Life Cycle Assessment of Classic and Innovative Batteries for Solar Home Systems in Europe

Abstract

1. Introduction

2. Methodology

- The design phase, in which the calculation of the components’ capacity is addressed.

- The modelling phase, which provides the dynamic simulation of the SHSs performances.

- The LCA for the SHSs environmental impact calculation.

2.1. Batteries Description

2.2. SHS Design

2.3. SHS Modelling

- The PV productivity profiles (), calculated with PV-GIS [47].

- The power demand profiles (), provided by Quoilin et al. [48].

- The BESS model that uses and as inputs to evaluate the missing ( and exceeding () power of the SHSs. and are calculated integrating and in time and an ageing model allows to estimate

- if the battery capacity is totally full (= 1), the BESS cannot be furtherly charged and the exceeding power is exported to the grid or, in off-grid SHSs, it is dumped.

- if the battery capacity has reached the minimum level (=), the BESS cannot be furtherly discharged and, in that case, the backup source intervenes.

- is the solution of (8).

- is the capacity of a reference battery (712.9 Wh).

- is the voltage of the reference battery (5 V).

- is the activation energy of the reaction of the reference battery (24,500 J ∙ mol−1).

- is the constant of gases.

- , , , , , are the ageing coefficients, calibrated to match with the values in Table 1 in nominal conditions ( = 298 K and = 1 h-1).

2.4. LCA

- Goal and scope definition: the objectives of the study are defined, thus the reference flow (RF) and the functional unit (FU) of the product system are set accordingly. Moreover, the system boundaries are drawn to choose which processes are included in the analysis and which ones are left outside.

- Life cycle inventory (LCI): all the input and output flows of matter and energy involved in the system boundaries are collected and quantified.

- Life cycle impact assessment (LCIA): in this step all the flows collected in the LCI are classified and multiplied for characterization factors to calculate the environmental impact indicators value.

- Interpretation: the results obtained should be carefully evaluated to point out possible improvements of the product system in accordance with the scope and goal of the assessment and, eventually, to modify and implement the LCA system model.

2.4.1. Goal and Scope Definition

2.4.2. Life Cycle Inventory (LCI)

- Phosphorous pentoxide inventory has been approximated to phosphoric acid having a similar structure.

- Triphosphorous pentanitride is prepared from ammonia and phosphorus pentachloride [54].

2.4.3. Life Cycle Impact Assessment (LCIA)

3. Case Studies

4. Results and Discussion

4.1. Design Phase Results

4.2. Modelling Phase Results

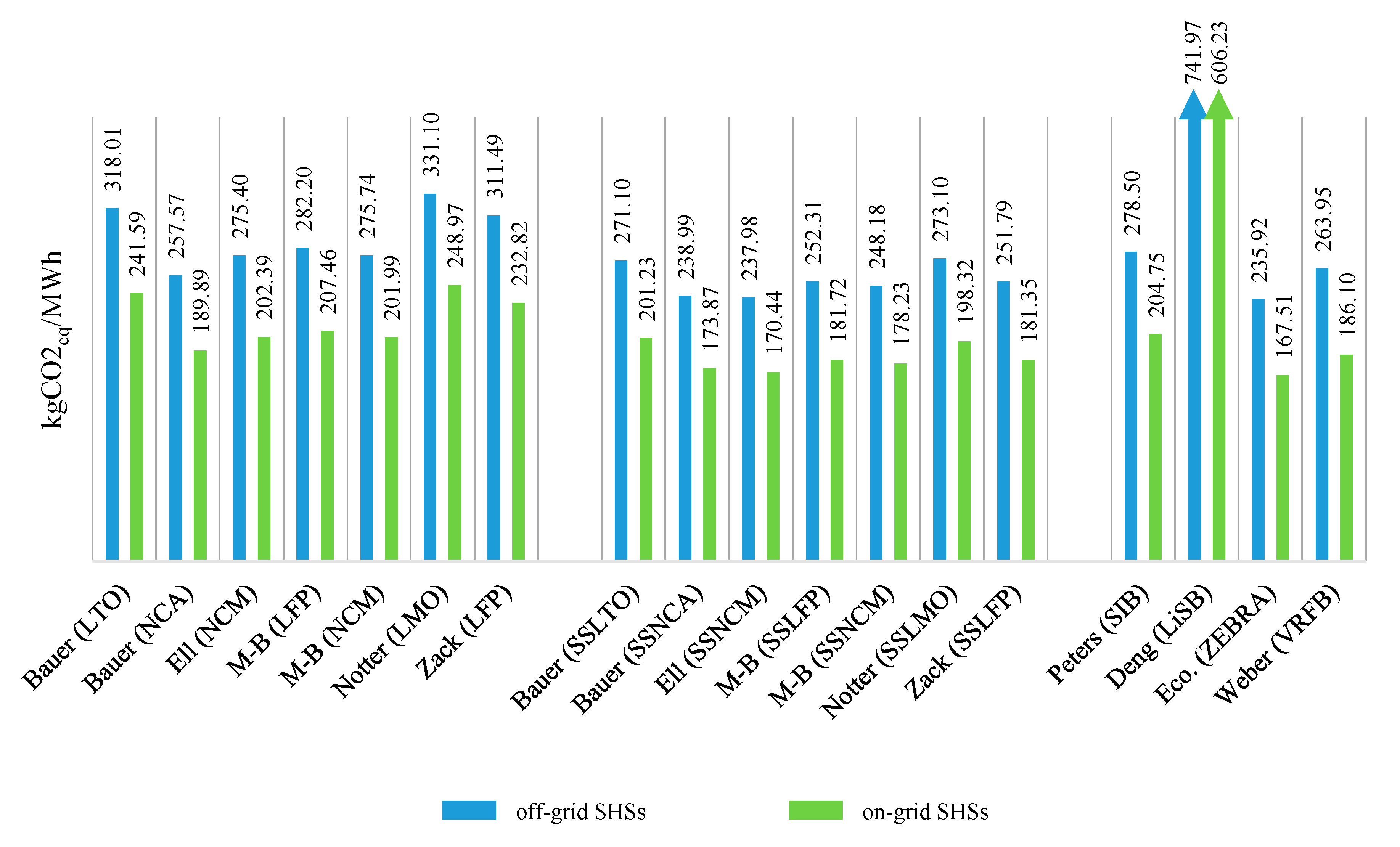

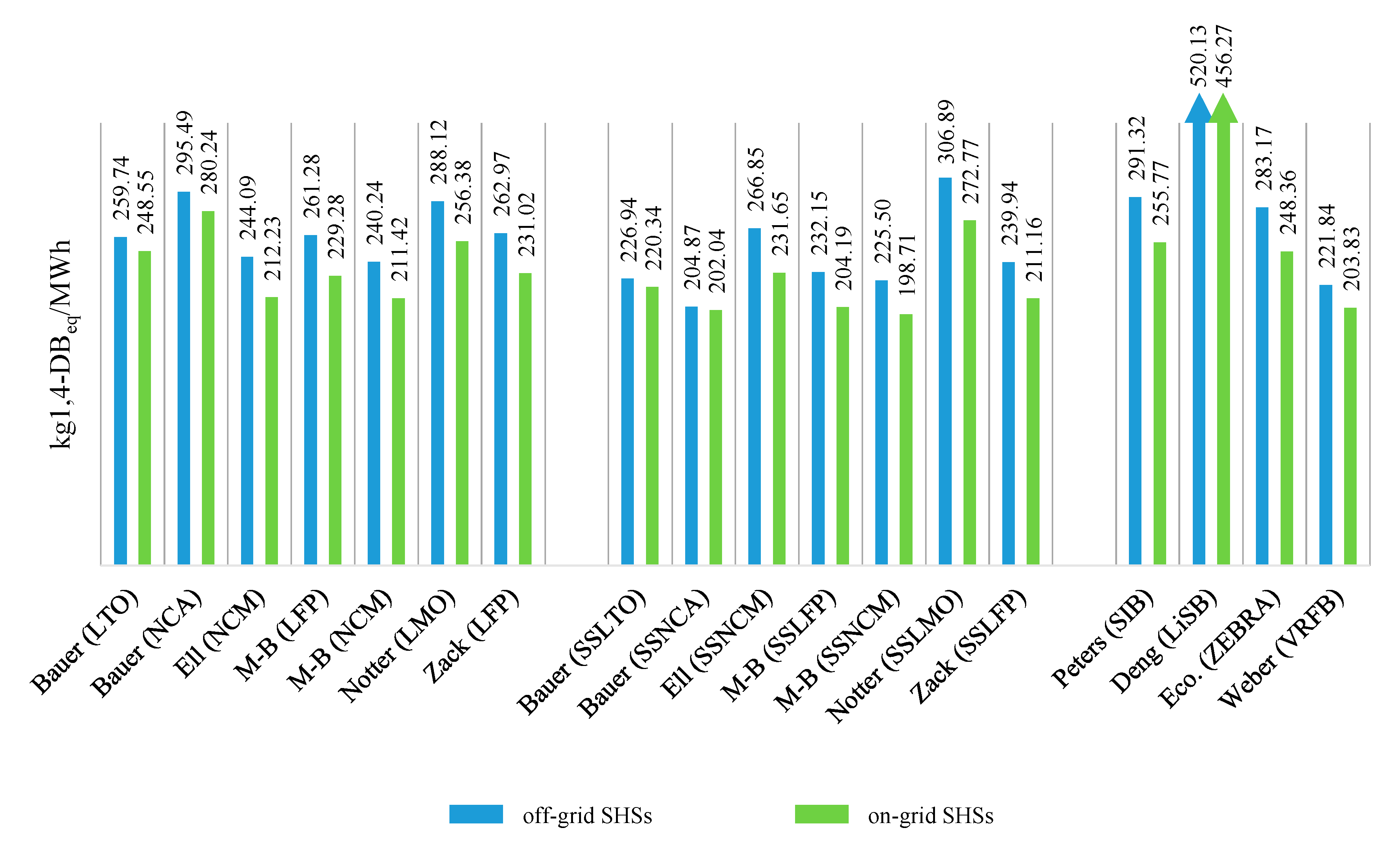

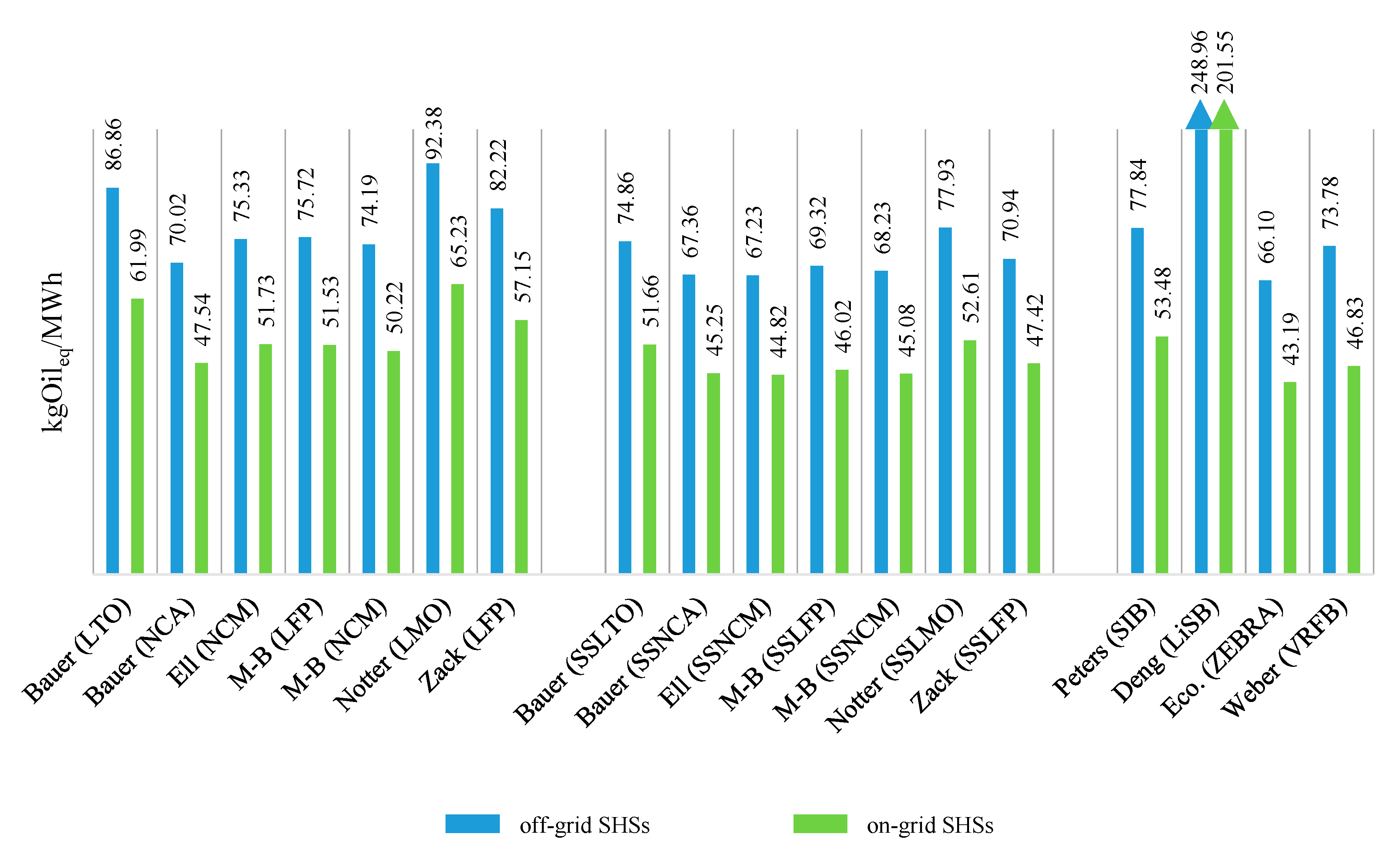

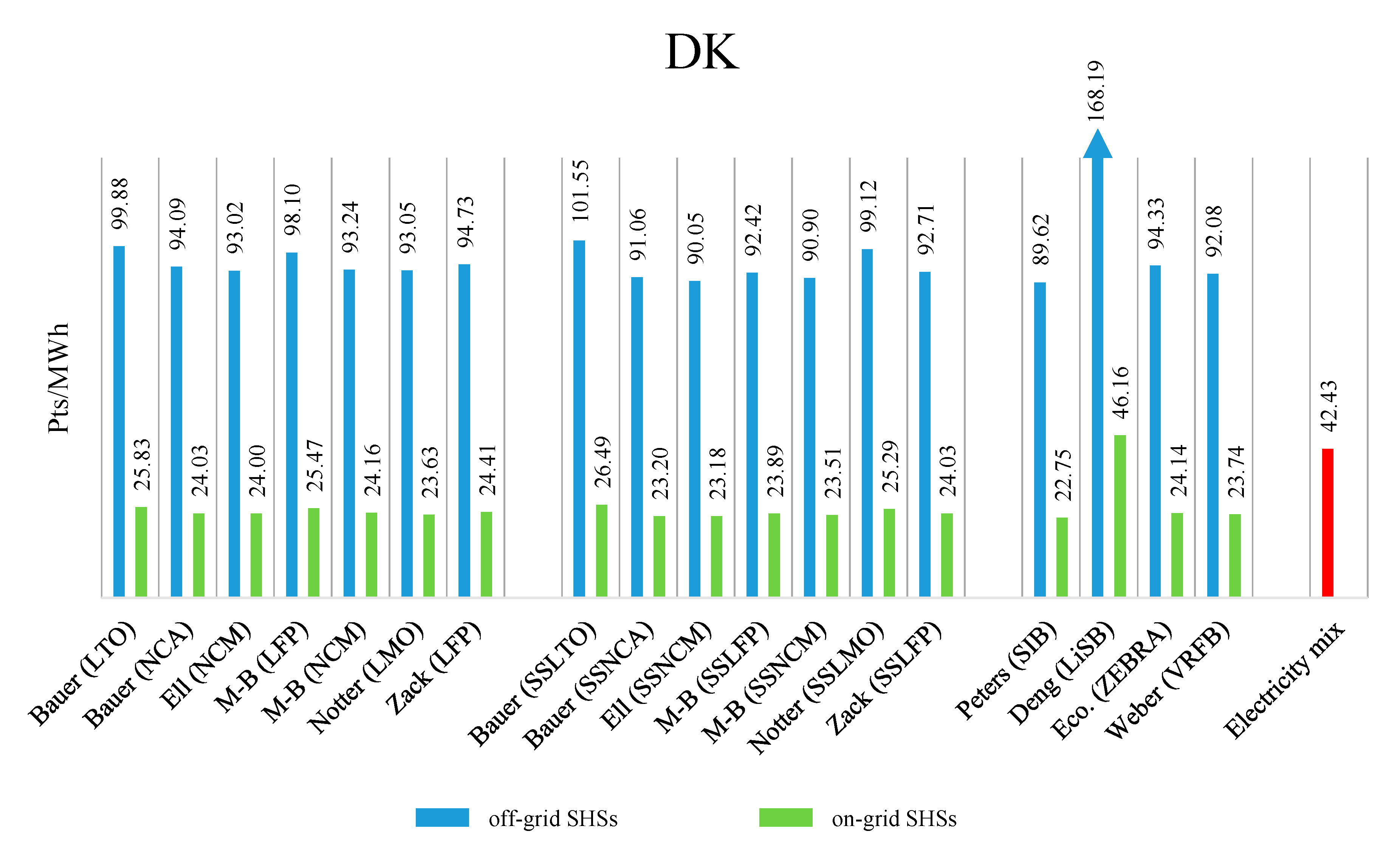

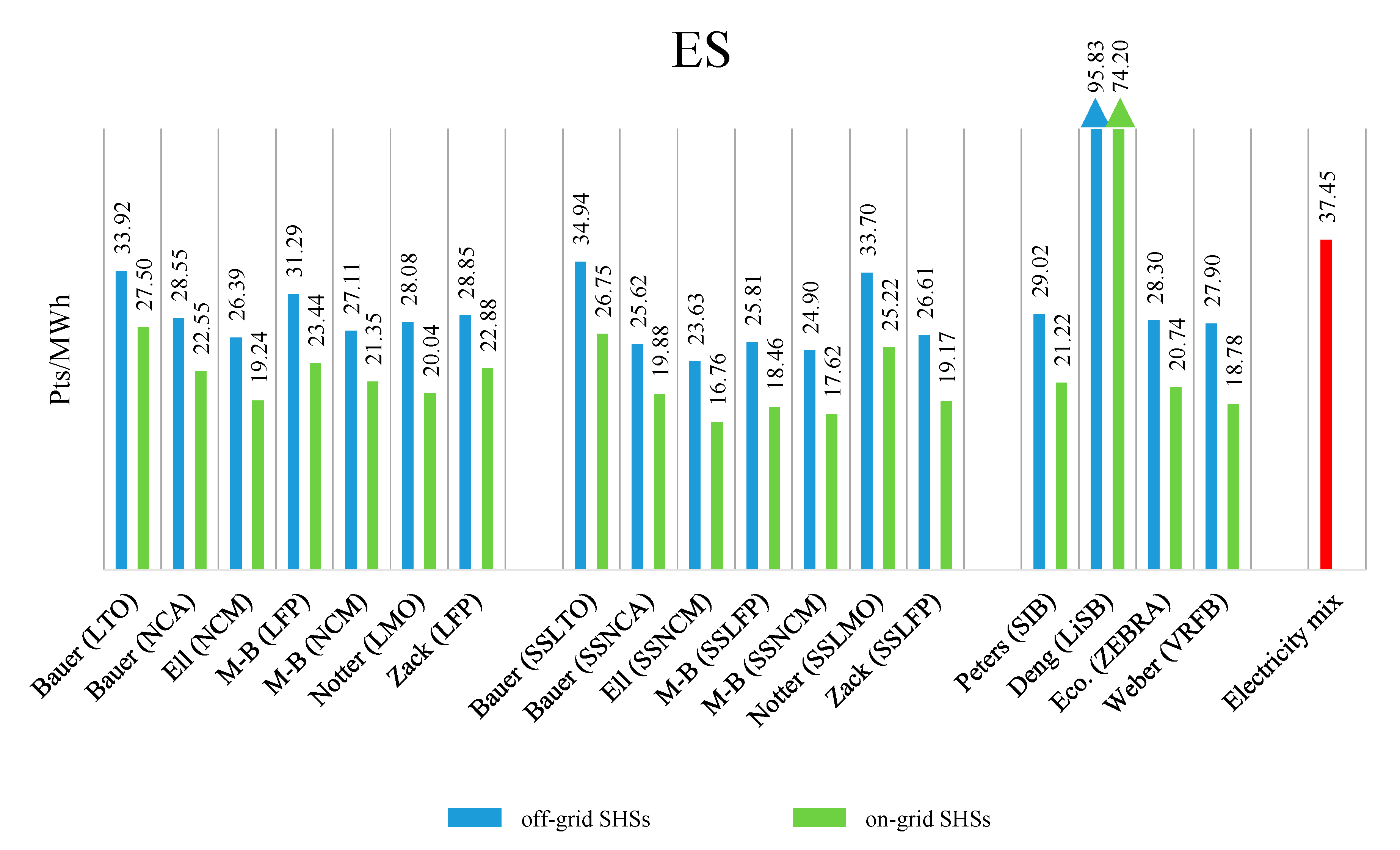

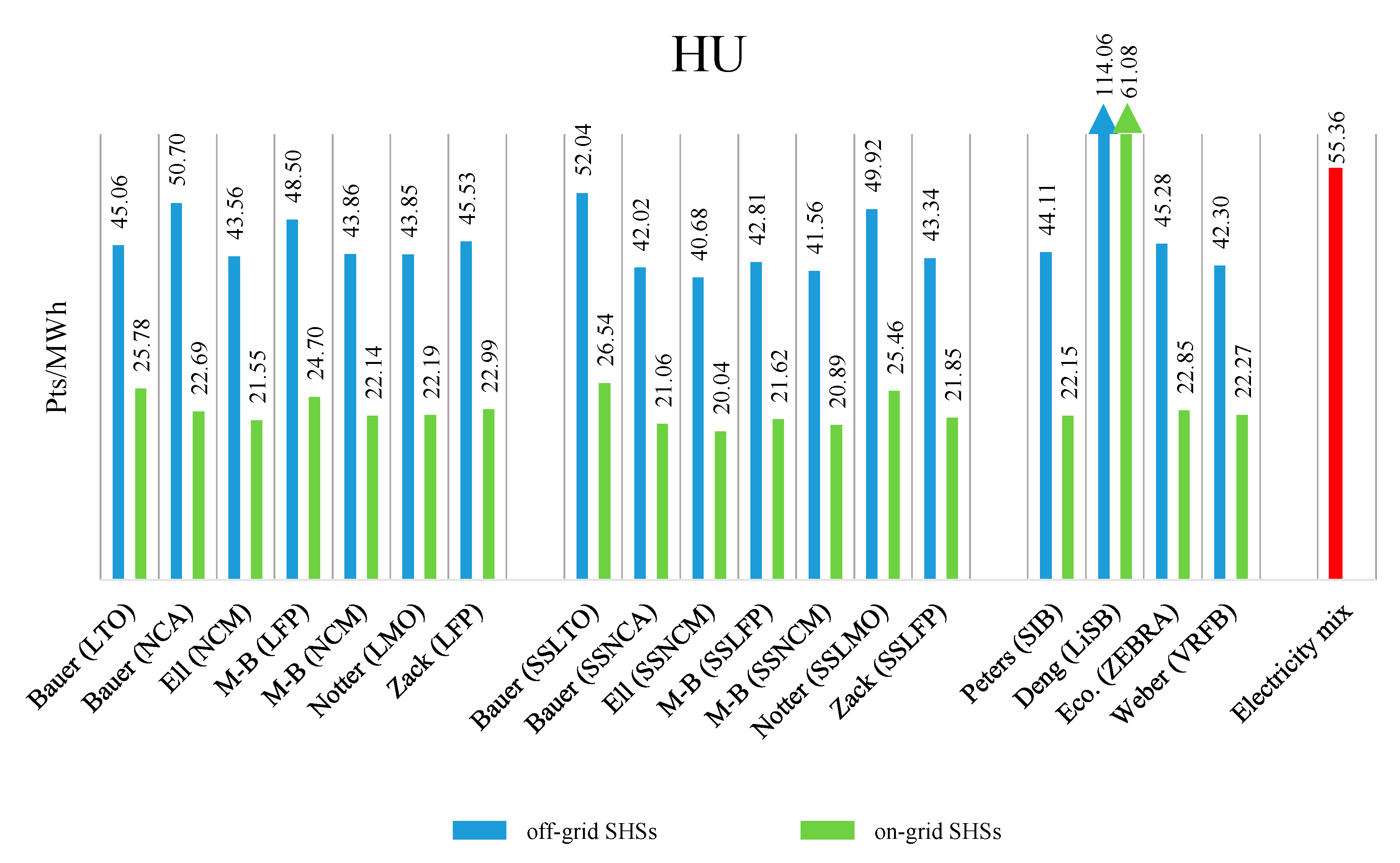

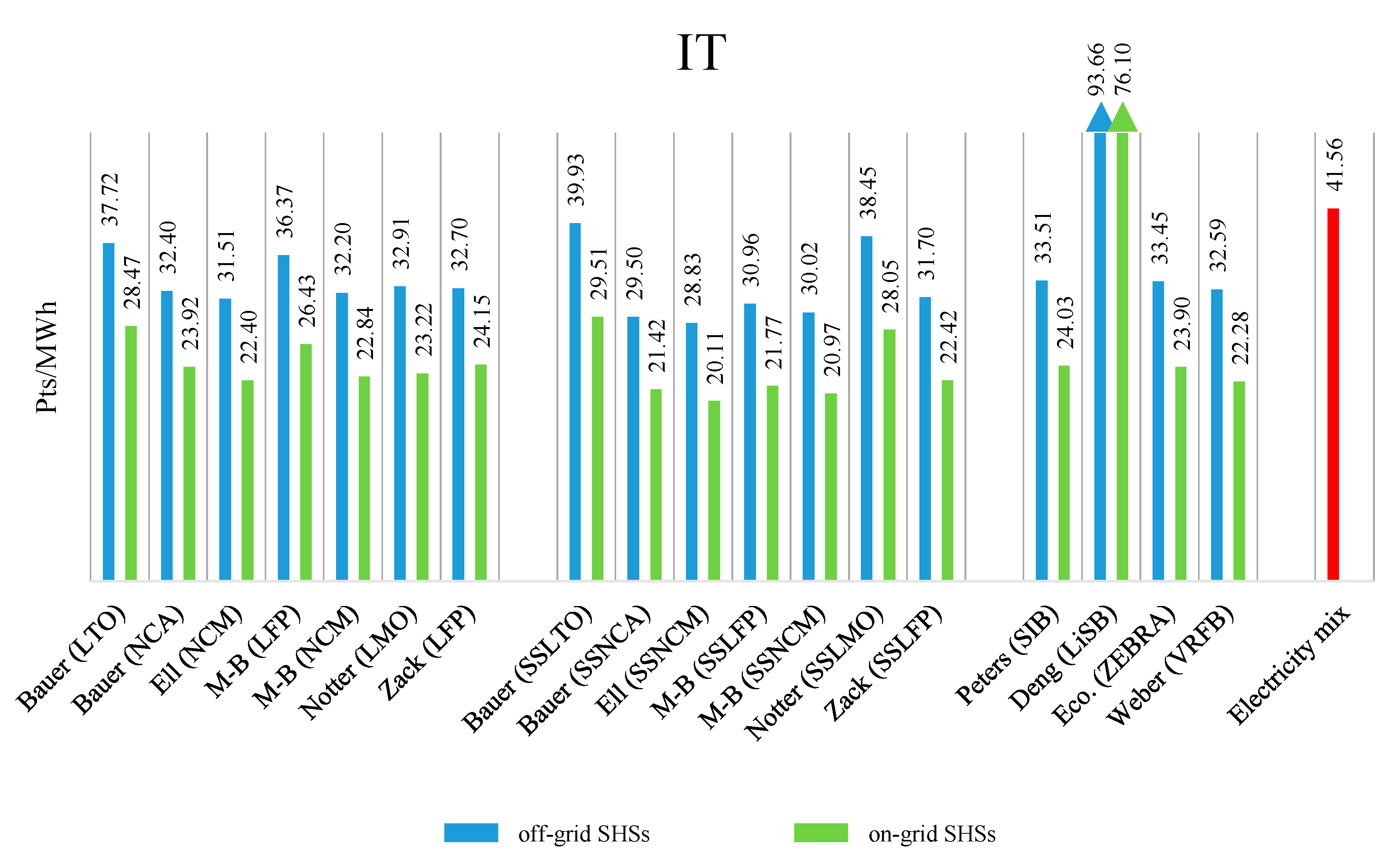

4.3. LCA Results

5. Conclusions

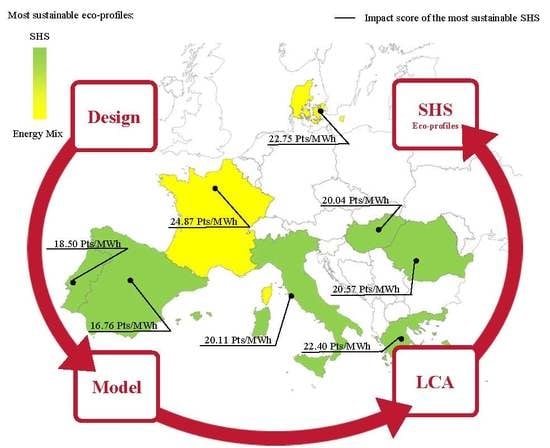

- Geographical dependencies on the variation of battery types: the choice of the most sustainable BESSs does not change significantly with the installation site. Regardless of the solar radiation profile and energy demand curves, Ell (SSNCM) batteries are assessed as the best in almost every country (16.76–24.87 Pts/MWh). M-B (SSNCM) (17.62–23.41 Pts/MWh), M-B (SSLFP) (18.46–26.13 Pts/MWh), Peters (SIB) (21.22–27.51 Pts/MWh) and Weber (VRFB) (18.38–26.31 Pts/MWh) environmental performances are all close to Ell (SSNCM).

- Structural properties and operative characteristics of batteries: the main strength of the mentioned SSLIBs is in having a high energy density. Peters (SIB) devices instead take great advantage of the low impact on natural resources consumption as sodium is more abundant on the Earth’s surface whereas Weber (VRFB) batteries have a very long lifespan. Even though SSLIBs guarantee an important improvement compared to simple LIBs and currently they have the most sustainable eco-profile, Peters systems (SIBs) probably have the lowest maturity level among the cited BESSs, therefore the highest potential for the future. Deng batteries (LiSBs), penalized by their short lifespan, are by far the most impactful battery whereas all the others have an intermediate environmental impact.

- SHSs’ environmental advantages and batteries contributions to their eco-profiles in the various European countries: extending the overview to the overall SHS, it is possible to conclude that the choice of the batteries affects the results in southern Europe countries where the percentage contribution is the most relevant, whereas in northern Europe they have a minor contribution. Considering the best batteries, their impact is usually of the order of 10% of the total thanks to the materials recovery in the EoL, while without this percentage it could be more than double. Grid-connected SHSs are always more profitable compared to the off-grid ones, especially in northern countries, thanks to the possibility to inject more electricity to the grid avoiding the use of a diesel generator. Both types of SHSs are generally more sustainable than the national electricity mix, except for FR where the grid electricity is estimated to have a very low impact, and DK where off-grid configuration is more impactful.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| aBESS | Alternative Battery Energy Storage System |

| AIB | Aluminium-ion Battery |

| BESS | Battery Energy Storage System |

| CC | Charge Controller |

| CO | Construction |

| DK | Denmark |

| DME | Dimethyl Glycol |

| DoD | Depth of Discharge |

| DOL | Dioxolane |

| EoL | End of Life |

| ES | Spain |

| FU | Functional Unit |

| FR | France |

| GR | Greece |

| HU | Hungary |

| In | Inverter |

| IT | Italy |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LCO | Lithium Cobalt Oxide |

| LCP | Lithium Cobalt Phosphate |

| LFP | Lithium Iron Phosphate |

| LIB | Lithium-ion battery |

| LiPON | Lithium Phosphorous Oxy-Nitride |

| LiSB | Lithium-sulphur Battery |

| LiTFSI | Lithium Bistrifluoromethanesulfonimidate |

| LMNO | Lithium Manganese Nickel Oxide |

| LMO | Lithium Manganese Oxide |

| LTO | Lithium Iron Titanate |

| NCA | Nickel Cobalt Aluminium |

| NCM | Nickel Cobalt Manganese |

| NMMT | Nickel Manganese Magnesium Titanium Oxide |

| OP | Operation |

| PON | Polyacrylonitrile |

| PT | Portugal |

| PV | Photovoltaic |

| PV-GIS | Photovoltaic Geographical Information System |

| RF | Reference Flow |

| RO | Romania |

| SHS | Solar Home System |

| SIB | Sodium-ion Battery |

| SOC | State of Charge |

| SOH | State of Health |

| SSLFP | Solid State Lithium Iron Phosphate |

| SSLIB | Solid State Lithium-ion Battery |

| SSLMO | Solid State Lithium Manganese Oxide |

| SSLTO | Solid State Lithium Iron Titanate |

| SSNCA | Solid State Nickel Cobalt Aluminium |

| SSNCM | Solid State Nickel Cobalt Manganese |

| VRFB | Vanadium Redox Flow Battery |

| ZEBRA | Zero Emissions Batteries Research Activity |

References

- Liu, N.; Cheng, M.; Yu, X.; Zhong, J.; Lei, J. Energy-Sharing Provider for PV Prosumer Clusters: A Hybrid Approach Using Stochastic Programming and Stackelberg Game. IEEE Trans. Ind. Electron. 2018, 65, 6740–6750. [Google Scholar] [CrossRef]

- Bashir, A.A.; Pourakbari-Kasmaei, M.; Contreras, J.; Lehtonen, M. A novel energy scheduling framework for reliable and economic operation of islanded and grid-connected microgrids. Electr. Power Syst. Res. 2019, 171, 85–96. [Google Scholar] [CrossRef]

- Pourakbari-Kasmaei, M.; Asensio, M.; Lehtonen, M.; Contreras, J. Trilateral Planning Model for Integrated Community Energy Systems and PV-Based Prosumers—A Bilevel Stochastic Programming Approach. IEEE Trans. Power Syst. 2020, 35, 346–361. [Google Scholar] [CrossRef]

- Mohammadi, S.; Soleymani, S.; Mozafari, B. Scenario-based stochastic operation management of MicroGrid including Wind, Photovoltaic, Micro-Turbine, Fuel Cell and Energy Storage Devices. Int. J. Electr. Power Energy Syst. 2014, 54, 525–535. [Google Scholar] [CrossRef]

- International Standards Organization. EN ISO 14040:2006—Valutazione del ciclo di vita Principi e Quadro di Riferimento; International Standards Organization: Geneva, Switzerland, 2010; p. 14040. [Google Scholar]

- International Standards Organization. UNI EN ISO 14044:2006—Gestione Ambientale—Valutazione del ciclo di vita—Requisiti e Linee Guida; International Standards Organization: Geneva, Switzerland, 2006. [Google Scholar]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Manfrida, G.; Basosi, R.; Sinicropi, A. Environmental impact analysis applied to solar pasteurization systems. J. Clean. Prod. 2019, 212, 1368–1380. [Google Scholar] [CrossRef]

- Bravi, M.; Parisi, M.L.; Tiezzi, E.; Basosi, R. Life Cycle Assessment of advanced technologies for photovoltaic panels production. Int. J. HEAT Technol. 2010, 28, 133–140. [Google Scholar] [CrossRef]

- Maranghi, S.; Parisi, M.L.; Basosi, R.; Sinicropi, A. Environmental Profile of the Manufacturing Process of Perovskite Photovoltaics: Harmonization of Life Cycle Assessment Studies. Energies 2019, 12, 3746. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Sinicropi, A.; Basosi, R. Development of dye sensitized solar cells: A life cycle perspective for the environmental and market potential assessment of a renewable energy technology. Int. J. Heat Technol. 2013, 31, 143–148. [Google Scholar] [CrossRef]

- Peters, J.F.; Weil, M. Providing a common base for life cycle assessments of Li-Ion batteries. J. Clean. Prod. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Bauer, C. Okobilanz Von Lithium-Ionen Batterien; Paul Scherrer Institut, Labor für Energiesystem-Analysen (LEA): Villingen, Switzerland, 2010. [Google Scholar]

- Ellingsen, L.A.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef]

- Majeau-bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- Notter, D.A.; Gauch, M.; Widmer, R.; Patrick, W.A.; Stamp, A.; Zah, R.; Althaus, R.G. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles e Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Bobba, S.; Ardente, F.; Cellura, M.; di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019, 215, 634–649. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Li, T.; Zhang, J.; Yang, F.; Yuan, C. Life cycle assessment of high capacity molybdenum disulfide lithium-ion battery for electric vehicles. Energy 2017, 123, 77–88. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the production and EoL recycling of a novel type of Li-ion battery for electric vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef]

- Senevirathne, K.; Day, C.S.; Gross, M.D.; Lachgar, A.; Holzwarth, N.A.W. A new crystalline LiPON electrolyte: Synthesis, properties, and electronic structure. Solid State Ionics 2013, 233, 95–101. [Google Scholar] [CrossRef]

- Troy, S.; Schreiber, A.; Reppert, T.; Gehrke, H.G.; Finsterbusch, M.; Uhlenbruck, S.; Stenzel, P. Life Cycle Assessment and resource analysis of all-solid-state batteries. Appl. Energy 2016, 169, 757–767. [Google Scholar] [CrossRef]

- Lastoskie, C.M.; Dai, Q. Comparative life cycle assessment of laminated and vacuum vapor-deposited thin fi lm solid-state batteries. J. Clean. Prod. 2015, 91, 158–169. [Google Scholar] [CrossRef]

- U.S. Department of the Interior, U.S. Geological Survey. Mineral Commodity Summaries 2018; U.S. Geological Survey: Washington, DC, USA, 2018.

- Grimsmo, B.; Strømman, A.H.; Ellingsen, L. Life Cycle Assessment LCA of Li-Ion Batteries for Electric Vehicles. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/2400819 (accessed on 18 February 2020).

- Peters, J.; Buchholz, D.; Passerini, S.; Weil, M. Life cycle assessment of sodium-ion batteries. Energy Environ. Sci. 2016, 9, 1744–1751. [Google Scholar] [CrossRef]

- Delgado, M.A.S.; Usai, L.; Ellingsen, L.A.W.; Pan, Q.; Strømman, A.H. Correction: Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications. Materials 2019, 12, 3270. [Google Scholar] [CrossRef] [PubMed]

- Hosseinifar, M.; Petric, A. High temperature versus low temperature Zebra (Na/NiCl 2) cell performance. J. Power Sources 2012, 206, 402–408. [Google Scholar] [CrossRef]

- Longo, S.; Antonucci, V.; Cellura, M.; Ferraro, M. Life cycle assessment of storage systems: The case study of a sodium/nickel chloride battery. J. Clean. Prod. 2014, 85, 337–346. [Google Scholar] [CrossRef]

- Weber, S.; Peters, J.F.; Baumann, M.; Weil, M. Life Cycle Assessment of a Vanadium Redox Flow Battery. Environ. Sci. Technol. 2018, 52, 10864–10873. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Li, J.; Li, T.; Gao, X.; Yuan, C. Life cycle assessment of lithium sulfur battery for electric vehicles. J. Power Sources 2017, 343, 284–295. [Google Scholar] [CrossRef]

- Zackrisson, M.; Fransson, K.; Hildenbrand, J.; Lampic, G.; O’Dwyer, C. Life cycle assessment of lithium-air battery cells. J. Clean. Prod. 2016, 135, 299–311. [Google Scholar] [CrossRef]

- Hiremath, M.; Derendorf, K.; Vogt, T. Comparative life cycle assessment of battery storage systems for stationary applications. Environ. Sci. Technol. 2015, 49, 4825–4833. [Google Scholar] [CrossRef]

- Montenegro, C.T.; Peters, J.F.; Zhao-Karger, Z.; Wolter, C.; Weil, M. CHAPTER 13 Life Cycle Analysis of a Magnesium–Sulfur Battery. In Magnesium Batteries; The Royal Society of Chemistry: London, UK, 2020; pp. 309–330. [Google Scholar] [CrossRef]

- Santos, F.; Urbina, A.; Abad, J.; López, R.; Toledo, C.; Romero, A.J.F. Environmental and economical assessment for a sustainable Zn/air battery. Chemosphere 2020, 250, 126273. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W. A review on state of health estimation for lithium ion batteries in photovoltaic systems. eTransportation 2019, 2, 100028. [Google Scholar] [CrossRef]

- Nagapurkar, P.; Joseph, D.S. Techno-Economic Optimization and Environmental Life Cycle Assessment (LCA) of Microgrids located in the US using Genetic Algorithm. Energy Convers. Manag. 2018, 181, 272–291. [Google Scholar] [CrossRef]

- Wang, R.; Lam, C.; Hsu, S.; Chen, J.; Engineering, E.; Hong, T.; Polytechnic, K.; Kong, H. Life cycle assessment and energy payback time of a standalone hybrid renewable energy commercial microgrid: A case study of Town Island in Hong Kong. Appl. Energy 2019, 250, 760–775. [Google Scholar] [CrossRef]

- Longo, S.; Beccali, M.; Cellura, M.; Guarino, F. Energy and environmental life-cycle impacts of solar-assisted systems: The application of the tool “ELISA”. Renew. Energy 2020, 145, 29–40. [Google Scholar] [CrossRef]

- Kabakian, V.; McManus, M.C.; Harajli, H. Attributional life cycle assessment of mounted 1.8kWp monocrystalline photovoltaic system with batteries and comparison with fossil energy production system. Appl. Energy 2015, 154, 428–437. [Google Scholar] [CrossRef]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Environmental analysis of a Nano-Grid: A Life Cycle Assessment. Sci. Total Environ. 2019, 700, 134814. [Google Scholar] [CrossRef]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Life Cycle Inventory datasets for nano-grid configurations. Data Br. 2020, 28, 104895. [Google Scholar] [CrossRef]

- Ease, EERA, European Energy Storage Technology Development; European Association for Storage of Energy (EASE): Brussels, Belgium, 2017.

- Yusoff, N.F.M.; Idris, N.H.; Din, M.F.M.; Majid, S.R.; Harun, N.A.; Rahman, M.M. Investigation on the Electrochemical Performances of Mn2O3 as a Potential Anode for Na-Ion Batteries. Sci. Rep. 2020, 10, 9207. [Google Scholar] [CrossRef]

- Wolff, D.; Casals, L.C.; Benveniste, G.; Corchero, C.; Trilla, L. The effects of lithium sulfur battery ageing on second-life possibilities and environmental life cycle assessment studies. Energies 2019, 12, 2440. [Google Scholar] [CrossRef]

- Bignucolo, F.; Coppo, M.; Crugnola, G.; Savio, A. Application of a simplified thermal-electric model of a sodium-nickel chloride battery energy storage system to a real case residential prosumer. Energies 2017, 10, 1497. [Google Scholar] [CrossRef]

- Ruiz, E.M.; Valsasina, L.; Brunner, F.; Symeonidis, A.; Fitzgerald, D.; Treyer, K.; Bourgault, G.; Wernet, G. Documentation of Changes Implemented in the Ecoinvent Database v3.4 (2018.08.23). Available online: https://www.ecoinvent.org/files/change_report_v3_4_20171004_1.pdf (accessed on 20 March 2020).

- Joint Research Center (JRC). Photovoltaic Geographical Information System (PVGIS). Jt. Res. Cent. (n.d.). Available online: http://re.jrc.ec.europa.eu/pvgis/ (accessed on 5 May 2019).

- Quoilin, S.; Kavvadias, K.; Mercier, A.; Pappone, I.; Zucker, A. Quantifying self-consumption linked to solar home battery systems: Statistical analysis and economic assessment. Appl. Energy 2016, 182, 58–67. [Google Scholar] [CrossRef]

- Cardoso, G.; Brouhard, T.; DeForest, N.; Wang, D.; Heleno, M.; Kotzur, L. Battery aging in multi-energy microgrid design using mixed integer linear programming. Appl. Energy 2018, 231, 1059–1069. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef]

- MIT Team Electric Vehicle Team. A Guide to Understanding Battery Specifications; MIT: Cambridge, MA, USA, 2008. [Google Scholar]

- Mathworks. Matlab/Simulink 2019b Software. 2018. Available online: https://it.mathworks.com/ (accessed on 20 March 2019).

- Tang, A.; Bao, J.; Skyllas-kazacos, M. Studies on pressure losses and fl ow rate optimization in vanadium redox fl ow battery. J. Power Sources 2014, 248, 154–162. [Google Scholar] [CrossRef]

- Tanifuji, T.; Nasu, S. Heat capacity and thermal decomposition of lithium peroxide. J. Nucl. Mater. 1979, 87, 189–195. [Google Scholar] [CrossRef]

- Amrical Elements. Lithium Powder Properties; Amrical Elements: Los Angeles, CA, USA, 2020. [Google Scholar]

- Huang, B. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- Bekkelund, K. A Comparative Life Cycle Assessment of PV Solar Systems. Master’s Thesis, Norwegian University of Science and Technology (NTNU), Trondheim, Noruega, 2013. 243p. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/235329/654872_FULLTEXT01.pdf?sequence=1 (accessed on 11 February 2020).

- Mastervolt. SCM60 MPPT-MB Datasheet, (n.d.). Available online: https://www.mastervolt.it/conversione/ (accessed on 5 May 2019).

- Mastervolt. Mass Combi Ultra 48/3500-50 (230 V) Datasheet, (n.d.). Available online: https://www.mastervolt.it/conversione/ (accessed on 5 May 2019).

- Tenka Solar. MONO CRYSTALLINE MODULE 300–330 Watt Technical Datasheet. 2017. Available online: http://www.tenkasolar.com/ (accessed on 20 March 2019).

- Latunussa, C.E.L.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Environmental effectiveness of the Solar Home Systems based on LCA. In Proceedings of the Atti Del XIII Convegno Della Rete Italiana LCA-VIII Convegno Dell’Associazione Rete Italiana LCA Roma, Rome, Italy, 13–14 June 2019; pp. 132–139. Available online: https://www.enea.it/it/seguici/pubblicazioni/pdf-volumi/2019/atti_lca_roma-2019.pdf (accessed on 10 March 2020).

- European Commission. Eurostat. 2017. Available online: https://ec.europa.eu/eurostat/web/gisco/geodata/reference-data (accessed on 1 February 2020).

- Buchamann, I. Batteries in a Portable World, 4th ed.; Cadex Electronics Inc.: Richmond, BC, Canada, 2016. [Google Scholar]

| LIBs/SSLIBs | aBESS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M-B (LFP) (1) | Zack (LFP) (2) | Bauer (LTO) (3) | Notter (LMO) (4) | Bauer (NCA) (5) | Ell (NCM) (6) | M-B (NCM) (7) | Peters (SIBs) (8) | Deng (LiSBs) (9) | Eco. (ZEBRA) (10) | Weber (VRFBs) (11) | |

| Cathode | LiFePO4 (b) | LiFePO4 | LiFePO4 | LiMn2O4 (c) | LiNiCoAlO2 (d) | LiNiMnCoO2 (e) | LiNiMnCoO2 (e) | NMMT | Graphene-sulfur composite | Nickel chloride | PAN |

| Anode | Graphite | Graphite | Li4Ti5O12 (f) | Graphite | Graphite | Graphite | Graphite | Hard carbon | Lithium metal | Sodium chloride | PAN |

| Electrolyte | LiPF6 (g) LiPON (j) (SS) | LiCl (h) LiPON (j) (SS) | NaBF4 (i) LiPON (j) (SS) | LiPF6 (g) LiPON (SS) | NaBF4 (i) LiPON (SS) | LiPF6 (g) LiPON (SS) | LiPF6 (g) LiPON (SS) | NaPF6 | LiTFSI, DOL, DME, LiNO3 | Sodium aluminium chloride | Vanadium, sulfuric acid, phosphoric acid, water |

| Energy Density [Wh/kg] | 109.3 218.6 (SS) | 82.9 165.8 (SS) | 52.4 104.8 (SS) | 116.1 232.2 (SS) | 133.1 266.2 (SS) | 130.3 260.6 (SS) | 139.1 278.2 (SS) | 102 | 220 | 116 | 28 |

| Lifespan [Cycles] | 6000 | 3000 | 10,000 | 1000 | 5000 | 2000 | 3000 | 2000 | 400 | 4500 | - |

| Lifespan [years] | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | - | 15 | 20 |

| DoD | 80% | 80% | 80% | 80% | 80% | 80% | 80% | 80% | 85% | 80% | 95% |

| Efficiency | 90% | 90% | 90% | 85% | 90% | 95% | 90% | 90% | 85% | 90% | 75% |

| BESS | ||||||

|---|---|---|---|---|---|---|

| [Ah-1 ∙ K-2] | [Ah-1 ∙ K-1] | [Ah-1] | [h K-1] | [h] | [s-0.5] | |

| Bauer (LTO, SSLTO) | 2.95 × 10−7 | −1.76 × 10−4 | 2.61 × 10−2 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Bauer (NCA, SSNCA) | 5.91 × 10−7 | −3.51 × 10−4 | 5.23 × 10−2 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Ell (NCM, SSNCM) | 1.48 × 10−6 | −8.78 × 10−4 | 1.31 × 10−1 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| M-B (LFP, SSLFP) | 4.92 × 10−7 | −2.93 × 10−4 | 4.35 × 10−2 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| M-B (NCM, SSNCM) | 9.84 × 10−7 | −5.85 × 10−4 | 8.71 × 10−2 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Notter (LMO, SSLMO) | 2.95 × 10−6 | −1.76 × 10−3 | 2.61 × 10−1 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Zack (LFP, SSLFP) | 9.84 × 10−7 | −5.85 × 10−4 | 8.71 × 10−2 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Peters (SIB) | 7.38 × 10−6 | −4.39 × 10−3 | 6.53 × 10−1 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Deng (LiSB) | 3.04 × 10−7 | −1.81 × 10−4 | 5.81 × 10−2 | −3.11 × 10−3 | 2.35 × 100 | 1.57 × 101 |

| Eco. (ZEBRA) | 1.48 × 10−6 | −8.78 × 10−4 | 1.31 × 10−1 | −6.70 × 10−3 | 2.35 × 100 | 1.93 × 101 |

| Weber (VRFB) | 0.00 × 100 | 0.00 × 100 | 0.00 × 100 | 0.00 × 100 | 0.00 × 100 | 1.36 × 101 |

| Figure | Process | Amount | Unit |

|---|---|---|---|

| Inputs | |||

| Heat | market for heat, district or industrial, natural gas—Europe without Switzerland | 0.23 | kWh |

| Hydrogen peroxide | market for hydrogen peroxide, without water, in 50% solution—GLO | 2.28 | kg |

| Lithium hydroxide | market for lithium hydroxide–GLO | 1.60 | kg |

| Outputs | |||

| Lithium oxide | Lithium oxide production | 1.00 | kg |

| Inputs | |||

| Ammonia | market for ammonia, liquid—RoW | 0.52 | kg |

| Phosphorus pentachloride | market for phosphorus pentachloride—GLO | 3.84 | kg |

| Outputs | |||

| Triphosphorous pentanitride | triphosphorous pentanitride production | 1.00 | kg |

| Inputs | |||

| Lithium oxide | Lithium oxide production | 0.67 | kg |

| Phosphorous pentoxide | market for phosphoric acid, industrial grade, without water, in 85% solution APOS, S—GLO | 0.13 | kg |

| Triphosphorous pentanitride | triphosphorous pentanitride production | 0.20 | kg |

| Heat | market for heat, district or industrial, natural gas—Europe without CH | 2.96 | kWh |

| Outputs | |||

| LiPON | LiPON production | 1 | kg |

| Bauer (LTO) | Bauer (NCA) | Ell (NCM) | M-B (LFP) | M-B (NCM) | Notter (LMO) | Zack (LFP) | Peters (SIBs) | ||

|---|---|---|---|---|---|---|---|---|---|

| Inputs | |||||||||

| Waste BESS | 1 | kg | |||||||

| Treatment of used Li-ion battery, hydrometallurgical GLO | 0.49 | 0.00 | 0.00 | 0.5 | 0.00 | 0.61 | 0.53 | 0.47 | kg |

| Treatment of used Li-ion battery, pyrometallurgical GLO | 0.00 | 0.52 | 0.6 | 0.00 | 0.5 | 0.00 | 0.00 | 0.00 | kg |

| Market for hazardous waste, for incineration Europe without CH | 0.44 | 0.4 | 0.35 | 0.41 | 0.41 | 0.39 | 0.39 | 0.14 | kg |

| Market for waste electric and electronic equipment GLO | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | kg |

| Market for scrap steel—Europe without CH | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.35 | kg |

| Market for inert waste, for final disposal RoW | 0.23 | 0.14 | 0.14 | 0.26 | 0.15 | 0.16 | 0.30 | 0.14 | kg |

| Market for diesel, burned in building machine GLO | 0.1 | MJ | |||||||

| Market for electricity, medium voltage Europe without CH | 0.01 | kWh | |||||||

| Outputs (Avoided Products) | |||||||||

| Market for lithium hexafluorophosphate GLO | 19 (l) 0 (s) | 15 (l) 0 (s) | 13 (s) 0 (s) | 16 (l) 0 (s) | 16 (l) 0 (s) | 15 (l) 0 (s) | 16 (l) 0 (s) | 0 | mg |

| Sodium hexafluorophosphate production | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 12 | mg |

| Market for lithium GLO | 10 | 8 | 9 | 12 | 8 | 6 | 15 | 20 | mg |

| Market for sodium GLO | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | mg |

| Market for cobalt GLO | 0 | 67 | 75 | 0 | 70 | 0 | 0 | 0 | mg |

| Market for copper GLO | 9 | 125 | 179 | 116 | 116 | 185 | 49 | 0 | mg |

| Market for aluminium scrap, new RER | 107 | 94 | 46 | 55 | 55 | 115 | 25 | 54 | mg |

| Market for nickel, 99.5% GLO | 0 | 67 | 75 | 0 | 70 | 0 | 0 | 8 | mg |

| Market for manganese GLO | 0 | 0 | 70 | 0 | 65 | 101 | 0 | 76 | mg |

| Market for steel, unalloyed GLO | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 308 | mg |

| Market for iron ore, beneficiated, 65% Fe GLO | 79 | 0 | 0 | 95 | 0 | 0 | 119 | 0 | mg |

| Market for titanium, primary GLO | 167 | 0 | 0 | 0 | 0 | 0 | 0 | 7 | mg |

| Market for graphite GLO | 0 | 148 | 121 | 94 | 111 | 162 | 134 | 210 | mg |

| Process | Amount | Unit | Description |

|---|---|---|---|

| Inputs | |||

| Market for photovoltaic slanted-roof installation, 3 kWp, single-Si, panel, mounted, on roof—GLO (inverter considered separately) | items | CO of the PV system, mounting system; the In has been excluded. | |

| Market for cable, unspecified cable, unspecified —GLO | 0.1 | kg | CO of cables for a 0.17 kW/m2 PV system [57]. |

| Market for tube insulation, elastomere—GLO | 0.06 | kg | CO of plastic wires coating for a 0.17 kW/m2 PV system [57]. |

| Market for inverter, 2.5kW—GLO | items | - | |

| Market for charger, electric passenger car—GLO | 1.53 | kg | CO of a DC/DC converter weighting 1.53 kg/kW [58]. |

| BESS | kWh | CO of the BESS [25,29,30,42,44]. | |

| VRFB stack | 10.02 | kg | In case of VRFB [29]. |

| VRFB periphery | 5.13 | kg | In case of VRFB [29]. |

| Market for electricity, low voltage | MWh | In case of grid-connected SHSs. | |

| Market for diesel, burned in diesel-electric generating set, 18.5kW—GLO | MWh | In case of off-grid SHSs. | |

| Market for waste electric wiring—GLO | −0.1 ∙10% | kg | EoL of cables for a 0.17 kW/m2 PV system supposing 90% recycling efficiency [57]. |

| Market for used cable—GLO | −0.1 ∙90% | kg | EoL of cables for a 0.17 kW/m2 PV system supposing 90% recycling efficiency [57]. |

| Market for waste wire plastic—GLO | −0.06 | kg | EoL of plastic wires coating for a 0.17 kW/m2 PV system [57]. |

| Market for waste electric and electronic equipment—GLO | −1.53 | kg | EoL of a DC/DC converter weighting 1.53 kg/kW [40,58]. |

| Market for waste electric and electronic equipment—GLO | −4.37 | kg | CO of a DC/AC converter weighting 4.37 kg/kW [40,59]. |

| Market for auxiliary heating unit, electric, 5kW—GLO | 0.001 | items | Number of electric heaters considering an energy supply of 6.67W per kWh of capacity [46] |

| Outputs | |||

| Electricity (RF) | MWh | In case of grid-connected SHS. | |

| MWh | In case of off-grid SHS. | ||

| Exhausted BESS, waste treatment | kWh | CO of a DC/AC converter weighting 4.37 kg/kW [40,59]. | |

| Exhausted PV, waste treatment | 4.29 | kg | EoL of PV modules weighting 4.29 kg/kW [40,60,61]. |

| Market for cable, unspecified—GLO | 0.1 ∙90% | kg | Avoided product, from cables recycling. |

| Component | Lifespan | Unit | ||

|---|---|---|---|---|

| PV | 25 | yr | [62] | |

| BESS | - | yr | [62] | |

| In | 10 | yr | [62] | |

| CC | 11 | yr | [62] | |

| Wiring | 10 | yr | [62] | |

| VRFB stack | 10 | yr | [29] | |

| VRFB periphery | 10 | yr | [29] | |

| ZEBRA battery heater | 10 | yr | [45] |

| Parameter | DK | ES | FR | GR | HU | IT | PT | RO |

|---|---|---|---|---|---|---|---|---|

| 5.4 | 4.5 | 7.2 | 5.6 | 3.3 | 3.2 | 3.8 | 1.8 | |

| 0.7 | 3.3 | 1.2 | 2.9 | 1.0 | 2.8 | 3.3 | 1.6 |

| LIBs, SSLIBs, SIBs, ZEBRA | LiSBs | VRFBs | ||||

|---|---|---|---|---|---|---|

| DK | 32.03 | 4.53 | 32.03 | 18.53 | 17.44 | 17.61 |

| ES | 4.33 | 2.55 | 4.33 | 15.41 | 14.51 | 12.98 |

| FR | 16.86 | 17.44 | 16.86 | 24.54 | 23.10 | 20.67 |

| GR | 6.52 | 5.64 | 6.52 | 19.05 | 17.93 | 16.04 |

| HU | 8.22 | 2.21 | 8.22 | 11.45 | 10.77 | 9.64 |

| IT | 3.82 | 3.56 | 3.82 | 10.89 | 10.25 | 9.17 |

| PT | 4.27 | 4.43 | 4.27 | 13.00 | 12.24 | 10.95 |

| RO | 4.01 | 1.55 | 4.01 | 6.27 | 5.90 | 5.28 |

| Min | Max | Min | Max | Min | Max | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DK | 1.63 | Deng (LiSB) | 8.31 | Eco. (ZEBRA) | 11.31 | Ell (NCM) | 13.93 | Weber (VRFB) | 337.73 | Deng (LiSBs) | 361.76 | Peters (SIB) |

| ES | 1.89 | Deng (LiSB) | 8.95 | Eco. (ZEBRA) | 7.30 | Ell (NCM) | 13.02 | Deng (LiSBs) | 6.21 | Weber (VRFB) | 19.28 | Deng (LiSBs) |

| FR | 1.59 | Deng (LiSB) | 8.13 | Eco. (ZEBRA) | 8.30 | Ell (NCM) | 11.67 | Notter (LMO) | 66.55 | Notter (LMO) | 103.48 | M-B (NCM) |

| GR | 1.86 | Deng (LiSB) | 8.86 | Eco. (ZEBRA) | 10.16 | Ell (NCM) | 13.54 | Weber (VRFB) | 26.74 | Weber (VRFB) | 36.24 | Ell (NCM) |

| HU | 1.72 | Deng (LiSB) | 8.52 | Eco. (ZEBRA) | 3.64 | Ell (NCM) | 4.90 | Weber (VRFB) | 62.16 | Weber (VRFB) | 75.35 | Ell (NCM) |

| IT | 1.97 | Deng (LiSB) | 9.06 | Eco. (ZEBRA) | 5.75 | Ell (NCM) | 8.31 | Weber (VRFB) | 9.60 | Weber (VRFB) | 13.64 | Ell (NCM) |

| PT | 1.71 | Deng (LiSB) | 8.52 | Eco. (ZEBRA) | 4.45 | Ell (NCM) | 6.31 | Weber (VRFB) | 11.23 | Weber (VRFB) | 16.57 | Ell (NCM) |

| RO | 1.86 | Deng (LiSB) | 8.88 | Eco. (ZEBRA) | 2.93 | Ell (NCM) | 3.67 | Weber (VRFB) | 29.86 | Weber (VRFB) | 34.14 | Ell (NCM) |

| Best SHS, with LIBs [Pts/MWh] | Best SHS, with SSLIBs [Pts/MWh] | Best SHS, with aBESS [Pts/MWh] | Mix | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| On-Grid | Off-Grid | On-Grid | On-Grid | Off-Grid | BESS | On-Grid | On-Grid | BESS | [Pts/MWh] | |

| DK | 24.00 | 93.02 | Ell (NCM) | 23.18 | 90.05 | Ell (SSNCM) | 22.75 | 89.62 | Peters (SIB) | 42.43 |

| ES | 19.24 | 26.39 | 16.76 | 23.63 | 18.78 | 27.90 | Weber (VRFB) | 37.45 | ||

| FR | 26.82 | 47.25 | 24.87 | 44.18 | 26.31 | 45.84 | Weber (VRFB) | 7.58 | ||

| GR | 24.59 | 31.10 | 22.40 | 28.34 | 25.99 | 31.13 | Weber (VRFB) | 112.96 | ||

| HU | 21.55 | 43.56 | 20.04 | 40.68 | 22.15 | 44.11 | Peters (SIB) | 55.36 | ||

| IT | 22.40 | 31.51 | 20.11 | 28.83 | 22.28 | 32.59 | Weber (VRFB) | 41.56 | ||

| PT | 20.95 | 28.12 | 18.50 | 25.23 | 20.02 | 27.36 | Weber (VRFB) | 39.53 | ||

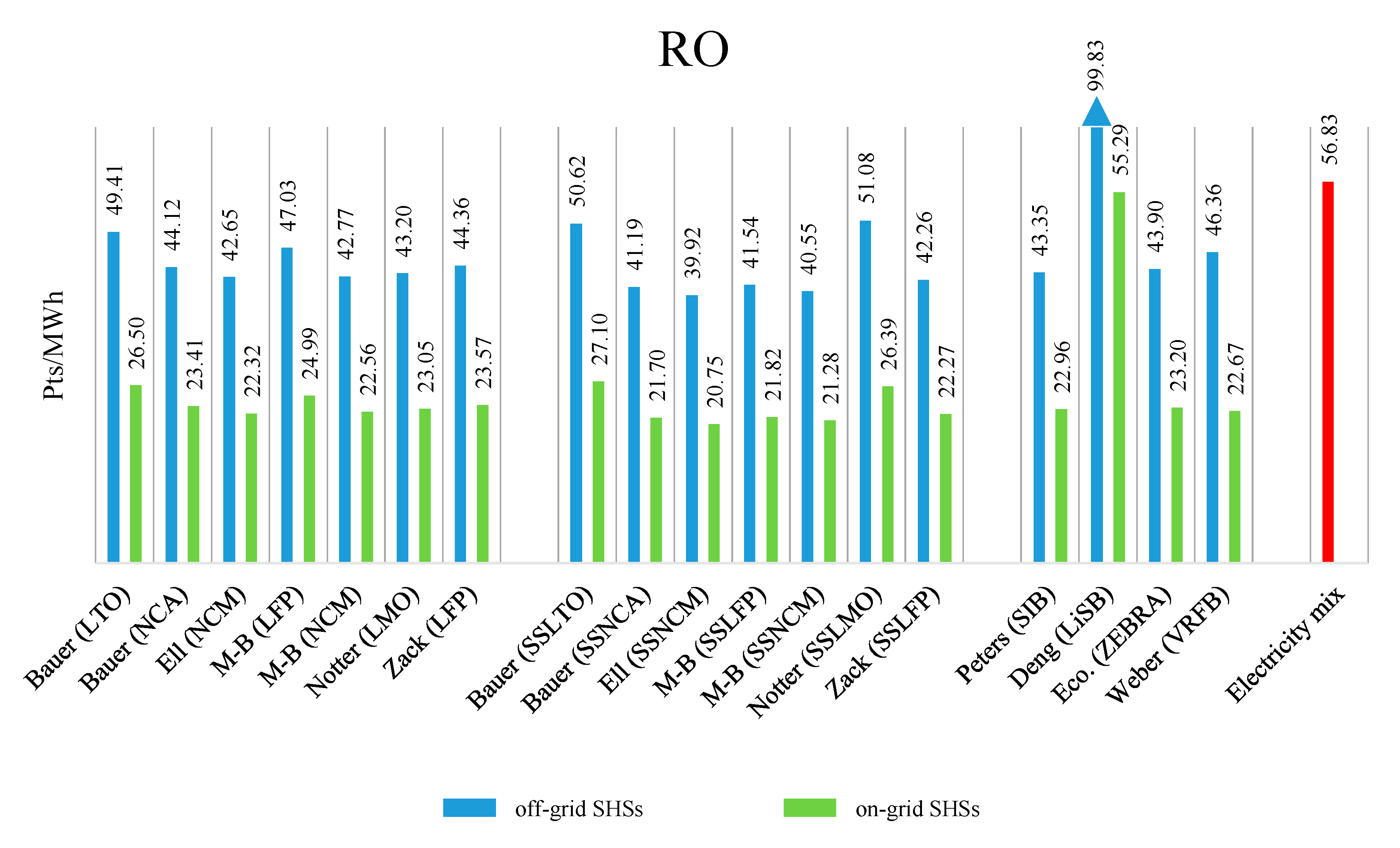

| RO | 22.32 | 42.65 | 20.75 | 39.91 | 22.67 | 46.36 | Weber (VRFB) | 56.83 | ||

| PV | BESS | In | CC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| On-Grid | Off-Grid | On-Grid | Off-Grid | On-Grid | Off-Grid | On-Grid | Off-Grid | On-Grid | Off-Grid | |

| DK | 83.24% | 77.63% | 9.76% | 9.11% | 2.46% | 2.30% | 0.29% | 0.27% | 4.25% | 10.69% |

| ES | 60.70% | 47.86% | 13.39% | 10.57% | 7.49% | 5.90% | 5.37% | 4.24% | 13.05% | 31.43% |

| FR | 70.50% | 45.14% | 7.11% | 6.31% | 15.25% | 13.54% | 6.24% | 5.54% | 0.90% | 29.47% |

| GR | 48.79% | 48.61% | 8.86% | 8.83% | 8.82% | 8.79% | 4.32% | 4.30% | 29.21% | 29.47% |

| HU | 75.85% | 71.06% | 6.85% | 6.41% | 4.26% | 3.99% | 6.71% | 6.29% | 6.33% | 12.25% |

| IT | 59.93% | 48.99% | 10.33% | 8.44% | 11.69% | 9.55% | 5.30% | 4.34% | 12.75% | 28.68% |

| PT | 60.84% | 52.38% | 12.04% | 10.37% | 13.21% | 11.38% | 5.39% | 4.64% | 8.52% | 21.23% |

| RO | 71.04% | 64.43% | 6.83% | 6.20% | 5.77% | 5.24% | 6.29% | 5.73% | 10.07% | 18.40% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, F.; Parisi, M.L.; Greven, S.; Basosi, R.; Sinicropi, A. Life Cycle Assessment of Classic and Innovative Batteries for Solar Home Systems in Europe. Energies 2020, 13, 3454. https://doi.org/10.3390/en13133454

Rossi F, Parisi ML, Greven S, Basosi R, Sinicropi A. Life Cycle Assessment of Classic and Innovative Batteries for Solar Home Systems in Europe. Energies. 2020; 13(13):3454. https://doi.org/10.3390/en13133454

Chicago/Turabian StyleRossi, Federico, Maria Laura Parisi, Sarah Greven, Riccardo Basosi, and Adalgisa Sinicropi. 2020. "Life Cycle Assessment of Classic and Innovative Batteries for Solar Home Systems in Europe" Energies 13, no. 13: 3454. https://doi.org/10.3390/en13133454

APA StyleRossi, F., Parisi, M. L., Greven, S., Basosi, R., & Sinicropi, A. (2020). Life Cycle Assessment of Classic and Innovative Batteries for Solar Home Systems in Europe. Energies, 13(13), 3454. https://doi.org/10.3390/en13133454