1. Introduction

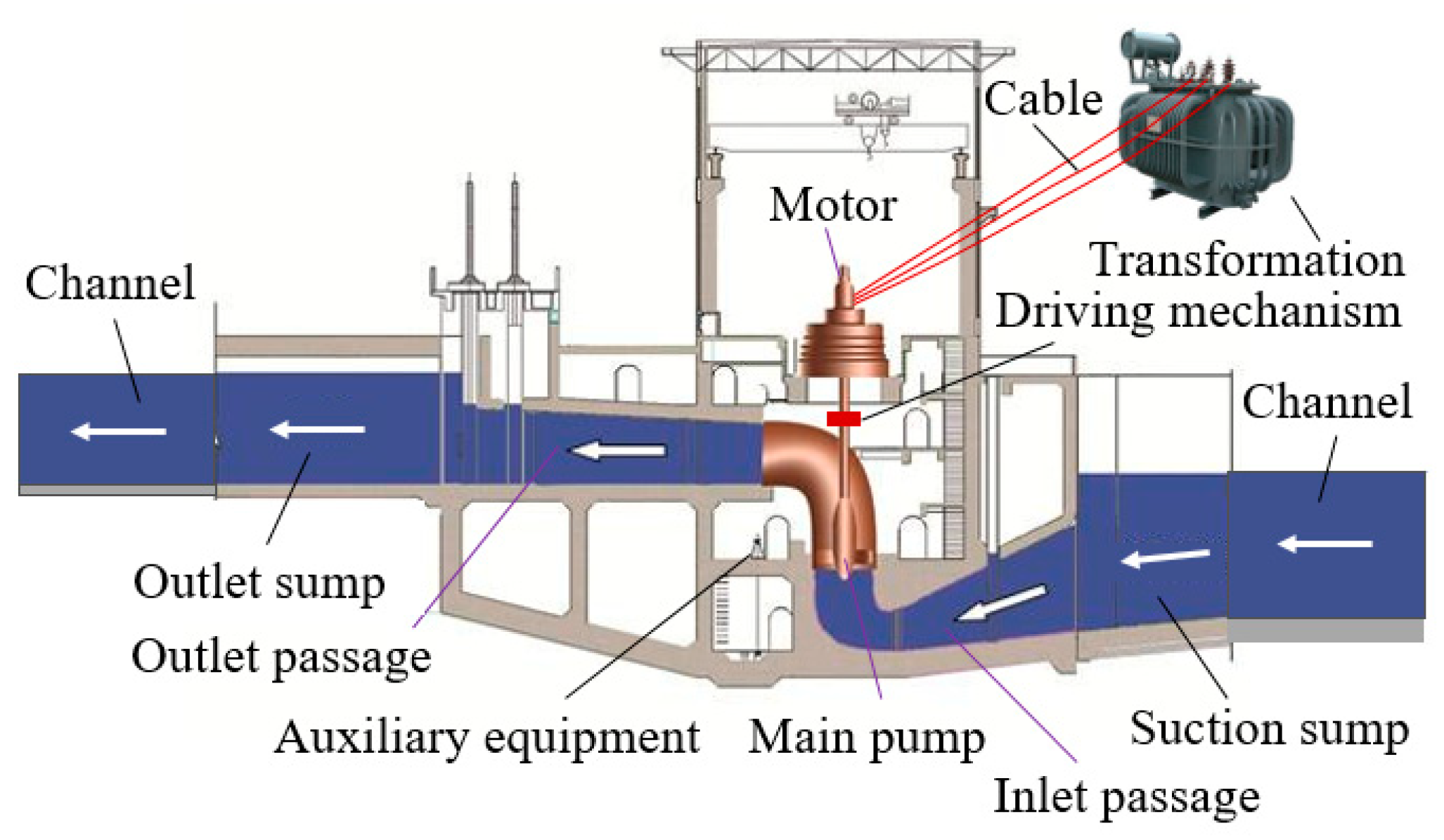

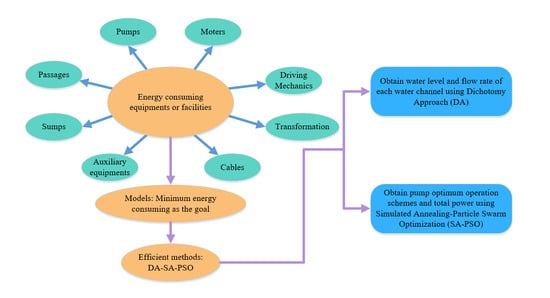

Pumping stations play a key role in agricultural irrigation and drainage, urban domestic water supply and sewage, industrial water supply and drainage, and ecological environment construction, and they have high energy costs. For a large open-channel water transfer system with pumping stations, power transmission facilities, pumping stations and water passing facilities are necessary to work together to transfer water from the source to the destination, and they are responsible for power transmission, energy conversion and water transport. During this process, energy loss is inevitable. Energy wasting equipment and water passing facilities include main water pumps, electrical motors, drive mechanisms, inlet and outlet passages and their accessories, suction and outlet sumps. In addition, power transmission, power transformation, and auxiliary equipment must also assist in the function of main pump units (see

Figure 1). Water transfer performance of the open-channel is interrelated with pump operation performance. Therefore, it is important to study operation optimization methods for an open-channel water transfer system to decrease energy consumption and improve energy savings.

Previous studies on optimization mainly focused on improving the efficiency of a single pump by adjusting pump blade angles, pump rotational speed or valve opening based on the varying head. Then, the goal expanded to developing high-efficiency pump assemblies (composed of the main pump, inlet passage and outlet passage) and pumping stations (considering main pumps, inlet passages, outlet passages, matching motors, driving mechanisms, a suction sump and an outlet sump). The focus has since shifted to lowering the power consumption and energy costs of pumping stations or a complex water transfer system entirely.

Many researchers have studied the operation optimization theories for water transfer pumping station systems. Olszewski [

1] investigated optimal operation for parallel pumps in a pumping system using the genetic algorithm, and regulated operation modes by adjusting valve opening, throttling and frequency conversion, aiming to achieve minimal power consumption, flow rate balance and maximum total efficiency. Feng et al. [

2] discussed the optimal operation of main pump units using the genetic algorithm, giving electricity cost savings of 4.73−31.27% in the schemes of adjusting blade angles and time-varying electrical price. Abkenar et al. [

3] established multiple objective nonlinear optimizing models for a water diversion system, considering the cost and energy consumption of environmental contamination emissions, and determined optimization schemes by applying the genetic algorithm with continuous and discrete coding. Ramos et al. [

4] studied the optimal operation of a water supply system in which the turbine generation and wind turbine afforded power for pumping stations, and the energy efficiency and hydraulic efficiency of the system were improved. Bohórquez et al. [

5] applied genetic algorithm (GA) to a water distribution system using EPANET software, allowing for 26% and 50% of energy cost and leakage reduction in the case of unique speed pumps, and 33% and 55% of that in the case of variable speed pumps. Zhang et al. [

6] utilized a neural network algorithm to model pump energy consumption and proposed an artificial immune network to schedule the model, achieving energy savings of 6–14%. Zhuan et al. [

7] proposed an extended reduced dynamic programming algorithm to solve the optimal operation scheduling of a pumping station with multiple pumps, and the results indicated the feasibility of reducing operation energy and maintenance costs with this method. Naoum-Sawaya et al. [

8] applied the simulation optimization method to study the optimal operation of pumps in water supply networks, ensuring the lowest operating cost and the least amount of seepage. Bagirov et al. [

9] put forward a novel approach for modelling explicit pump scheduling to minimize energy consumption that was based on the combination of the grid search with the Hooke–Jeeves pattern search method. Ghaddar et al. [

10] presented a Lagrangian decomposition approach for pump scheduling in water networks, and the results illustrate significant costs savings. Charles and Bauer [

11] optimized the operation of cascade pumping stations considering river water loss. Zhang and Zhuan [

12] investigated the operation optimization problem of the third Huaiyin pumping station to save on electricity while satisfying the required flow demand; the results indicate that the operational electricity tariff is reduced by 7.71% by the improved dynamic programming algorithm in comparison with the benchmark scheduling. Gong and Cheng [

13] reported a method for optimizing the operation of cascade pumping stations based on the head decomposition–dynamic programming aggregation method considering water level requirements. Zhao and Feng [

14] reported an evaluation strategy of particle swarm optimization to achieve the optimal operation of a pumping station system. Liu et al. [

15] proposed an improved self-adaptive grey wolf optimization (IAGWO) to solve the operation problems of cascaded pumping stations. Compared to the present scheme, the schemes employing IAGWO, adaptive grey wolf optimization (AGWO), grey wolf optimization (GWO) and particle swarm optimization (PSO) could save 0.80268%, 0.80189%, 0.77369% and 0.45331% of daily operating expenses, respectively. Zhuan et al. [

16] studied operation optimization of the fourth Huai’an stations of the east route of the South-to-North Water Transfer Project and proposed a decomposition method to solve the model; the result of which was 2.54% energy saving compared with the benchmark scheduling scheme. Zhang et al. [

17] optimized the scheduling of cascade pumping stations in an open-channel water transfer systems based on station skipping. Turci et al. [

18] reported two adaptive and one improved multi-population-based nature-inspired optimization algorithms for water pump station scheduling, comparing it with GA, PSO and ant colony optimization (ACO) to show its better performance. Dong and Yang [

19] proposed a data-driven model to carry out the operation optimization scheduling of water diversion and drainage pumping stations in the presence of complex hydrometeorological constraints. The results clearly confirm its effectiveness and improved economic performance compared to the existing benchmark solution. Parvez et al. [

20] reviewed the prior research work for hydro-scheduling by considering various constraints, different solutions and modelling techniques. Cimorelli et al. [

21] reported that a well-designed GA is capable of tackling optimal pump scheduling. In addition, a new decision-variable representation was proposed, specifically suited to parallel pump systems.

In the contemporary research, the pump assembly (only composed of a pump and inlet and outlet passages) or pump unit (only composed of a pump, motor and driving device) is taken as the study subject, and energy loss of other equipment or facilities is partly considered in some studies. For example, water quantity loss is considered in the literature [

5,

11]. In short, optimization methods were focused on in previous research, and energy consumption or cost in models were considered incomplete factors. Thus, energy savings could be further improved.

The goal of this study is to present a methodology for improving energy saving by optimizing the operation strategies of pumping stations, targeting parallel pumping stations in an open-channel water transfer system with double lines that transfers water from the Sanjiangying intake of the Yangtze River to the Huai’an pumping station in the eastern route of South-to-North Water Transfer Project in China. The novelty of this study is that energy consumption is considered more comprehensively than in previous work. The energy consumption includes not only the power of main electrical motors in the pumping stations but also the power of auxiliary equipment (including water supply pumps, water drainage pumps, fans and so on) for main pumps, power transmission and transformation equipment, and hydraulic and water quantity losses (including evaporation and leakage) of the channel. Using this approach, computation load and time would be increased greatly by repeated iterations of flow rate and channel water level. An efficient methodology is presented in which the dichotomy approach is employed to optimize the flow rate distribution of double water lines to determine the head and flow rate of each pumping station; simulated annealing-particle swarm optimization is implemented to optimize power consumption in pumping stations. This paper presents data verifying that the proposed method is more time efficient than double-layer simulated annealing–particle swarm optimization (dSA–PSO), and yields higher energy savings than the benchmark operation strategy for pumping stations.

2. Description of Parallel Pumping Stations in an Open-Channel System

The South-to-North Water Diversion Project is a large-scale interbasin water transfer project in China. Water is transferred from the Yangtze River in southern China to the more arid northern regions through eastern, middle and western routes. In the eastern route project, 13 stages, including 34 pumping stations, are located along the double open-channel water conveyance lines. The first-stage of the eastern route project is combined with the 1st, 2nd, 3rd, 4th Jiangdu pumping station and the Baoying pumping station, power transmission and transformation equipment, and the water transferring open-channel. The water transfer diagram is shown in

Figure 2.

In

Figure 2, the arrows represent flow direction, and the numbers are the compute nodes. The water flows from the Sanjiangying intake (source) in the Yangtz River to the Jiangdu West Gate, after which point some water is pumped by the Jiangdu pumping stations and flows to Dashanzi along the Li Canal continuously, while some flows from the Jiangdu West Gate to the Baoying pumping station, passing by the Jiangdu East Gate along the Sanyang River and the Tong River. The two flows meet at Dashanzi, after which the water flows along the Li Canal to the downstream of the Huai’an pumping stations in the second stage of the eastern route project, passing by the West Gate of North Canal.

Table 1 shows the channel parameters, where evaporation is the long-term month mean value, which is related to temperature, air relative humidity, and wind speed, among other factors.

In the 1st, 2nd, 3rd, 4th Jiangdu pumping stations and the Baoying pumping station, there are 8, 8, 10, 7 and 4 axial flow pump units installed, respectively. The pump types are 1.75ZLQ-7, 1.75ZLQ-7, 2000ZLQ13.5-7.8, 2900ZLQ30-7.8, and 3500HDQ34-7.6, with rated power of 1000, 1000, 1600, 3400 and 3400 kW, respectively. The 1st, 2nd and 3rd Jiangdu pumping station share one 40,000 kVA transformer, and the others use one transformer separately. From the power substation to the transformer, the power transmission cable length is approximately 7 km for the Jiangdu pumping stations, and 27 km for the Baoying pumping station, with 110 kV voltage. The cable lengths from the transformer to electric motors are about 231, 251, 220, 462 and 20 m, and the voltage is 6 kV for the Jiangdu pumping stations and 10 kV for the Baoying pumping station.

Auxiliary equipment is installed in each pumping station. For instance, in-station water supply pumps are installed for cooling and lubrication. In-station water drainage pumps are used for draining water in the collecting gallery of the pump house during running, non-running and overhauling. Fans reduce heat generated from motors and solar radiation. Trash-removal equipment is installed to prevent trash from entering the main pumps.

5. Results and Analysis

When zha is 6.0 m and Qha is 300, 200, and 100 m3/s, system operation schemes of different discharge distribution ratio are determined at different zsjy such as 3.00, 2.19, and 1.40 m.

The downstream water level zbyd of the Baoying pumping station is related closely to water level and flow rate of Sanjiangying. Considering the navigation requirements of the Sanyang River and the Tong River, zbyd is limited between 0 and 2.60 m.

The maximum flow rate of the Baoying pumping station is 150 m3/s based on the pump assembly performance. Given the 300, 200, and 100 m3/s flow rate of the Huai’an pumping stations, the corresponding minimum discharge distribution ratio is 0.5, 0.25, and 0, respectively. The flow rate of the Sanyang River and the Tong River has more influences on hydraulic loss than that of the Li Canal. The hydraulic loss is positively correlated with the flow rate, so the flow rate of the Sanyang River and the Tong River is limited. In the range of 1.0–3.5 m of source water level, considering the demanding water level of the Baoying pumping station downstream, feasible ranges of the discharge distribution ratio could be calculated. In this study, the calculation accuracy of discharge distribution ratio k is 0.01.

Figure 6 shows the relations between the source water level

zsjy and the discharge distribution ratio

k under the water level constraints. Taking

Qha = 300 m

3/s as a case, when

zsjy is 2.19 m, we can see that the feasible interval of

k is [0.73, 1.0]. According to

Figure 5, in the range of 1.0–3.5 m of source water level, the feasible interval of flow distribution ratio corresponding to any source water level can be determined, and the results are listed in

Table 2.

The pump cannot operate normally if the flow rate is too high or low. The flow rate of a single pump unit in the Baoying pumping station is subjected to maximum and minimum values,

k ∉ [0.83, 1.0). Under the constraints of water level and flow rate,

k ∈ [0.73, 0.82] ∪ {1.0}, where

k ∈ {1.0} represents that none of pumps runs in the Baoying pumping station, and the flowrate is zero. For different

zsjy and

Qha, the feasible interval of

k can be determined in the same manner, and the results are listed in

Table 3.

In calculation,

k is varied approaching the optimal value by the DA algorithm.

Figure 7 shows the relation between discharge distribution ratio

k and system input power

P for different

zsjy and

Qha, and the optimal discharge distribution ratios

kopt are listed in

Table 4. From the above results, at a given flow rate of the Huai’an pumping stations, when the source water level is raised, the feasible intervals of discharge distribution ratio are enlarged, and the system input power and optimal discharge distribution ratio are decreased. At a given source water level, when the required flow rate of the Huai’an pumping stations is decreased, the system input power and optimal discharge distribution ratio decrease as well, but the feasible intervals of discharge distribution ratio are increased.

Table 5 and

Table 6 show water level of compute nodes and optimized results of pump units with the optimal discharge distribution ratio. In

Table 5, “—” represents the pump unit does not run. The operation scheme of the 3rd Jiangdu pumping station is not listed because this station does not need to run (i.e., its flow rate is zero). The total computation time using DA−SA−PSO is approximately 20 min. A decision within 30 min is regarded as real time for an open-channel water transfer system.

For a given zsjy, the pump assembly head increases with an increase in flow rate to meet the requirements due to the hydraulic loss increases. The pump assembly head of the Baoying pumping station is higher than that of the Jiangdu pumping stations, which indicates that the hydraulic loss of the channel starting from the Sanyang River and the Tong River to the Baoying pumping station downstream is larger than that of the channel starting from the Jiangdu pumping station to Dashanzi along the Li Canal.

The optimal discharge distribution ratio increases with flow rate increment of the Huai’an pumping stations. For a given flow rate of the Huai’an pumping stations, the pump assembly head and optimal discharge distribution ratio decrease with an increase in source water level. Namely, the flow rate of the Jiangdu pumping stations decreases, while that of the Baoying pumping station increases. This is because the pump assembly head decreases with an increase in source water level, and the efficiency increment of the Jiangdu pumping stations is more than that of the Baoying pumping station.

Meanwhile, with an increase in source water level, the source flow rate increases to less than 0.1%, which could be regarded as an invariant. One possible reason is that the depth of the channel and wetted perimeter increase, but the water flows slowly, resulting in slightly increased loss from water leakage. The operation characteristics of pumping stations exhibit close relationships with water level and flow rate.

For the South-to-North Water Transfer Project, the original flow rates of the Jiangdu pumping stations and the Baoying pumping station are 400 m

3/s and 100 m

3/s, and the discharge distribution ratio

k is 0.8. The input power of the optimal and original discharge distribution ratio is listed in

Table 7, where “—” represents the system could not operate normally under original discharge distribution. From the table, the input power could be saved by 0.2–2% using the optimal solution.

An explanation is that in the scheme of original discharge distribution ratio, flow rate (or blade angles) and the number of running pumps of each type are optimized using SA−PSO. In actuality, the pumping stations operate according to managerial experience with a lack of scientific guidance. Under a given water level and required flowrate, the pump blade angles are regulated to a fixed value (which is usually is 0°), and the pump assembly with high efficiency is preferred to be operated. For the case in this study, the pump unit operation schemes and input power are calculated under the assumption that the pump blade angles are all 0°, as shown in

Table 8. Due to the constraints of fixed blade angles and the integer number of running pumps, the total flow rate may be greater than what is required, resulting in flow rate waste and a great increase in input power. Compared with

Table 8, the input power of optimal discharge distribution ratio is saved by 14–35% in

Table 7.

The mathematical model could also be solved by double-layer SA−PSO (dSA−PSO). The optimal discharge distribution

k is regarded as a variable in the first layer and is determined by SA−PSO, where the population size is 20, the maximum number of iterations is 30, and the other parameters are the same those listed above. The calculating amount is quite large, with a long computation time of approximately 10 h. Good solutions could be obtained by the two methods, and the results are shown in

Table 9.

The results indicate that the accuracy of discharge distribution ratio is higher, and the input power is approximately 0.067% lower by dSA−PSO than that by DA−SA−PSO, while the difference of kopt is approximately 0.5% between the two methods. The computation time is only approximately 20 min by DA−SA−PSO, which is 1/30 of that by dSA−PSO, because repeated iterations of water level and flow rate are avoided. Therefore, the DA−SA−PSO algorithm exhibits more advantages in terms of calculation amount and speed, and is efficient for obtaining optimal solutions in real time according to frequently varying water levels of the source or destination, required flow rate, or technical equipment conditions for parallel pumping stations in an open-channel water transfer system with double water lines. The dSA−PSO is useful for calculating optimal solutions in advance, lessening the impact of time restrictions. The solutions could be stored digitally and used based on different conditions.

For a more complex water diversion system, such as three or more water diversion lines and more pumping stations, the modelling method and solving process are similar to above. The difference is the increasing number of variables, working load and computation time.

6. Conclusions

This paper proposes an efficient methodology for optimizing energy use of parallel pumping stations in an open-channel water transfer system with double water lines. The energy consumption includes the power of main electrical motors and auxiliary equipment, and power transmission, transformation equipment, hydraulic, and water volume losses. To avoid repeat iterations of flow rate and water level of the channel, the DA was applied to optimize the flow rate distribution of double water lines to determine the head and flow rate of each pumping station, and SA-PSO was implemented to optimize power consumption in pumping stations. The following conclusions can be obtained:

(1) Using the hybrid DA−SA−PSO, the calculation time is 1/30 of dSA−PSO. Compared with the original scheme, the system input power of the schemes with optimal discharge distribution could save 14%–35% of energy. DA−SA−PSO is useful for solving optimization problems in real time considering frequently varying conditions.

(2) When the flow rate of the transfer destination is a given value, such as 300, 200 and 100 m3/s, the feasible range of discharge distribution ratio is enlarged with the increase in source water level, and the pump assembly head, optimal discharge distribution ratio, and system operation power are decreased. When the source water level is a given value, such as 3.00, 2.19 or 1.40 m, the feasible range of discharge distribution ratio is shortened with the increasing flow rate of the destination, and the optimal discharge distribution ratio, pump assembly head and system input power are all increased. The operation characteristics of pumping stations are relevant to the water lever and flow rate.

(3) For complex systems with more water transfer lines and pumping station stages, the modelling method and solving process could also be applied.