2.1. Entry Data and Design of the Computational Model

In terms of input data for the calculation of the parameters of the PV system, the first step was the determination of solar radiation parameters. In determining the required performance of the PVS and the installation area, we have considered the values of the radiation for Latitude 48.8 in Europe, which is the mean annual value for European countries of 1240 kWh·m

−2. This figure is the average for the years 2010–2016 obtained from the PVGIS web application (Photovoltaic Geographical Information System, Version: 5.1, European Commission Joint Research Centre, at the JRC site in Ispra, Italy) [

13].

Energy consumption of EVs depends on several factors, in research, we have considered the following:

The basis for establishing EV energy consumption intervals (EC

EV) was the results of the tests according to the methodology established by EPA (Environmental Protection Agency). The minimum consumption was 14.9 kWh/100 km–Tesla Model 3 Standard Range Plus 2020. The maximum consumption was 31.1 kWh/100 km–Porsche Taycan Turbo S 2020 [

14]. For analysis, therefore, intervals with a range of 10 kWh/100 km were created in the range of minimum and maximum, rounded to tens below. All symbols are explained on first use or in

Table 1.

The calculation of the total average consumption of EV per day

ECD was calculated using:

Dd—the number of kilometers traveled by EV per day has also been determined at intervals the minimum and maximum of which has been determined by research in the area. Long-term research suggests that 75% of the car users drive equal to or less than 40 km [

15].

The individual driving distance distribution of weekdays are shown in

Figure 1. The given data are valid for Denmark, because it is one of the developed European countries with a high share of RES in the energy mix and this is the EU’s goal for all European country.

The number of days of accumulation is often considered in the calculations of the performance of the PV system. This represents the maximum time to bridge the lack of solar energy. In case of accumulation of electricity into batteries for charging in time without sunshine, the size of the accumulation system should be considered. As its capacity increases, the necessary performance of the PV system increases, while the price increases. As part of our research, we considered the case that the electricity produced by the PV system is either delivered directly to the EV battery or the storage system. That means we are not thinking about overcoming bad weather. The battery size is set for the storage of electricity produced by the PV system for one day. We are considering a hybrid system connected to the network, so increasing battery capacity results in a deterioration of the system’s economic parameters. In the analyzes and modeling, we considered batteries suitable and commonly used in PV battery systems. The considered PV charging system will consist of a PV generator, a charge controller, a battery. The electricity obtained from the PV system is either stored directly in the battery of the electric vehicle (in case it is present during the day) or is stored in the solar battery of the PV system. From it, the electric car is subsequently charged at night or at times without sunlight. Input data for data calculation for statistical processing are shown in

Table 1.

The area of the PV field (

APV) was calculated by reference to:

ηPVT—total efficiency of PV technology.

HMd—daily average irradiation in a given month.

As part of the calculations, we considered a value of 15.48%, which corresponds to the efficiency of the PV panels of 18% and the PV system losses of 14%.

The efficiency of the PV panels and components of the PV system also depend on its unit performance in relation to the surface area of PV panels and STC (Standard Test Conditions). It is calculated according to the relationship:

The total required installed power PV of the system for the selected daily electricity consumption is calculated according to the relationship:

In the absence of EV at the time of the PV system’s electricity generation system, the energy must be stored in the battery. A variety of factors influence the overall required battery capacity. The most important are:

U—voltage of the system (V);

TDOD—depth of battery discharge (%);

ηΙΝV—efficiency of the inverter (%);

ηD—efficiency of energy distribution (%).

The required battery capacity is calculated according to the relationship [

16]:

Other battery parameters are also important for the EV owner, such as

EDBAT—energy density of battery (Wh/kg);

MBAT—battery weight (kg);

CBAT—battery cost (EUR/Ah).

The parameters entering the calculation model also take into account the required operating parameters, such as battery life and battery efficiency. They are listed in next text and tables. Within the research [

5], these parameters are considered in the variable

ηD-Efficiency of energy distribution (

Table 1).

Since the objective of the research was to optimize the PV system with accumulation, it was necessary to create a computational model for obtaining data for statistical processing, taking into account all variables in each step. For the above parameters and their context, we created a calculation model in MS Excel with the input data given in the table.

Calculations have been made for all variants of the combinations of specified input data ranges—

Table 1. Variants are calculated by selecting the range from the green cells listed in

Table 2.

HMd values were calculated for each month based on data from the PVGIS program for the selected geographical area of Europe [

13].

2.2. Calculation of Parameters for Statistical Data Analysis

The results of each calculation step were the values of quantities entering the next phase—the analysis of numerical variables using descriptive statistics are shown in

Table 3. The total number of data for these input data was 3120. It is the sum number of the number of outputs from the created model for the combination of all inputs for one type of PV system (standard configuration in Europe) and for the two mentioned battery types. For one input listed in

Table 1, the output of the model is 26 outputs (

Table 2). Statistically, it is necessary to process for a given data system configuration 3120 for one PV charging system with one battery type.

The aim was to find and define the dependencies of individual variables entering the process of selecting a PV system with accumulation for charging EV. The method developed, thus allows instant calculation of parameters for a specific PV technology, battery and EV. The values of these parameters are inserted into the model into yellow cells. An example is the calculation result for polycrystalline PV technology, the LTO—Lithium Titanate Oxid Battery Cell battery (the parameters are highlighted in Table 5 and the input conditions are according to

Table 1).

For illustration, we list the selected results of the calculations of the proposed model for the changed values in

Table 4:

Dd = 40 km/day

HMD = 5.464 kWh/day (June)

Battery parameters derived from the results of research in the field were used in the calculation. The main factors influencing the calculation were price, capacity, charging costs and weight of batteries. Selected parameters used in the calculations are listed in

Table 5 [

16].

The resulting economic parameters of the PV system depend primarily on the ability of efficient consumption of electricity produced by the PV system and from system management operational dispatching. According to [

17], it is possible to increase energy savings from the PV system by up to 45% by suitable technical and economic dimensioning; the demand for PV energy has decreased by up to 10% and the need for a backup source has been reduced by 92%. Even research has shown that the annual capacity of the battery will increase by up to 10%. In our research, we focused on the PV system used exclusively for charging EV with battery support. Different variants of calculations have one common problem. This is the determination of the optimal performance of the PV system and the size of the battery in terms of the economics of operation. We analyzed the system from the point of view of the investment costs of the generator, the battery and from the point of view of the EV charging costs. We looked for the optimal cost ratio for electricity purchases from the grid and electricity generation and storage of the proposed PV system.

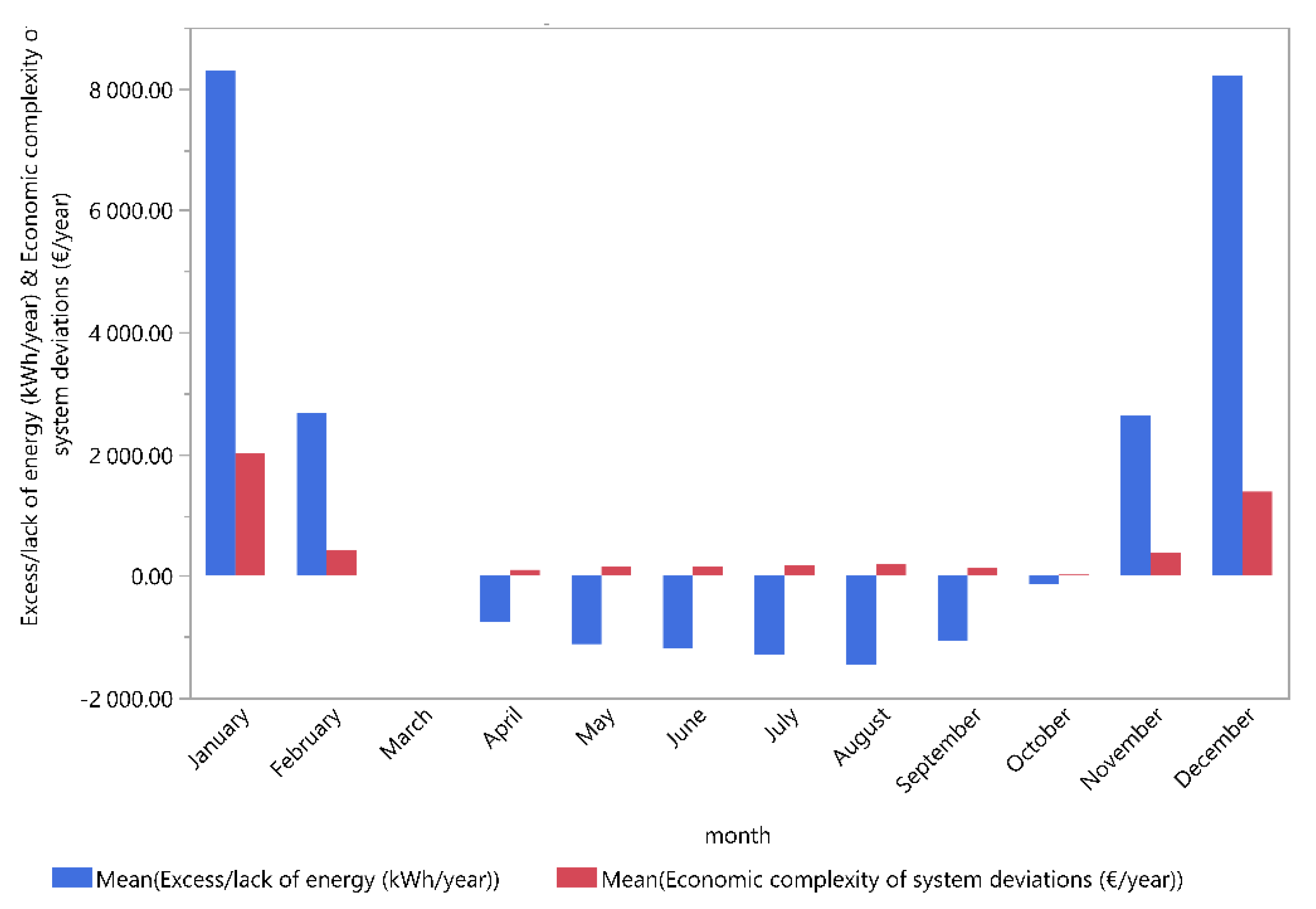

It is known that the PV system designed to produce 100% of the energy demand in the summer months will not have sufficient performance in winter. This will result in a higher share of electricity from the network and an increase in operating costs. Conversely, the PV system designed to cover 100% of electricity needs in the winter months will have a significant overproduction of electricity in the summer. This will translate into high investment costs, especially in case of the impossibility of supplying excess electricity to the grid, as is the case in Slovakia, for example. An appropriate design of the PV system performance and battery size according to the user’s requirements can optimize investment and operating costs in combination with the use of electricity from the grid.

In this part of the research, we determined the annual production of PV charging system with accumulation

EPY (kWh/year) according to the specified input parameters EV, PV, and accumulator. The result was the rate of oversized or subdivision of the PV system in individual months. We called this calculated measure a “monthly deviation factor

fDM” and it was calculated by:

EPY—annual production of PV charging system with accumulation (kWh/year).

ECY—annual electric car consumption (kWh/year).

Approaching factor to 1 means optimizing the design of the PV charging system with accumulation for specific conditions and specifically EV. Based on this indicator, it was possible to define an economically optimal PV charging system EV. This occurs in the case fDM = 1. For this purpose, statistical analyses of the data obtained had to be carried out.

2.3. Analysis of Data

The analysis of numerical variables using descriptive statistics established the basic statistical characteristics for each indicator—mean, Std Dev, minimum, maximum, and coefficient of variability (CV) are shown in

Table 6.

Coefficient of variation (CV) values indicate high variability of variables–ECD, APV, PPV, QBAT, MBAT and C, some of which have a volatility of up to 100%. We further explored what causes such a high variability.

ANOVA: Analysis of variability by month

Using the ANOVA analysis, we assessed the variability of the values of selected variables by the impact of months. This was confirmed to be statistically significant in the three variables—the required area (

APV), the required performance of the

PPV, and the price of the PV system, which is directly related to the area (

Figure 2). For these three indicators, the Prob > F value is less than 0.0001, which is lower than the significance level alpha = 0.05, which means that the difference between the average values in the individual months is statistically significant. The partial indicators of the analysis (degree of freedom (DF), Sum of Squares, Mean Square, F Ratio, Prob > F) are explained below

Figure 2.

DF records an associated degree of freedom (DF for short) for each source of variation. The degrees of freedom for C. The total is N-1, where N is the total number of observations used in the analysis. If the X factor has k levels, then the model has k-1 degrees of freedom. The error degrees of freedom is the difference between the C. The total degrees of freedom and the model degrees of freedom (in other words, N-k) [

18].

Sum of Squares-Records a sum of squares (SS for short) for each source of variation. The total (C. Total) sum of squares of each response from the overall response mean. The C. Total sum of squares is the base model used for comparison with all other models. The sum of squared distances from each point to its respective group mean. This is the remaining unexplained Error (residual) SS after fitting the analysis of variance model. The total SS minus the error SS gives the sum of squares attributed to the model. This tells you how much of the total variation is explained by the model.

The mean square is the sum of squares divided by its associated degrees of freedom. The model mean square estimates the variance of the error, but only under the hypothesis that the group means are equal. The error mean square estimates the variance of the error term independently of the model mean square and is unconditioned by any model hypothesis [

18].

The F Ratio is the model mean square divided by the error mean square. If the hypothesis that the group means are equal (there is no real difference between them) is true, then both the mean square for error and the mean square for model estimate the error variance. Their ratio has an F distribution. If the analysis of variance model results in a significant reduction in variation from the total, the F ratio is higher than expected [

18].

Prob > F-Probability of obtaining (by chance alone) an F value greater than the one calculated if, in reality, there is no difference in the population group means. Observed significance probabilities of 0.05 or less are often considered evidence that there are differences in the group means [

18].

The results show significantly higher values of indicators in the winter months of November–January and significantly lower values in the summer months of May–September. In the month of April, all three indicators are valued at the average of the year. This month was established as the reference for determining the economic optimism of the installed power of the PV system. We were based on annual electricity requirements defined according to EV consumption.