Heating Performance Analysis of an Air-to-Water Heat Pump Using Underground Air for Greenhouse Farming

Abstract

:1. Introduction

2. Heat Transfer from Underground Air to Heat Pumps

3. Method

3.1. The AWHP at the Greenhouse

3.2. COP of the AWHP

4. Results

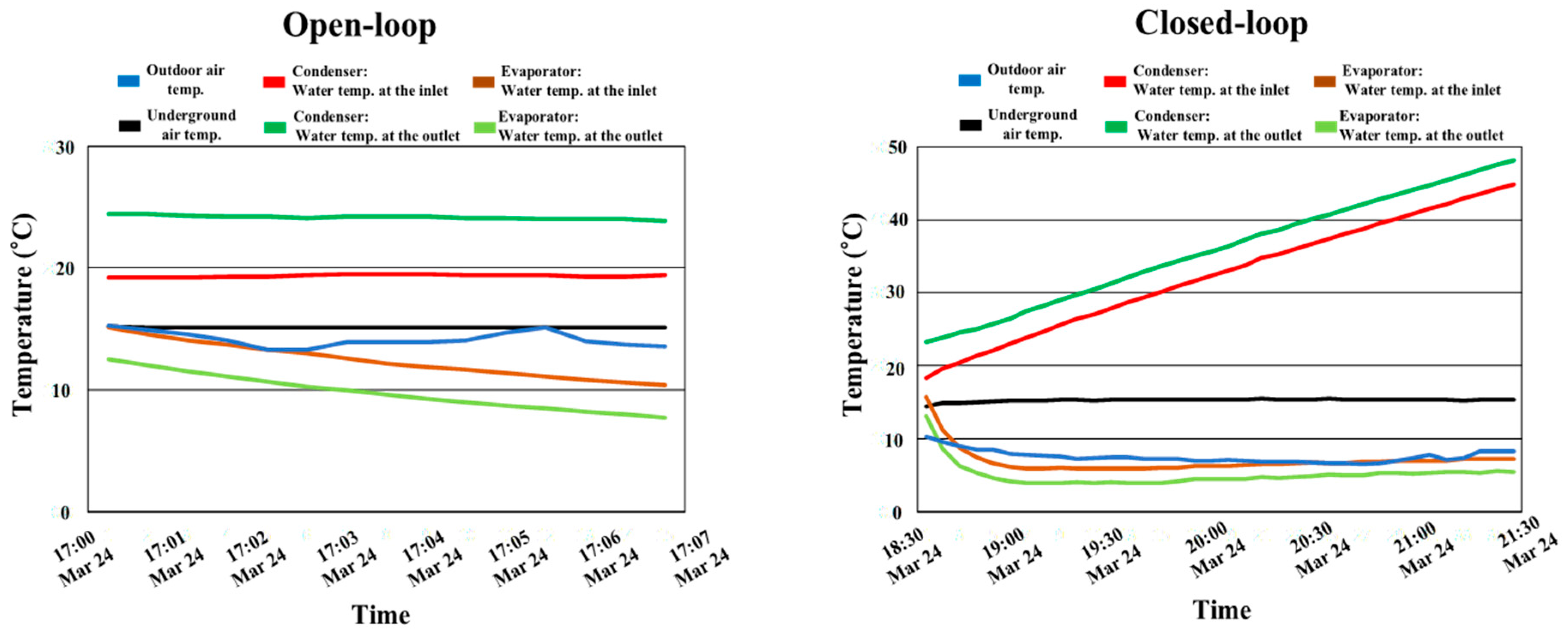

4.1. The Temperature Profiles of the System During the Condenser Operation

4.2. Heating Capacity for the Heating Application

4.3. Economic Assessment of the AWHP

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Gonzato, S.; Chimento, J.; O’Dwyer, E.; Bustos-Turu, G.; Acha, S.; Shah, N. Hierarchical price coordination of heat pumps in a building network controlled using model predictive control. Energy Build. 2019, 202, 109421. [Google Scholar] [CrossRef]

- Jim, C.Y. Air-conditioning energy consumption due to green roofs with different building thermal insulation. Appl. Energy 2014, 128, 49–59. [Google Scholar] [CrossRef]

- Stavrakakis, G.M.; Androutsopoulos, A.V.; Vyörykkä, J. Experimental and numerical assessment of cool-roof impact on thermal and energy performance of a school building in Greece. Energy Build. 2016, 130, 64–84. [Google Scholar] [CrossRef]

- Zagorskas, J.; Zavadskas, E.K.; Turskis, Z.; Burinskienė, M.; Blumberga, A.; Blumberga, D. Thermal insulation alternatives of historic brick buildings in Baltic sea region. Energy Build. 2014, 78, 35–42. [Google Scholar] [CrossRef]

- Jiang, A.; O’Meara, A. Accommodating thermal features of commercial building systems to mitigate energy consumption in Florida due to global climate change. Energy Build. 2018, 179, 86–98. [Google Scholar] [CrossRef]

- Hong, G.; Kim, D.D. Airtightness of electrical, mechanical and architectural components in South Korean apartment buildings using the fan pressurization and tracer gas method. Build. Environ. 2018, 132, 21–29. [Google Scholar] [CrossRef]

- Martinez, A.; Díaz de Garayo, S.; Aranguren, P.; Astrain, D. Assessing the reliability of current simulation of thermoelectric heat pumps for nearly zero energy buildings: Expected deviations and general guidelines. Energy Convers. Manag. 2019, 198, 111834. [Google Scholar] [CrossRef]

- D’Ettorre, F.; De Rosa, M.; Conti, P.; Testi, D.; Finn, D. Mapping the energy flexibility potential of single buildings equipped with optimally-controlled heat pump, gas boilers and thermal storage. Sustain. Cities Soc. 2019, 50, 101689. [Google Scholar] [CrossRef]

- Clauß, J.; Georges, L. Model complexity of heat pump systems to investigate the building energy flexibility and guidelines for model implementation. Appl. Energy 2019, 255, 113847. [Google Scholar] [CrossRef]

- Neirotti, F.; Noussan, M.; Simonetti, M. Towards the electrification of buildings heating—real heat pumps electricity mixes based on high resolution operational profiles. Energy 2020, 195, 116974. [Google Scholar] [CrossRef]

- Li, S.; Gong, G.; Peng, J. Dynamic coupling method between air-source heat pumps and buildings in China’s hot-summer/cold-winter zone. Appl. Energy 2019, 254, 113664. [Google Scholar] [CrossRef]

- Lozano Miralles, J.A.; López García, R.; Palomar Carnicero, J.M.; Martínez, F.J.R. Comparative study of heat pump system and biomass boiler system to a tertiary building using the life cycle assessment (LCA). Renew. Energy 2020, 152, 1439–1450. [Google Scholar] [CrossRef]

- Potočnik, P.; Vidrih, B.; Kitanovski, A.; Govekar, E. Analysis and optimization of thermal comfort in residential buildings by means of a weather-controlled air-to-water heat pump. Build. Environ. 2018, 140, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Yu, Q.d. Applied research on water loop heat pump system based on a novel mechanism of energy conversion. Appl. Therm. Eng. 2019, 153, 575–582. [Google Scholar] [CrossRef]

- Le, K.X.; Huang, M.J.; Shah, N.N.; Wilson, C.; Artain, P.M.; Byrne, R.; Hewitt, N.J. Techno-economic assessment of cascade air-to-water heat pump retrofitted into residential buildings using experimentally validated simulations. Appl. Energy 2019, 250, 633–652. [Google Scholar] [CrossRef]

- Daghigh, R.; Ruslan, M.H.; Sulaiman, M.Y.; Sopian, K. Review of solar assisted heat pump drying systems for agricultural and marine products. Renew. Sustain. Energy Rev. 2010, 14, 2564–2579. [Google Scholar] [CrossRef]

- Koşan, M.; Demirtaş, M.; Aktaş, M.; Dişli, E. Performance analyses of sustainable PV/T assisted heat pump drying system. Sol. Energy 2020, 199, 657–672. [Google Scholar] [CrossRef]

- Ashok Kumar, M.; Kumaresan, G.; Rajakarunakaran, S. Experimental study of moisture removal rate in Moringa leaves under vacuum pressure in closed-loop heat pump dryer. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Singh, A.; Sarkar, J.; Sahoo, R.R. Experimental energy, exergy, economic and exergoeconomic analyses of batch-type solar-assisted heat pump dryer. Renew. Energy 2020, 156, 1107–1116. [Google Scholar] [CrossRef]

- Hasan Ismaeel, H.; Yumrutaş, R. Investigation of a solar assisted heat pump wheat drying system with underground thermal energy storage tank. Sol. Energy 2020, 199, 538–551. [Google Scholar] [CrossRef]

- Kuan, M.; Shakir, Y.; Mohanraj, M.; Belyayev, Y.; Jayaraj, S.; Kaltayev, A. Numerical simulation of a heat pump assisted solar dryer for continental climates. Renew. Energy 2019, 143, 214–225. [Google Scholar] [CrossRef]

- Fadhel, M.I.; Sopian, K.; Daud, W.R.W.; Alghoul, M.A. Review on advanced of solar assisted chemical heat pump dryer for agriculture produce. Renew. Sustain. Energy Rev. 2011, 15, 1152–1168. [Google Scholar] [CrossRef]

- Tunckal, C.; Doymaz, İ. Performance analysis and mathematical modelling of banana slices in a heat pump drying system. Renew. Energy 2020, 150, 918–923. [Google Scholar] [CrossRef]

- Yang, L.-H.; Huang, B.-H.; Hsu, C.-Y.; Chen, S.-L. Performance analysis of an earth–air heat exchanger integrated into an agricultural irrigation system for a greenhouse environmental temperature-control system. Energy Build. 2019, 202, 109381. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Performance analysis of a solar-assisted ground-source heat pump system for greenhouse heating: An experimental study. Build. Environ. 2005, 40, 1040–1050. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Experimental performance analysis of a solar assisted ground-source heat pump greenhouse heating system. Energy Build. 2005, 37, 101–110. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Exergoeconomic analysis of a solar assisted ground-source heat pump greenhouse heating system. Appl. Therm. Eng. 2005, 25, 1459–1471. [Google Scholar] [CrossRef]

- Ozgener, O. Use of solar assisted geothermal heat pump and small wind turbine systems for heating agricultural and residential buildings. Energy 2010, 35, 262–268. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Modeling and performance evaluation of ground source (geothermal) heat pump systems. Energy Build. 2007, 39, 66–75. [Google Scholar] [CrossRef]

- Jeju Special Self-Governing Province. Available online: https://www.Jeju.Go.Kr/ (accessed on 28 June 2020).

- Dizaji, H.S.; Jafarmadar, S.; Khalilarya, S. Novel experiments on cop improvement of thermoelectric air coolers. Energy Convers. Manag. 2019, 187, 328–338. [Google Scholar] [CrossRef]

| Component | Specification | ||

|---|---|---|---|

| Air/water direct contact heat exchanger | Material | Stainless steel | |

| Diameter (mm) | 1000 | ||

| Height (mm) | 2500 | ||

| Heat transfer fluid | Normal water | ||

| Heat pump | Compressor | Type | High-temperature scroll type |

| Capacity | 35 kW (10 RT) | ||

| Voltage | 380 V (3 Phase) | ||

| Condenser/Evaporator | Flat type heat exchanger | ||

| Refrigerant | R22 | ||

| Heat storage tank | Diameter (mm) | 2000 | |

| Height (mm) | 2000 | ||

| Heat storage fluid | Normal water | ||

| Turbo blower | Capacity | 7.5 kW | |

| Airflow rate | 102 m3/min | ||

| PT868 |

|

| CW240 |

|

| System | Energy Consumption | Total Heating Cost | Comparison (%) | |

|---|---|---|---|---|

| South Korea Won | US Dollar | |||

| AWHP | 4064 kWh/m2 (Electricity) | ₩184,912 | $154 | 24.7 |

| Conventional air heater | 889.8 liters of diesel/m2 | ₩747,432 | $621 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, T.; Baik, Y.-K.; Kim, D.D. Heating Performance Analysis of an Air-to-Water Heat Pump Using Underground Air for Greenhouse Farming. Energies 2020, 13, 3863. https://doi.org/10.3390/en13153863

Lim T, Baik Y-K, Kim DD. Heating Performance Analysis of an Air-to-Water Heat Pump Using Underground Air for Greenhouse Farming. Energies. 2020; 13(15):3863. https://doi.org/10.3390/en13153863

Chicago/Turabian StyleLim, Taesub, Yong-Kyu Baik, and Daeung Danny Kim. 2020. "Heating Performance Analysis of an Air-to-Water Heat Pump Using Underground Air for Greenhouse Farming" Energies 13, no. 15: 3863. https://doi.org/10.3390/en13153863

APA StyleLim, T., Baik, Y.-K., & Kim, D. D. (2020). Heating Performance Analysis of an Air-to-Water Heat Pump Using Underground Air for Greenhouse Farming. Energies, 13(15), 3863. https://doi.org/10.3390/en13153863