On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals

Abstract

1. Introduction

2. Design and Implementation of On-Line PD Monitoring System

2.1. General Structure of On-Line PD Monitoring System

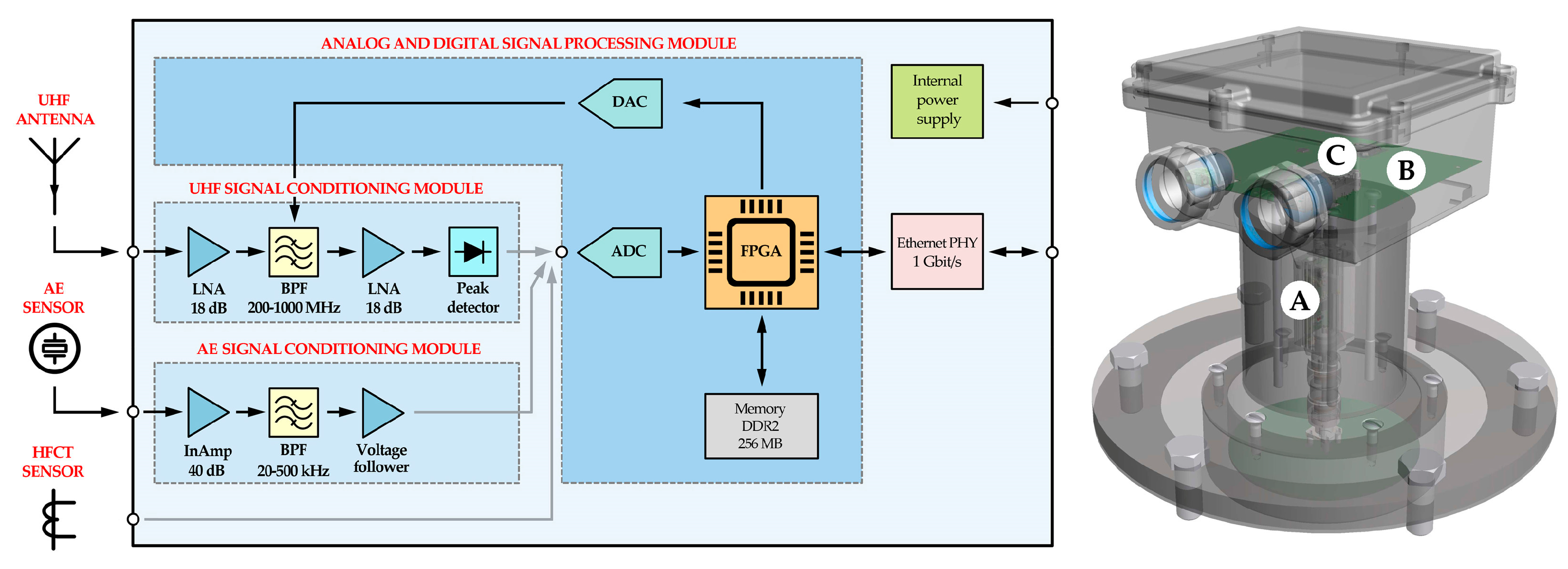

2.2. Partial Discharge Detectors

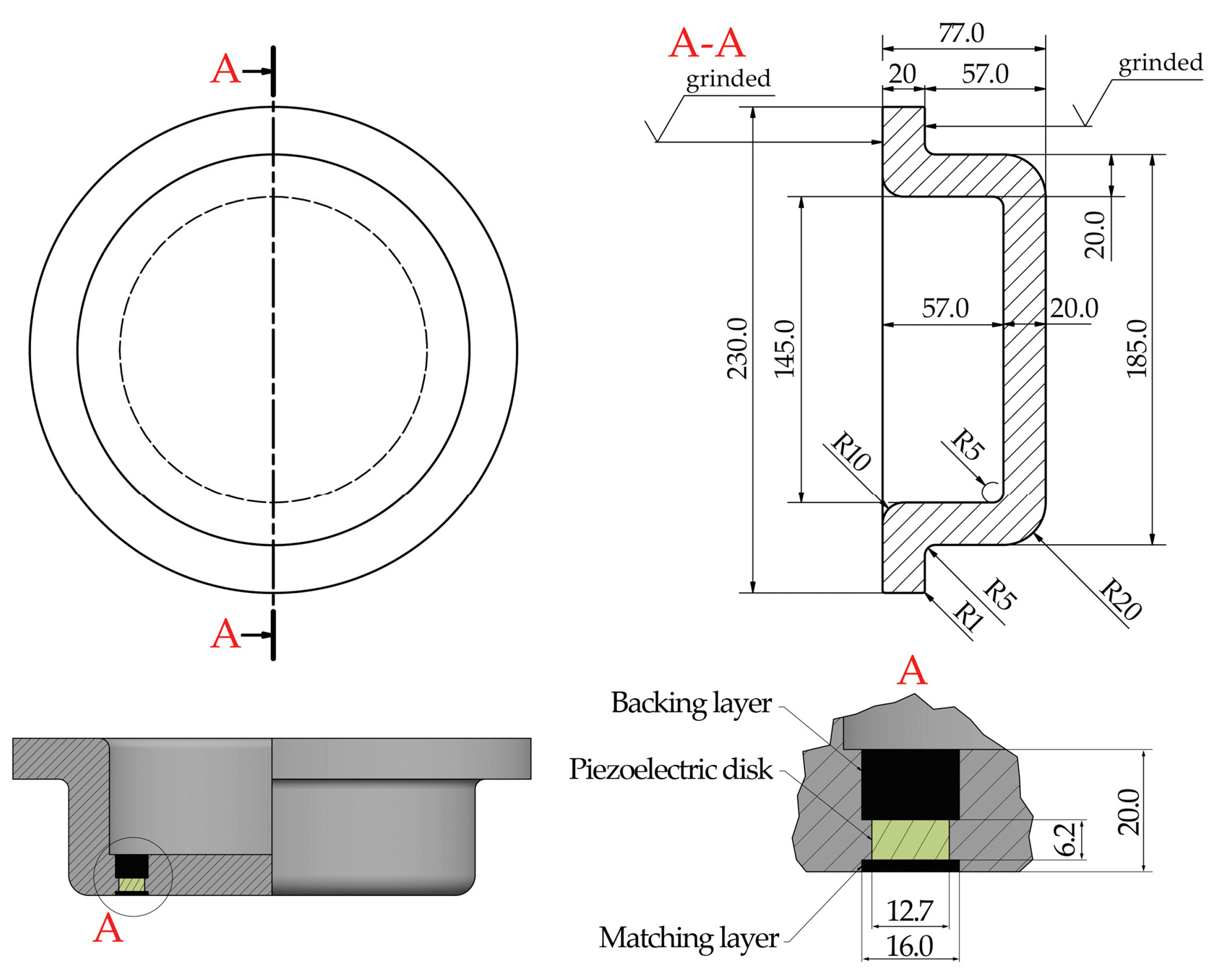

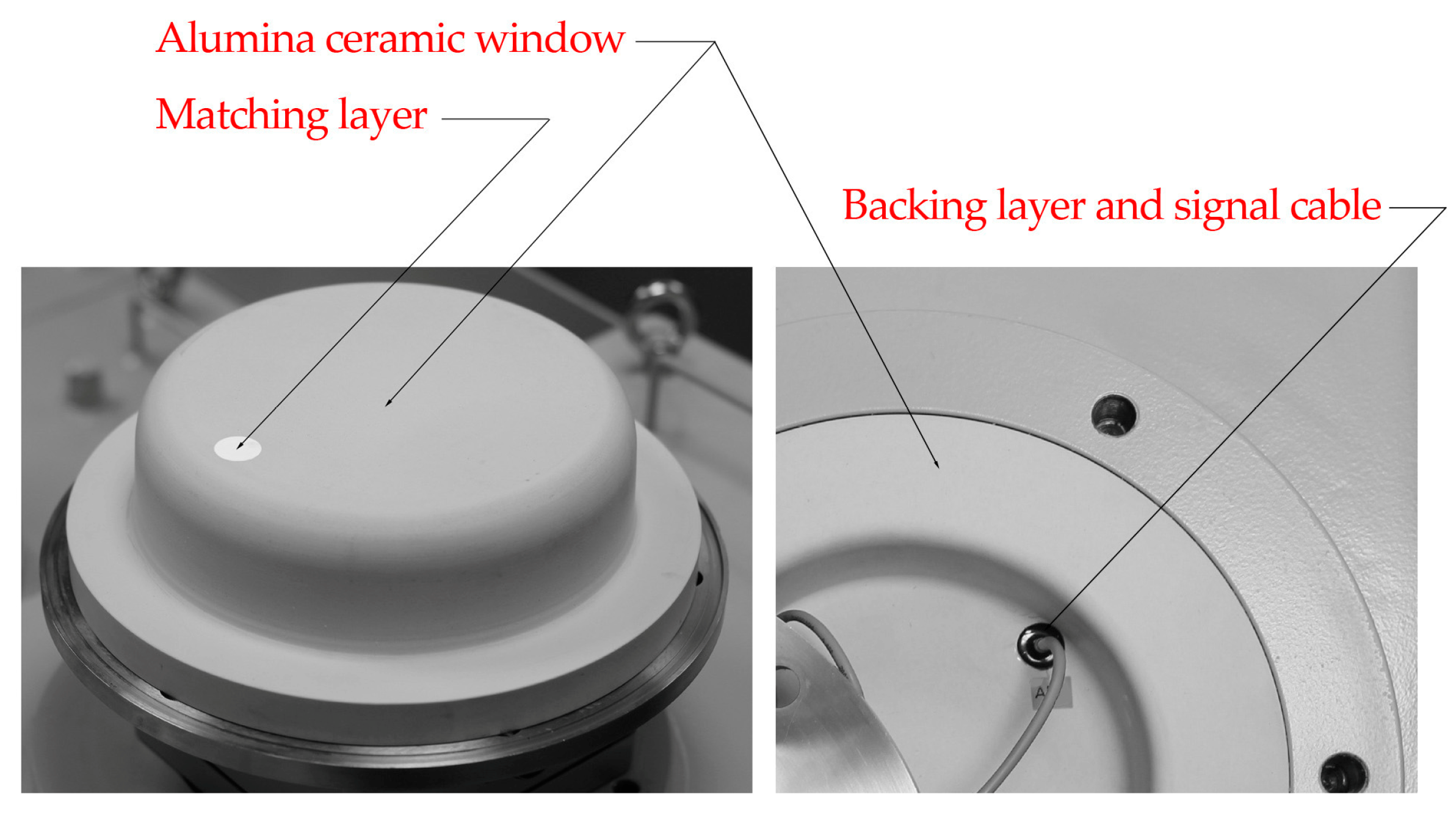

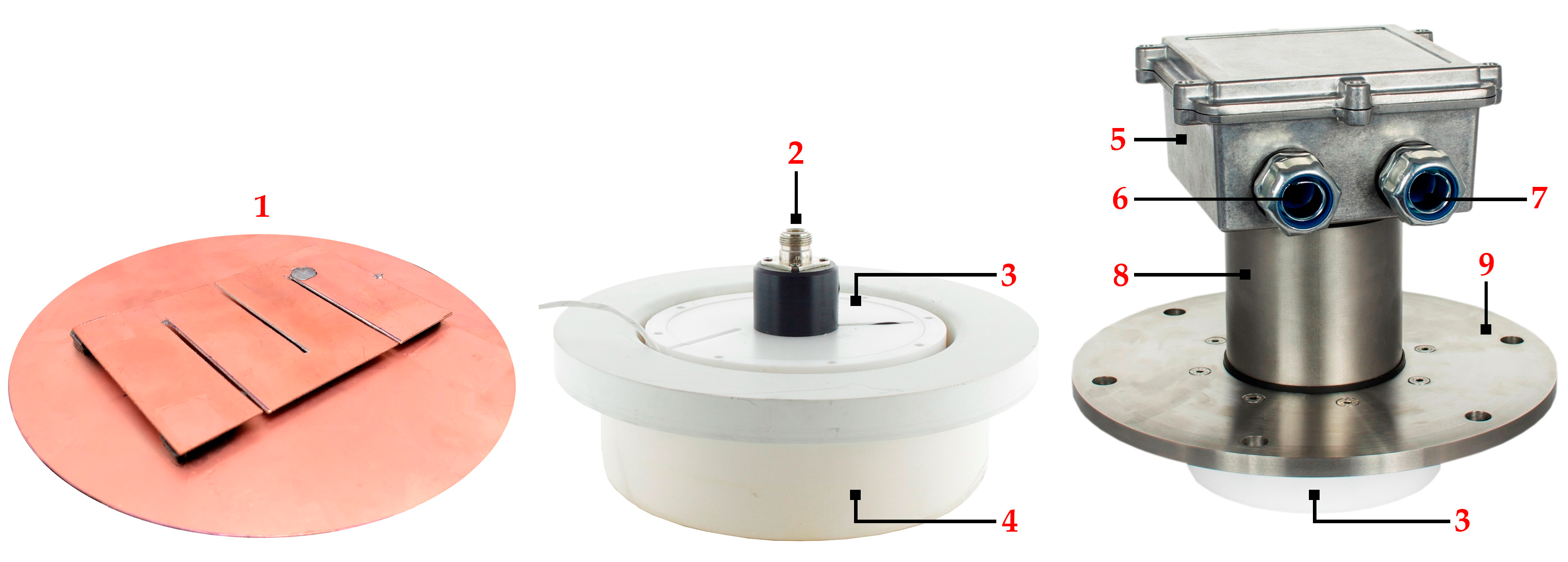

2.2.1. Active Dielectric Window

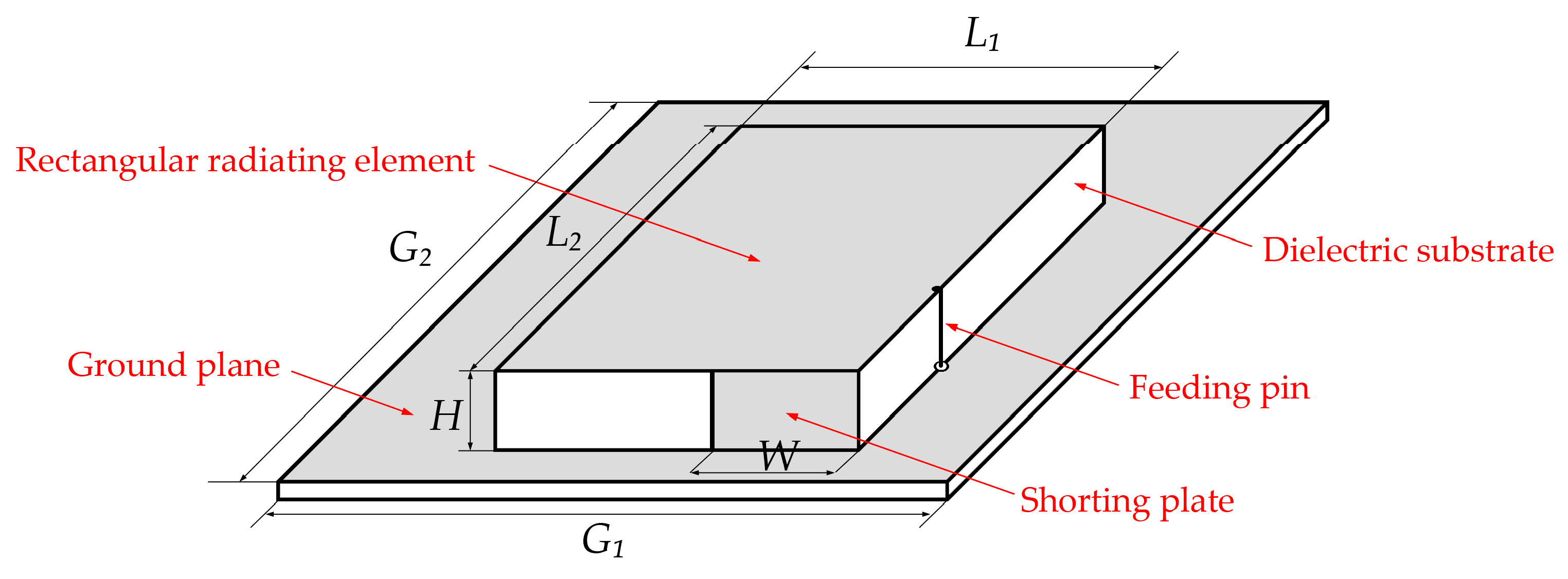

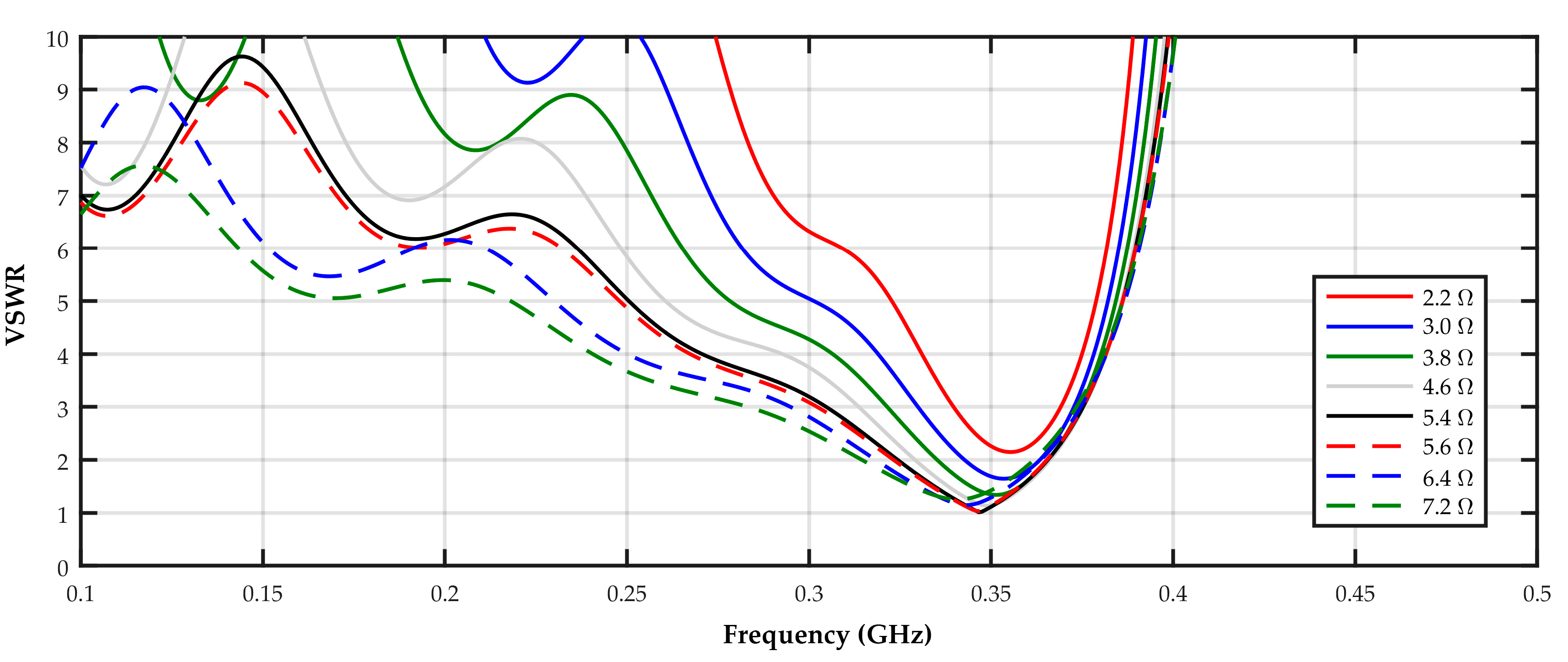

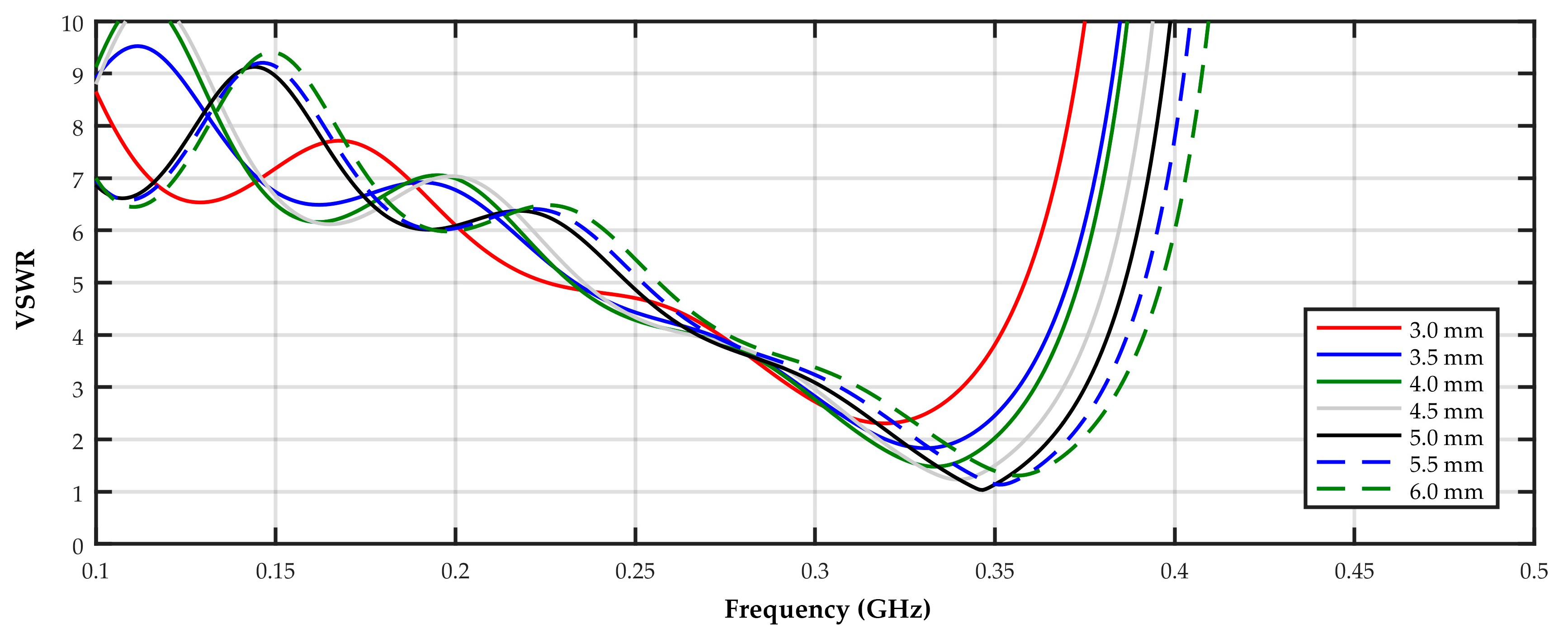

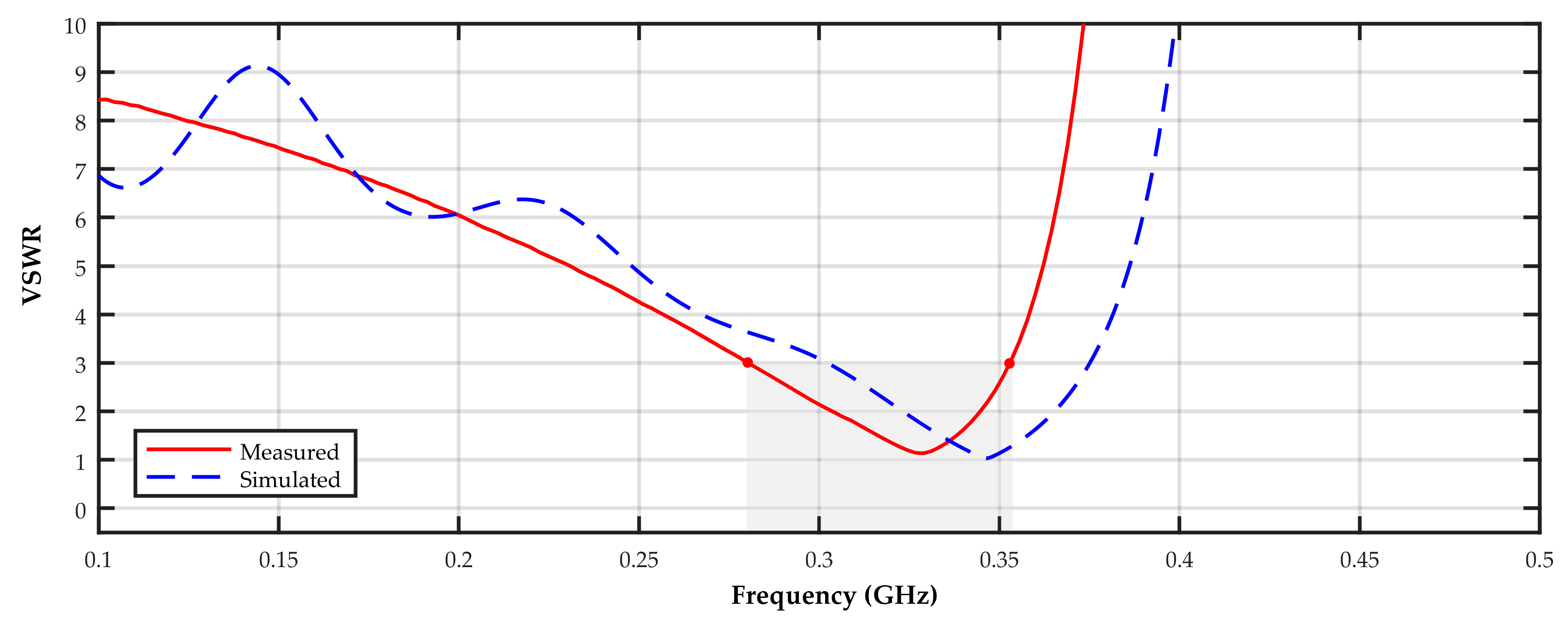

2.2.2. Ultra-High Frequency Antenna

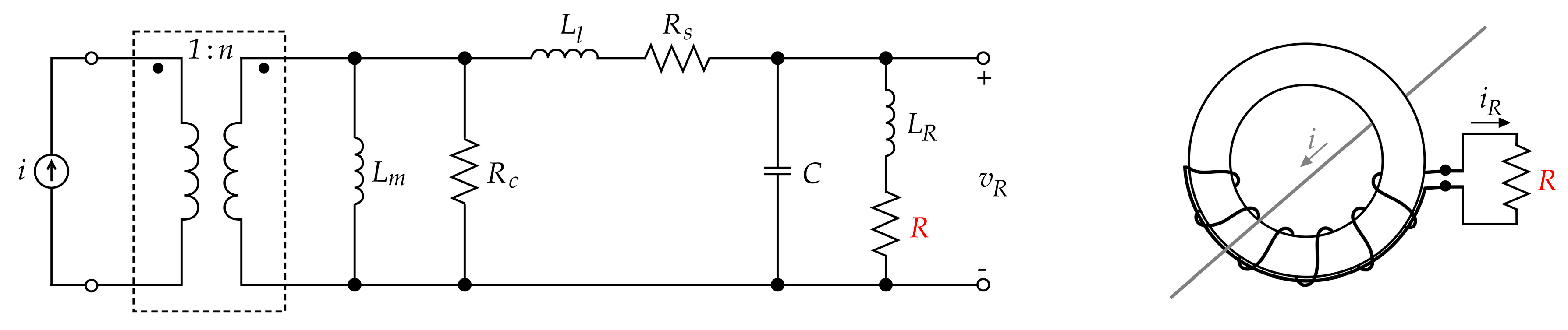

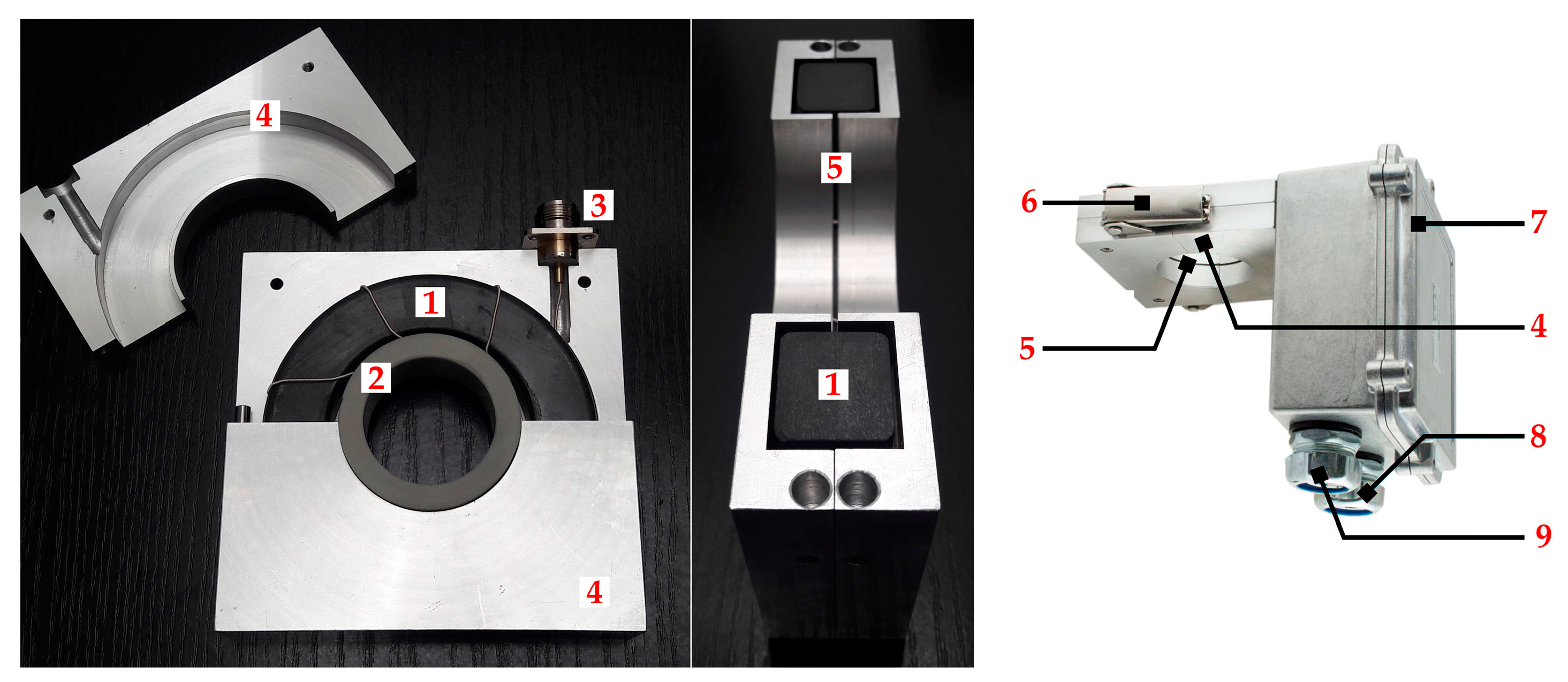

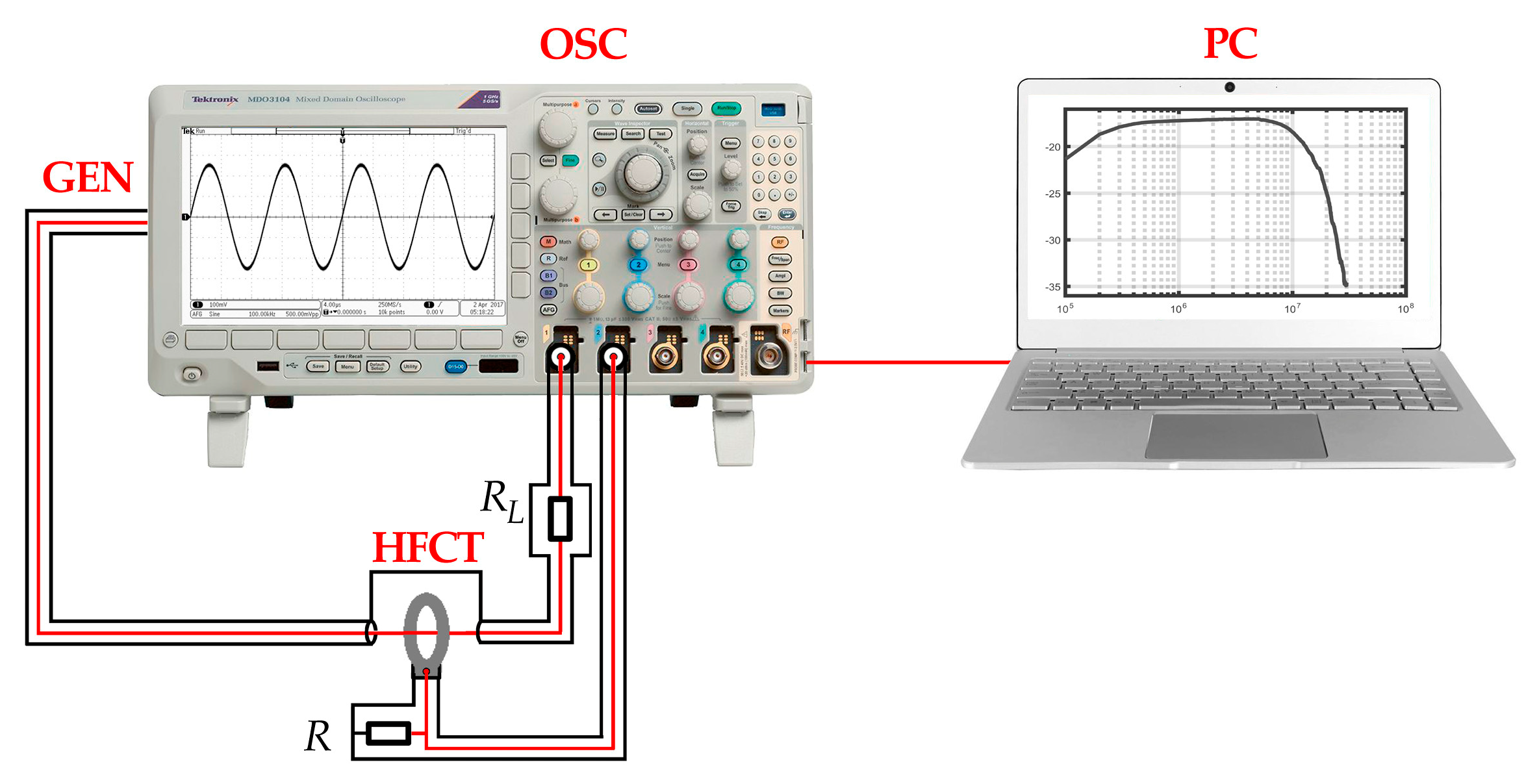

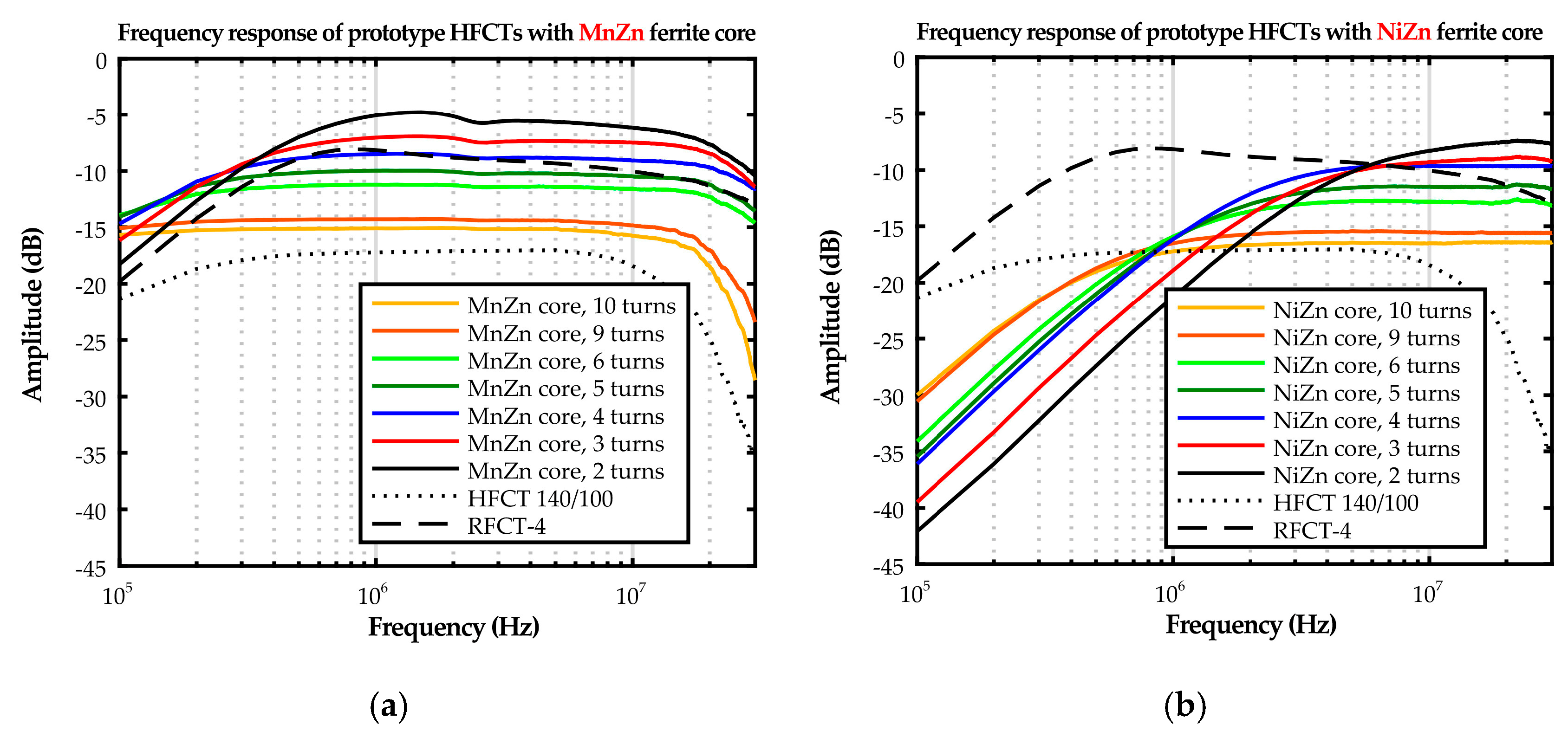

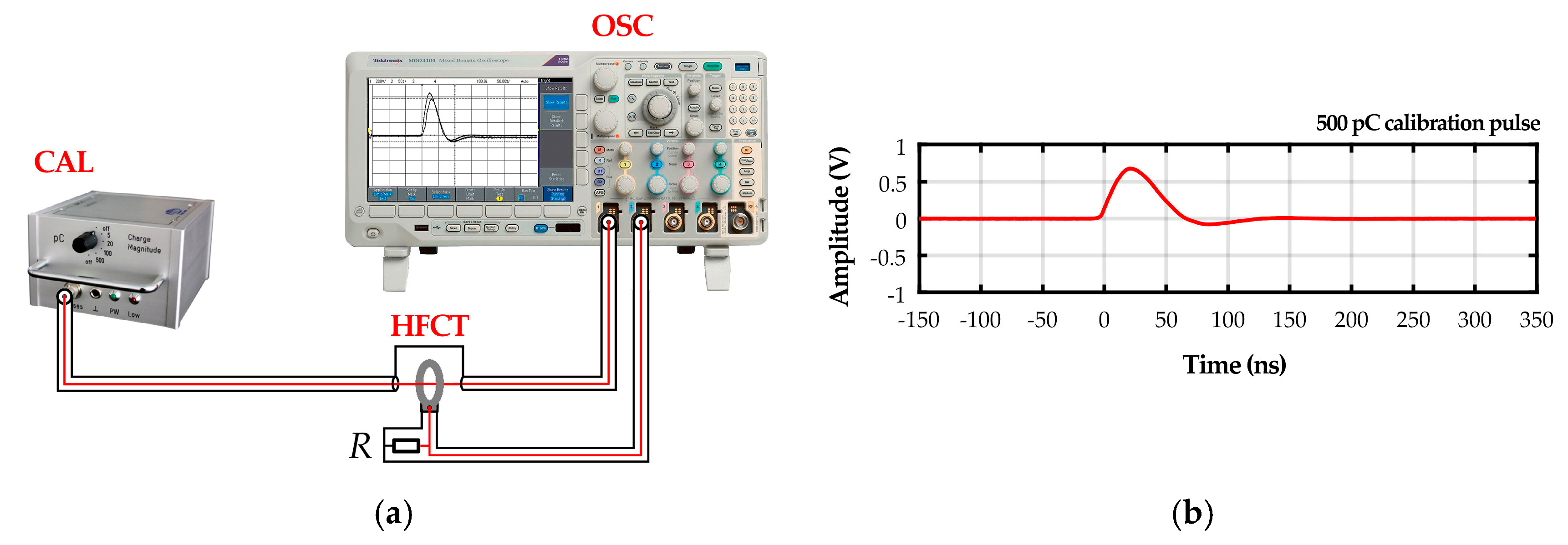

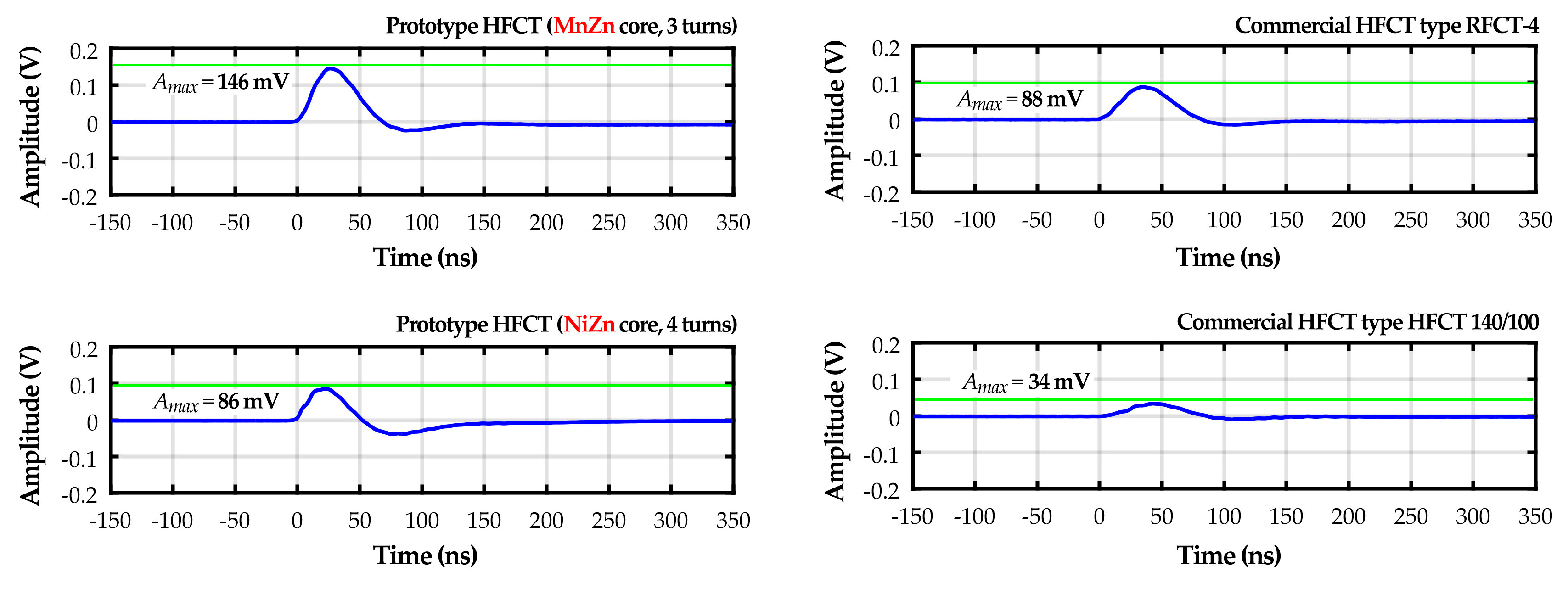

2.2.3. High-Frequency Current Transformer

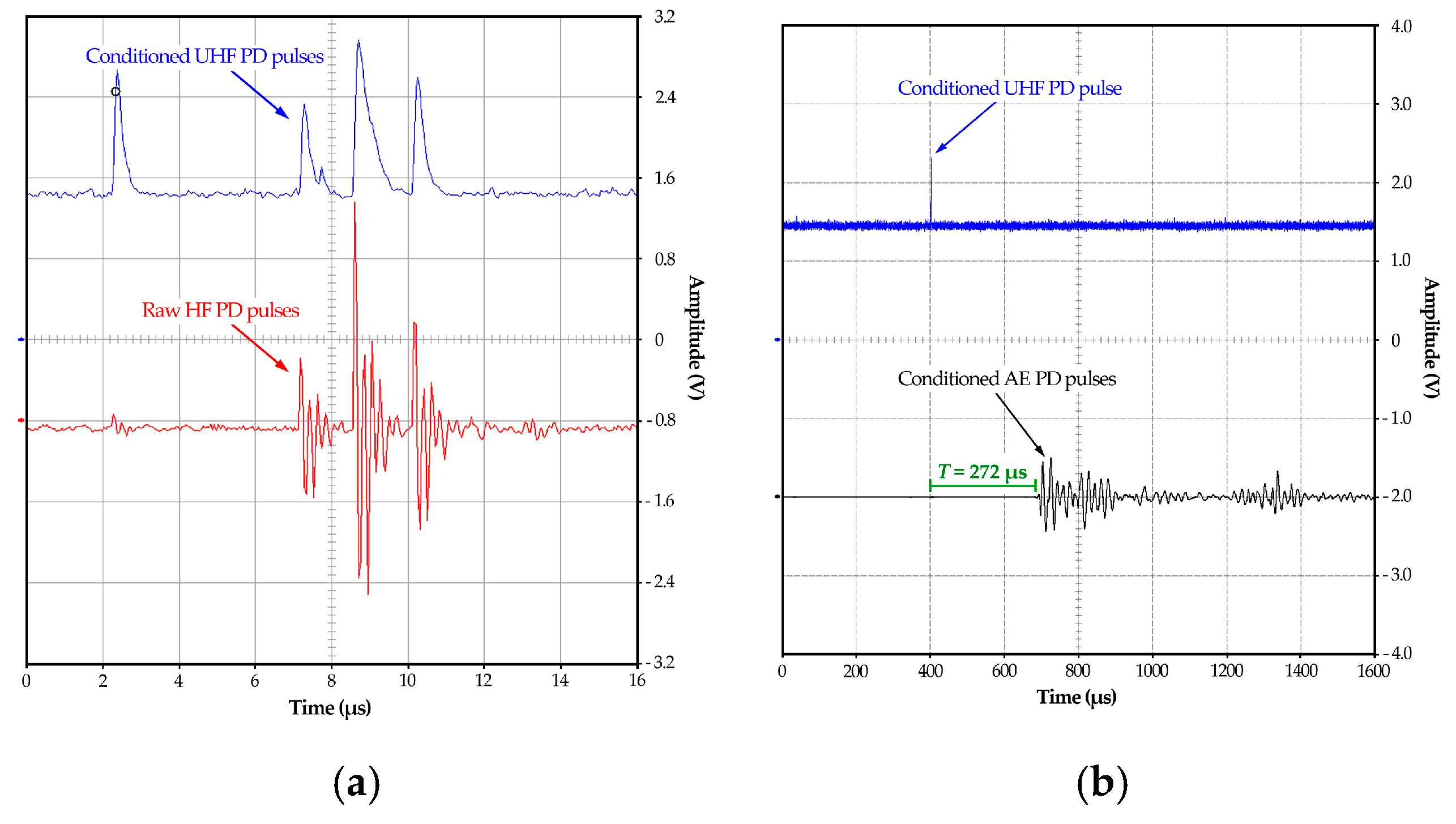

2.3. Module for Conditioning and Analog-to-Digital Signal Processing of PD Pulses

- the number of pulses detected (n),

- the maximal amplitude of the pulses (Amax),

- the maximal energy of the pulses (Emax),

- the average amplitude of the pulses (Amean),

- the average energy of the pulses (Emean).

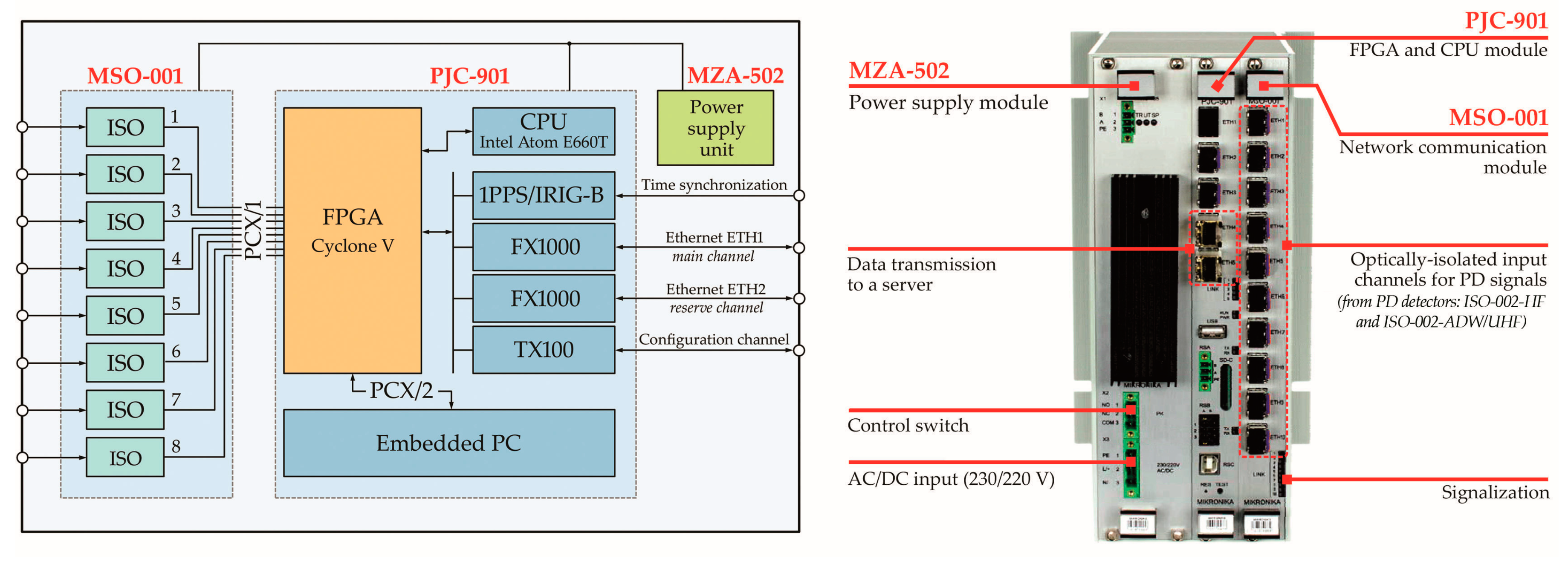

2.4. Multi-Channel Data Concentrator Module

- the basic channel of the Ethernet network in standard FX1000 used for data transmission, warning signals, download the parameterization from the server,

- configuration channel in TX100 standard dedicated to programming, local parameterization, and service,

- synchronizing channel in 1PPS or IRIGB standard.

2.5. Modules of Server Software

- the number of detected PD pulses and the average value of their energies and amplitudes,

- the result of self-diagnosis of measurement channels,

- warning or alarm state after exceeding the threshold values for the sum of registered pulses, their average energy, and amplitude for various time intervals: 15 min, 60 min, 24 h, and 30 days,

- the warning or alarm state when the values of PD parameters collected during last week and last month show a rising trend.

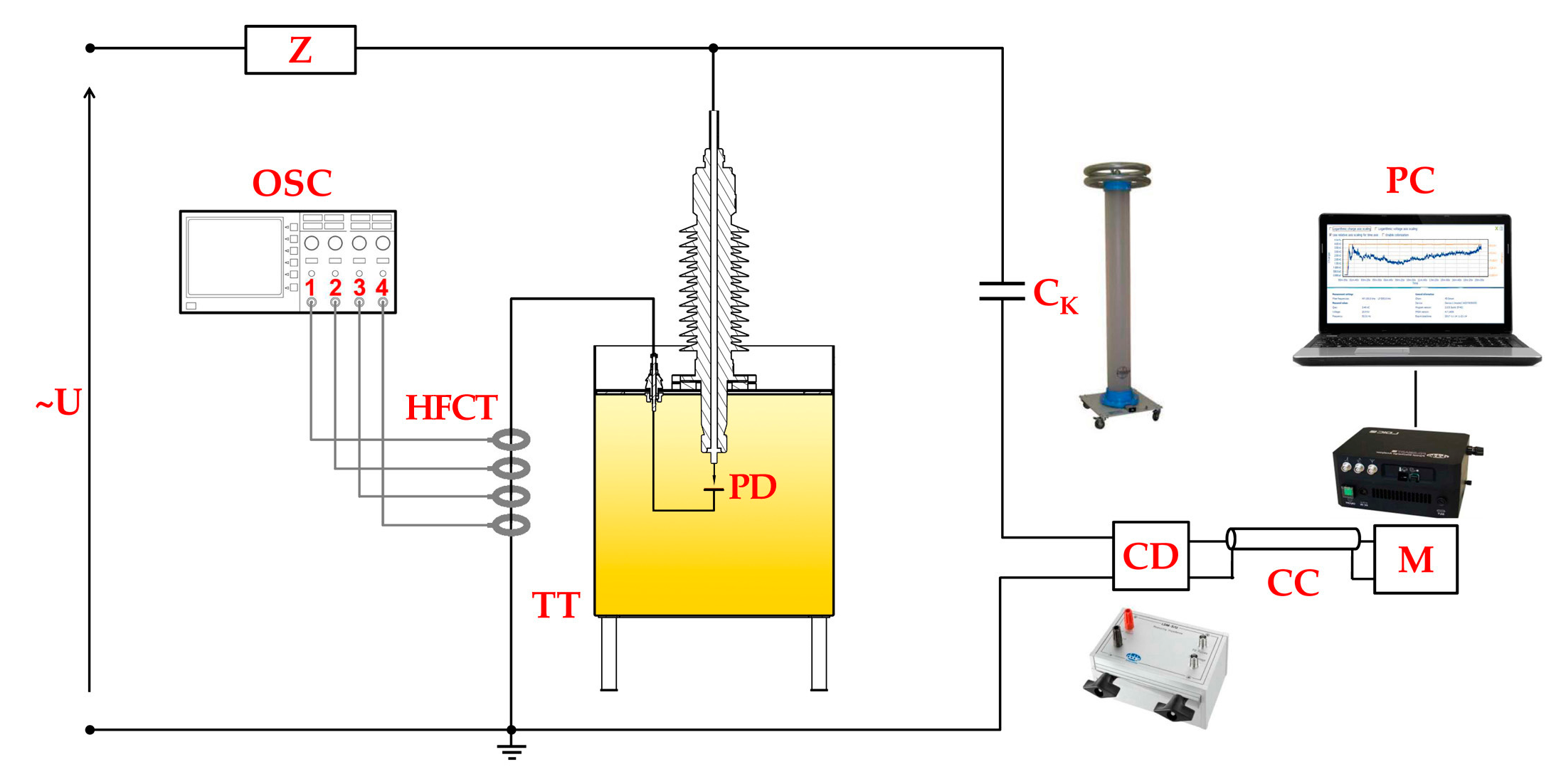

3. Tests of the Developed PD Monitoring System on Power Transformers

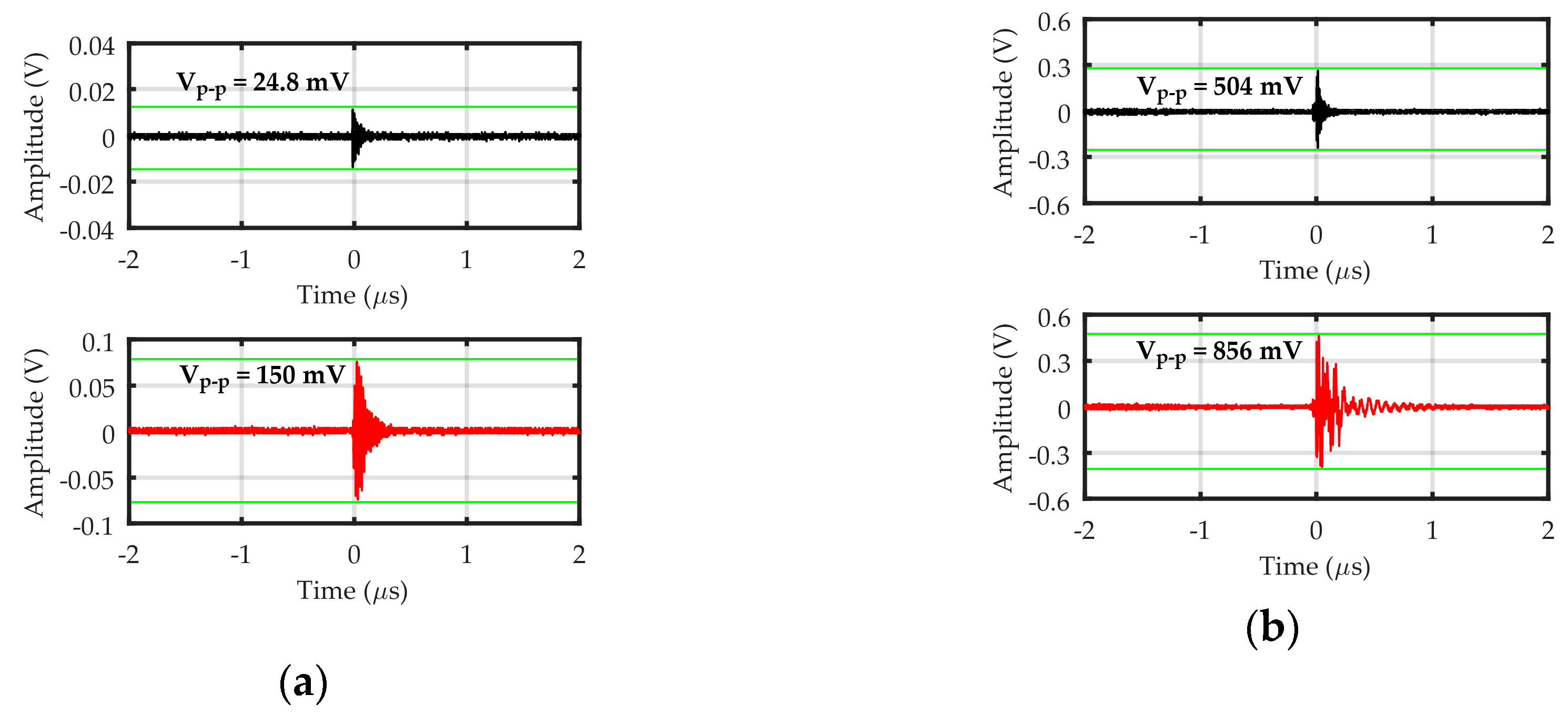

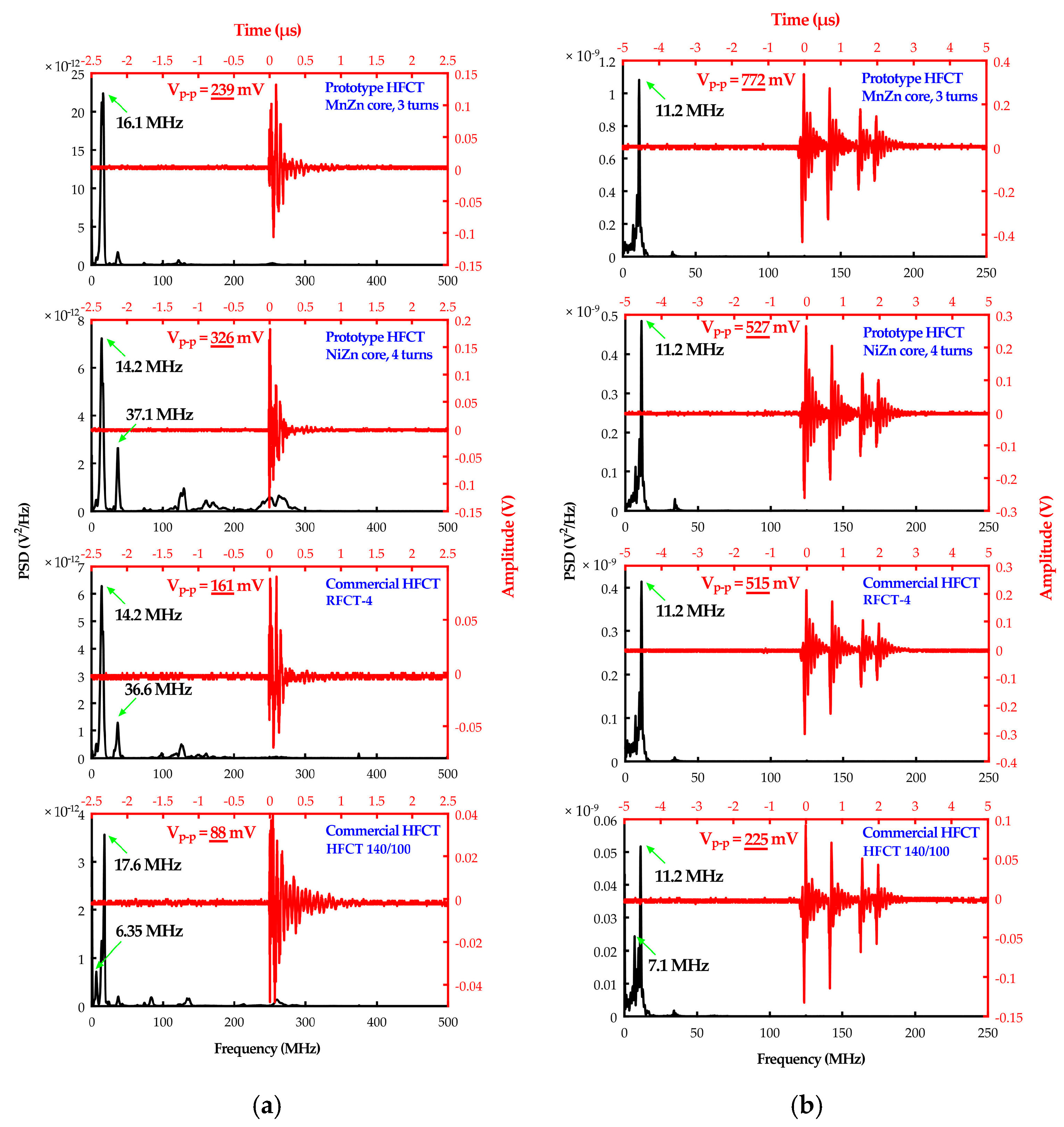

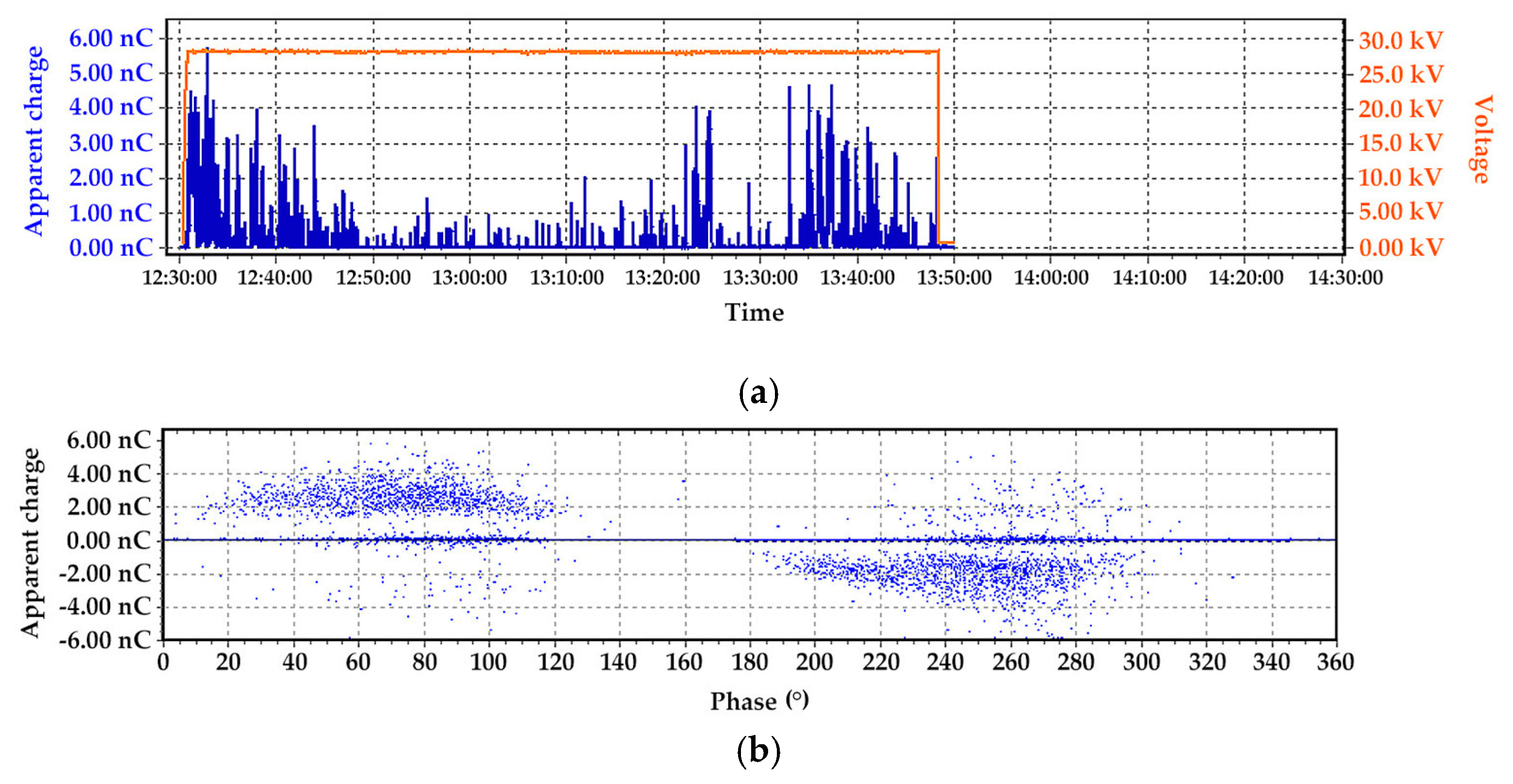

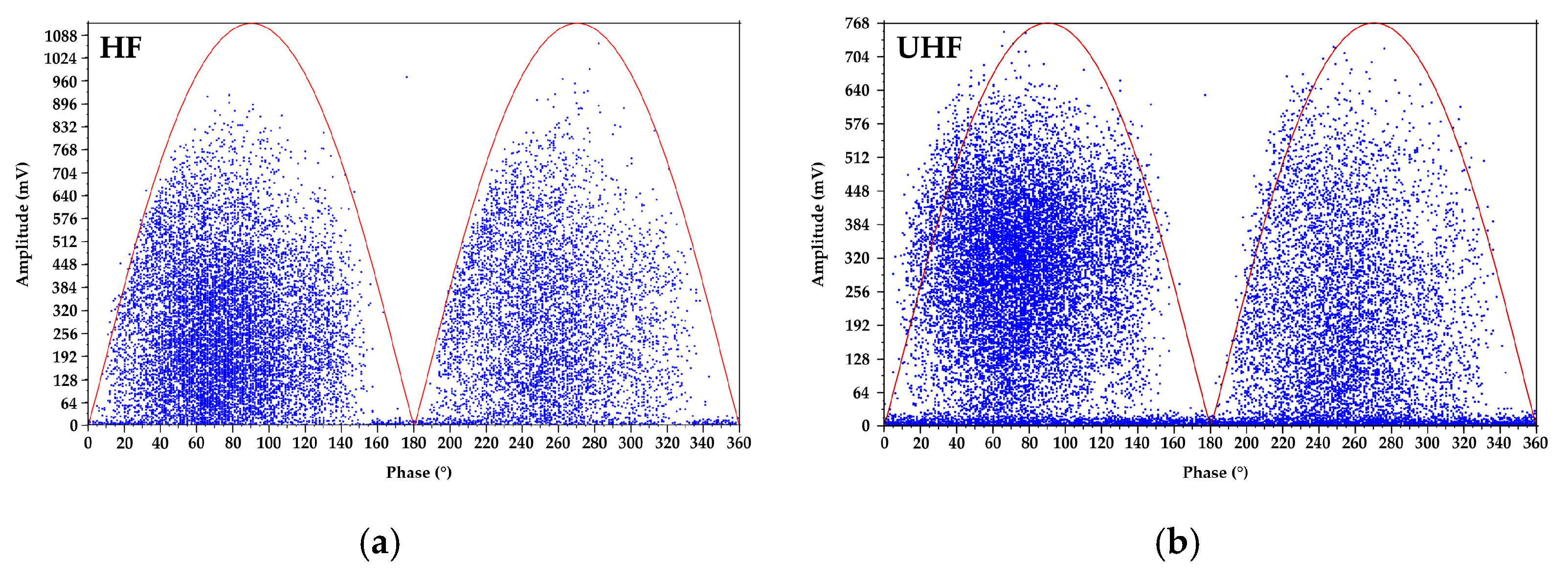

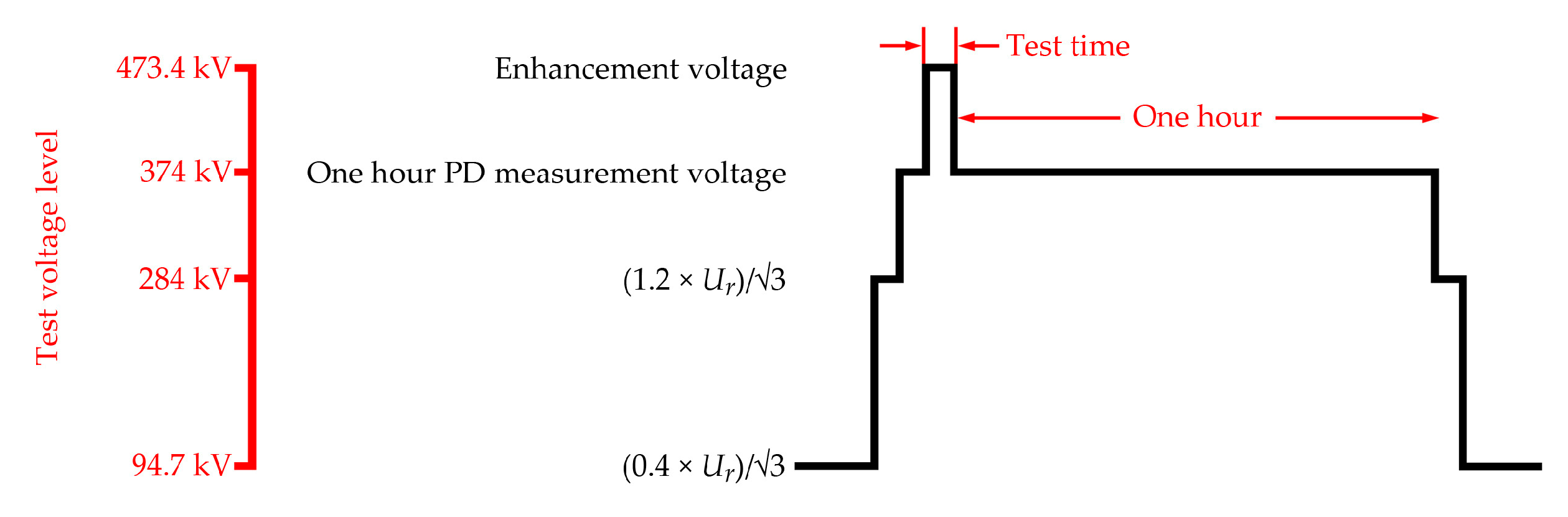

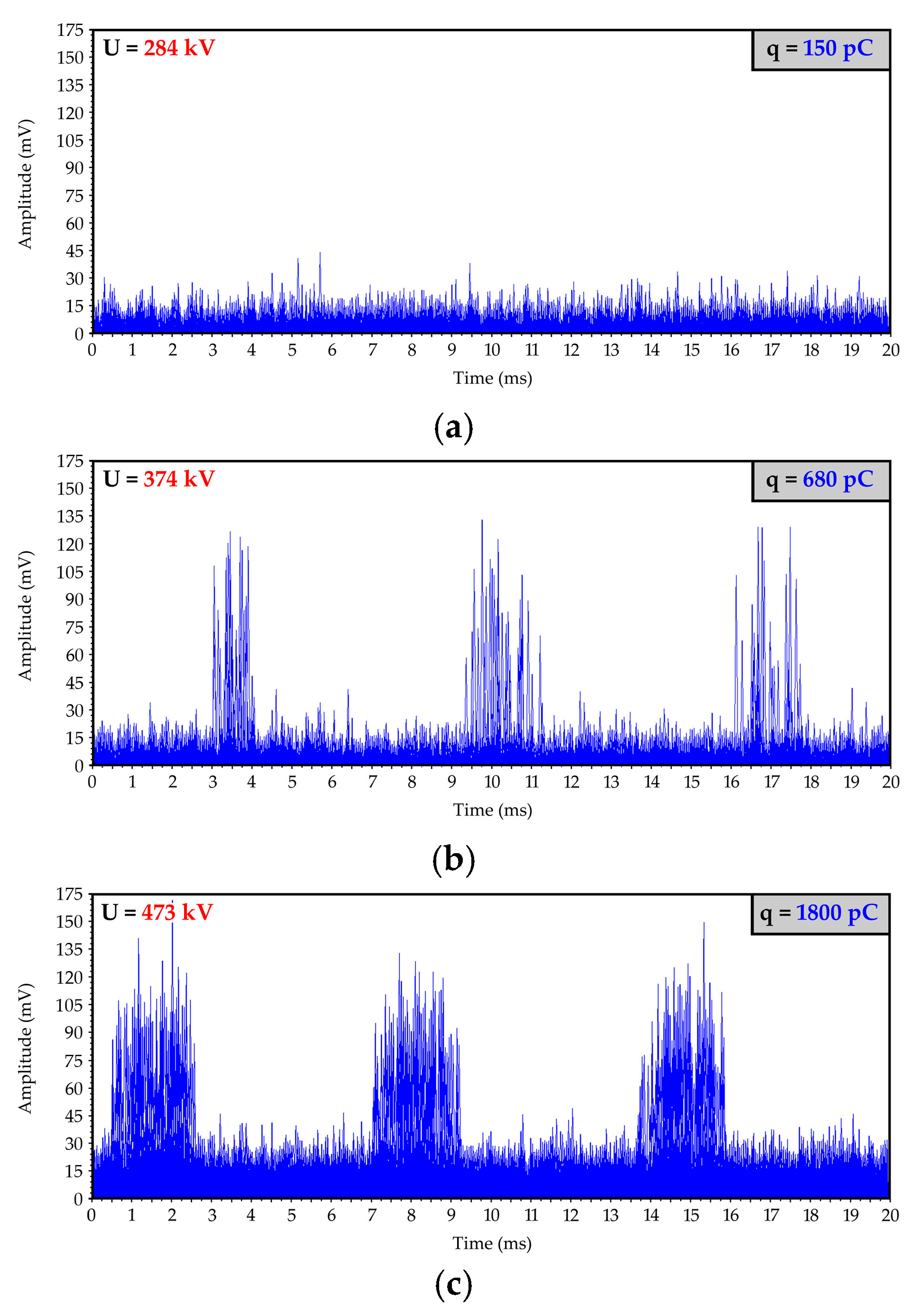

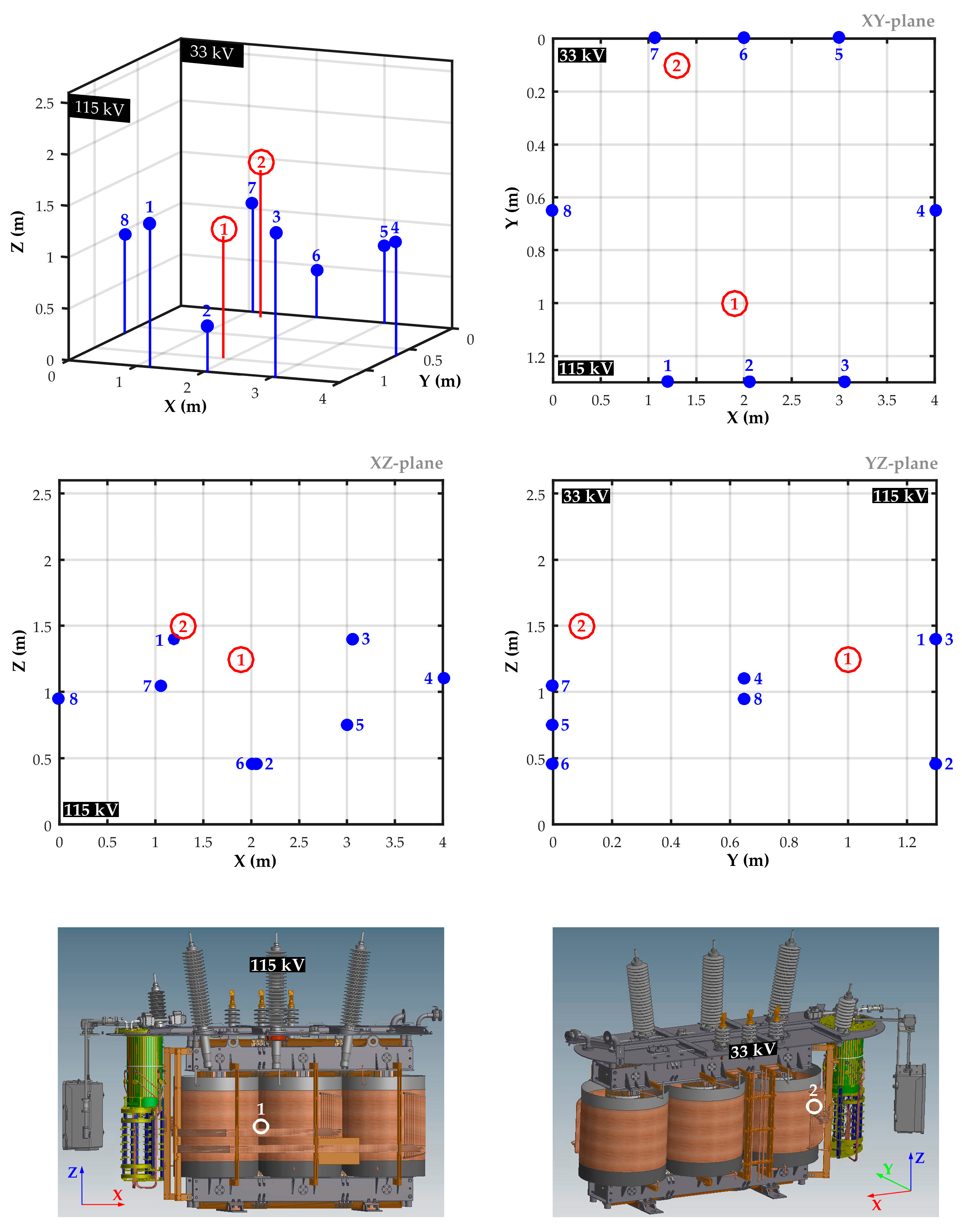

3.1. Test of the Monitoring System During Induced Voltage Test of 330 MVA Power Transformer

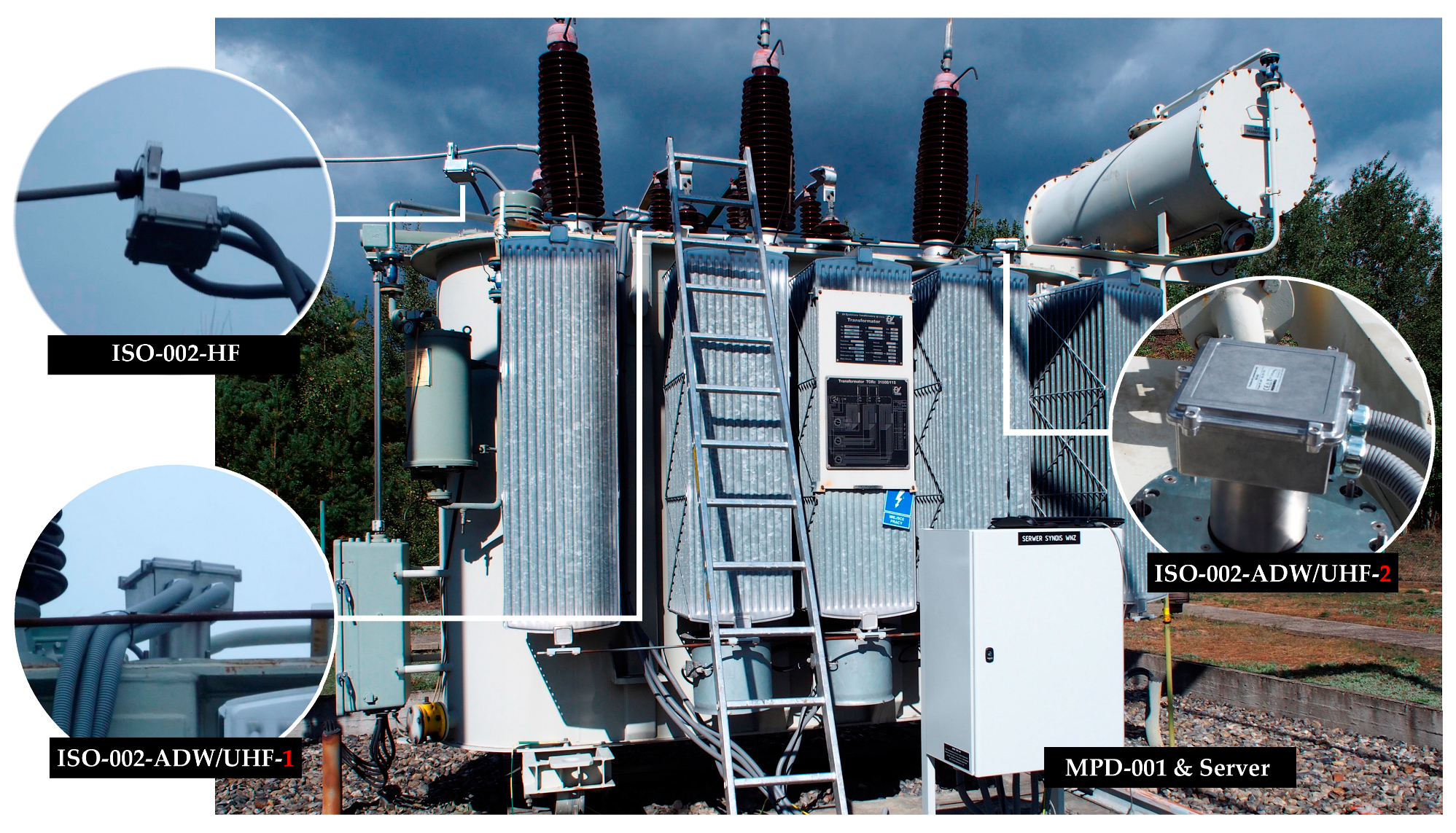

3.2. Test of the System on 31.5 MVA Power Transformer

- Partial discharges were registered every day, and their activity was the highest mainly for hours from 8:45 a.m. to 5:45 p.m. (these time intervals are indicated in Figure 32 as grey bands). The sum of PD pulses from this time intervals constitutes 68.9% of all registered pulses.

- The peak intensity of partial discharges occurred between 1:00 p.m. and 3:00 p.m. In this short period, almost one-quarter (24.4 %) of all PD pulses were detected.

- The Pearson correlation coefficient between the hourly distribution of the UHF and AE pulses for sensor ISO-002-ADW/UHF-1 was r = 0.87 with significance p = 0.001 (very strong positive correlation), and for sensor ISO-002-ADW/UHF-2 it was r = 0.45 with significance p = 0.027 (moderate positive correlation). Both hourly distributions of the UHF and AE pulses are presented in Figure 33.

- The hourly distribution of the PD pulses registered with the high-frequency current transformer ISO-002-HF was correlated the most with the distribution obtained for the AE transducer (r = 0.68, p < 0.001) and the UHF antenna (r = 0.62; p = 0.001) of the sensor ISO-002-ADW/UHF-1. In the case of the sensor ISO-002-ADW/UHF-2 the correlation was lower at the level of r = 0.44 with significance p = 0.029 for the distribution obtained for the AE transducer and r = 0.22 with significance p = 0.031 for the distribution obtained for the UHF antenna.

- The voltage value was changing in a narrow range from 113.3 to 117.6 kV, wherein the average, variance, and standard deviation were, respectively, equal to M = 115.3 kV, s2 = 0.47, and SD = 0.69. Due to the small voltage variation, it was decided not to investigate its influence on partial discharges intensity.

- During the 8-days-operation of the system, the power transformer was loaded with relatively low power from only 0.68 to 11.34 MVA, which constituted, respectively, 2.15% and 36.00% of its rated power. The average value of the load was equal to M = 5.31 MVA, variance s2 = 6.16, and standard deviation SD = 2.48.

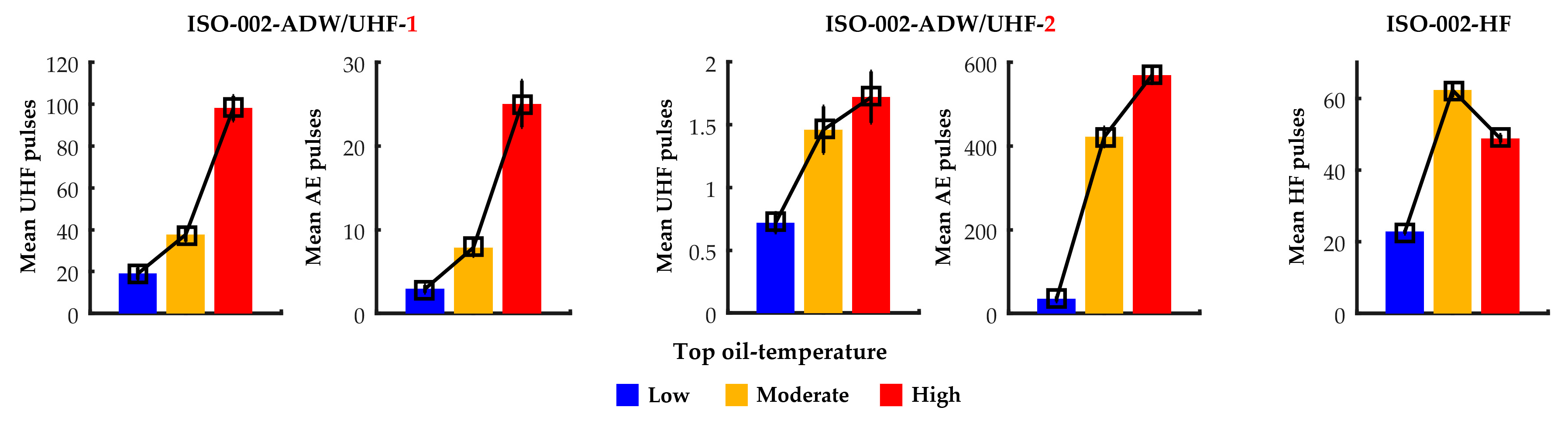

- The oil temperature was changing in a wide band from 14.0 to 36.1 °C. It was observed that daily “hills” and local peaks of the oil temperature curve overlap the period of higher activity of partial discharges. (from 8:45 a.m. to 5:45 p.m.) (see Figure 32). In turn, for daily “valleys” of the oil temperature curve, a clear reduction or complete disappearance of the partial discharges activity was observed. In order to test the hypothesis relating to the influence of the level of oil temperature on partial discharges intensity in the monitored power transformer, it was decided to conduct a one-way analysis of variance (ANOVA) for independent samples. One of the main assumptions of the ANOVA is that the independent variable consists of two or more categorical, independent, and equinumerous groups. The categorization of the daily oil temperature values (independent variable) was carried out using tertiles, in order to obtain three equinumerous groups. The “low” temperature category was ascribed to lower tertile, whereas “moderate” and “high” temperature categories to middle and higher tertiles, respectively. Since the assumption of homogeneity of variance was violated (Levene’s test for equality of variances was statistically significant), therefore the Brown–Forsythe and Welch F-ratios are reported. The results of both robust tests of equality of means are listed in Table 6. The results of the analysis showed that the compared groups differ from one another statistically, which means that the oil temperature level differentiates the number of PD pulses. Figure 34 illustrates the value of the average number of the AE, UHF, and HF pulses between particular oil temperature levels (low, moderate, and high), which indicate a strong causal relationship between these variables. Figures obtained for the sensors ISO-002-ADW/UHF1 and ISO-002-ADW/UHF2 show that the higher the oil temperature level was, the higher was the number of the registered AE and UHF pulses. The exception is the high-frequency current transformer ISO-002-HF sensor, for which the highest average number of HF pulses was registered for the average oil temperature level. To investigate which compared groups are statistically significantly different from one another, the Gamesa–Howell post hoc test, which is recommended in the situation when the assumption of homogeneity of variance in the compared groups was violated. The post hoc comparisons revealed statistically significant differences (p < 0.0005) between all groups (oil temperature levels) except the groups “moderate” and “high” temperature for the UHF pulses registered with the sensor ISO-002-ADW/UHF-2 (Table 7). The highest differences in the number of PD pulses were observed between groups “low” and “high” temperature. As it was mentioned before, the voltage value variability was low. Therefore, while interpreting the obtained results it may be concluded that in the monitored power transformer, the oil temperature growth is a significant factor inducing partial discharges. This hypothesis is in line with the research results, which showed that the temperature growth in combination with an increased moisture content of the oil-paper insulation system may induce the activity growth of partial discharges [107,108,109,110]. Additionally, the presence of water molecules in oil as a result of the moisture migration process, as well as the effect of gas bubbles exuding from cellulose insulation, may significantly influence the intensification of the PD phenomenon [15,111,112,113,114,115,116].

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tenbohlen, S.; Jagers, J.; Vahidi, F.; Bastos, G.; Desai, B.; Diggin, B.; Fuhr, J.; Gebauer, J.; Krüger, M.; Lapworth, J.; et al. Transformer Reliability Survey; Technical Brochure 642; CIGRE: Paris, France, 2015. [Google Scholar]

- Foros, J.; Istad, M. Health Index, Risk and Remaining Lifetime Estimation of Power Transformers. IEEE Trans. Power Deliv. Early Access 2020, 7. [Google Scholar] [CrossRef]

- Ortiz, F.; Fernandez, I.; Ortiz, A.; Renedo, C.J.; Delgado, F.; Fernandez, C. Health indexes for power transformers: A case study. IEEE Electr. Insul. Mag. 2016, 32, 7–17. [Google Scholar] [CrossRef]

- Krüger, M.; Koch, M.; Kraetge, A.; Rethmeier, K.; Energy, O.; Dierks, A.A. Diagnostic measurements on power transformers. Energetyka 2009, 5, 299–305. [Google Scholar]

- Hori, M.; Nishioka, M.; Ikeda, Y.; Noguchi, K.; Kajimura, K.; Motoyama, H.; Kawamura, T. Internal winding failure due to resonance overvoltage in distribution transformer caused by winter lightning. IEEE Trans. Power Deliv. 2006, 21, 1600–1606. [Google Scholar] [CrossRef]

- Metwally, I.A. Failures, monitoring and new trends of power transformers. IEEE Potentials 2011, 30, 36–43. [Google Scholar] [CrossRef]

- Kassi, K.S.; Fofana, I.; Meghnefi, F.; Yeo, Z. Impact of local overheating on conventional and hybrid insulations for power transformers. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2543–2553. [Google Scholar] [CrossRef]

- Paoletti, G.; Golubev, A. Partial discharge theory and applications to electrical systems. In Proceedings of the Conference Record of 1999 Annual Pulp and Paper Industry Technical Conference (Cat. No. 99CH36338), Seattle, WA, USA, 21–25 June 1999; pp. 124–138. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K. PDtracker–system monitoringu wyładowań niezupełnych w transformatorze energetycznym. Prz. Elektrotechniczny 2014, 10, 45–49. [Google Scholar]

- Badicu, L.V.; Broniecki, U.; Koltunowicz, W.; Körber, S.; Krüger, M.; Voegel, E. Prevention of transformer failure through continuous monitoring. In Proceedings of the XIXth International Symposium on High Voltage Engineering (ISH), Pilsen, Czech Republic, 23–28 August 2015. Paper Number 274. [Google Scholar]

- Gockenbach, E.; Borsi, H. Condition monitoring and diagnosis of power transformers. In Proceedings of the 2008 International Conference on Condition Monitoring and Diagnosis, Beijing, China, 21–24 April 2008; pp. 894–897. [Google Scholar] [CrossRef]

- Mondal, M.; Kumbhar, G.B. Detection, measurement, and classification of partial discharge in a power transformer: Methods, trends, and future research. IETE Tech. Rev. 2018, 35, 483–493. [Google Scholar] [CrossRef]

- IEEE Guide for Application for Monitoring Equipment to Liquid-Inmersed Transformers and Components; IEEE: Piscataway, NJ, USA, 2012.

- Zhao, W.B.; Zhang, G.J.; Sun, Y.; Yan, Z.; Xu, D.K. Online Multisensor Monitoring System For Insulation Condition Of Oil-Immersed Power Transformer. In Proceedings of the IEEE International Symposium on Electrical Insulation, Indianapolis, IN, USA, 19–22 September 2004; pp. 89–92. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture migration in an oil-paper insulation system in relation to online partial discharge monitoring of power transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Moranda, H.; Gil, W.; Andrzejewski, M. Partial discharge on-line monitoring system based on acoustic emission method—Operational experiences. Prz. Elektrotechniczny 2012, 88, 117–121. [Google Scholar]

- Castro, B.; Clerice, G.; Ramos, C.; Andreoli, A.; Baptista, F.; Campos, F.; Ulson, J. partial discharge monitoring in power transformers using low-cost piezoelectric sensors. Sensors 2016, 16, 1266. [Google Scholar] [CrossRef]

- Tenbohlen, S.; Beltle, M.; Siegel, M. PD monitoring of power transformers by UHF sensors. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 12–15 September 2017; Volume 1, pp. 303–306. [Google Scholar] [CrossRef]

- Judd, M.D.; Yang, L.; Hunter, I.B. Partial discharge monitoring of power transformers using UHF sensors. Part I: Sensors and signal interpretation. IEEE Electr. Insul. Mag. 2005, 21, 5–14. [Google Scholar] [CrossRef]

- Judd, M.D. Experience with UHF partial discharge detection and location in power transformers. In Proceedings of the Electrical Insulation Conference (EIC), Annapolis, MD, USA, 5–8 June 2011; pp. 201–205. [Google Scholar] [CrossRef]

- Chai, H.; Phung, B.T.; Mitchell, S. Application of UHF sensors in power system equipment for partial discharge detection: a review. Sensors 2019, 19, 1029. [Google Scholar] [CrossRef]

- Braunlich, R.; Hassig, M.; Fuhr, J.; Aschwanden, T. Assessment of insulation condition of large power transformers by on-site electrical diagnostic methods. In Proceedings of the IEEE International Symposium on Electrical Insulation, Anaheim, CA, USA, 2–5 April 2000; pp. 368–372. [Google Scholar] [CrossRef]

- International Electrotechnical Commission (IEC). High Voltage Test Techniques—Measurement of Partial Discharges by Electromagnetic and Acoustic Methods; IEC TS 62478:2016; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2016. [Google Scholar]

- Sikorski, W. Development of acoustic emission sensor optimized for partial discharge monitoring in power transformers. Sensors 2019, 19, 1865. [Google Scholar] [CrossRef] [PubMed]

- Mackenzie, E.A.; Crossey, J.; DePablo, A.; Ferguson, W. On-line monitoring and diagnostics for power transformers. In Proceedings of the IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar] [CrossRef]

- IEEE Guide for the Detection, Location and Interpretation of Sources of Acoustic Emissions from Electrical Discharges in Power Transformers and Power Reactors; IEEE Std C57.127-2018 (Revision of IEEE Std C57.127-2007); IEEE 2019. Available online: https://ieeexplore.ieee.org/document/8664690 (accessed on 24 June 2020). [CrossRef]

- Cavallini, A.; Ramos, C.G.A.; Montanari, G.C.; Saad, H.; Tozzi, M. UHF detection of PD in power transformers: The influence of disturbances. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 16–19 October 2011; pp. 436–439. [Google Scholar] [CrossRef]

- Cavallini, A.; Rubio Serrano, J.; Azcarraga Ramos, C.G.; Garcia Souto, J.A.; Montanari, G.C. Comparison of ultrasonic, electrical and UHF characteristics of partial discharge emission in oil/paper insulation systems. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 16–19 October 2011; pp. 440–443. [Google Scholar] [CrossRef]

- Witos, F.; Gacek, Z. Application of the joint electro-acoustic method for partial discharge investigations within a power transformer. Eur. Phys. J. Spec. Top. 2008, 154, 1951–6401. [Google Scholar] [CrossRef]

- Fuangsoongnern, U.; Plueksawan, W. A measurement technique to identify and locate partial discharge in transformer with AE and HFCT. Int. J. Eng. Res. Appl. 2014, 4, 51–58. [Google Scholar]

- Coenen, S.; Müller, A.; Beltle, M.; Kornhuber, S. UHF and acoustic partial discharge localisation in power transformers. In Proceedings of the XVII International Symposium on High Voltage Engineering, Hannover, Germany, 22–26 August 2011. [Google Scholar]

- Markalous, S.M.; Tenbohlen, S.; Feser, K. Detection and location of partial discharges in power transformers using acoustic and electromagnetic signals. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1576–1583. [Google Scholar] [CrossRef]

- Sikorski, W. Active Dielectric Window: A new concept of combined acoustic emission and electromagnetic partial discharge detector for power transformers. Energies 2019, 12, 115. [Google Scholar] [CrossRef]

- Krimholtz, R.; Leedom, D.A.; Matthaei, G.L. New equivalent circuits for elementary piezoelectric transducers. Electron. Lett. 1970, 6, 398–399. [Google Scholar] [CrossRef]

- Devaney, A.J.; Levine, H. Effective elastic parameters of random composites. Appl. Phys. Lett. 1980, 37, 377–379. [Google Scholar] [CrossRef]

- Meijer, S.; Gulski, E.; Smit, J.J.; Reijnders, H.F. Sensitivity check for UHF PD detection on power transformers. In Proceedings of the Conference Record of the 2004 IEEE International Symposium on Electrical Insulation, Indianapolis, IN, USA, 19–22 September 2004; pp. 58–61. [Google Scholar] [CrossRef]

- Judd, M.D.; Farish, O.; Pearson, J.S.; Hampton, B.F. Dielectric windows for UHF partial discharge detection. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 953–958. [Google Scholar] [CrossRef]

- Siegel, M.; Beltle, M.; Tenbohlen, S.; Coenen, S. Application of UHF sensors for PD measurement at power transformers. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 331–339. [Google Scholar] [CrossRef]

- Jahangir, H.; Akbari, A.; Werle, P.; Szczechowski, J. UHF PD measurements on power transformers-advantages and limitations. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3933–3940. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, G.; Li, Y.; Zhang, J.; Huang, R. On the feasibility of gap detection of power transformer partial discharge UHF signals: Gap propagation characteristics of electromagnetic waves. Energies 2017, 10, 1531. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, J.; Ding, D.; Liu, W.; Liang, H. A feasibility study on bushing tap UHF sensing method for partial discharge in transformer. In Proceedings of the VIIth International Conference on Condition Monitoring and Diagnosis (CMD), Perth, Australia, 23–26 September 2018. [Google Scholar]

- Coenen, S.; Tenbohlen, S. Location of PD sources in power transformers by UHF and acoustic measurements. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1934–1940. [Google Scholar] [CrossRef]

- Li, M.; Guo, C.; Peng, Z. Design of meander antenna for UHF partial discharge detection of transformers. Sens. Transducers 2014, 171, 232–238. [Google Scholar]

- Li, T.; Rong, M.; Zheng, C.; Wang, X. Development simulation and experiment study on UHF Partial Discharge Sensor in GIS. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1421–1430. [Google Scholar] [CrossRef]

- Khosronejad, M.; Gentili, G.G. Design of an archimedean spiral UHF antenna for pulse monitoring application. In Proceedings of the Loughborough Antennas and Propagation Conference (LAPC), Loughborough, UK, 2–3 November 2015; pp. 1–4. [Google Scholar]

- Wu, Q.; Liu, G.; Xia, Z.; Lu, L. The study of archimedean spiral antenna for partial discharge measurement. In Proceedings of the IVth International Conference on Intelligent Control and Information Processing (ICICIP), Beijing, China, 9–11 June 2013; pp. 694–698. [Google Scholar] [CrossRef]

- Robles, G.; Albarracín, R.; Vázquez-Roy, J.L.; Rajo-Iglesias, E.; Martínez-Tarifa, J.M.; Rojas-Moreno, M.V.; Ardila-Rey, J. On the use of vivaldi Antennas in the detection of partial discharges. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 302–305. [Google Scholar] [CrossRef]

- Sarkar, B.; Mishra, D.K.; Koley, C.; Roy, N.K. Microstrip patch antenna based UHF Sensor for detection of partial discharge in high voltage electrical equipments. In Proceedings of the 2014 Annual IEEE India Conference (INDICON), Pune, India, 11–13 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Polak, F.; Sikorski, W.; Siodla, K. Location of partial discharges sources using sensor arrays. Proceedings of 2014 ICHVE International Conference on High Voltage Engineering and Application, Poznan, Poland, 8–11 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Ju, T.; Zhongrong, X.; Xiaoxing, Z.; Caixin, S. GIS partial discharge quantitative measurements using UHF microstrip antenna sensors. In Proceedings of the 2007 Annual Report-Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007; pp. 116–119. [Google Scholar] [CrossRef]

- Nobrega, L.A.M.M.; Xavier, G.V.R.; Aquino, M.V.D.; Serres, A.J.R.; Albuquerque, C.C.R.; Costa, E.G. Design and development of a bio-inspired UHF sensor for partial discharge detection in power transformers. Sensors 2019, 19, 653. [Google Scholar] [CrossRef]

- Cruz, J.N.; Serres, A.J.R.; de Oliveira, A.C.; Xavier, G.V.R.; de Albuquerque, C.C.R.; da Costa, E.G.; Freire, R.C.S. Bio-inspired printed monopole antenna applied to partial discharge detection. Sensors 2019, 19, 628. [Google Scholar] [CrossRef]

- Sikorski, W.; Szymczak, C.; Siodła, K.; Polak, F. Hilbert curve fractal antenna for detection and on-line monitoring of partial discharges in power transformers. Eksploat. I Niezawodn. – Maint. Reliab. 2018, 20, 343–351. [Google Scholar] [CrossRef]

- Li, J.; Jiang, T.; Wang, C.; Cheng, C. Optimization of UHF Hilbert antenna for partial discharge detection of transformers. IEEE Trans. Antennas Propag. 2012, 60, 2536–2540. [Google Scholar] [CrossRef]

- Szymczak, C.; Sikorski, W. Design and optimization of UHF antennas for partial discharge monitoring in power transformer. Prz. Elektrotechniczny 2016, 92, 75–79. [Google Scholar]

- Li, J.; Li, X.; Du, L.; Cao, M.; Qian, G. An intelligent sensor for the ultra-high-frequency partial discharge online monitoring of power transformers. Energies 2016, 9, 383. [Google Scholar] [CrossRef]

- Wang, F.; Bin, F.; Sun, Q.; Fan, J.; Liang, F.; Xiao, X. A novel UHF Minkowski fractal antenna for partial discharge detection. Microw. Opt. Technol. Lett. 2017, 59, 1812–1819. [Google Scholar] [CrossRef]

- Jahangir, H.; Akbari, A.; Werle, P.; Akbari, M.; Szczechowski, J. UHF characteristics of different types of PD sources in power transformers. In Proceedings of the Iranian Conference on Electrical Engineering (ICEE), Tehran, Iran, 2–4 May 2017. [Google Scholar] [CrossRef]

- Szymczak, C.; Sikorski, W.; Siodla, K.; Grabia, M. Construction UHF antenna PIFA type for partial discharges monitoring in power transformer. Prz. Elektrotechniczny 2018, 94, 138–142. [Google Scholar]

- Palantei, E.; Madika, R.S.; Baharuddin, M.; Syarif, S. Design of reconfigurable planar inverted-F antenna for 5g implementation. In Proceedings of the IEEE International Conference on Communication, Networks and Satellite (Comnetsat), Makassar, Indonesia, 1–3 August 2019; pp. 41–46. [Google Scholar] [CrossRef]

- El Halaoui, M.; Asselman, H.; Kaabal, A.; Ahyoud, S. Design and simulation of a planar inverted-F antenna (PIFA) for Wi-Fi and LTE Applications. Int. J. Innov. Appl. Stud. 2014, 9, 1048. [Google Scholar]

- Wong, H.; Luk, K.M.; Chan, C.H.; Xue, Q.; So, K.K.; Lai, H.W. Small antennas in wireless communications. Proc. IEEE 2012, 100, 2109–2121. [Google Scholar] [CrossRef]

- Khan, N. Design of planar Inverted-F antenna. Int. J. Adv. Technol. Eng. Sci. 2014, 2, 20–31. [Google Scholar]

- Jean-Charles, Y.T.; Ungvichian, V.; Barbosa, J.A. Effects of substrate permittivity on planar inverted-F antenna performances. J. Comput. 2009, 4, 610–614. [Google Scholar] [CrossRef][Green Version]

- Chattha, H.T.; Huang, Y.; Zhu, X.; Lu, Y. An empirical equation for predicting the resonant frequency of planar inverted-F antennas. IEEE Antennas Wirel. Propag. Lett. 2009, 8, 856–860. [Google Scholar] [CrossRef]

- Khan, M.M.; Abbasi, Q.H.; Ashique, R.H. Comprehensive design and propagation study of a compact dual band antenna for healthcare applications. J. Sens. Actuator Netw. 2015, 4, 50–66. [Google Scholar] [CrossRef]

- Luhaib, S.W.; Quboa, K.M.; Abaoy, B.M. Design and simulation dual-band PIFA antenna for GSM systems. In Proceedings of the International Multi-Conference on Systems, Signals and Devices, Chemnitz, Germany, 20–23 March 2012; pp. 1–4. [Google Scholar] [CrossRef]

- AbuTarboush, H.F.; Nilavalan, R.; Budimir, D.; Al-Raweshidy, H.S. Compact planar inverted-F antenna (PIFA) for WiMAX application. In Proceedings of the 2009 IEEE Antennas and Propagation Society International Symposium, North Charleston, SC, USA, 1–5 June 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Lawan, A.M.; Su, H.T.; Then, Y.L.; Zhang, J. Parallel dual-slot PIFA for 2.45 GHz rectenna applications. In Proceedings of the 2018 IEEE Sensors Applications Symposium (SAS), Seoul, Korea, 12–14 March 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Fakih, M.A.; Diallo, A.; Le Thuc, P.; Staraj, R.; Mourad, O.; Rachid, E.A. Optimization of efficient dual band pifa system for MIMO half-duplex 4G/LTE and full-duplex 5G communications. IEEE Access 2019, 7, 128881–128895. [Google Scholar] [CrossRef]

- Gomez-Villanueva, R.; Linares-y-Miranda, R.; Tirado-Mendez, J.A.; Jardon-Aguilar, H. Ultra-wideband planar inverted-F antenna (PIFA) for mobile phone frequencies and ultra-wideband applications. Prog. Electromagn. Res. 2013, 43, 109–120. [Google Scholar] [CrossRef][Green Version]

- Gómez-Villanueva, R.; Jardón-Aguilar, H.; Linares-y-Miranda, R. Broadband PIFA antenna for mobile communications terminals. In Proceedings of the XIth International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Campeche, Mexico, 29 September–3 October 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Anguera, J.; Sanz, I.; Mumbrú, J.; Puente, C. Multiband handset antenna with a parallel excitation of PIFA and slot radiators. IEEE Trans. Antennas Propag. 2009, 58, 348–356. [Google Scholar] [CrossRef]

- Naji, D.K.; Abdul-kareem, A. A dual-band U-slot PIFA antenna with ground slit for RFID applications. J. Emerg. Trends Comput. Inf. Sci. 2013, 4, 213–219. [Google Scholar]

- Mohammad, T.I.; Md. Amanath, U.; Touhidul, A.; Mandeep, J.S.; Mengu, C. Microwave imaging sensor using low profile modified stacked type planar inverted-F Antenna. Sensors 2018, 18, 2949. [Google Scholar] [CrossRef]

- Garbaruk, M.; Mieczynska, M. Design and characteristics of multilayer PIFA antenna for GPS and Bluetooth systems. Prz. Elektrotechniczny 2018, 94, 91–94. [Google Scholar]

- Liu, W.C.; Yeh, F.M.; Ghavami, M. Miniaturized implantable broadband antenna for biotelemetry communication. Microw. Opt. Technol. Lett. 2008, 50, 2407–2409. [Google Scholar] [CrossRef]

- Lee, C.M.; Yo, T.C.; Luo, C.H.; Tu, C.H.; Juang, Y.Z. Compact broadband stacked implantable antenna for biotelemetry with medical devices. Electron. Lett. 2007, 43, 660–662. [Google Scholar] [CrossRef]

- Nayeri, P.; Lee, K.F.; Elsherbeni, A.Z.; Yang, F. Dual-band circularly polarized antennas using stacked patches with asymmetric U-slots. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 492–495. [Google Scholar] [CrossRef]

- Panayi, P.K.; Al-Nuaimi, M.; Ivrissimtzis, L.P. Tuning techniques for the planar inverted-F antenna. In Proceedings of the IEE National Conference on Antennas and Propagation, York, UK, 1 April–March 1999. [Google Scholar] [CrossRef]

- Chattha, H.T.; Huang, Y.; Lu, Y. PIFA bandwidth enhancement by changing the widths of feed and shorting plates. IEEE Antennas Wirel. Propag. Lett. 2009, 8, 637–640. [Google Scholar] [CrossRef]

- Wong, K.L. Compact and Broadband Microstrip Antennas; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Wong, K.L.; Yang, K.P. Modified planar inverted-F antenna. Electron. Lett. 1998, 34, 7–8. [Google Scholar] [CrossRef]

- Verma, A.; Raghava, N.S. Compact slotted meandered PIFA antenna for wireless applications. J. Adv. Res. Dyn. Control. Syst. 2017, 9, 28–34. [Google Scholar]

- Karilainen, A.O.; Ikonen, P.M.; Simovski, C.R.; Tretyakov, S.A.; Lagarkov, A.N.; Maklakov, S.A.; Starostenko, S.N. Experimental studies on antenna miniaturisation using magneto-dielectric and dielectric materials. Iet Microw. Antennas Propag. 2011, 5, 495–502. [Google Scholar] [CrossRef]

- Tang, I.T.; Lin, D.B.; Chen, W.L.; Horng, J.H.; Li, C.M. Compact five-band meandered PIFA by using meandered slots structure. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Honolulu, HI, USA, 9–15 June 2007; pp. 653–656. [Google Scholar] [CrossRef]

- Chen, H.T.; Wong, K.L.; Chiou, T.W. PIFA with a meandered and folded patch for the dual-band mobile phone application. IEEE Trans. Antennas Propag. 2003, 51, 2468–2471. [Google Scholar] [CrossRef]

- Verma, A.; Saini, G. Design of meandered PIFA antenna for wireless application. Int. J. Adv. Commun. Technol. 2014, 1, 27–29. [Google Scholar]

- Azremi, A.A.H.; Saidatul, N.A.; Ahmad, R.B.; Soh, P.J. A parametric study of broadband planar inverted F antenna (PIFA) for WLAN application. In Proceedings of the International Conference on Electronic Design, Penang, Malaysia, 1–3 December 2008; pp. 1–6. [Google Scholar] [CrossRef]

- International Electrotechnical Comission (IEC). High-Voltage Test Techniques—Partial Discharge Measurements; IEC 60270:2000+AMD1:2015 CSV; IEC: Geneva, Switzerland, 2015. [Google Scholar]

- Kondrath, N.; Kazimierczuk, M.K. Bandwidth of current transformers. IEEE Trans. Instrum. Meas. 2008, 58, 2008–2016. [Google Scholar] [CrossRef]

- Álvarez, F.; Garnacho, F.; Ortego, J.; Sánchez-Urán, M.Á. Application of HFCT and UHF sensors in on-line partial discharge measurements for insulation diagnosis of high voltage equipment. Sensors 2015, 15, 7360–7387. [Google Scholar] [CrossRef]

- Albarracín-Sánchez, R.; Álvarez-Gómez, F.; Vera-Romero, C.A.; Rodríguez-Serna, J.M. Separation of partial discharge sources measured in the high-frequency range with HFCT sensors using PRPD-teff patterns. Sensors 2020, 20, 382. [Google Scholar] [CrossRef]

- Rodrigo, M.A.; Castro Heredia, L.C.; Munoz, F.A. A Novel Approach for partial discharge measurements on GIS using HFCT sensors. Sensors 2018, 18, 4482. [Google Scholar] [CrossRef]

- Kazimierczuk, M.K. High-Frequency Magnetic Components; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Zhu, J.; Yang, L.; Jia, J.; Zhang, Q. The design of Rogowski coil with wide band using for partial discharge measurements. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Kitakyushu, Japan, 5–9 June 2005; Volume 2, pp. 518–521. [Google Scholar] [CrossRef]

- Zachariades, C.; Shuttleworth, R.; Giussani, R.; MacKinlay, R. Optimization of a high-frequency current transformer sensor for partial discharge detection using finite-element analysis. IEEE Sens. J. 2016, 16, 7526–7533. [Google Scholar] [CrossRef]

- Kunicki, M. Comparison of capacitive and inductive sensors designed for partial discharges measurements in electrical power apparatus. In Proceedings of the E3S Web of Conferences, EDP Sciences, Polanica-Zdrój, Poland, 13–15 September 2017; Volume 19, p. 01035. [Google Scholar]

- Vedral, J.; Kříž, M. Signal processing in partial discharge measurement. Metrol. Meas. Syst. 2010, 7, 55–64. [Google Scholar] [CrossRef][Green Version]

- Baker, P.C.; Judd, M.D.; McArthur, S.D.J. A frequency-based RF partial discharge detector for low-power wireless sensing. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 133–140. [Google Scholar] [CrossRef]

- IEEE Instrument and Measurement Society. IEEE Standard for a Precision Clock Synchronization Protocol for Networked Measurement and Control Systems. IEEE 1588–2008 Standard. Available online: https://ieeexplore.ieee.org/document/4579760 (accessed on 24 June 2020).

- IEEE Standard for Local and Metropolitan Area Networks—Timing and Synchronization for Time-Sensitive Applications. P802.1AS-Rev. Available online: https://ieeexplore.ieee.org/document/5741898 (accessed on 24 June 2020).

- International Electrotechnical Comission (IEC). Communication Networks and System for Utility Automation—Part 1: Introduction and Overview, 2nd ed.; IEC 61850-1; IEC: Geneva, Switzerland, 2012. [Google Scholar]

- International Electrotechnical Comission (IEC). Measuring Relays and Protection Equipment—Part 26: Electromagnetic Compatibility Requirement; IEC 60255-26:2013; IEC: Geneva, Switzerland, 2013. [Google Scholar]

- Walczak, K. Zdalny pomiar napiecia na stanowisku probierczym w laboratorium wysokich napiec. Prz. Elektrotechniczny 2008, 84, 207–209. [Google Scholar]

- International Electrotechnical Comission (IEC). Power Transformers—Part 3: Insulation Levels, Dielectric Tests and External Clearances in Air; IEC 60076-3:2013; IEC: Geneva, Switzerland, 2013. [Google Scholar]

- Wang, H.; Li, C.; He, H. Influence of temperature to developing processes of surface discharges in oil-paper insulation. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Diego, CA, USA, 6–9 June 2010. [Google Scholar] [CrossRef]

- Lia, R.; Hao, J.; Chen, G.; Ma, Z.; Yang, L. A comparative study of physicochemical, dielectric and thermal properties of pressboard insulation impregnated with natural ester and mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1626–1637. [Google Scholar] [CrossRef]

- Buerschaper, B.; Kleboth-Lugova, O.; Leibfried, T. The electrical strength of transformer oil in a transformerboard-oil system during moisture non-equilibrium. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; pp. 269–272. [Google Scholar] [CrossRef]

- Niasar, M.G. Partial Discharge Signatures of Defects in Insulation Systems Consisting of Oil and Oil-impregnated Paper. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Borsi, H.; Schroder, U. Initiation and Formation of partial discharges in mineralbased insulating oil. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 419–425. [Google Scholar] [CrossRef]

- Dai, J.; Wang, Z.D.; Jarman, P. Moisture and aging effect on the creepage discharge characteristics at the oil/transformer-board interface under divergent field. In Proceedings of the Conference on Electrical Insulation Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008. [Google Scholar] [CrossRef]

- Partial Discharges in Transformer Insulation-CIGRE Task Force 15.01.04. Paris. 2000. Available online: https://e-cigre.org/publication/676-partial-discharges-in-transformers (accessed on 24 June 2020).

- Przybylek, P. Water saturation limit of insulating liquids and hygroscopicity of cellulose in aspect of moisture determination in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1886–1893. [Google Scholar] [CrossRef]

- Gielniak, J.; Graczkowski, A.; Moranda, H.; Przybylek, P.; Walczak, K.; Nadolny, Z.; Moscicka-Grzesiak, H.; Feser, K.; Gubanski, S.M. Moisture in cellulose insulation of power transformers-statistics. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 982–987. [Google Scholar] [CrossRef]

- Przybylek, P.; Nadolny, Z.; Moscicka-Grzesiak, H. Bubble effect as a consequence of dielectric losses in cellulose insulation. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 913–919. [Google Scholar] [CrossRef]

- Gil, W.; Maslowski, W.; Wronek, P.; Jechorek, E.; Sikorski, W.; Walczak, K. Development and Implementation of Partial Discharges On-Line Monitoring Module in GIS 110kV Switchgears; CIGRE Session 2020; CIGRE: Paris, France, 2020; accepted for printing. [Google Scholar]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Apparent (bulk) density 1 | ρb | 2500 | kg/m3 |

| Flexural strength 1 | σ | 140 | MPa |

| Fracture toughness 1 | K | 2.0 | MPa·m1/2 |

| Young’s modulus 1 | E | 100 | GPa |

| Abrasion resistance (volume loss) | WV | 172 | mm3 |

| Dielectric strength 1 | VB | 20 | kV/mm |

| Resistivity 1 | ρ | 1013 | Ω·cm |

| Thermal shock resistance 1 | Tc | 150 | K |

| Component | Parameter | Symbol | Value | Unit |

|---|---|---|---|---|

| Matching layer 1 | Thickness | d | 5.05 | mm |

| Density | ρ | 2079 | kg/m3 | |

| Longitudinal velocity | VL | 3029 | m/s | |

| Shear velocity | VS | 1640 | m/s | |

| Bulk modulus | K | 11.62 | GPa | |

| Shear modulus | G | 5.59 | GPa | |

| Acoustic impedance | ZM | 6.3 | MRayl | |

| Piezoelectric ceramics (PZT-5A disc) | Thickness | d | 6.2 | mm |

| Radius | r | 6.35 | mm | |

| Area | A | 126.61 | mm2 | |

| Acoustic impedance | Z0 | 31.0 | MRayl | |

| Backing layer 2 | Thickness | d | 8.8 | mm |

| Density | ρ | 2546 | kg/m3 | |

| Longitudinal velocity | VL | 1790 | m/s | |

| Shear velocity | VS | 845 | m/s | |

| Acoustic impedance | ZB | 4.56 | MRayl | |

| Bulk modulus | K | 5.74 | GPa | |

| Shear modulus | G | 1.82 | GPa |

| Parameter | Indication | Value (mm) |

|---|---|---|

| Width of the patch | L1 | 62.5 |

| Length of the patch | L2 | 100 |

| Length of the slit | S1 | 50 |

| Width of the slit | S2 | 2 |

| Distance between patch and ground plane | H | 5 |

| Diameter of the circular ground plane | D | 14 |

| Distance between feeding point and resistor | d | 26.3 |

| Ferrite Type | Parameter | Symbol | Value | Unit | Conditions |

|---|---|---|---|---|---|

| MnZn | Initial permeability | µi | 900 ± 20% | − | 25 °C; ≤ 10 kHz; 0.25 mT |

| Amplitude permeability | µa | ≈ 1700 | − | 100 °C; 25 kHz; 200 mT | |

| Magnetic flux density | B | ≈ 410 | mT | 25 °C; 10 kHz; 1200 A/m | |

| Specific power loss | Pv | ≈ 130 | kW/m3 | 100 °C; 1 MHz; 30 mT | |

| Loss factor | tan | n/a | − | − | |

| Resistivity | ρ | ≈ 10 | Ωm | DC; 25 °C | |

| Curie temperature | Tc | ≥ 220 | °C | − | |

| Density | D | ≈ 4700 | kg/m3 | − | |

| NiZn | Initial permeability | µi | 125 ± 20% | − | 25 °C; ≤ 10 kHz; 0.25 mT |

| Amplitude permeability | µa | n/a | − | − | |

| Magnetic flux density | B | ≈ 380 | mT | 25 °C; 10 kHz; 3000 A/m | |

| Specific power loss | Pv | n/a | − | − | |

| Loss factor | tan | ≤ 80 × 10-6 | − | 25 °C; 3 MHz; 0.25 mT | |

| Resistivity | ρ | ≈ 105 | Ωm | DC; 25 °C | |

| Curie temperature | Tc | ≥ 350 | °C | − | |

| Density | D | ≈ 4500 | kg/m3 | − |

| Sensor Index | X (m) | Y (m) | Z (m) |

|---|---|---|---|

| 1 | 1.20 | 1.40 | 1.30 |

| 2 | 2.05 | 0.45 | 1.30 |

| 3 | 3.05 | 1.40 | 1.30 |

| 4 | 4.00 | 1.10 | 0.65 |

| 5 | 3.00 | 0.75 | 0.00 |

| 6 | 2.00 | 0.45 | 0.00 |

| 7 | 1.06 | 1.05 | 0.00 |

| 8 | 0.00 | 0.95 | 0.65 |

| PD Sensor Label | Pulses | Test | Statistics 1 | df1 | df2 | p |

|---|---|---|---|---|---|---|

| ISO-002-ADW/UHF-1 | UHF | Welch | 289.93 | 2 | 28,969.85 | < 0.0005 |

| Brown–Forsythe | 371.11 | 2 | 32,492.03 | < 0.0005 | ||

| AE | Welch | 149.51 | 2 | 24,644.93 | < 0.0005 | |

| Brown–Forsythe | 176.34 | 2 | 20,351.35 | < 0.0005 | ||

| ISO-002-ADW/UHF-2 | UHF | Welch | 60.18 | 2 | 25,693.85 | < 0.0005 |

| Brown–Forsythe | 39.05 | 2 | 35,227.18 | < 0.0005 | ||

| AE | Welch | 1772.95 | 2 | 23,518.60 | < 0.0005 | |

| Brown–Forsythe | 977.32 | 2 | 32,563.54 | < 0.0005 | ||

| ISO-002-HF | HFCT | Welch | 1486.10 | 2 | 25,652.90 | < 0.0005 |

| Brown–Forsythe | 914.83 | 2 | 26,939.20 | < 0.0005 |

| PD Sensor Label | Pulses | Temperature Groups | Mean Difference | p |

|---|---|---|---|---|

| ISO-002-ADW/UHF-1 | UHF | Low vs. Moderate | −18.60 * | < 0.0005 |

| Low vs. High | −79.08 * | < 0.0005 | ||

| Moderate vs. High | −60.49 * | < 0.0005 | ||

| AE | Low vs. Moderate | −4.95 * | < 0.0005 | |

| Low vs. High | −22.10 * | < 0.0005 | ||

| Moderate vs. High | −17.15 * | < 0.0005 | ||

| ISO-002-ADW/UHF-2 | UHF | Low vs. Moderate | −0.74 * | < 0.0005 |

| Low vs. High | −1.00 * | < 0.0005 | ||

| Moderate vs. High | −0.26 | 0.154 | ||

| AE | Low vs. Moderate | −386.96 * | < 0.0005 | |

| Low vs. High | −534.64 * | < 0.0005 | ||

| Moderate vs. High | −147.68 * | < 0.0005 | ||

| ISO-002-HF | HFCT | Low vs. Moderate | −39.46 * | < 0.0005 |

| Low vs. High | −25.98 * | < 0.0005 | ||

| Moderate vs. High | 13.48 * | < 0.0005 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikorski, W.; Walczak, K.; Gil, W.; Szymczak, C. On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals. Energies 2020, 13, 3271. https://doi.org/10.3390/en13123271

Sikorski W, Walczak K, Gil W, Szymczak C. On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals. Energies. 2020; 13(12):3271. https://doi.org/10.3390/en13123271

Chicago/Turabian StyleSikorski, Wojciech, Krzysztof Walczak, Wieslaw Gil, and Cyprian Szymczak. 2020. "On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals" Energies 13, no. 12: 3271. https://doi.org/10.3390/en13123271

APA StyleSikorski, W., Walczak, K., Gil, W., & Szymczak, C. (2020). On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals. Energies, 13(12), 3271. https://doi.org/10.3390/en13123271