electron. 1968, 11, 833–868. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, X.; Li, J.; Liu, Z.; Liscio, F.; Milita, S.; Schroeder, B.C.; Fenwick, O. Enhanced control of self-doping in halide perovskites for improved thermoelectric performance. Nat. Commun. 2019, 10, 5750. [Google Scholar] [CrossRef]

- Mao, L.; Yin, Y.; Zhang, Q.; Liu, G.-Q.; Wang, H.; Guo, Z.; Hu, H.; Xiao, Y.; Tan, X.; Jiang, J. Fermi-surface dynamics and high thermoelectric performance along the out-of-plane direction in n-type SnSe crystals. Energy Environ. Sci. 2020, 13, 616–621. [Google Scholar] [CrossRef]

- Mushtaq, M.; Sattar, M.A.; Dar, S.A. Phonon phase stability, structural, mechanical, electronic, and thermoelectric properties of two new semiconducting quaternary Heusler alloys CoCuZrZ (Z = Ge and Sn). Int. J. Energy Res. 2020, 44, 5936–5946. [Google Scholar] [CrossRef]

- He, W.; Wang, D.; Wu, H.; Xiao, Y.; Zhang, Y.; He, D.; Feng, Y.; Hao, Y.-J.; Dong, J.-F.; Chetty, R.; et al. High thermoelectric performance in low-cost SnS0.91Se0.09 crystals. Sci. 2019, 365, 1418–1424. [Google Scholar] [CrossRef]

- You, L.; Zhang, J.; Pan, S.; Jiang, Y.; Wang, K.; Yang, J.; Pei, Y.; Zhu, Q.; Agne, M.T.; Snyder, G.J.; et al. Realization of higher thermoelectric performance by dynamic doping of copper in n-type PbTe. Energy Environ. Sci. 2019, 12, 3089–3098. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Liu, G.; Fu, Y.; Tan, X.; Shao, H.; Jiang, H. Optimization of thermoelectric properties in n-type SnSe doped with BiCl3. Appl. Phys. Lett. 2016, 108, 83902. [Google Scholar] [CrossRef]

- Mao, J.; Zhu, H.; Ding, Z.; Liu, Z.; Gamage, G.A.; Chen, G.; Ren, Z. High thermoelectric cooling performance of n-type Mg3Bi2-based materials. Science 2019, 365, 495–498. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Qiu, Y.; Witting, I.; Zhang, L.; Fu, C.; Li, J.-W.; Huang, Y.; Sun, F.-H.; He, J.; Snyder, G.J.; et al. Synergistic modulation of mobility and thermal conductivity in (Bi,Sb)2Te3 towards high thermoelectric performance. Energy Environ. Sci. 2019, 12, 624–630. [Google Scholar] [CrossRef]

- Zhu, H.; Mao, J.; Li, Y.; Sun, J.; Wang, Y.; Zhu, Q.; Li, G.; Song, Q.; Zhou, J.; Fu, Y.; et al. Discovery of TaFeSb-based half-Heuslers with high thermoelectric performance. Nat. Commun. 2019, 10, 270. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.I.; Lee, K.H.; A Mun, H.; Kim, H.S.; Hwang, S.W.; Roh, J.W.; Yang, D.J.; Shin, W.H.; Li, X.S.; Lee, Y.H.; et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 2015, 348, 109–114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, L.; Zhu, T.; Liu, X.; Zhao, X. Point Defect Engineering of High-Performance Bismuth-Telluride-Based Thermoelectric Materials. Adv. Funct. Mater. 2014, 24, 5211–5218. [Google Scholar] [CrossRef]

- Witting, I.T.; Chasapis, T.C.; Ricci, F.; Peters, M.; Heinz, N.A.; Hautier, G.; Snyder, G.J. The Thermoelectric Properties of Bismuth Telluride. Adv. Electron. Mater. 2019, 5, 1800904. [Google Scholar] [CrossRef]

- Shi, X.-L.; Tao, X.; Zou, J.; Chen, Z.-G. High-Performance Thermoelectric SnSe: Aqueous Synthesis, Innovations, and Challenges. Adv. Sci. 2020, 7, 1902923. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.-D.; Tan, G.; Hao, S.; He, J.; Pei, Y.; Chi, H.; Wang, H.; Gong, S.; Xu, H.; Dravid, V.P.; et al. Ultrahigh power factor and thermoelectric performance in hole-doped single-crystal SnSe. Science 2015, 351, 141–144. [Google Scholar] [CrossRef] [Green Version]

- Chere, E.K.; Zhang, Q.; Dahal, K.; Cao, F.; Mao, J.; Ren, Z. Studies on thermoelectric figure of merit of Na-doped p-type polycrystalline SnSe. J. Mater. Chem. A 2016, 4, 1848–1854. [Google Scholar] [CrossRef]

- Zheng, Z.; Su, X.; Deng, R.; Stoumpos, C.C.; Xie, H.; Liu, W.; Yan, Y.; Hao, S.; Uher, C.; Wolverton, C.; et al. Rhombohedral to Cubic Conversion of GeTe via MnTe Alloying Leads to Ultralow Thermal Conductivity, Electronic Band Convergence, and High Thermoelectric Performance. J. Am. Chem. Soc. 2018, 140, 2673–2686. [Google Scholar] [CrossRef]

- Kang, J.; Jung, D.W.; Park, S.; Lee, J.-H.; Ko, J.; Kim, J. Corrigendum to “Accelerated test analysis of reversal potential caused by fuel starvation during PEMFCs operation” [International Journal of Hydrogen Energy 35 (2010) 3727–3735]. Int. J. Hydrogen Energy 2010, 35, 8815. [Google Scholar] [CrossRef]

- Fu, Y.; Yang, J.; Qin, H.; Shao, H.; Xu, J.; Liu, G.-Q.; Tan, X.; Jiang, H.; Liang, B. Enhanced thermoelectric performance in p-type polycrystalline SnSe benefiting from texture modulation. J. Mater. Chem. C 2016, 4, 1201–1207. [Google Scholar] [CrossRef]

- Qin, B.; Wang, D.; He, W.; Zhang, Y.; Wu, H.; Pennycook, S.J.; Zhao, L.-D. Realizing High Thermoelectric Performance in p-Type SnSe through Crystal Structure Modification. J. Am. Chem. Soc. 2018, 141, 1141–1149. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.-R.; Tan, G.; Zhang, X.; Wu, C.-F.; Li, J.-F.; Dravid, V.P.; Snyder, G.J.; Kanatzidis, M.G. Distinct Impact of Alkali-Ion Doping on Electrical Transport Properties of Thermoelectric p-Type Polycrystalline SnSe. J. Am. Chem. Soc. 2016, 138, 8875–8882. [Google Scholar] [CrossRef] [PubMed]

- Peng, K.; Lu, X.; Zhan, H.; Hui, S.; Tang, X.; Wang, G.; Dai, J.; Uher, C.; Wang, G.; Zhou, X. Broad temperature plateau for high ZTs in heavily doped p-type SnSe single crystals. Energy Environ. Sci. 2016, 9, 454–460. [Google Scholar] [CrossRef]

- Tan, G.; Shi, F.; Hao, S.; Chi, H.; Zhao, L.D.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Codoping in SnTe: Enhancement of Thermoelectric Performance through Synergy of Resonance Levels and Band Convergence. J. Am. Chem. Soc. 2015, 137, 5100–5112. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.-G.; Hong, M.; Wang, L.; Kong, D.; Huang, L.; Han, G.; Zou, Y.-C.; Dargusch, M.; Zou, J. n-type Bi-doped PbTe Nanocubes with Enhanced Thermoelectric Performance. Nano Energy 2017, 31, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Shuai, J.; Sun, Y.; Tan, X.; Mori, T. Manipulating the Ge Vacancies and Ge Precipitates through Cr Doping for Realizing the High-Performance GeTe Thermoelectric Material. Small 2020, 16, e1906921. [Google Scholar] [CrossRef]

- Pan, Y.; Aydemir, U.; Grovogui, J.A.; Witting, I.T.; Hanus, R.; Xu, Y.; Wu, J.; Wu, C.-F.; Sun, F.-H.; Zhuang, H.-L.; et al. Melt-Centrifuged (Bi,Sb)2 Te3: Engineering Microstructure toward High Thermoelectric Efficiency. Adv. Mater. 2018, 30, 1802016. [Google Scholar] [CrossRef]

- Takaki, H.; Kobayashi, K.; Shimono, M.; Kobayashi, N.; Hirose, K. First-principles calculations of thermoelectric properties of TiN/MgO superlattices: The route for an enhancement of thermoelectric effects in artificial nanostructures. J. Appl. Phys. 2016, 119, 014302. [Google Scholar] [CrossRef]

- Song, D.; Ma, W.; Zhang, X. Lattice thermal conductivity of Si/Ge composite thermoelectric material: Effect of Si particle distribution. Int. J. Energy Res. 2018, 43, 379–390. [Google Scholar] [CrossRef] [Green Version]

- Niemelä, J.-P.; Karttunen, A.J.; Karppinen, M. Inorganic–organic superlattice thin films for thermoelectrics. J. Mater. Chem. C 2015, 3, 10349–10361. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.; Chen, G. Nanostructured thermoelectric materials: From superlattices to nanocomposites. Mater. Integr. 2005, 18, 31–36. [Google Scholar]

- Shakouri, A. Recent Developments in Semiconductor Thermoelectric Physics and Materials. Annu. Rev. Mater. Res. 2011, 41, 399–431. [Google Scholar] [CrossRef]

- Beyer, H.; Nurnus, J.; Böttner, H.; Lambrecht, A.; Wagner, E.; Bauer, G. High thermoelectric figure of merit ZT in PbTe and Bi2Te3-based superlattices by a reduction of the thermal conductivity. Phys. E Low-Dimens. Syst. Nanostructures 2002, 13, 965–968. [Google Scholar] [CrossRef]

- Harman, T.C. Quantum Dot Superlattice Thermoelectric Materials and Devices. Science 2002, 297, 2229–2232. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-M.; Cahill, D.G.; Venkatasubramanian, R. Thermal conductivity of Si–Ge superlattices. Appl. Phys. Lett. 1997, 70, 2957–2959. [Google Scholar] [CrossRef]

- Zeng, G.; Shakouri, A.; LaBounty, C.; Robinson, G.; Croke, E.; Abraham, P.; Fan, X.; Reese, H.; Bowers, J. SiGe micro-cooler. Electron. Lett. 1999, 35, 2146–2147. [Google Scholar] [CrossRef]

- Harman, T.C.; Taylor, P.J.; Spears, D.L.; Walsh, M.P. Thermoelectric quantum-dot superlattices with high ZT. J. Electron. Mater. 2000, 29, L1–L2. [Google Scholar] [CrossRef]

- Zong, P.A.; Zhang, P.; Yin, S.; Huang, Y.; Wang, Y.; Wan, C. Fabrication and Characterization of a Hybrid Bi2Se3/Organic Superlattice for Thermoelectric Energy Conversion. Adv. Electr. Mater. 2019, 5, 1800842. [Google Scholar] [CrossRef]

- Hicks, L.D.; Harman, T.C.; Sun, X.; Dresselhaus, M.S. Experimental study of the effect of quantum-well structures on the thermoelectric figure of merit. Phys. Rev. B 1996, 53, R10493–R10496. [Google Scholar] [CrossRef] [PubMed]

- Tritt, T.M. Thermal Conductivity: Theory, Properties, and Applications; Springer Science & Business Media: Berlin, Germany, 2004. [Google Scholar]

- Harman, T.C.; Walsh, M.P.; Turner, G.W. Nanostructured thermoelectric materials. J. Electr. Mater. 2005, 34, L19–L22. [Google Scholar] [CrossRef]

- Park, N.W.; Lee, W.Y.; Yoon, Y.S.; Kim, G.S.; Yoon, Y.G.; Lee, S.K. Achieving Out-of-Plane Thermoelectric Figure of Merit ZT=1.44 in a p-Type Bi2Te3/Bi0.5Sb1.5Te3 Superlattice Film with Low Interfacial Resistance. ACS Appl. Mater. Interfaces 2019, 11, 38247–38254. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshi, P.; Sharma, A.; Mukherjee, S.; Muralidharan, B. Superlattice design for optimal thermoelectric generator performance. J. Phys. D: Appl. Phys. 2018, 51, 185301. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Zhao, L.-D. Promising Thermoelectric Bulk Materials with 2D Structures. Adv. Mater. 2017, 29, 1702676. [Google Scholar] [CrossRef]

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renew. Sustain. Energy Rev. 2018, 82, 4159–4169. [Google Scholar] [CrossRef]

- Rowe, D.M. Thermoelectrics Handbook: Macro to Nano; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Hicks, L.D.; Dresselhaus, M.S. The Effect of Quantum Well Structures on the Thermoelectric Figure of Merit. MRS Proc. 1992, 281, 450–453. [Google Scholar] [CrossRef]

- Venkatasubramanian, R. Chapter 4 Phonon blocking electron transmitting superlattice structures as advanced thin film thermoelectric materials. Semiconduct. Semimet. 2001, 71, 175–201. [Google Scholar]

- Tritt, T.M. Recent Trends in Thermoelectric Materials Research III; Semiconductors and Semimetals—Preface; Academic Press: New York, NY, USA, 2001; Volume 71, pp. 9–14. [Google Scholar]

- Hicks, L.D.; Dresselhaus, M.S. Effect of quantum-well structures on the thermoelectric figure of merit. Phys. Rev. B 1993, 47, 12727–12731. [Google Scholar] [CrossRef]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.-K.; Iii, W.A.G.; Heath, J.R. Silicon nanowires as efficient thermoelectric materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef]

- Yu, J.-K.; Mitrovic, S.; Tham, D.; Varghese, J.; Heath, J.R. Reduction of thermal conductivity in phononic nanomesh structures. Nat. Nanotechnol. 2010, 5, 718–721. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sadeghi, H.; Sangtarash, S.; Lambert, C.J. Enhancing the thermoelectric figure of merit in engineered graphene nanoribbons. Beilstein J. Nanotechnol. 2015, 6, 1176–1182. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Chen, Y.; McCuskey, S.R.; Chen, L.; Bazan, G.C.; Liang, Z. Recent Advances in n-Type Thermoelectric Nanocomposites. Adv. Electr. Mater. 2019, 5, 1800943. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.-Y.; Kang, H.; Li, Y.; Yaer, X.; Li, J.; Tan, Q.; Zhang, S.; Fan, G.-H.; Liu, C.-Y.; et al. Record high thermoelectric performance in bulk SrTiO3 via nano-scale modulation doping. Nano Energy 2017, 35, 387–395. [Google Scholar] [CrossRef]

- Tran, V.T.; Saint-Martin, J.; Dollfus, P.; Volz, S. Optimizing the thermoelectric performance of graphene nano-ribbons without degrading the electronic properties. Sci. Rep. 2017, 7, 2313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hossain, S.; Huynh, D.H.; Jiang, L.; Rahman, S.; Nguyen, P.D.; Al-Dirini, F.; Hossain, F.M.; Bahk, J.-H.; Skafidas, E.; Skafidas, S. Investigating enhanced thermoelectric performance of graphene-based nano-structures. Nanoscale 2018, 10, 4786–4792. [Google Scholar] [CrossRef]

- Li, K.-M.; Xie, Z.-X.; Su, K.-L.; Luo, W.; Zhang, Y. Ballistic thermoelectric properties in double-bend graphene nanoribbons. Phys. Lett. A 2014, 378, 1383–1387. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Ibánez, M.; Luo, Z.; Genc, A.; Piveteau, L.; Ortega, S.; Cadavid, D.; Dobrozhan, O.; Liu, Y.; Nachtegaal, M.; Zebarjadi, M.; et al. High-performance thermoelectric nanocomposites from nanocrystal building blocks. Nat. Commun. 2016, 7, 10766. [Google Scholar] [CrossRef] [Green Version]

- Karana, D.R.; Sahoo, R.R. Influence of geometric parameter on the performance of a new asymmetrical and segmented thermoelectric generator. Energy 2019, 179, 90–99. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Liu, C.; Li, M.; Lv, Y.; Jia, L.; Jiang, S. Enhanced Efficiency of Thermoelectric Generator by Optimizing Mechanical and Electrical Structures. Energies 2017, 10, 1329. [Google Scholar] [CrossRef] [Green Version]

- Lv, S.; Liu, M.; He, W.; Li, X.; Gong, W.; Shen, S. Study of thermal insulation materials influence on the performance of thermoelectric generators by creating a significant effective temperature difference. Energy Convers. Manag. 2020, 207, 112516. [Google Scholar] [CrossRef]

- Lundgaard, C.; Sigmund, O.; Bjørk, R. Topology Optimization of Segmented Thermoelectric Generators. J. Electron. Mater. 2018, 47, 6959–6971. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, H.; Su, W.; Mehmood, F.; Zhai, J.; Wang, T.; Chen, T.; Wang, C. Geometric structural design for lead tellurium thermoelectric power generation application. Renew. Energy 2019, 141, 88–95. [Google Scholar] [CrossRef]

- Ali, H.; Yilbas, B.S.; Al-Sharafi, A. Segmented thermoelectric generator: Exponential area variation in leg. Int. J. Energy Res. 2018, 42, 477–489. [Google Scholar] [CrossRef]

- Ming, T.; Yang, W.; Wu, Y.; Xiang, Y.; Huang, X.; Cheng, J.; Li, X.; Zhao, J. Numerical analysis on the thermal behavior of a segmented thermoelectric generator. Int. J. Hydrogen Energy 2017, 42, 3521–3535. [Google Scholar] [CrossRef]

- Sun, H.; Ge, Y.; Liu, W.; Liu, Z. Geometric optimization of two-stage thermoelectric generator using genetic algorithms and thermodynamic analysis. Energy 2019, 171, 37–48. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Zhao, X.; Ma, X.; Akhlaghi, Y.G.; Ayodele, E. Optimized high performance thermoelectric generator with combined segmented and asymmetrical legs under pulsed heat input power. J. Power Sources 2019, 428, 53–66. [Google Scholar] [CrossRef]

- Meng, J.-H.; Zhang, X.; Wang, X.-D. Multi-objective and multi-parameter optimization of a thermoelectric generator module. Energy 2014, 71, 367–376. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, B.; Pang, D.; Chen, J.; Wang, J.; Du, J. Influence of leg geometry configuration and contact resistance on the performance of annular thermoelectric generators. Energy Convers. Manag. 2018, 166, 337–342. [Google Scholar] [CrossRef]

- Teixeira, S.F.; Pereira, A.M. Geometrical optimization of a thermoelectric device: Numerical simulations. Energy Convers. Manag. 2018, 169, 217–227. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. A review of thermoelectric cooling: Materials, modeling and applications. Appl. Therm. Eng. 2014, 66, 15–24. [Google Scholar] [CrossRef]

- Badillo-Ruiz, C.A.; Olivares-Robles, M.A.; Ortega, P.E.R. Performance of Segmented Thermoelectric Cooler Micro-Elements with Different Geometric Shapes and Temperature-Dependent Properties. Entropy 2018, 20, 118. [Google Scholar] [CrossRef] [Green Version]

- Tzeng, S.C.; Jeng, T.M.; Lin, Y.L. Parametric study of heat-transfer design on the thermoelectric generator system. Int. Commun. Heat Mass Transf. 2014, 52, 97–105. [Google Scholar] [CrossRef]

- Lee, H.-B.; Yang, H.J.; We, J.H.; Kim, K.; Choi, K.C.; Cho, B.J. Thin-Film Thermoelectric Module for Power Generator Applications Using a Screen-Printing Method. J. Electron. Mater. 2011, 40, 615–619. [Google Scholar] [CrossRef]

- Bahk, J.-H.; Fang, H.; Yazawa, K.; Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 2015, 3, 10362–10374. [Google Scholar] [CrossRef]

- Kim, F.; Kwon, B.; Eom, Y.; Lee, J.E.; Park, S.; Jo, S.; Park, S.H.; Kim, B.S.; Im, H.J.; Lee, M.H.; et al. 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nat. Commun. 2018, 3, 301–309. [Google Scholar] [CrossRef]

- Huu, T.N.; Van, T.N.; Takahito, O. Flexible thermoelectric power generator with Y-type structure using electrochemical deposition process. Appl. Energy 2018, 210, 467–476. [Google Scholar] [CrossRef]

- Park, S.H.; Jo, S.; Kwon, B.; Kim, F.; Ban, H.W.; Lee, J.E.; Gu, D.H.; Lee, S.H.; Hwang, Y.; Kim, J.-S.; et al. High-performance shape-engineerable thermoelectric painting. Nat. Commun. 2016, 7, 13403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hwang, J.; Kim, H.; Wijethunge, D.; Nandihalli, N.; Eom, Y.; Park, H.; Kim, J.; Kim, W. More than half reduction in price per watt of thermoelectric device without increasing the thermoelectric figure of merit of materials. Appl. Energy 2017, 205, 1459–1466. [Google Scholar] [CrossRef]

- Elghool, A.; Basrawi, F.; Ibrahim, T.K.; Habib, K.; Ibrahim, H.; Idris, D.M.N.D. A review on heat sink for thermo-electric power generation: Classifications and parameters affecting performance. Energy Convers. Manag. 2017, 134, 260–277. [Google Scholar] [CrossRef]

- Astrain, D.; Aranguren, P.; Martinez, A.; Rodríguez, A.; Pérez-Artieda, G. A comparative study of different heat exchange systems in a thermoelectric refrigerator and their influence on the efficiency. Appl. Therm. Eng. 2016, 103, 1289–1298. [Google Scholar] [CrossRef]

- Wang, T.; Ma, S. Thermoelectric generator heat performance study about improved fin structures. Therm. Sci. 2018, 22, 101–112. [Google Scholar] [CrossRef]

- Sarkar, A.; Mahapatra, S.K. Role of surface radiation on the functionality of thermoelectric cooler with heat sink. Appl. Therm. Eng. 2014, 69, 39–45. [Google Scholar] [CrossRef]

- Xiao, L.; Wu, S.Y.; Yang, S.L. Parametric study on the thermoelectric conversion performance of a concentrated solar-driven thermionic-thermoelectric hybrid generator. Int. J. Energy Res. 2018, 42, 656–672. [Google Scholar] [CrossRef]

- Al-Nimr, M.D.A.; Qananba, K.S. A solar hybrid thermoelectric generator and distillation system. Int. J. Green Energy 2018, 15, 473–488. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.-X.; Bao, W.; Li, H.-X.; Liu, Q. Experimental study of high power LEDs heat dissipation based on corona discharge. Appl. Therm. Eng. 2016, 98, 420–429. [Google Scholar] [CrossRef]

- Najjar, Y.S.H.; Kseibi, M. Evaluation of experimental JUST thermoelectric stove for electricity—Deprived regions. Renew. Sustain. Energy Rev. 2017, 69, 854–861. [Google Scholar] [CrossRef]

- Tsai, H.-L.; Le, P.T. Self-sufficient energy recycling of light emitter diode/thermoelectric generator module for its active-cooling application. Energy Convers. Manag. 2016, 118, 170–178. [Google Scholar] [CrossRef]

- Khalil, H.; Hassan, H. Enhancement thermoelectric generators output power from heat recovery of chimneys by using flaps. J. Power Sources 2019, 443, 227266. [Google Scholar] [CrossRef]

- Patowary, R.; Baruah, D.C. Thermoelectric conversion of waste heat from IC engine-driven vehicles: A review of its application, issues, and solutions. Int. J. Energy Res. 2018, 42, 2595–2614. [Google Scholar] [CrossRef]

- Mirhosseini, M.; Rezania, A.; Rosendahl, L.A. Power optimization and economic evaluation of thermoelectric waste heat recovery system around a rotary cement kiln. J. Clean. Prod. 2019, 232, 1321–1334. [Google Scholar] [CrossRef]

- Ong, K.S.; Tan, C.; Lai, K.; Tan, K. Heat spreading and heat transfer coefficient with fin heat sink. Appl. Therm. Eng. 2017, 112, 1638–1647. [Google Scholar] [CrossRef]

- Lv, S.; He, W.; Hu, D.; Zhu, J.; Li, G.; Chen, H.; Liu, M. Study on a high-performance solar thermoelectric system for combined heat and power. Energy Convers. Manag. 2017, 143, 459–469. [Google Scholar] [CrossRef]

- Lv, S.; He, W.; Jiang, Q.; Hu, Z.; Liu, X.; Chen, H.; Liu, M. Study of different heat exchange technologies influence on the performance of thermoelectric generators. Energy Convers. Manag. 2018, 156, 167–177. [Google Scholar] [CrossRef]

- Martínez, A.; Astrain, D.; Aranguren, P. Thermoelectric self-cooling for power electronics: Increasing the cooling power. Energy 2016, 112, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.-W.; Chang, C.-C.; Ke, M.-T.; Chen, S.-L. Thermoelectric air-cooling module for electronic devices. Appl. Therm. Eng. 2009, 29, 2731–2737. [Google Scholar] [CrossRef]

- Alghoul, M.; Shahahmadi, S.A.; Yeganeh, B.; Asim, N.; Elbreki, A.; Sopian, K.; Tiong, S.; Amin, N. A review of thermoelectric power generation systems: Roles of existing test rigs/ prototypes and their associated cooling units on output performance. Energy Convers. Manag. 2018, 174, 138–156. [Google Scholar] [CrossRef]

- Huang, H.-S.; Weng, Y.-C.; Chang, Y.-W.; Chen, S.-L.; Ke, M.-T. Thermoelectric water-cooling device applied to electronic equipment. Int. Commun. Heat Mass Transf. 2010, 37, 140–146. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Hommalee, C.; Naphon, P. Thermal cooling enhancement of dual processors computer with thermoelectric air cooler module. CASE Stud. Therm. Eng. 2019, 14, 10045. [Google Scholar] [CrossRef]

- Hu, H.; Ge, T.; Dai, Y.; Wang, R. Experimental study on water-cooled thermoelectric cooler for CPU under severe environment. Int. J. Refrig. 2016, 62, 30–38. [Google Scholar] [CrossRef]

- Meng, F.; Chen, L.; Sun, F.; Yang, B. Thermoelectric power generation driven by blast furnace slag flushing water. Energy 2014, 66, 965–972. [Google Scholar] [CrossRef]

- Li, W.; Peng, J.; Xiao, W.; Wang, H.; Zeng, J.; Xie, J.; Huang, Q.; Mao, K.; Zhang, L. The temperature distribution and electrical performance of fluid heat exchanger-based thermoelectric generator. Appl. Therm. Eng. 2017, 118, 742–747. [Google Scholar] [CrossRef]

- Junior, M.F.; Bezerra, U.H.; Leite, J.C.; Moya-Rodríguez, J.L. Maintenance Tools applied to Electric Generators to Improve Energy Efficiency and Power Quality of Thermoelectric Power Plants. Energies 2017, 10, 1091. [Google Scholar] [CrossRef] [Green Version]

- Shixue, H.W.W. Performance Comparison of Different Exhaust Exchanger Types Considering Peak Net Power and Optimal Dimension in a Thermoelectric Generator System. Adv. Theory Simul. 2018, 1, 1800012. [Google Scholar]

- Xiao, G.Q.; Zhang, Z. Coupled simulation of a thermoelectric generator of a thermoelectric generator applied in diesel engine exhaust waste heat recovery. Therm. Sci. 2020, 24, 281–292. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Wang, S.; Ge, M.; Li, Y.; Liang, Z.; Yang, Y. Performance analysis of a thermoelectric generator applied to wet flue gas waste heat recovery. Appl. Energy 2018, 228, 2080–2089. [Google Scholar] [CrossRef]

- Meng, F.; Chen, L.; Feng, Y.; Xiong, B. Thermoelectric generator for industrial gas phase waste heat recovery. Energy 2017, 135, 83–90. [Google Scholar] [CrossRef]

- Lu, B.; Meng, X.; Tian, Y.; Zhu, M.; Suzuki, R.O. Thermoelectric performance using counter-flowing thermal fluids. Int. J. Hydrogen Energy 2017, 42, 20835–20842. [Google Scholar] [CrossRef]

- Liu, X.; Yu, J. Numerical study on performances of mini-channel heat sinks with non-uniform inlets. Appl. Therm. Eng. 2016, 93, 856–864. [Google Scholar] [CrossRef]

- Faraji, A.Y.; Akbarzadeh, A. Analysis of a symbiotic thermoelectric system for power generation and liquid preheating. Appl. Therm. Eng. 2014, 71, 501–507. [Google Scholar] [CrossRef]

- Lesage, F.J.; Sempels, E.; Lalande-Bertrand, N. A study on heat transfer enhancement using flow channel inserts for thermoelectric power generation. Energy Convers. Manag. 2013, 75, 532–541. [Google Scholar] [CrossRef]

- Lu, H.; Wu, T.; Bai, S.; Xu, K.; Huang, Y.; Gao, W.; Yin, X.; Chen, L. Experiment on thermal uniformity and pressure drop of exhaust heat exchanger for automotive thermoelectric generator. Energy 2013, 54, 372–377. [Google Scholar] [CrossRef]

- Nia, M.H.; Nejad, A.A.; Goudarzi, A.; Valizadeh, M.; Samadian, P. Cogeneration solar system using thermoelectric module and fresnel lens. Energy Convers. Manag. 2014, 84, 305–310. [Google Scholar] [CrossRef]

- Lian, D.; Jitian, H.; Chong, H.; Linlin, C. Natural circulation heat transfer characteristics of nanofluid in thermoelectric refrigeration liquid cooling suits. J. Southeast Univ. 2018, 48, 220–225. [Google Scholar]

- Xing, J.-J.; Wu, Z.; Xie, H.; Wang, Y.-Y.; Li, Y.-H.; Mao, J.-H. Performance of thermoelectric generator with graphene nanofluid cooling. Chin. Phys. B 2017, 26, 104401. [Google Scholar] [CrossRef]

- Mohammadian, S.K.; Zhang, Y. Analysis of nanofluid effects on thermoelectric cooling by micro-pin-fin heat exchangers. Appl. Therm. Eng. 2014, 70, 282–290. [Google Scholar] [CrossRef]

- Ahammed, N.; Asirvatham, L.G.; Wongwises, S. Entropy generation analysis of graphene–alumina hybrid nanofluid in multiport minichannel heat exchanger coupled with thermoelectric cooler. Int. J. Heat Mass Transf. 2016, 103, 1084–1097. [Google Scholar] [CrossRef]

- Shabgard, H.; Allen, M.J.; Sharifi, N.; Benn, S.P.; Faghri, A.; Bergman, T.L. Heat pipe heat exchangers and heat sinks: Opportunities, challenges, applications, analysis, and state of the art. Int. J. Heat Mass Transf. 2015, 89, 138–158. [Google Scholar] [CrossRef]

- Omer, G.; Yavuz, H.; Ahiska, R. Heat pipes thermoelectric solar collectors for energy applications. Int. J. Hydrogen Energy 2017, 42, 8310–8313. [Google Scholar] [CrossRef]

- Zhang, M.; Miao, L.; Kang, Y.P.; Tanemura, S.; Fisher, C.A.J.; Xu, G.; Li, C.X.; Fan, G.Z. Efficient, low-cost solar thermoelectric cogenerators comprising evacuated tubular solar collectors and thermoelectric modules. Appl. Energy 2013, 109, 51–59. [Google Scholar] [CrossRef]

- Aranguren, P.; Astrain, D.; Rodríguez, A.; Martinez, A. Experimental investigation of the applicability of a thermoelectric generator to recover waste heat from a combustion chamber. Appl. Energy 2015, 152, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Vian, J.; Astrain, D. Development of a heat exchanger for the cold side of a thermoelectric module. Appl. Therm. Eng. 2008, 28, 1514–1521. [Google Scholar] [CrossRef]

- Araiz, M.; Martinez, A.; Astrain, D.; Aranguren, P. Experimental and computational study on thermoelectric generators using thermosyphons with phase change as heat exchangers. Energy Convers. Manag. 2017, 137, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Riffat, S.; Ma, X. Improving the coefficient of performance of thermoelectric cooling systems: A review. Int. J. Energy Res. 2004, 28, 753–768. [Google Scholar] [CrossRef]

- Lu, X.; Zhao, D.; Ma, T.; Wang, Q.; Fan, J.; Yang, R. Thermal resistance matching for thermoelectric cooling systems. Energy Convers. Manag. 2018, 169, 186–193. [Google Scholar] [CrossRef]

- Sakamoto, T.; Iida, T.; Sekiguchi, T.; Taguchi, Y.; Hirayama, N.; Nishio, K.; Takanashi, Y. Selection and Evaluation of Thermal Interface Materials for Reduction of the Thermal Contact Resistance of Thermoelectric Generators. J. Electron. Mater. 2014, 43, 3792–3800. [Google Scholar] [CrossRef]

- Wang, S.; Xie, T.; Xie, H. Experimental study of the effects of the thermal contact resistance on the performance of thermoelectric generator. Appl. Therm. Eng. 2018, 130, 847–853. [Google Scholar] [CrossRef]

- Siouane, S.; Poure, P.; Jovanović, S. Fully Electrical Modeling of Thermoelectric Generators with Contact Thermal Resistance Under Different Operating Conditions. J. Electron. Mater. 2016, 46, 40–50. [Google Scholar] [CrossRef]

- Bjørk, R. An Analytical Model for the Influence of Contact Resistance on Thermoelectric Efficiency. J. Electron. Mater. 2015, 45, 1301–1308. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Kim, C.N. Effects of the cross-sectional area ratios and contact resistance on the performance of a cascaded thermoelectric generator. Int. J. Energy Res. 2019, 43, 2172–2187. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y. Investigation on the effect of thermal resistances on a highly concentrated photovoltaic-thermoelectric hybrid system. Energy Convers. Manag. 2016, 129, 1–10. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.; Dusel, E. The effect of thermal contact resistance on heat management in the electronic packaging. Appl. Surf. Sci. 2005, 246, 290–302. [Google Scholar] [CrossRef]

- Lin, C.; Chung, D. Nanoclay Paste as a Thermal Interface Material for Smooth Surfaces. J. Electron. Mater. 2008, 37, 1698–1709. [Google Scholar] [CrossRef] [Green Version]

- Beltrán-Pitarch, B.; Vidan, F.; García-Cañadas, J. Characterization of thermal contacts between heat exchangers and a thermoelectric module by impedance spectroscopy. Appl. Therm. Eng. 2020, 165, 114361. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, S.; Wu, Q.; Wan, N.; Pan, D.; Bai, Y. Improved electrochemical and thermal performances of layered Li[Li0.2Ni0.17Co0.07Mn0.56]O2 via Li2ZrO3 surface modification. J. Power Sources 2015, 282, 378–384. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.; Wang, F.; Wang, X.; Li, S.; Xue, M. Experimental and Numerical Study on the Effect of Interfacial Heat Transfer on Performance of Thermoelectric Generators. Energies 2019, 12, 3797. [Google Scholar] [CrossRef] [Green Version]

- Chung, D. A review of exfoliated graphite. J. Mater. Sci. 2015, 51, 554–568. [Google Scholar] [CrossRef]

- Díez, G.G.; Gordillo, J.M.S.; Pujadó, M.P.; Salleras, M.; Fonseca, L.; Morata, Á.; Rubio, A.T. Enhanced thermoelectric figure of merit of individual Si nanowires with ultralow contact resistances. Nano Energy 2020, 67, 104191. [Google Scholar] [CrossRef]

- Jeong, S.; Cruz, F.J.; Chen, S.; Gravier, L.; Liu, J.; Wu, Z.; Hjort, K.; Zhang, S.-L.; Zhang, Z. Stretchable Thermoelectric Generators Metallized with Liquid Alloy. ACS Appl. Mater. Interfaces 2017, 9, 15791–15797. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, H.; Mao, C.; Li, C.M. Silk fabric-based wearable thermoelectric generator for energy harvesting from the human body. Appl. Energy 2016, 164, 57–63. [Google Scholar] [CrossRef]

- Lee, W.; Lee, J. Development of a compact thermoelectric generator consisting of printed circuit heat exchangers. Energy Convers. Manag. 2018, 171, 1302–1310. [Google Scholar] [CrossRef]

- Madan, D.; Wang, Z.; Wright, P.K.; Evans, J.W. Printed flexible thermoelectric generators for use on low levels of waste heat. Appl. Energy 2015, 156, 587–592. [Google Scholar] [CrossRef]

- Karwa, N.; Stanley, C.; Intwala, H.; Rosengarten, G. Development of a low thermal resistance water jet cooled heat sink for thermoelectric refrigerators. Appl. Therm. Eng. 2017, 111, 1596–1602. [Google Scholar] [CrossRef]

| Application | Material | ZT | Temperature, K | Ref |

|---|---|---|---|---|

| Power generations | CuxSn1S4 | 0.6 | 370∼570 K | [12] |

| Phase-separated PbTe0.7S0.3 | >2 | 673∼923 K | [13] | |

| Mm0.9Fe3.5Co0.5Sb12-based | 0.9 | 773∼973 K | [14] | |

| Bi2Te3/Sb2Te3 superlattice | 2.4 | Room temperature | [15] | |

| Bi2(Te,Se)3 nanowire array | 1.01 | Room temperature | [16] | |

| PbTe(1−x)Se(x) alloys | 1.5 | 400∼900 K | [17] | |

| 3,4-Ethylenedioxythiophene | 0.42 | Room temperature | [18] | |

| Heat engine | CdZnTe | 283 K∼313 K | [19] | |

| Sb2Te3/Bi2Te3 Bi2Te3−xSex | 1.5 | Room temperature | [20] | |

| Bi2Te3-based thin-film superlattice | >2 | [21] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, S.; Qian, Z.; Hu, D.; Li, X.; He, W. A Comprehensive Review of Strategies and Approaches for Enhancing the Performance of Thermoelectric Module. Energies 2020, 13, 3142. https://doi.org/10.3390/en13123142

Lv S, Qian Z, Hu D, Li X, He W. A Comprehensive Review of Strategies and Approaches for Enhancing the Performance of Thermoelectric Module. Energies. 2020; 13(12):3142. https://doi.org/10.3390/en13123142

Chicago/Turabian StyleLv, Song, Zuoqin Qian, Dengyun Hu, Xiaoyuan Li, and Wei He. 2020. "A Comprehensive Review of Strategies and Approaches for Enhancing the Performance of Thermoelectric Module" Energies 13, no. 12: 3142. https://doi.org/10.3390/en13123142