1. Introduction

Over the past few years, the number of sensitive loads such as medical equipment in hospitals and health clinics, schools, prisons, etc. has quadrupled which makes the power quality of the sensitive loads a pressing concern [

1]. If the power quality is not high, there could be dire consequences like substantial economic losses, production losses, sensitive and critical loads outage, and missing data [

2]. This is why having high power quality is key to the customers, utilities, and also electrical devices producers. Voltage sags, voltage swells, transients, harmonics, fluctuations, flickers, and interruptions are the essential power quality issues [

3,

4,

5,

6]. They will be all explained further in the following section.

These power quality issues and voltage disturbances must be averted when it comes to sensitive and critical loads. To that end, a wide variety of solutions have been presented among which, power electronics-based devices known as Custom Power Devices (CPDs) are considered as the best and the most cost-effective solution for compensating and mitigating voltage disturbances [

7,

8]. CPDs can be connected in parallel, like the Distribution Static Synchronous Compensator (DSTATCOM), in series like the Dynamic Voltage Restorer (DVR), and as parallel-series like the Unified Power Quality Conditioner (UPQC). They serve as compensation systems, and each one has a different control method and application. Their applications/functions will all be explained further in the following section. DSTATCOM is employed to correct the power factor.

UPQC can inject voltage in series and current in parallel at the same time. The size and cost of UPQC and DSTATCOM are more, however, as opposed to DVR [

9]. DVR is used as the most cost-effective solution to mitigate voltage sags, as they are the most severe and common power quality issues in the modern power system [

10].

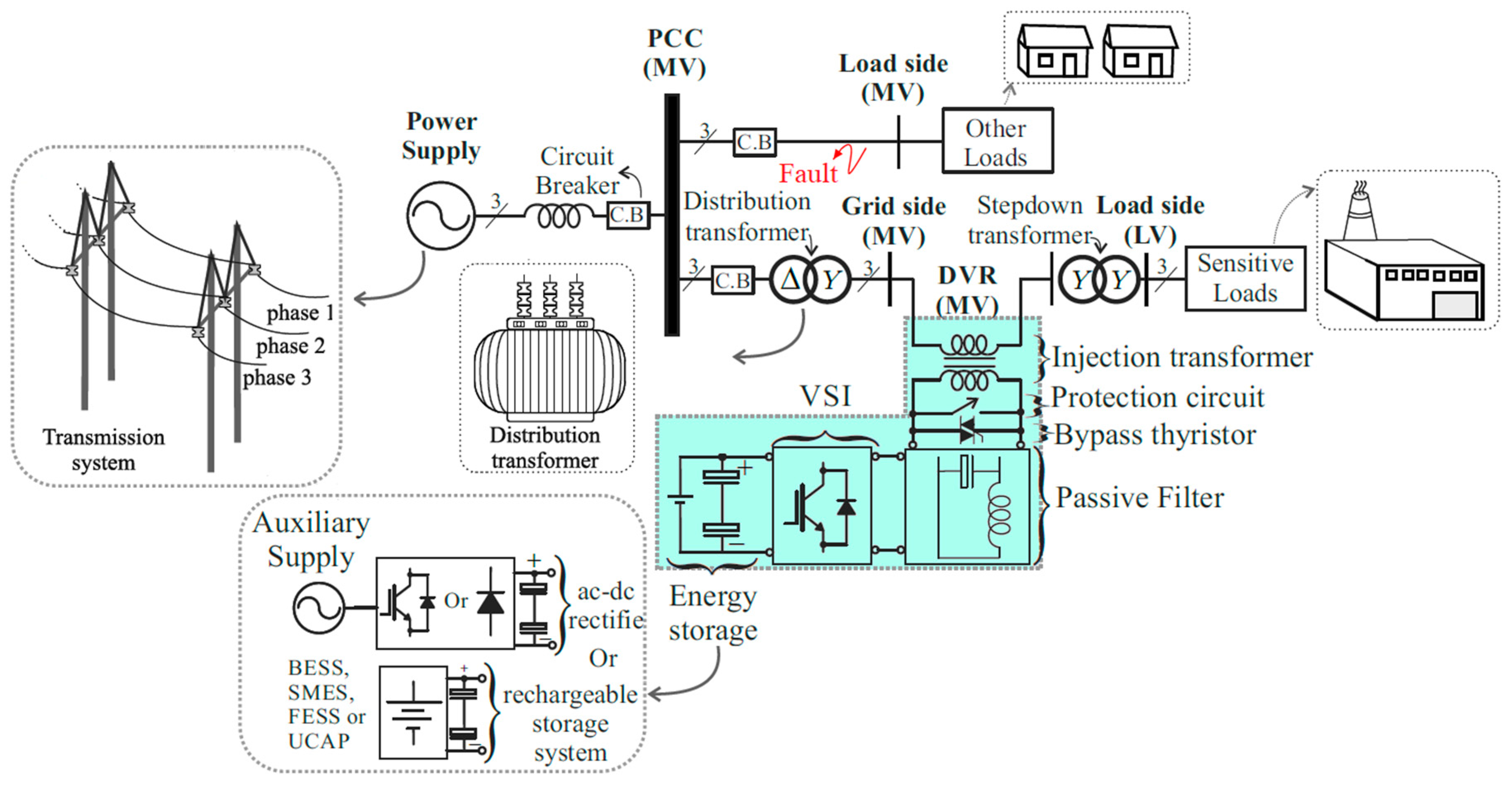

Figure 1 shows the DVR schematic in the low voltage network. The DVR as a power electronic-based device injects the desired voltage to the load-side when there is a voltage disturbance at the supply-side. As well as that, the DVR can protect sensitive and critical loads against supply-side disturbances [

11,

12]. This means that the DVR plays a prominent role in voltage sag compensation and sensitive load protection as well. The DVR is the most effective CPD because its cost is low, its size is small, and it is capable of responding fast to the voltage disturbances. For instance, the installation cost of DVR for the power range of 2–10 MVA is USD 300/kVA, yet the installation cost of Uninterruptible Power Supply (UPS) is USD 500/kVA.

The maintenance and operation costs of DVR are about 5% of its initial cost, but this value is considerably more (about 15%) [

3]. UPQC is a combination of DSTATCOM and DVR in which two power converters are used. Therefore, from the viewpoint of structure, the DVR is smaller than UPQC. DVR and DSTATCOM are similar, but DVR can protect sensitive loads from supply disturbances, and DSTATCOM protects such loads against disturbances of the load side. Plus, the DVR usually responds to voltage disturbances quite fast (less than 1/4 cycle), as opposed to the other CPDs like Static VAR Compensator (SVC) (2–3 cycles) [

13].

For improving the power quality, reducing the cost, and enhancing the DVR’s performance, many DVR topologies from the different viewpoints of the energy storage, power converter, and control system have been studied.

Moreover, modifying the DVR topology and the integration of renewable energy resources with the DVR has become more popular. Some general reviews on the DVRs have been provided that lack an in-depth study on modified configurations of DVR and its integration with renewable energy technologies [

14,

15,

16]. A comprehensive review of different DVR topologies, the modified DVR topologies, and also the integration of distributed generations with DVR will serve as an extensive reference for those researchers and engineers who are working on power quality issues and voltage disturbance mitigation. The significant contribution of this work is to provide a detailed review on the most critical aspects of the DVR, like principles, operation modes, components, different topologies of DVR from the viewpoint of energy storage, power converters, control units, compensation methods, modulation strategies, and also modified configurations and DVR integration with distributed generation.

The organization of this paper is as follows. The power quality issues, standards, classifications, causes, and effects are provided in

Section 2. Additionally, the most crucial custom power devices and their applications are elucidated. In

Section 3, the principle of DVR and its different operation modes are described. The components of the DVR power circuit such as injection transformer, energy storage unit, voltage source inverter, filter, and bypass switch are presented in

Section 4. DVR topologies from the viewpoint of energy storage are studied in

Section 5. In

Section 6, different single-/three-phase DVR power converter topologies are discussed. Following this, DVR control units, including voltage disturbance detection methods, reference generation, voltage and current control, and modulation strategies are reviewed in

Section 7. Finally, different DVR-modified configurations along with distributed generation integration with DVR are provided in

Section 8, followed by the conclusions along with scopes for future work in

Section 9.

2. Power Quality

Power quality has become a significant concern for electricity providers and their customers. From the customers’ viewpoint, the financial repercussions of disturbances can be hundreds of dollars to millions of dollars in generation loss. From the viewpoint of utilities, disturbances bring about customer satisfaction loss and also load and revenue losses. In general, any deviation from the normal of a voltage source can be categorized as a power quality issue. Power quality issues can be rapid events such as voltage impulses, voltage transients, high-frequency noise, faults, voltage swells/sags, and total power loss. Thus, power quality issues have a direct effect on electrical equipment [

17,

18,

19]. The disturbances that may cause power quality issues can be lightning and natural phenomena, energization of capacitor banks and transformers, start-up or switching of large loads like motors, operation of non-linear and unbalanced loads, or failure of equipment like transformers and cables.

IEEE and IEC are the two primary standards related to power quality issues. The newest revisions of these standards are provided in

Table 1 [

20,

21,

22,

23,

24,

25,

26,

27,

28,

29]. The classification of power quality issues based on IEEE 519 standards is shown in

Figure 2 [

20]. The most critical power quality issues, their definitions, causes, and effects are provided in

Table 2, along with their duration and magnitude in

Table 3 [

20,

21,

22,

23,

24,

25,

26,

27,

28,

29].

Custom Power Devices (CPDs)

Storage units are used for critical equipment protection against interruption, leading to voltage sags. Uninterruptible Power Supply (UPS), Superconducting Magnetic Energy Storage (SMES), Ultracapacitors (UCAP), Flywheel Energy Storage System (FESS), and Batteries are some examples of storage systems. These are used to compensate for the energy that is needed because of faults and voltage sags. Among the many different methods of mitigating voltage sags/swells, custom power devices (CPDs) are the most efficient method. Just as Flexible AC Transmission Systems (FACTS) can improve the power quality and stability of the modern power system, CPDs make sure customers receive high quality and reliability of supply [

30,

31]. The most essential CPDs are provided below.

Table 4 provides some of the CPDs’ applications for mitigating power quality issues.

Active Power Filter (APF), Battery Energy Storage Systems (BESS), Distribution Static Synchronous Compensator (DSTATCOM), Dynamic Voltage Restorer (DVR), Interline Power Flow Controller (IPFC), Solid-State Transfer Switch (SSTS), Solid-State Circuit Breaker (SSCB), Static Current Limiter (SCL), Static Synchronous Compensator (STATCOM), Static Synchronous Series Compensator (SSSC), Static VAR Compensator (SVC), Superconducting Magnet Energy Storage (SMES), Surge Arrester (SA), Transient Voltage Surge Suppressors (TVSS), Unified Power Flow Controller (UPFC), Unified Power Quality Conditioner (UPQC), Uninterruptible Power Supply (UPS).

3. DVR: Principle

For the prevention of interruptions caused by voltage sag, particularly in critical loads, the foremost choice is the DVR. The principles of DVR’s performance dictate the fact that DVR injects the desired voltage and mitigates every balanced/imbalanced voltage [

32]. The DVR supplies its active power from the Direct Current (DC) power supply and therefore injects its reactive power into the system. Moreover, DVR operates in standby mode in normal conditions, unless abnormal conditions occur in the network. The DVR is the supplier of the voltage difference (during voltage sag) between lines and maintain the nominal voltage value at the load-side. By and large, it can be applied to protect critical loads by halting sudden alterations in voltage.

The DVR is composed of injection transformers, protection circuit, bypass thyristor, passive filters, voltage source inverter (VSI), and energy storage (see

Figure 1) [

33,

34,

35,

36,

37,

38,

39,

40,

41]. When a voltage sag/swell happens, the DVR injects a series voltage (

) into the network via the transformer. Therefore, the magnitude of load voltage can be maintained to its nominal value. The injected voltage is expressed below (

Figure 3) [

33]:

where

,

, and

are the load, the sagged supply, and the injected voltages, respectively. The load power of each phase under reasonable voltage condition is [

33]:

where

and

are the active and reactive power of load during sags/swells and

is the load current. Once the DVR restores the desired voltage to normal, Equation (2) can be expressed as below [

33]:

3.1. Operation Modes

The DVR operates in three modes which are the protection mode, the standby mode, and the injection mode.

3.1.1. Protection Mode

In this mode of operation, DVR is protected from the high current on the load-side that exceeds an acceptable limit. This high current caused by faults on the load-side can damage the DVR. Thus, the DVR must be protected from such fault currents. An alternative path can do this, which is typically made by the breakers and thyristors. Not considering this alternative path causes an overvoltage happening in the injection transformers [

42].

3.1.2. Standby Mode ()

In this mode of operation, the DVR does not inject voltage because no voltage disturbances are detected. Therefore, the bypass switch bypassed the DVR to prevent any possible little voltage injection. Once a voltage disturbance is identified, the low voltage winding of the injection transformer is short-circuited via the VSI [

42,

43].

3.1.3. Injection Mode ()

In this mode of operation, the DVR switches from the standby mode to this mode if a voltage disturbance is found. Then, the DVR injects the desired voltage through the injection transformer until the voltage is wholly mitigated and returned to its healthy condition [

43].

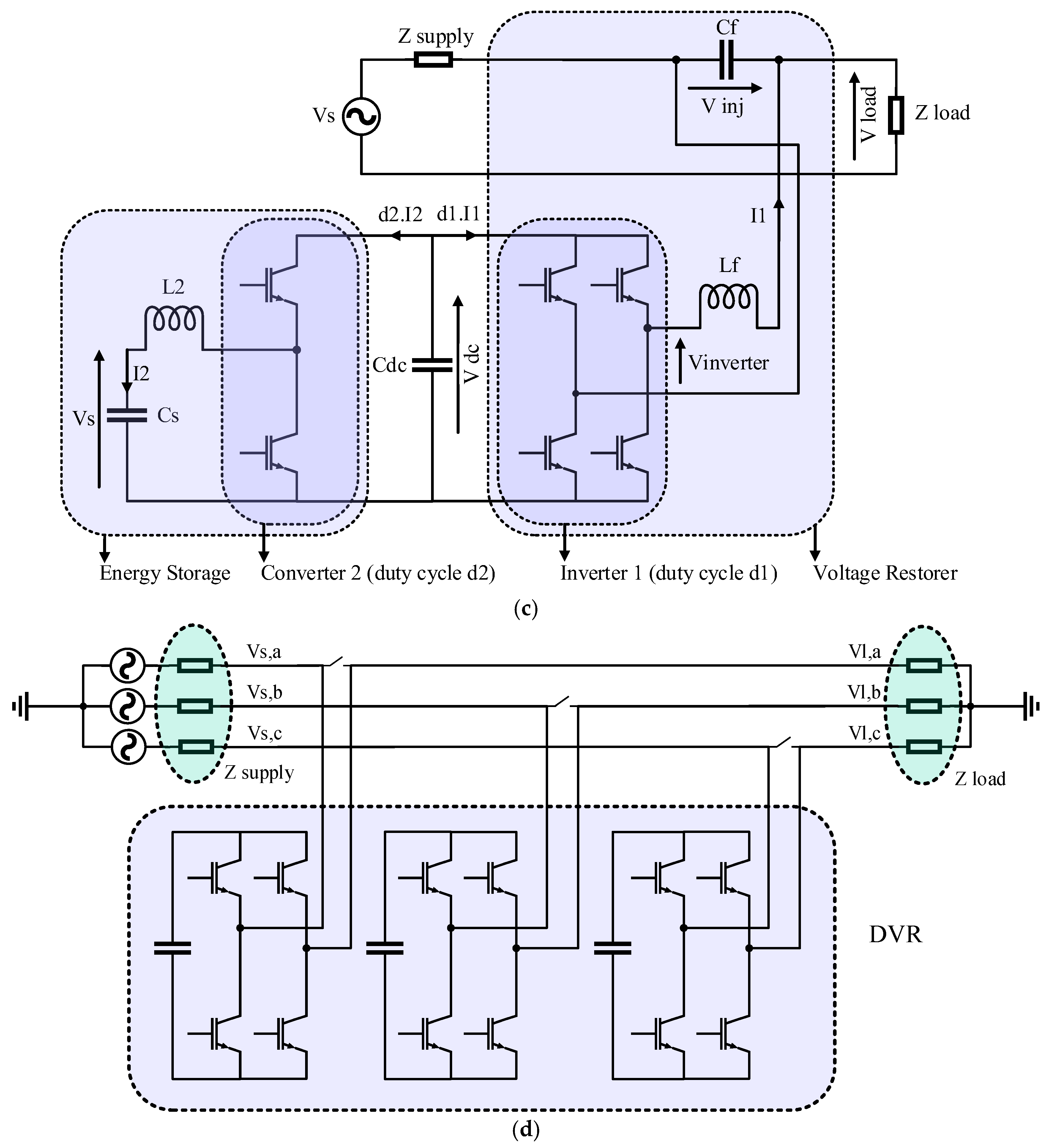

6. DVR: Power Converter Topologies

From the power converter viewpoint, DVR can be categorized into single-/three-phase DVR topologies (

Figure 7) [

55,

56,

57,

58,

59,

60,

61,

62]. Full-bridge, known as H-bridge, and half-bridge are the most common power converters used in single-phase topologies of the DVR. Although direct AC/AC power converters, multilevel inverters (MLIs), and impedance-source inverter (ZSI) families are deployed in single-phase topologies of the DVR, they are mostly utilized for three-phase topologies of the DVRs [

55,

56,

57,

58]. The power converter topologies used mostly in three-phase DVRs are three full-bridge inverters, four-leg inverters, two-level inverters (four-wire), also split-capacitor two-level inverters [

59,

60,

61,

62].

For LV grid applications, DVR topologies with two-level power converters are typically used because the switching method—Pulse Width Modulation (PWM)—is simple, and it costs less than MLIs. Two-level power converter topologies cannot be applied for Medium-Voltage (MV) grid applications because of the high voltages on switches, which is why power-electronic devices are typically used in the MV grid connections. One option to address this problem is to employ series- or parallel-connected switches. However, a better option is employing MLIs. The MLIs have good harmonic characteristics (lower harmonic components), higher power quality, reliable operation at higher voltage levels, and lower switching stress across the switches. The MLIs can be classified into Diode-Clamped MLI (DC MLI) known as Neutral-Point Clamped MLI (NPC MLI), Flying Capacitor MLI (FC MLI), and Cascaded H-Bridge MLI (CHB MLI). The last MLI topology, CHB MLI, is the most renowned one.

In the NPC MLI topology, as the number of voltage level increases more than three, the balancing of capacitors’ voltage is far from easy, which is why the three-level NPC MLI is typically used [

63,

64,

65,

66]. In the FC MLI topology, not only is the selection of switches more flexible but also the voltage balance of capacitors is more controllable. Therefore, the higher voltage level applications are not challenging, as opposed to the NPC MLI topology. However, the FC MLI has a downside that if the voltage level goes up, the number of capacitors goes up [

67,

68,

69]. The CHB MLI topology, the most common MLI topology as previously mentioned, has a modularity feature, thereby increasing its reliability. The only disadvantage of CHB MLI topology is that isolated DC sources are needed for each H-bridge. One solution is to connect a low-frequency transformer to each H-bridge output. By doing so, rather than using several isolated DC sources, one DC source is used [

53,

70,

71,

72,

73,

74,

75,

76,

77,

78]. Other hybrid or modified MLI topologies, aside from the MLI mentioned above topologies, have also been presented in DVR [

79,

80,

81].

It should be pointed out that apart from the advantages mentioned above of MLIs, they have a disadvantage of requiring a surplus of clamping diodes, switches, and energy storage units based on the MLI’s type.

One of the power converter topologies of the DVR is AC/AC converters which can be in unique structures like direct, matrix, and ZSI [

82,

83,

84,

85,

86,

87,

88,

89,

90,

91,

92,

93]. In this topology, there is no need for DC-link and energy storage. This is the main outstanding advantage of DVRs with AC/AC power converter topology, which results in lower weight, volume, and cost. The elimination of DC-link and energy storage units can also increase the reliability of topology. Moreover, this topology can compensate and mitigate prolonged voltage disturbances. Like other topologies, this topology has some disadvantages. To cite a few, the operation of bidirectional semiconductor switches is not smooth as they are used primarily in this topology. Plus, voltage drops can occur on the line as more current must be drawn from the grid for providing the load with equal power. This drawback exists in topologies that have no energy storage, and chances are the current exceeds the line limits. Therefore, the AC/AC power converter topology cannot compensate and mitigate deep sags, mainly when the DVR is linked to a weak network.

The DVR topologies from the power converter (three-phase) perspective, along with their merits and demerits are provided in

Table 6 [

82,

83,

84,

85,

86,

87,

88,

89,

90,

91,

92,

93].

Figure 8 illustrates three-phase power converter topologies of DVR based on the two-level inverter, split-capacitor two-level inverter, three full-bridge inverters, and ZSI [

82,

83,

84,

85,

86,

87,

88,

89,

90,

91,

92,

93]. Note that

Figure 8c shows the transformer connected DVR with three full-bridge inverters. The transformer-less DVR (TDVR) with three-phase full-bridge inverters will be explained and shown in

Section 8.

7. DVR: Control Unit

Controlling the magnitude, frequency, and phase angle is the primary function of the control unit in DVR as an essential part of DVR. The control unit has several stages from selecting the operation mode and detecting the voltage disturbance to pulse generation for VSI and injecting the desired voltage.

Figure 9 depicts different stages of the control unit in DVR.

First off, the input data, including load- and supply-side voltage, line current, and supplementary information like the nominal voltage, must be collected. The voltage and current values of each side (supply/load) are delivered to the operation mode and voltage disturbance system. This system has to determine what the DVR operation mode is. As previously described in

Section 5, the DVR’s operation mode can be protection, standby, and injection.

If the standby mode is determined, the bypass switch is turned on, and all the converter semiconductor switches are turned off. If the fault current decreases, then the DVR operation mode switches to protection mode. Based on the measured voltage, the voltage disturbance detection system detects the disturbance type like voltage sag/swell or harmonic. Thus, if a voltage sag or swell is identified, then the DVR operation mode switches to the mode of compensation, thereby generating the reference voltages. This system is to generate the desired voltage that is needed for injection by the DVR. Either an open-loop and closed-loop control can be used. If the former is used, the reference generation system’s output is separated by the DC-link to generate reference voltages. If the latter is used, which happens to be more preferable, the generation system’s output supplies the voltage and current controllers. Thus, the controller’s output is the reference voltage. Finally, it is designated to the modulation to create switching pulses of the VSI.

Several different methods have been introduced and presented for every abovementioned stage of the control unit in the DVR. The most commonly used methods for every stage are illustrated in

Figure 10 [

7,

42,

69,

94,

95,

96,

97,

98,

99,

100,

101,

102,

103,

104,

105,

106,

107,

108,

109,

110,

111,

112,

113,

114,

115,

116,

117,

118,

119,

120,

121,

122,

123,

124,

125,

126,

127,

128,

129,

130,

131,

132,

133,

134,

135,

136,

137,

138,

139,

140,

141,

142,

143,

144,

145,

146,

147,

148,

149,

150,

151,

152,

153,

154,

155,

156,

157,

158,

159,

160,

161,

162,

163,

164,

165,

166,

167,

168,

169,

170].

7.1. Voltage Disturbance Detection Methods

The first stage in the control unit of the DVR is the detection of voltage disturbances. The detection system plays a crucial role when it comes to sensitive loads. This means that quick and accurate voltage disturbance detection is of vital importance for DVR performance. As can be seen in

Figure 10, several methods have been presented for voltage disturbance detection [

94,

95,

96,

97,

98,

99,

100,

101,

102,

103,

104,

105,

106,

107] like Root Mean Square (RMS), Peak Value, Fourier Transform (FT), Discrete FT (DFT), Windowed Fast FT (WFFT),

Transformation, Wavelet Transform (WT), Kalman Filter (KF), and Phase-Locked Loop (PLL), and Synchronously Rotating Frame (SRF). The advantages and disadvantages of the most critical voltage disturbance detection methods are provided in

Table 7. Some of them are described below.

The traditional methods like RMS method or Peak Value, the RMS variation, or peak voltage variation is measured to detect voltage disturbance. In the RMS method, the start-/end-points of voltage disturbance are detected by RMS measurement of supply voltage and then comparing with the initial reference value. Usually, a threshold voltage value is specified. If the difference between the RMS and the initial reference values is exceeded, a voltage disturbance exists. The advantage of the RMS method is its simplicity; however, it cannot operate fast. Therefore, the RMS method is not appropriate for DVR applications.

However, advanced methods outperform conventional methods. The FT method provides data on depth and phase shift of sags, magnitude, and phase of supply, in particular when the supply voltage has harmonics. Like the RMS method, this method is not fast.

The WT method finds the start/end-points of sag by an analysis of the wavelet transform coefficient. The WT method, however, requires the proper selection of wavelet prototype for accurate detection. Although this method operates faster in the detection of any alteration in supply voltage phases, it has some disadvantages. The information provided by the WT method can be far from easy to convey. Additionally, there may be a delay regarding wavelet prototypes.

Another method is transformation. To detect voltage disturbances in this method, is compared with the reference value. The advantage of this method is that it is so fast and straightforward to implement. The drawback of this method is that it may not perform adequately with unbalanced voltage disturbances. In imbalanced voltage sags, the positive/negative sequence’s elements of supply voltage are singled out, thereby employing the transformation for each one individually. This transformation must be adjusted. To that end, a PLL is used which can provide data on the supply voltage. Note that the voltage data in this paper are considered as its magnitude and phase angle to avoid repetition.

Once the voltage disturbance is detected, the reference voltage data should be provided. Depending on the voltage compensation method, the injected voltage data vary. The voltage compensation method may mitigate just one of the voltage data or both of them simultaneously. The following section will describe different voltage compensation methods.

7.2. Voltage Compensation Methods

Depending on the DVR power rate, load types, conditions, fault types, etc., the voltage compensation method is chosen. This is mainly because some loads are very sensitive to phase angle jump, and some are not. There are four voltage injection/compensation strategies [

126,

127].

7.2.1. Pre-Sag Compensation Method

This method always tracks the supply voltage all the time to detect any voltage disturbances, thereby generating and injecting the difference voltage. That way, the load voltage is kept unaltered as the pre-sag voltage. The pre-sag compensation method is capable of restoring the sensitive load voltage to the same phase angle and magnitude as the nominal pre-sag voltage. This method is recommended for non-linear loads which are very sensitive to phase angle jumps. This requires a higher rating of the DVR. Moreover, the DVR in this method supplies active/reactive power both from the VSI. However, high capacity energy storage is needed as no control of the active power during the compensation stage exists [

103,

128,

129,

130,

131].

The phasor diagram of the pre-sag compensation method is shown in

Figure 11a [

129]. Note that here,

,

,

and

remark variables after the sag, and

,

and

are related to the variables before the sag. Plus,

is the phase angle difference between the load current and voltage, and

is the phase jump of supply voltage throughout the sag. The active power between the DVR and supply, the magnitude, and phase angle of injected voltage are provided in (4)–(6), respectively [

129].

where

is the line-to-neutral supply voltage (RMS) in phase

,

is the line-to-neutral load voltage (RMS), and

is the phase jump in phase

.

7.2.2. In-Phase Compensation Method

In this method, the injected and the supply voltages are in-phase with one another. As the injected voltage magnitude is minimized [

34], the voltage rating of the DC-link or storage unit is marginal. This method requires compensation for active power. Plus, it is just able to mitigate the magnitude of load voltage, not its phase jump. As phase jumps happen in most voltage sag cases, this method is not appropriate for sensitive loads. However, the in-phase compensation method is suitable for linear loads that the voltage magnitude is important.

Figure 11b depicts the phase diagram of this method [

129].

7.2.3. Energy-Minimized Compensation Method

In pre-sag and in-phase methods, the active power must be provided at the DC-link. However, in the energy-minimized (EM) method, there is no exchange of active power during the compensation stage. In other words, this method either inject to or absorb from the power supply to a greater extent for sag mitigation [

34,

75,

76,

128]. As the DVR does not exchange active power with power supply, the active power can be minimized. Not needing active power aside, the EM method has two downsides: the occurrence of phase jumps (so this method is not suitable for critical equipment that voltage magnitude is essential) and the magnitude of the injected voltage that may be higher [

132]. What follows is the explanation of this compensation method in both balanced (

Figure 11c) and unbalanced voltage sags (

Figure 11d) [

129].

EM for Balanced Sag

In

Figure 11c, in which the EM compensation method is shown, the angle of

is the load voltage phase variation after sag [

129]. As explained above,

is zero to avert exchanging the active power. In turn, the injected voltage phasor is perpendicular to the load current phasor. Plus, this method is not suitable when it comes to under-voltage sags. One solution is using a thyristor-switched inductor connected in parallel with the DVR [

76].

is defined here to simplify the calculation of the injected voltage data as follows [

129]:

EM for Imbalanced Sag

Figure 11d illustrates the EM compensation method for imbalanced voltage sags [

129]. As can be seen, the injected voltage phasor is not perpendicular to the load current phasor. As a result, the exchanged active power in each phase is not zero. However, the total exchanged active power is zero. This means that if the active power in one phase is negative, the active power in the other two phases is positive. That way, the total exchanged active power is zero. The injected voltage data can be written as follows [

129]:

Similar to the balanced voltage sag, the problem of deep voltage sags exists. The solution proposed in [

76] can be applied to create the possibility of voltage sag compensation without active power. It is worth pointing out that the performance of the voltage compensation method can be affected by the type of load. A comparison of three voltage compensation methods is provided in

Table 8 [

126,

127,

128,

129].

7.3. Reference Generation and Modulation Stages

The most commonly used method for generating reference voltage is Clarke and Park transformations (

Figure 12) [

69]. The description of this method is as follows. The three-phase supply voltage (

) is transformed into the two-phase supply voltage (

). The first transform does this (

transform). The

is adjusted with the PLL, the output of which is the angle (

). This angle is needed for the second transform (

transform). The output of this transform is

. Next, with subtracting this

from the DC values of the reference voltage (here the DVR reference load voltage),

, the reference injected voltage in the

reference frame,

. Note that

. The following is the transformation of this reference value back to

reference frame (

transform). The output is

and then the transformation of the two-phase supply voltage back to the three-phase supply voltage, thereby providing the injected voltages’ reference values for each phase. For each voltage compensation method, the calculation of

varies. In the in-phase method, the PLL is locked to the supply voltage, thereby adjusting the system with the supply voltage. However, the PLL in the pre-sag method is maintained to the pre-sag value to modify

with the pre-sag supply voltage. However,

in the EM compensation method is measured by the PLL and this compensation method’s equations as well.

There are also other reference generation methods like Symmetric Component Estimation [

133,

134], Instantaneous Power Theory (PQR) [

135,

136], and Phasor Parameter Estimation [

137]. After the reference voltages are generated, they are given to the pulse generation unit for creating pulses for the converter. To that end, the feed-forward controller, which is simple to implement and stable, serves the purpose. This method has the disadvantages of slow response and steady-state error. One solution is feedback or the hybrid of feedback and feed-forward controllers [

138]. A comparison between feedback, feed-forward, and composite controllers is provided in

Table 9 [

138]. The calculated DVR voltage or load voltage in the feedback controller is affected by a voltage controller, like Proportional-Resonant (PR) [

139], H infinity (

) [

140,

141], Repetitive [

67,

142,

143], Predictive [

7,

144,

145], combined Feed-Forward and State Feedback [

146], State Variable [

147], Feedback Linearization [

148], Sliding Mode (SMC) [

149,

150,

151,

152], and Metaheuristic Algorithms like Fuzzy Logic (FLC) [

95,

153,

154], Hybrid Genetic Algorithm (GA) and FLC (GA FCL) [

155], Cuckoo Search (CS) [

156], Chaotic Accelerated PSO (CAPSO) [

157], Artificial Neural Network (ANN) [

46,

158,

159], to name just a few.

After the reference voltage is generated, they are used for the generation of switching pulses for the converter. There are several methods for this purpose like Sinusoidal PWM (SPWM) and Space Vector PWM (SVPWM) [

160,

161,

162,

163,

164], Selective Harmonic Eliminated PWM (SHE PWM) [

164,

165], Fundamental Frequency [

113,

166], Hysteresis and dead-band [

167,

168,

169], Level-Shifted Carrier PWM (LSPWM) and Single-Carrier PWM (SCPWM) [

170].

8. DVR: Modified Configurations

The conventional DVR configurations have some disadvantages, like being costly or the need for energy storage when there are prolonged voltage disturbances. To address this, many improved DVR configurations have been presented. The most important ones are described below.

After fault detection, the chances are that the fault current experienced in the DVR cause damage in the DVR. One idea is to protect the DVR from the fault current. Although many bypass switches can do this, a better solution is to combine the DVR with Fault Current Limiter or Controller (FCC) (

Figure 13a) [

78,

171,

172,

173,

174]. The FCC DVR is more than capable of limiting the fault current and averts any damage to the DVR. The FCC DVR has two operation modes of voltage disturbance compensation and short-circuits current limitations. Another modified DVR configuration is an Interline DVR (IDVR) which is a cost-effective approach since it is comprised of several DVR systems on different lines with a common DC-link that results in a significant reduction in the DC-link’s size, as opposed to the idea of using several DVRs and considering energy storage for every single DVR [

175]. It also enables the active power exchange between two or more DVRs. If one of the DVRs mitigates the sag and provides real power from the sharing DC-link, the rest of the DVRs are to supply it to keep its voltage above a specific threshold value [

176]. However, some optimized and modified IDVRs have been presented [

175,

177,

178,

179,

180,

181]. In an IDVR with two different feeders shown in

Figure 13b, the active power required for voltage is provided by the DC-link capacitor or by the nearest feeder.

One idea is to connect renewable energy sources and batteries across the common DC-link to share the required active power when the nearest feeder cannot compensate the sag, or there are two sags on both feeders at the same time. Transformer-less DVR (TDVR) is another DVR configuration [

113,

144,

182,

183]. TDVR topology, like its name suggests, has no injection transformers (see

Figure 13c). TDVR has two operation modes of self-charging and voltage disturbance compensation. Under normal and healthy conditions, TDVR is in the self-charging mode. Once a voltage disturbance occurs, the TDVR switches to the voltage disturbance compensation mode. There is no transformer saturation and inrush current issues in TDVR, therefore, the cost, volume, and weight are reduced. However, TDVR topology is not appropriate for HV applications. Additionally, the TDVR with three full-bridge inverters is illustrated in

Figure 13d [

73] (see

Figure 8c) for the transformer connected DVR with three full-bridge inverters. It should be pointed out that the injection transformer can be removed, provided the DVR has the energy storage or the DC-link. Moreover, the injection transformer is required for isolation if the DC-link is provided from the supply.

Distributed Generation Integration with DVR

The DVR only works if a voltage disturbance is found. However, in healthy conditions, the DVR exists in standby mode. In conventional DVRs, high capacity DC storage units like UCAPs, Batteries, FESS, or SMES. Over the years, however, renewable energy sources have become popular, and researchers are leaning toward using such sources [

184], especially their integration with FACTS [

185]. A great idea is the integration of Photovoltaic (PV) and DVR (PV DVR) in a way that, under normal conditions, the PV DVR injects the power of PV into the supply, and when a voltage disturbance happens, the PV is employed to mitigate the voltage disturbance. In fact, in healthy conditions, the PV DVR serves as online UPS for the injection of the PV power to the load. Although the PV DVR provides a series voltage to the supply, the injected voltage data must be controlled to keep the magnitude of load voltage unchanged [

186,

187,

188]. Note that the injection of PV power into the supply through the DVR may not be a good idea for the increase in the inverter’s ratings. In [

189], a continuous and online control strategy has been proposed for DVR used in residential networks with PV systems to provide voltage quality improvement and maximize PV power injection. Using a Fuel Cell in DVR (FC DVR) as an energy source is another solution [

120]. However, it may not be a cost-effective approach. The advantages and disadvantages of modified DVR configurations, including IDVR, TDVR, DVR based on direct AC/AC converters, and PV DVR are provided in

Table 10 [

175,

176,

177,

178,

179,

180,

181,

182,

183,

186,

187,

188].

The integration of DGs and DVR has become popular [

190,

191,

192]. This is even important for Low-Voltage Ride-Through (LVRT) capabilities in wind turbines. Having this capability sets the stage for maintaining wind turbines, particularly DFIG wind turbines, connected to the supply during sags [

138,

193,

194,

195,

196,

197,

198]. The optimal scheduling of a microgrid including thermal and electrical loads, DGs like PV solar and wind turbine, Combined Heat and Power (CHP), traditional energy sources like boiler and microturbine, energy storage systems, and DVR has been studied in [

199]. In grid-connected PV systems, voltage sags can be caused by Partial Shading Conditions (PSC) due to reasons like passing clouds, nearby buildings, and growing trees. In this case, Maximum Power Point Tracking (MPPT) methods are used to extract the maximum PV power [

200,

201] and as well as that the DVR is connected in series with PCC to compensate and mitigate voltage sags due to PSCs [

18,

192]. An in-depth review of different control strategies and algorithms for the integration of DGs with distributed FACTS like DVR and DSTATCOM has been provided in [

202].

9. Conclusions

In this paper, a comprehensive review of various types of DVR systems, and its practical difficulties and future scope for research trends are presented. Studies that have reviewed the DVR are many, but different power quality issues, the DVR principle, and operation modes, along with the DVR components, the DVR topologies based on energy storage, or the lack thereof are discussed in this paper. In particular, the DVR topologies based on power converters, and the DVR topologies based on control units and their different stages for each operation mode, are all explained based on the state-of-the-art in literature in detail. Various modified and improved DVR configurations, along with the integration of renewable energy sources, are also presented. This review paves the way for singling out the best, most reasonably-priced, and high-performance DVR topology as per the wants and needs of researchers and scientists whose research interests are within this field of research for futuristic tends.

The scopes of the art for future research are many. Some important aspects are recommended, but not limited to:

Voltage sags were just considered as voltage disturbances in many studies and the DVR was used to mitigate them. Voltage swells must be included for better analysis of the DVR. Additionally, voltage spikes were neglected, as they occur in the initial and final stages of voltage disturbances. Eliminating or decreasing them causes a harmonic reduction.

Using modified power converters in DVR is another idea. That way, we can improve the performance of DVR in terms of cost, efficiency, reliability, LVRT capability, deep/long voltage sags/swells compensation simultaneously, harmonic, etc.

The method used in the detection stage can be modified in a way that the detection process becomes highly reliable, particularly when it comes to deep/long voltage sags/swells.

Hybrid metaheuristic algorithms to find the best optimal solutions.

Modified DVR configurations can improve DVR efficiency. However, they have more elements. Coming up with a solution to reduce passive elements will cut down on the cost.

The integration of DGs and DVR has become popular. The main focus of studies, however, has been on the integration of DVR and PV systems per se or wind turbines. For future works, the integration of DVR and smart grids and microgrids should be considered.