Detection Technology for Battery Safety in Electric Vehicles: A Review

Abstract

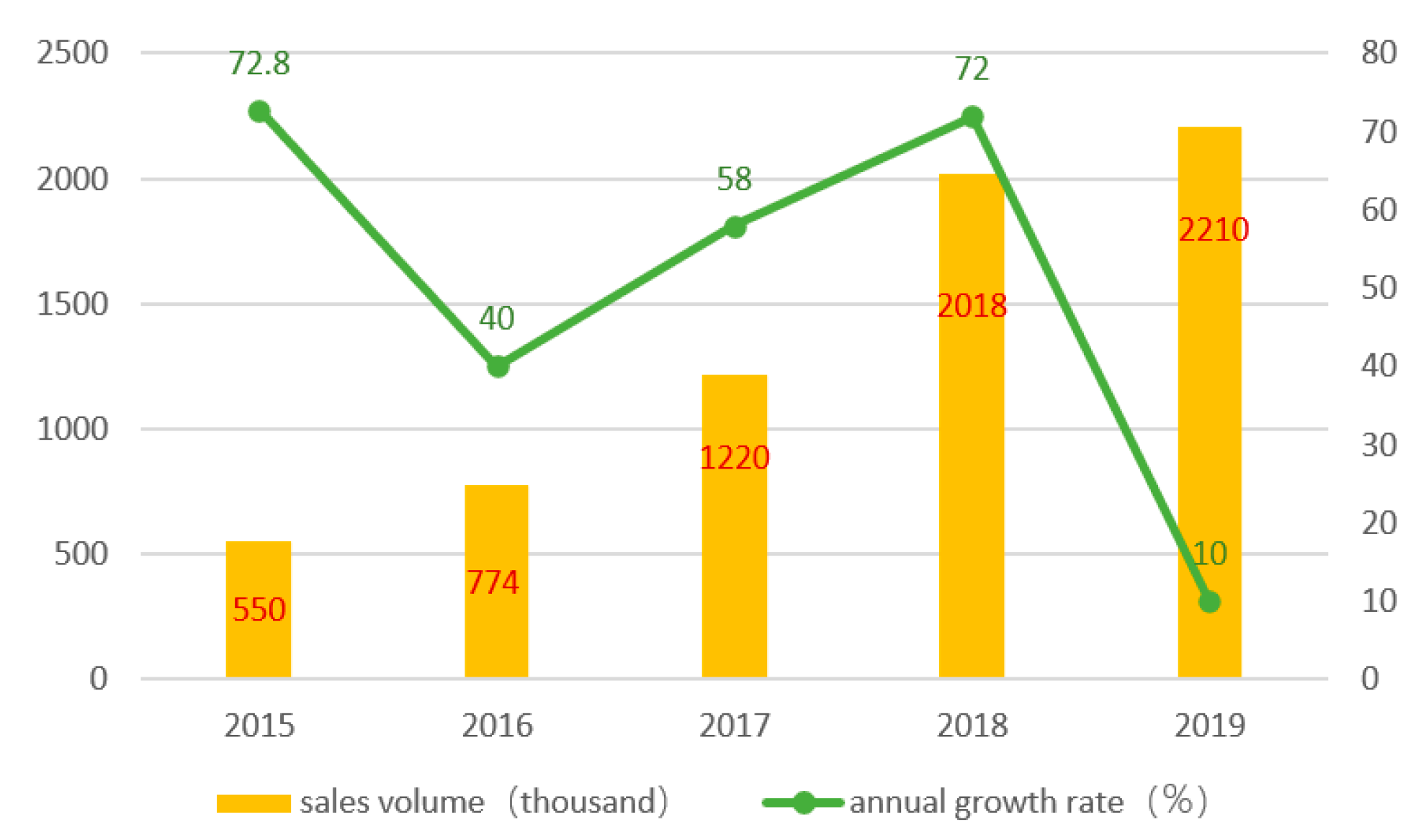

:1. Introduction

2. Mechanical Tests

2.1. Crush/Crash Test

2.2. Penetration Test

2.3. Vibration Test

3. Environmental Tests

3.1. Overheating Test

3.2. Fire Test

4. Electrical Tests

4.1. Overcharge Test

4.2. Overdischarge Test

4.3. ISC Test

5. Summary and Outlook

- (1)

- Comprehensive research on safety detection of LIBs

- (2)

- Optimization and improvement of detection methods

- (3)

- Accurate positioning of ISC and early warning of TR

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EV | Electric vehicle |

| SOC | State of charge |

| HRR | Heat release rate |

| THR | Total heat release |

| LIB | Lithium ion battery |

| TR | Thermal runaway |

| ISC | Internal short circuit |

| DOD | Depth of discharge |

| OCV | Open circuit voltage |

| tim | Immersion time |

References

- Ma, H.R.; Balthser, F.; Tait, N.; Riera-Palou, X.; Harrison, A. A new comparison between the life cycle greenhouse gas emissions of battery electric vehicles and internal comubstion vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar] [CrossRef]

- Chen, H.; He, J.J.; Zhong, X.L. Engine combustion and emission fuelled with natural gas: A review. J. Energy Inst. 2019, 92, 1123–1136. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.Q.; Chen, Y.S. NOx emission of biodiesel compared to diesel: Higher or lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Li, L.; You, S.; Yang, C.; Yan, B.J.; Song, J.; Chen, Z. Driving-behavior-aware stochastic model predictive control for plug-in hybrid electric buses. Appl. Energy 2016, 162, 868–879. [Google Scholar] [CrossRef]

- Restrepo, J.; Rosero, J.; Tellez, S. Performance testing of electric vehicles on operating conditions in Bogotá DC, Colombia. In Proceedings of the 2014 IEEE PES Transmission & Distribution Conference & Exposition-Latin America, Medellin, Colombia, 10–13 September 2014. [Google Scholar]

- Qiao, Q.Y.; Zhao, F.Q.; Liu, Z.W.; Jiang, S.H.; Hao, H. Cradle-to-gate greenhouse gas emissions of battery electric and internal combustion engine vehicles in China. Appl. Energy 2017, 204, 1399–1411. [Google Scholar] [CrossRef]

- Casals, L.C.; Laserna, E.M.; García, B.A.; Nieto, N. Sustainability analysis of the electric vehicle use in Europe for CO2 emissions reduction. J. Clean. Prod. 2016, 127, 425–437. [Google Scholar] [CrossRef]

- Kim, I.; Kim, H.J.; Lee, J. Dynamic analysis of well-to-wheel electric and hydrogen vehicles greenhouse gas emissions: Focusing on consumer preferences and power mix changes in South Korea. Appl. Energy 2020, 260, 114281. [Google Scholar] [CrossRef]

- Wu, Z.X.; Wang, M.; Zheng, J.H.; Sun, X.; Zhao, M.N.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Su, L.Y.; Wang, Y.; Chen, Q. Prospective for Energy and Environmental Performances of Battery Electric Vehicle in China. Adv. Clim. Chang. Res. 2013, 9, 284–290. [Google Scholar]

- Huo, H.; Cai, H.; Zhang, Q.; Liu, F.; He, D. Life-cycle assessment of greenhouse gas and air emissions of electric vehicles: A comparison between China and the US. Atmos. Environ. 2015, 108, 107–116. [Google Scholar] [CrossRef]

- Zhang, H.J.; Yang, B. Study on the fuel-saving efficiency of electric vehicles under empirical test. Appl. Mech. Mater. 2014, 494, 95–99. [Google Scholar] [CrossRef]

- Scaling-Up the Transition to Electric Mobility. Global EV Outlook. 2019. Available online: https://www.iea.org/reports/global-ev-outlook-2019 (accessed on 8 March 2020).

- Global BEV & PHEV Sales. 2019. Available online: http://www.ev-volumes.com/country/total-world-plug-in-vehicle-volumes (accessed on 8 March 2020).

- Wager, G.; McHenry, M.P.; Whale, J.; Bräunl, T. Testing energy efficiency and driving range of electric vehicles in relation to gear selection. Renew. Energy 2014, 62, 303–312. [Google Scholar] [CrossRef]

- Gass, V.; Schmidt, J.; Schmid, E. Analysis of alternative policy instruments to promote electric vehicles in Austria. Renew. Energy 2014, 61, 96–101. [Google Scholar] [CrossRef]

- Liao, Z.H.; Zhang, S.; Li, K.; Zhao, N.Y.; Qiu, Z.J.; Zhang, G.Q.; Habetlerc, T. Hazard analysis of thermally abused lithium-ion batteries at different state of charges. J. Energy Storage 2020, 27, 101065. [Google Scholar] [CrossRef]

- Wang, W.W.; Li, Y.D.; Lin, C.; Su, Y.F.; Yang, S. State of charge-dependent failure prediction model for cylindrical lithiumion batteries under mechanical abuse. Appl. Energy 2019, 251, 113365. [Google Scholar]

- Wang, Q.S.; Ping, P.; Zhao, X.J.; Chu, G.Q.; Sun, J.H.; Chen, C.H. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2011, 196, 210–224. [Google Scholar] [CrossRef]

- Kim, G.H.; Smith, K.; Ireland, J.; Pesaran, A. Fail-safe design for large capacity lithium-ion battery system. J. Power Sources 2012, 210, 243–253. [Google Scholar] [CrossRef]

- Gandoman, F.H.; Jaguemont, J.; Goutam, S.; Gopalakrishnan, R. Concept of reliability and safety assessment of lithium-ion batteries in electric vehicles: Basics, progress, and challenges. Appl. Energy 2019, 251, 113343. [Google Scholar] [CrossRef]

- Eren, Y.; Erdinc, O.; Gorgun, H.; Uzunoglu, M.; Vural, B. A fuzzy logic based supervisory controller for an FC/UC hybrid vehicular power system. Int. J. Hydrog. Energy 2009, 34, 8681–8694. [Google Scholar] [CrossRef]

- Bitsche, O.; Gutmann, G. Systems for hybrid cars. J. Power Sources 2004, 127, 8–15. [Google Scholar] [CrossRef]

- Cheng, K.W.E.; Divakar, B.P.; Wu, H.J.; Kai, D.; Ho, F.H. Battery-management system (BMS) and SOC development for electrical vehicles. Trans. Veh. Technol. 2011, 60, 76–88. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, J.; Chu, G. Lithium ion battery fire and explosion. Fire Saf. Sci. 2005, 8, 375–382. [Google Scholar] [CrossRef]

- Liu, X.; Ren, D.S.; Hsu, H.J.; Feng, X.N.; Xu, G.L.; Zhuang, M.H.; Gao, H.; Lu, L.G.; Han, X.B.; Chu, Z.Y.; et al. Thermal runaway of lithium-ion batteries without internal short circuit. Joule 2018, 2, 2047–2064. [Google Scholar] [CrossRef] [Green Version]

- Ren, D.S.; Liu, X.; Feng, X.N.; Lu, L.G.; Ouyang, M.G.; Li, J.Q.; He, X.M. Model-based thermal runaway prediction of lithium-ion batteries from kinetics analysis of cell components. Appl. Energy 2018, 228, 633–644. [Google Scholar] [CrossRef]

- Feng, X.; He, X.; Lu, L.; Ouyang, M.G. Analysis on the fault features for internal short circuit detection using an electrochemical-thermal coupled model. J. Electrochem. Soc. 2018, 165, A155–A167. [Google Scholar] [CrossRef]

- Feng, X.N.; Pan, Y.; He, X.M.; Wang, L.; Ouyang, M.G. Detecting the internal short circuit in large-format lithium-ion battery using model-based fault-diagnosis algorithm. J. Energy Storage 2018, 18, 26–39. [Google Scholar] [CrossRef]

- Zheng, S.Q.; Wang, L.; Feng, X.N.; He, X.M. Probing the heat sources during thermal runaway process by thermal analysis of different battery chemistries. J. Power Sources 2018, 378, 527–536. [Google Scholar] [CrossRef]

- Feng, X.N.; Ouyang, M.G.; Liu, X.; Lu, L.G.; Xia, Y.; He, X.M. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Ren, D.S.; Feng, X.N.; Lu, L.G.; Ouyang, M.G.; Zheng, S.Q.; Li, J.Q.; He, X.M. An electrochemical-thermal coupled overcharge-to-thermal-runaway model for lithium ion battery. J. Power Sources 2017, 364, 328–340. [Google Scholar] [CrossRef]

- UN/ECE Regulation. Uniform provisions concerning the approval of vehicles with regard to specific requirements for the electric power train. Off. J. Eur. Union 2013, 57. [Google Scholar]

- SAE J2929. Safety Standards for Electric and Hybrid Vehicle Propulsion Battery Systems Utilizing Lithium-Based Rechargeable Cells; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- SAE J2464. Electric and Hybrid Electric Vehicle Rechargeable Energy Storage System (RESS) Safety and Abuse Testing; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- UL 2580. Batteries for Use in Electric Vehicles; Underwriters Laboratories Inc.: Northbrook, IL, USA, 2013. [Google Scholar]

- Doughty, D.H.; Crafts, C.C. SAND 2005 3123: Freedom Car Electrical Energy Storage Systems Abuse Test Manual for Electric and Hybrid Electric Vehicle Applications; Sandia National Laboratories: Albuquerque, NM, USA, 2005.

- IEC 62660–2. Rechargeable Cells Standards Publication Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles Part 2: Reliability and Abuse Testing; International Electrotechnical Commission: Paris, France, 2011. [Google Scholar]

- IEC 62660–3. Rechargeable Cells Standards Publication Secondary Lithiumion Cells for the Propulsion of Electric Road Vehicles Part 3: Safety Requirements of Cells and Modules; International Electrotechnical Commission: Paris, France, 2016. [Google Scholar]

- ISO 12405–1. Electrically Propelled Road Vehicles Test Specification for Lithiumion Traction Battery Packs and Systems Part 1: High-Power Applications; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- ISO 12405–2. Electrically Propelled Road Vehicles Test Specification for Lithiumion Traction Battery Packs and Systems Part 2: High-Energy Applications; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- ISO 12405–3. Electrically Propelled Road Vehicles Test Specification for Lithiumion Traction Battery Packs and Systems Part 3: Safety Performance Requirements; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van Den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Spielbauer, M.; Berg, P.; Ringat, M.; Bohlen, O.; Jossen, A. Experimental study of the impedance behavior of 18650 lithium-ion battery cells under deforming mechanical abuse. J. Energy Storage 2019, 26, 101039. [Google Scholar] [CrossRef]

- Wang, H.; Simunovic, S.; Maleki, H.; Howard, J.N.; Hallmark, J.A. Internal configuration of prismatic lithium-ion cells at the onset of mechanically induced short circuit. J. Power Sources 2016, 306, 424–430. [Google Scholar] [CrossRef] [Green Version]

- Cai, W.; Wang, H.; Maleki, H. Experimental simulation of internal short circuit in Li-ion and Li-ion-polymer cells. J. Power Sources 2011, 196, 7779–7783. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sources 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Sahraei, E. Homogenized mechanical properties for the jellyroll of cylindrical Lithium-ion cells. J. Power Sources 2013, 241, 467–476. [Google Scholar] [CrossRef]

- Sahraei, E.; Campbell, J.; Wierzbicki, T. Modeling and short circuit detection of 18650 Li-ion cells under mechanical abuse conditions. J. Power Sources 2012, 220, 360–372. [Google Scholar] [CrossRef]

- Wang, L.B.; Yin, S.; Xu, J. A detailed computational model for cylindrical lithium-ion batteries under mechanical loading: From cell deformation to short-circuit onset. J. Power Sources 2019, 413, 284–292. [Google Scholar] [CrossRef]

- Kim, C.S.; Yoo, J.S.; Jeong, K.M.; Kim, K.; Yi, C.W. Investigation on internal short circuits of lithium polymer batteries with a ceramic-coated separator during nail penetration. J. Power Sources 2015, 289, 41–49. [Google Scholar] [CrossRef]

- Yokoshima, T.; Mukoyama, D.; Maeda, F.; Osaka, T.; Takazawa, K.; Egusa, S.; Naoi, S.; Ishikura, S.; Yamamoto, K. Direct observation of internal state of thermal runaway in lithium ion battery during nail-penetration test. J. Power Sources 2018, 393, 67–74. [Google Scholar] [CrossRef]

- Chiu, K.C.; Lin, C.H.; Yeh, S.F.; Lin, Y.H.; Chen, K.C. An electrochemical modeling of lithium-ion battery nail penetration. J. Power Sources 2014, 251, 254–263. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, J.; Gu, J.J. A comprehensive study on Li-ion battery nail penetrations and the possible solutions. Energy 2017, 123, 392–401. [Google Scholar] [CrossRef]

- Yamanaka, T.; Takagishi, Y.; Tozuka, Y.; Yamaue, T. Modeling lithium ion battery nail penetration tests and quantitative evaluation of the degree of combustion risk. J. Power Sources 2019, 416, 132–140. [Google Scholar] [CrossRef]

- Liu, B.H.; Yin, S.; Xu, J. Integrated computation model of lithium-ion battery subject to nail penetration. Appl. Energy 2016, 183, 278–289. [Google Scholar] [CrossRef] [Green Version]

- Berg, P.; Spielbauer, M.; Tillinger, M.; Merkel, M.; Jossen, A. Durability of lithium-ion 18650 cells under random vibration load with respect to the inner cell design. J. Energy Storage 2020, 31, 1–18. [Google Scholar] [CrossRef]

- Hooper, M.J.; Marco, J.; Chouchelamane, G.H.; Chevalier, J.D.S.; Williams, D. Multi-axis vibration durability testing of lithium ion 18650 NCA cylindrical cells. J. Energy Storage 2018, 15, 103–123. [Google Scholar] [CrossRef]

- Kim, J.; Na, W.; Lee, S. Cell Failure Evaluations under Environmental and Safety Tests of Multiple 18650 Li-Ion NCA and NMC Cells for Space Cells Qualification Estabilishment. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 2033–2038. [Google Scholar]

- Brand, M.J.; Schuster, S.F.; Bach, T.; Fleder, E.; Stelz, M.; Glaeser, S.; Müller, J.; Sextl, G.; Jossen, A. Effects of vibrations and shocks on lithium-ion cells. J. Power Sources 2015, 288, 62–69. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, H.; Li, Y.; Wang, G.; Wang, J. Thermal runaway and fire behaviors of large-scale lithium ion batteries with different heating methods. J. Hazard. Mater. 2019, 379, 120730. [Google Scholar] [CrossRef]

- Ouyang, D.X.; Liu, J.H.; Chen, M.Y.; Weng, J.W.; Wang, J. An Experimental Study on the Thermal Failure Propagation in Lithium-Ion Battery Pack. J. Electrochem. Soc. 2018, 165, A2184–A2193. [Google Scholar] [CrossRef]

- Wu, T.Q.; Chen, H.D.; Wang, Q.S.; Sun, J.H. Comparison analysis on the thermal runaway of lithium-ion battery under two heating modes. J. Hazard. Mater. 2018, 344, 733–741. [Google Scholar] [CrossRef]

- Li, H.; Chen, H.D.; Zhong, G.B.; Wang, Y.; Wang, Q.S. Experimental study on thermal runaway risk of 18650 lithium ion battery under side-heating condition. J. Loss Prev. Process Ind. 2019, 61, 122–129. [Google Scholar] [CrossRef]

- Ribiere, P.; Grugeon, S.; Morcrette, M.; Boyanov, S.; Laruelle, S.; Marlair, G. Investigation on the fire-induced hazards of Li-ion battery cells by fire calorimetry. Energy Environ. Sci. 2012, 5, 5271–5280. [Google Scholar] [CrossRef]

- Larsson, F.; Andersson, P.; Blomqvist, P.; Loren, A.; Mellander, B. Characteristics of lithium-ion batteries during fire tests. J. Power Sources 2014, 271, 414–420. [Google Scholar] [CrossRef]

- Ping, P.; Wang, Q.S.; Huang, P.F.; Sun, L.K.; Kong, J.H.; Chen, D.P.; Hua, H. Study of the fire behavior of high-energy lithium-ion batteries with full-scale burning test. J. Power Sources 2015, 285, 80–89. [Google Scholar] [CrossRef]

- Fu, Y.Y.; Lu, S.; Li, K.Y.; Liu, C.C.; Cheng, X.D.; Zhang, H.P. An experimental study on burning behaviors of 18650 lithium ion batteries using a cone calorimeter. J. Power Sources 2015, 273, 216–222. [Google Scholar] [CrossRef]

- Larsson, F.; Andersson, P.; Blomqvist, P. Lithium-Ion Battery Aspects on Fires in Electrified Vehicles on the Basis of Experimental Abuse Tests. Batteries 2016, 2, 9. [Google Scholar] [CrossRef]

- Tao, C.F.; Ye, Q.P.; Wang, C.M.; Qian, Y.J.; Wang, C.F.; Zhou, T.T.; Tang, Z.G. An experimental investigation on the burning behaviors of lithium ion batteries after different immersion times. J. Clean. Prod. 2020, 242, 118539. [Google Scholar] [CrossRef]

- Spotnitz, R.; Franklin, J. Abuse behavior of high-power lithium-ion cells. J. Power Sources 2003, 113, 81–100. [Google Scholar] [CrossRef]

- Hossain, S.; Kim, Y.K.; Saleh, Y.; Loutfy, R. Overcharge studies of carbon fiber composite-based lithium-ion cells. J. Power Sources 2006, 161, 640–647. [Google Scholar] [CrossRef]

- Ouyang, M.G.; Ren, D.S.; Lu, L.G.; Li, J.Q.; Feng, X.N.; Han, X.B.; Liu, G.M. Overcharge-induced capacity fading analysis for large format lithium-ion batteries with LiyNi1/3Co1/3Mn1/3O2+LiyMn2O4 composite cathode. J. Power Sources 2015, 279, 626–635. [Google Scholar] [CrossRef]

- Ren, D.S.; Feng, X.N.; Lu, L.G.; He, X.M.; Ouyang, M.G. Overcharge behaviors and failure mechanism of lithium-ion batteries under different test conditions. Appl. Energy 2019, 250, 323–332. [Google Scholar] [CrossRef]

- Wang, Y.; Chu, Z.Y.; Feng, X.N.; Han, X.B.; Lu, L.G.; Li, J.Q.; Ouyang, M.G. Overcharge durability of Li4Ti5O12 based lithium-ion batteries at low temperature. J. Energy Storage 2018, 19, 302–310. [Google Scholar] [CrossRef]

- Belov, D.; Yang, M.H. Investigation of the kinetic mechanism in overcharge process for Li-ion battery. Sci. Direct 2008, 179, 1816–1821. [Google Scholar] [CrossRef]

- Ohsaki, T.; Kishi, T.; Kuboki, T.; Takami, N.; Shimura, N.; Sato, Y.C.; Sekino, M.; Satoh, A. Overcharge reaction of lithium-ion batteries. J. Power Sources 2005, 146, 97–100. [Google Scholar] [CrossRef]

- Huang, L.W.; Zhang, Z.S.; Wang, Z.P.; Zhang, L.; Zhu, X.Q.; Dorrell, D.D. Thermal runaway behavior during overcharge for large-format Lithium-ion batteries with different packaging patterns. J. Energy Storage 2019, 25, 100811. [Google Scholar] [CrossRef]

- Kosilov, V.V.; Potapenko, A.V.; Kirillov, S.A. Effect of overdischarge (overlithiation) on electrochemical properties of LiMn2O4 samples of different origin. J. Solid State Electrochem. 2017, 21, 3269–3279. [Google Scholar]

- Maleki, H.; Howard, J.N. Effects of overdischarge on performance and thermal stability of a Li-ion cell. J. Power Sources 2006, 160, 1395–1402. [Google Scholar] [CrossRef]

- Lai, X.; Zheng, Y.J.; Zhou, L.; Gao, W.K. Electrical behavior of overdischarge-induced internal short circuit in lithium-ion cells. Electrochim. Acta 2018, 278, 245–254. [Google Scholar] [CrossRef]

- Ouyang, D.X.; Weng, J.W.; Chen, M.Y.; Wang, J. Impacts of Current Rates on the Degradation Behaviors of Lithium-Ion Batteries under Over-Discharge Conditions. J. Electrochem. Soc. 2019, 166, A3432–A3440. [Google Scholar] [CrossRef]

- Wu, C.; Sun, J.L.; Zhu, C.B.; Ge, Y.W.; Zhao, Y.P. Research on overcharge and overdischarge effect on lithium-ion batteries. In Proceedings of the 12th IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015. [Google Scholar]

- Guo, R.; Lu, L.G.; Ouyang, M.G.; Feng, X.N. Mechanism of the entire overdischarge process and overdischarge-induced internal short circuit in lithium-ion batteries. Sci. Rep. 2016, 6, 30248. [Google Scholar] [CrossRef] [Green Version]

- Maleki, H.; Howard, J.N. Internal short circuit in Li-ion cells. J. Power Sources 2009, 191, 568–574. [Google Scholar] [CrossRef]

- Zhang, P.; Zhu, J.; Wang, M.; Imanishi, N.; Yamamoto, O. Lithium dendrite suppression and cycling efficiency of lithium anode. Electrochem. Commun. 2018, 87, 27–30. [Google Scholar] [CrossRef]

- Zhang, M.; Du, J.; Liu, L.; Stefanopoulou, A.; Siegel, J.; Lu, L.G.; He, X.M.; Xie, X.Y.; Ouyang, M.G. Internal short circuit trigger method for lithium-ion battery based on shape memory alloy. J. Electrochem. Soc. 2017, 164, A3038–A3044. [Google Scholar] [CrossRef] [Green Version]

- Nagguib, M.; Allu, S.; Simunovic, S.; Li, J.L.; Wang, H.; Dudney, N.J. Limiting internal short-circuit damage by electrode partition for impact-tolerant Li-ion batteries. Joule 2018, 2, 155–167. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.S.; Feng, X.N.; Zheng, M.X.; Lu, L.G.; Han, X.B.; Han, X.M.; Ouyang, M.G. Comparative study on substitute triggering approaches for internal short circuit in lithium-ion batteries. Appl. Energy 2020, 259, 114143. [Google Scholar] [CrossRef]

- Feng, X.N.; Weng, C.N.; Ouyang, M.G.; Sun, J. Online internal short circuit detection for a large format lithium ion battery. Appl. Energy 2016, 161, 168–180. [Google Scholar] [CrossRef] [Green Version]

- Seo, M.H.; Goh, T.D.; Park, M.J.; Kim, S.W. Detection Method for Soft Internal Short Circuit in Lithium-Ion Battery Pack by Extracting Open Circuit Voltage of Faulted Cell. Energies 2018, 11, 1669. [Google Scholar] [CrossRef] [Green Version]

- Zhao, R.; Liu, J.; Gu, J.J. Simulation and experimental study on lithium ion battery short circuit. Appl. Energy 2016, 173, 29–39. [Google Scholar] [CrossRef]

- Yang, S.; Wang, W.; Lin, C.; Shen, W.X.; Li, Y. Investigation of Internal Short Circuits of Lithium-Ion Batteries under Mechanical Abusive Conditions. Energies 2019, 12, 1885. [Google Scholar] [CrossRef] [Green Version]

- Ouyang, M.G.; Zheng, M.X.; Feng, X.N.; Lu, L.G.; Lu, J.Q.; Han, X.B.; Zheng, Y.M.; Ouyang, M.G.; Zhang, M.X.; Feng, X.N.; et al. Internal short circuit detection for battery pack using equivalent parameter and consistency method. J. Power Sources 2015, 294, 272–283. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Ma, J.; Zhao, X.; Chen, H.; Xu, B.; Wu, X. Detection Technology for Battery Safety in Electric Vehicles: A Review. Energies 2020, 13, 4636. https://doi.org/10.3390/en13184636

Xu J, Ma J, Zhao X, Chen H, Xu B, Wu X. Detection Technology for Battery Safety in Electric Vehicles: A Review. Energies. 2020; 13(18):4636. https://doi.org/10.3390/en13184636

Chicago/Turabian StyleXu, JiYang, Jian Ma, Xuan Zhao, Hao Chen, Bin Xu, and XueQin Wu. 2020. "Detection Technology for Battery Safety in Electric Vehicles: A Review" Energies 13, no. 18: 4636. https://doi.org/10.3390/en13184636

APA StyleXu, J., Ma, J., Zhao, X., Chen, H., Xu, B., & Wu, X. (2020). Detection Technology for Battery Safety in Electric Vehicles: A Review. Energies, 13(18), 4636. https://doi.org/10.3390/en13184636