An Overview of Modelling Techniques and Control Strategies for Modular Multilevel Matrix Converters

Abstract

:1. Introduction

- To the best of the author’s knowledge, this is the first review paper discussing and comparing modelling methodologies, and control of the . In the field of MMCCs, there are other review papers available. For instance, various papers deal with modelling and control of the [2,9,20,33,34]. There are also some review papers related to the Hexverter power converter [14], and performance comparison between the and for drive applications [8,28]. However, none of those papers fully describe the operation and control of the for DFM and EFM operation. Neither control nor modelling approaches have been thoroughly discussed before.

- The problem of the floating capacitor voltages in the is detailed, and numerical analysis is presented to describe and map the nature of the voltage oscillations as a function of the electrical parameters at the input and output port of the converter.

- In this work, the modelling methodologies and control strategies reported in the literature (for the ) are discussed and classified in terms of the type of linear transformation used to represent the currents and voltages of the converter.

- The currently proposed control strategies for EFM operation are revised and discussed, and the available methods for the selection of the common-mode voltage and circulating currents are fully described.

- Finally, future trends are presented to highlight the unsolved problems related to the control and future research topics.

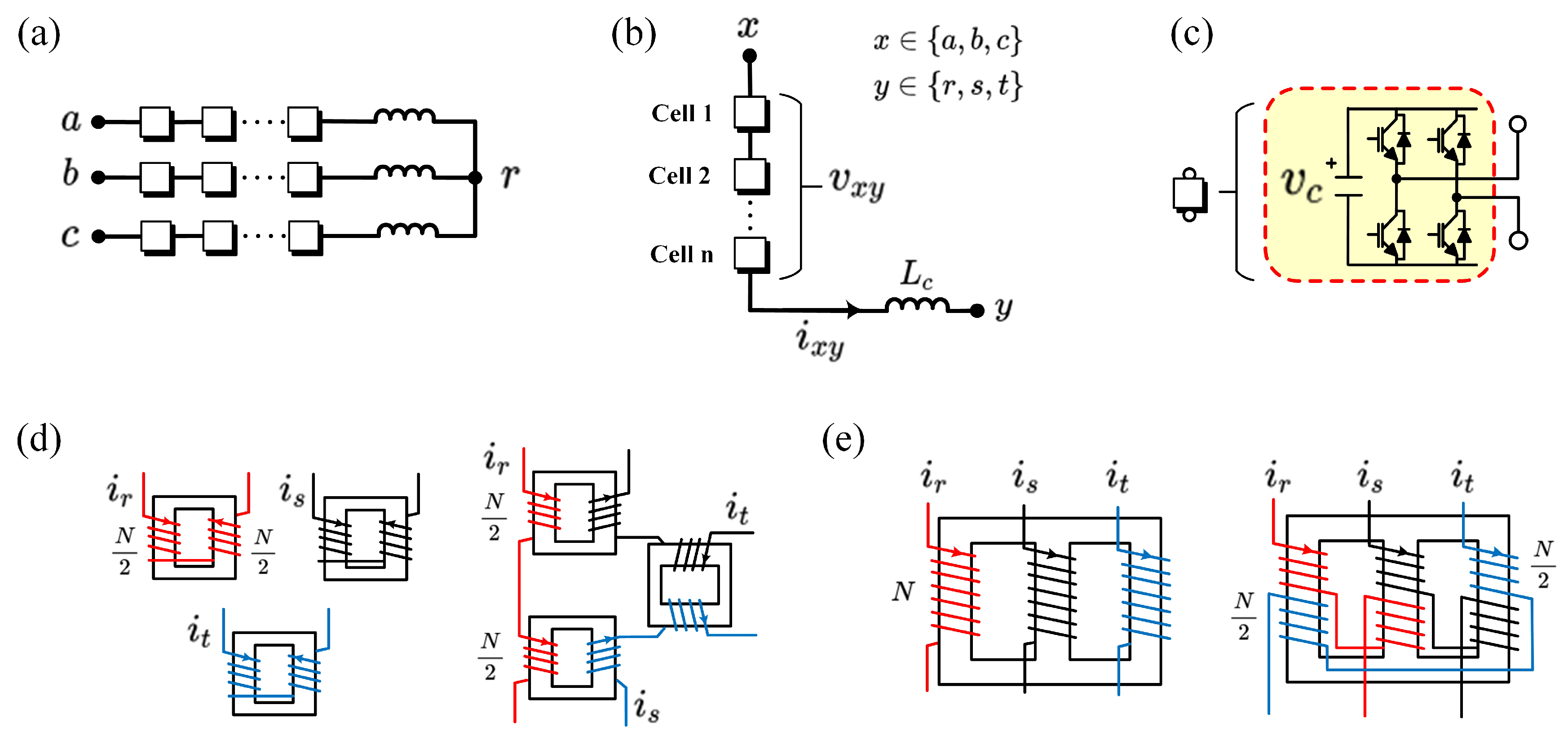

2. The Modular Multilevel Matrix Converter

Floating Capacitor Voltage Oscillations

3. Modelling of the Converter

3.1. Natural Frame Modelling

3.1.1. Voltage-Current Model

3.1.2. Capacitor Voltage-Power Model

3.1.3. Circulating Current Identification

3.2. Double Frame Modelling

3.2.1. Voltage-Current Model of the

3.2.2. Power-CCV Model

- is linked to the total active power being injected/consumed for the . It can be used to impose the average value of all the CCVs.

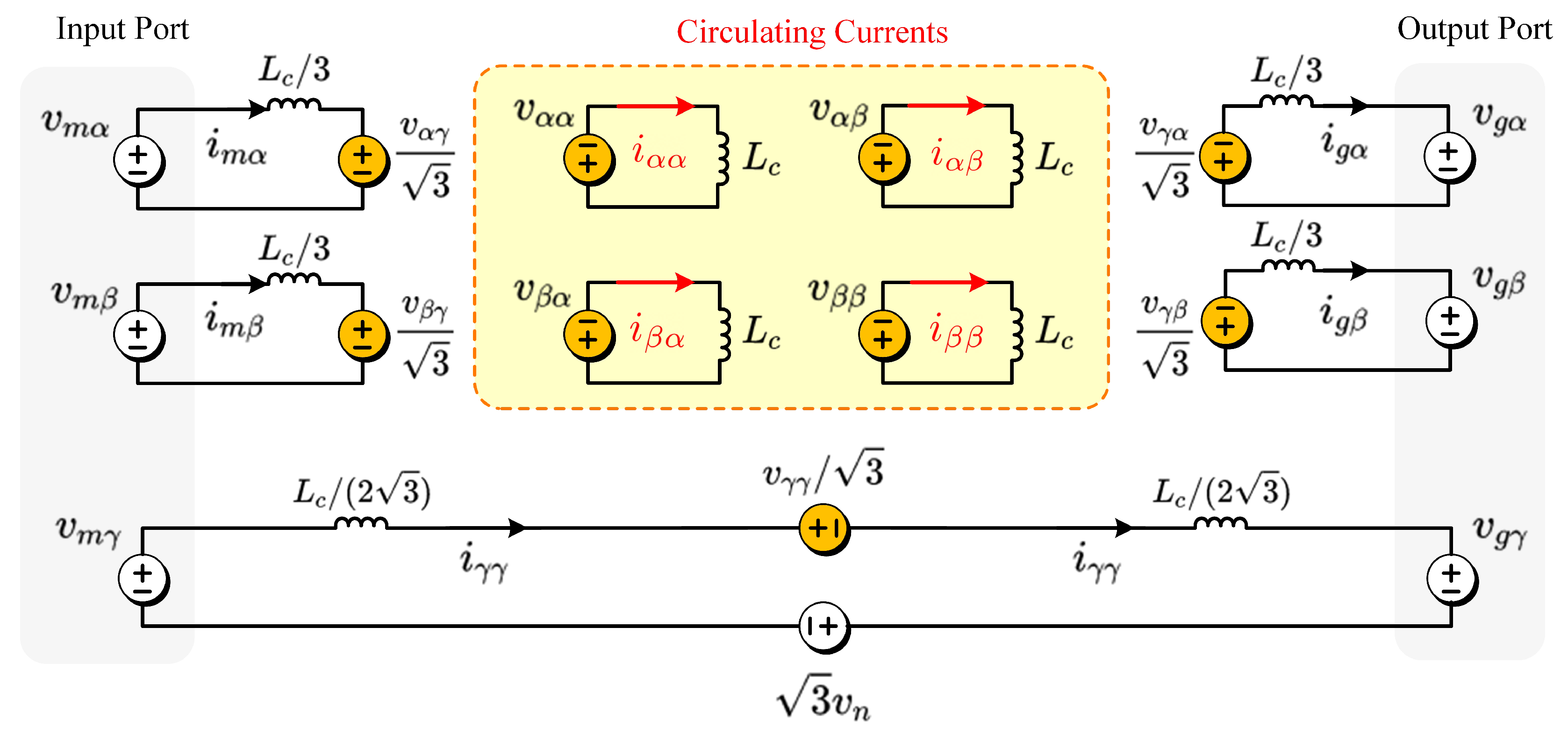

3.3. Frame Modelling

3.4. Vector Power-CCV Modelling

- has a dominant frequency oscillation of .

- has a dominant frequency oscillation of .

- has a dominant frequency oscillation of .

- has a dominant frequency oscillation of .

3.5. Comparison of Modelling Approaches

- In Double frame, the CCVs, i.e., , , , , have two main oscillatory components inversely proportional to the frequencies and . Therefore, the CCV presents unacceptable voltage oscillations when and/or .

- In Double frame, the CCV, i.e., and , have just one oscillatory component. The CCV component presents unacceptable voltage oscillations when , and presents unacceptable voltage oscillations when .

4. Control of the

4.1. Cluster Capacitor Voltage Control

- Control strategies based on Negative-Sequence Current Regulation (NSCR).

- Control strategies based on Circulating Current Regulation (CCR).

4.1.1. Control Strategies Based on Negative-Sequence Current Regulation

4.1.2. Control Strategies Based on Circulating Current Regulation

4.1.3. NSCR and CCR Comparison

4.2. CCV Control Based on CCR

4.2.1. Average Capacitor Voltage Control

4.2.2. CCV Balancing Control:

4.2.3. Circulating Current Control

4.3. Input-Port and Output-Port Control Systems

4.4. Local Cell Balancing Control and Modulation

- An additional closed-loop system based on a proportional controller is used to locally balance the capacitor voltages belonging to the same cluster using compensating signals. This supplementary control loop was firstly introduced for a three-phase transformerless cascade STATCOM [4]. Since then, it has been expanded to other MMCC topologies such as the [71], and the [24,27].The control approach proposed in [4] is illustrated in Figure 10a. In this approach, the ith capacitor voltage is compared to its desired reference value . The resulting error is multiplied by the sign of the cluster current , and by the controller gain , in order to obtain a compensation signal which is used to regulate the floating capacitor voltage in each cell. According to [27], the compensation signal for the ith power cell in the cluster is given by:A slightly different approach is presented in [24], where the instantaneous value of the cluster current is used instead of , affecting the loop gain and increasing the voltage ripple [72]. As shown in Equation (56), one of the main drawbacks related to this LCB strategy is that the closed-loop performance depends on the designed controller gain .The compensating signal Equation (56) is added to the desired output voltage, forming an active power between the output voltage of each cell and the respective cluster current. Thus, the reference voltage signal to be synthesised by each power cell is given by:After calculating Equation (57), PS-PWM can be used to synthesise the voltage references as proposed in [73]. PS-PWM is relatively simple to execute in commercial Field-Programmable Gate Array (FPGA) based control platforms. The main advantages of this modulation method rely on the generation of an output switching frequency of times the carrier frequency and evenly distributed power losses among the power cells within the same cluster.If the reference value is directly set as the nominal capacitor voltage [4,27] in the control law (56), a distortion could be produced in the cluster output voltage since the sum of every compensation signals Equation (56) is not necessarily zero, which could negatively impact on the performance of the modulator and thus the current control loops [49]. Nevertheless, if the reference value of the LCB method is set as the average value of the capacitor voltages in the cluster, i.e.,:The sum of the compensation signals in Equation (56) is equal to zero, and thus, according to Equation (57), the cluster output voltage is equal to the desired output voltage . Therefore, no interference is given between the LCB control algorithm and the current control loops, due to the fact that the reference signal in Equation (58) depends on the actual capacitor voltages, and a preloading method must be first implemented to provide energy to the capacitor voltages. To this end, a simple strategy is to initialise this LCB algorithm with the nominal capacitor voltage reference value , and then it switches to the reference value given in Equation (58). The modified LCB method was addressed for a PWM STATCOM based on an in [67], and then applied to the in [24]. The mathematical analysis regarding the modified LCB strategy is addressed in [49].

- On the other hand, the method proposed in [13,41] can be used as the LCB control. In this LCB strategy, the desired output voltage is formed by modulating only one power cell during a switching period, while keeping the remaining power cells in the ON or OFF state. The set of power cells to be utilised in this modulation process is based on sorting, in decreasing/increasing order, of the capacitor voltages and the state of charging/discharging of the cluster.The operation principle of this method is illustrated in Figure 10b, considering an with five power cells per cluster. The capacitor voltages are measured and sorted in an ascending or descending order depending on the cluster power flow. Then, the necessary number of cells are switched ON and just one power cell is modulated with the required duty cycle to synthesize the desired output voltage . The other cells are switched OFF. As illustrated in Figure 10b, if the cluster is absorbing active power, the power-cells are turned ON in ascending order of their capacitor voltages. In contrast, the power-cells with higher capacitor voltages are firstly switched ON if the cluster is injecting active power. According to [13], the power-cell capacitor voltage balancing is always ensured by using this sorting-based method since the cells with the lowest capacitor voltages are charged, and the power-cells with the most elevated voltages are discharged.

- Model predictive control has also been proposed to control multilevel converters [17,40,50,57,74]. Two LCB strategies based on Model Predictive Control (MPC) have been presented in recent literature [50]. The aims of the LCB strategies introduced in [50] is to simultaneously control the mean value of each capacitor voltage and the output voltage (averaged over a switching cycle) generated by a cluster. Using this assumption, the capacitor voltage balancing problem is formulated as the following Constrained Optimal Control Problem (COCP):where is the modulation index of the ith cell, is the maximum increment/decrement of the capacitor voltage when the maximum modulation index is applied to the power cell, and . Please note that Equation (62) is a restriction of the optimisation problem presented above. As shown in the above COCP, the capacitor voltage errors are considered in the cost function of Equation (59), while the additional control target is considered in the constraint Equation (61) to ensure that the cluster applies desired output voltage . Furthermore, it is worth indicating that the modulation index for every power cell is the decision variable related to the COCP in Equation (59).Two methodologies have been proposed to reduce the complexity of Equation (59) and are proposed in [50]. On the one hand, the first method relaxes the constraint Equation (62), preserving its original cost function. The second method uses a linear approximation of the cost function maintaining all its constraints. Consequently, both methodologies can be implemented in applications featuring a relatively high number of power cells. Additionally, the first method can be easily integrated with PS-PWM and the second LCB strategy is simple to combine with LS-PWM.The first MPC-based method computes specific modulation indexes for each module using an explicit closed-form solution of a relaxed version of the original optimisation problem in Equation (59). Thus, this solution does not ensure feasibility, and therefore it must be saturated to ensure that the modulation indexes belong to the control set . Like [4,24,27], the explicit solution presented in [50] contains two components: the first one proportional to the desired cluster voltage , while the second one is proportional to the difference between the capacitor voltage reference and the cell voltage . The experimental results presented in [50] validates that the dual-MPC method achieves faster dynamic responses with a steady-state performance similar to the existing PS-PWM based LCB algorithms. Moreover, the closed-loop performance does not depend on the design of a controller gain, as it is the case of [4,24,27].On the other hand, the second approach proposed in [50] (primal-MPC method) reduces the complexity of the initial difficulty by linearising the objective function. The resulting optimisation problem is solved by using a greedy algorithm based on a fast sorting network implemented in an FPGA control platform. This control strategy presents the lowest computational burden, and thus, it can be effortlessly applied in with a large number of power cells. The Primal-CVB method produces a slightly higher harmonic distortion than that generated by PS-PWM based schemes. Nevertheless, the experimental results validate that this strategy has the fastest dynamic performance. In addition, the primal-MPC method can be easily extended for the Nearest Level Modulation strategy or properly adapted to include a Selective Harmonic Elimination method as proposed in [75].

Comparison of LCB Control

4.5. CCV Mitigation Control

4.5.1. Feedforward Control Strategies

- A

- Mitigation using circulating currentsTo mitigate the capacitor-voltage fluctuation produced when the input port frequency gets closer to the output port frequency, a superimposed circulating current reference is added to the control strategy presented in Figure 8.As presented in [68], these references can be derived from the Equations (26)–(29). In Double frame, the extra circulating current references are obtained as:This method requires the fulfilment of to achieve good mitigation of the voltages oscillations [68]. This operational restriction is also verified in [48], where the authors employ an equivalent control strategy (also based on Double) to provide cluster energy control based on circulating currents reallocation.As discussed in [68], the restriction implies that the relation of must also be fulfiled as indicated in [53]. Hence, the requires an appropriate adjustment of either or . For motor drive applications, is manipulated as is a requirement of the magnetising current of the machine.If Equations (63)–(66) and are satisfied, it is claimed in [53] that correct regulation of the CCV is achieved during EFM. Nevertheless, according to the aforementioned publication, the main shortcoming of this method is the up-to increment in the cluster current. Additionally, an additional reactive power from the grid implies a larger cluster current, especially for drive applications feeding induction motors [68].

- B

- Mitigation using circulating currents and common mode voltageAs discussed in [7,29], this method is characterised by injecting common-mode voltage and circulating currents. The common-mode voltage is usually be defined as:where is the peak value for the common mode voltage, and has a frequency and a natural frequency .As mentioned in [7,29], the common-mode voltage can be purposely designed. Nevertheless, the common-mode frequency should reject frequency values close or equal to the input and output port frequencies to limit producing low-frequency capacitor voltage oscillations. The main issue of this balancing control is how to design the common-mode voltage peak amplitude and frequency. On the one hand, high-amplitude of implies an over-rating of the cluster in terms of voltage. On the other hand, a small would demand an unnecessary high circulating current for compensation. As for , a higher frequency makes it challenging to control the circulating current, while a lower one brings low-frequency oscillations in the CCVs [29].Considering Equation (67), the circulating current references from Equations (26)–(29) can be selected as:In [72,76,77], details regarding the selection of and are presented. These functions can be designed as sinusoidal, sinusoidal plus third order harmonic, square-wave and trapezoidal waveforms. For the , and are used in [29]. Additionally, and are used in [53], and are utilised in [78]. Note that hybrid method tends to a square waveform when m is large enough [79].The and waveforms used in the and are summarised in Table 5. The non-zero coefficients of are presented in Table 6.Further investigations on optimising the common-mode voltage selection have been proposed. In [53], the common-mode voltage amplitude and frequency are tuned based on a theoretical analysis based on reducing the CCV voltage oscillations. The amplitude is selected to minimise cluster voltage stress and overmodulation, and the frequency is set at the minimum value among being higher than and and lower than half of the switching frequency. This optimisation method decreases the magnitude of the voltage fluctuations and cluster currents. Further, a predictive control algorithm is used to optimise the selection of the common-mode voltage [57]. The algorithm introduces restrictions to limit the magnitude of the common-mode voltage and circulating currents to prevent cluster current and voltage stress. In both papers, a CCV Balancing Control is implemented (similar to Figure 8), and the circulating currents and optimised common-mode are feedforwarded to the control system to allow EFM operation.

- C

- Operational RestrictionsThe CCV mitigation strategies mentioned above are based on superimposing circulating currents and/or common-mode voltage to cancel out the most dominant frequency oscillation contained in the CCV. On the one hand, the amplitude of each cluster current reaches twice as high as that when no circulating current is considered. On the other hand, the injection of the common-mode voltage implies a cluster voltage stress, and it has been criticised when is relatively high because it can produce isolation damage in motor drive applications [81,82].Therefore, [30] presents a practical solution characterised for defining operational restrictions. This proposal is feasible for based drive applications. As stated in [30], in order to eliminate the low-frequency oscillations produced in EFM operation, the following requirements must be satisfied:The first condition is dependant on the machine- design and in some cases, a small degree of variation of could be achieved by manipulating the magnetising current (e.g., in induction machines and wound rotor synchronous machines). Moreover, the second condition can be accomplished by controlling the grid reactive current as a function of the reactive power demanded by the machine [30].

4.5.2. Feedback Control Strategies

4.5.3. Comparison of CCV Mitigation Control Strategies

5. Future Trends for Control of the

5.1. Advanced Controllers Applied to the

5.2. Sensorless Based Control Strategies

5.3. Distributed Control Strategies

5.4. Fault Tolerance Capability

5.5. Fault Ride through Control

5.6. Stability Studies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marquardt, R.; Lesnicar, A. A new modular voltage source inverter topology. In Proceedings of the European Power Electronics Conference (EPE), Toulouse, France, 2–4 September 2003; pp. 1–10. [Google Scholar]

- Marquardt, R. Modular Multilevel Converter: An universal concept for HVDC-Networks and extended DC-bus-applications. In Proceedings of the 2010 International Power Electronics Conference ECCE Asia, IPEC 2010, Sapporo, Japan, 21–24 June 2010; pp. 502–507. [Google Scholar] [CrossRef]

- Pereira, M.; Retzmann, D.; Lottes, J.; Wiesinger, M.; Wong, G. SVC PLUS: An MMC STATCOM for network and grid access applications. In Proceedings of the 2011 IEEE PES Trondheim PowerTech: The Power of Technology for a Sustainable Society, POWERTECH 2011, Trondheim, Norway, 19–23 June 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Akagi, H.; Inoue, S.; Yoshii, T. Control and performance of a transformerless cascade PWM STATCOM with star configuration. IEEE Trans. Ind. Appl. 2007, 43, 1041–1049. [Google Scholar] [CrossRef]

- Debnath, S.; Saeedifard, M. A new hybrid modular multilevel converter for grid connection of large wind turbines. IEEE Trans. Sustain. Energy 2013, 4, 1051–1064. [Google Scholar] [CrossRef]

- Vidal-Albalate, R.; Beltran, H.; Rolán, A.; Belenguer, E.; Peña, R.; Blasco-Gimenez, R. Analysis of the Performance of MMC under Fault Conditions in HVDC-Based Offshore Wind Farms. IEEE Trans. Power Deliv. 2016, 31, 839–847. [Google Scholar] [CrossRef] [Green Version]

- Kolb, J.; Kammerer, F.; Braun, M. Dimensioning and design of a modular multilevel converter for drive applications. In Proceedings of the 15th International Power Electronics and Motion Control Conference and Exposition, EPE-PEMC 2012 ECCE Europe, Novi Sad, Serbia, 4–6 September 2012; p. 1. [Google Scholar] [CrossRef]

- Okazaki, Y.; Kawamura, W.; Hagiwara, M.; Akagi, H.; Ishida, T.; Tsukakoshi, M.; Nakamura, R. Experimental Comparisons Between Modular Multilevel DSCC Inverters and TSBC Converters for Medium-Voltage Motor Drives. IEEE Trans. Power Electron. 2017, 32, 1802–1817. [Google Scholar] [CrossRef]

- Debnath, S.; Qin, J.; Bahrani, B.; Saeedifard, M.; Barbosa, P. Operation, control, and applications of the modular multilevel converter: A review. IEEE Trans. Power Electron. 2015, 30, 37–53. [Google Scholar] [CrossRef]

- Akagi, H. Multilevel Converters: Fundamental Circuits and Systems. Proc. IEEE 2017, 105, 2048–2065. [Google Scholar] [CrossRef]

- Akagi, H. Classification, terminology, and application of the modular multilevel cascade converter (MMCC). IEEE Trans. Power Electron. 2011, 26, 3119–3130. [Google Scholar] [CrossRef]

- Prabaharan, N.; Salam, Z.; Cecati, C.; Palanisamy, K. Design and Implementation of New Multilevel Inverter Topology for Trinary Sequence Using Unipolar Pulsewidth Modulation. IEEE Trans. Ind. Electron. 2020, 67, 3573–3582. [Google Scholar] [CrossRef]

- Kammerer, F.; Kolb, J.; Braun, M. A novel cascaded vector control scheme for the Modular Multilevel Matrix Converter. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Melbourne, VIC, Australia, 7–10 November 2011; pp. 1097–1102. [Google Scholar] [CrossRef] [Green Version]

- Karwatzki, D.; Baruschka, L.; Mertens, A. Survey on the Hexverter topology—A modular multilevel AC/AC converter. In Proceedings of the 9th International Conference on Power Electronics—ECCE Asia: “Green World with Power Electronics”, ICPE 2015-ECCE Asia, Seoul, Korea, 1–5 June 2015; pp. 1075–1082. [Google Scholar] [CrossRef]

- Karwatzki, D.; Mertens, A. Generalized Control Approach for a Class of Modular Multilevel Converter Topologies. IEEE Trans. Power Electron. 2018, 33, 2888–2900. [Google Scholar] [CrossRef]

- Soto-Sanchez, D.E.; Pena, R.; Cardenas, R.; Clare, J.; Wheeler, P. A cascade multilevel frequency changing converter for high-power applications. IEEE Trans. Ind. Electron. 2013, 60, 2118–2130. [Google Scholar] [CrossRef]

- Donoso, F.; Mora, A.; Espinoza, M.; Urrutia, M.; Espina, E.; Cardenas, R. Predictive-based Modulation Schemes for the Hybrid Modular Multilevel Converter. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE ’19 ECCE Europe), Genova, Italy, 3–5 September 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Zeng, R.; Xu, L.; Yao, L.; Williams, B.W. Design and operation of a hybrid modular multilevel converter. IEEE Trans. Power Electron. 2015, 30, 1137–1146. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Adam, G.P.; Holliday, D.; Fletcher, J.E.; Williams, B.W. Hybrid Cascaded Modular Multilevel Converter with DC Fault Ride-Through Capability for the HVDC Transmission System. IEEE Trans. Power Deliv. 2015, 30, 1853–1862. [Google Scholar] [CrossRef] [Green Version]

- Behrouzian, E.; Bongiorno, M.; De La Parra, H.Z. An overview of multilevel converter topologies for grid connected applications. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications, EPE 2013, Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar] [CrossRef]

- Kucka, J.; Karwatzki, D.; Mertens, A. AC/AC modular multilevel converters in wind energy applications: Design considerations. In Proceedings of the 2016 18th European Conference on Power Electronics and Applications, EPE 2016 ECCE Europe, Karlsruhe, Germany, 5–9 September 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Ilves, K.; Bessegato, L.; Norrga, S. Comparison of cascaded multilevel converter topologies for AC/AC conversion. In Proceedings of the 2014 International Power Electronics Conference, IPEC-Hiroshima—ECCE Asia 2014, Hiroshima, Japan, 18–21 May 2014; pp. 1087–1094. [Google Scholar] [CrossRef]

- Hammond, P.W. A new approach to enhance power quality for medium voltage AC drives. IEEE Trans. Ind. Appl. 1997, 33, 202–208. [Google Scholar] [CrossRef]

- Kawamura, W.; Hagiwara, M.; Akagi, H. Control and Experiment of a Modular Multilevel Cascade Converter Based on Triple-Star Bridge Cells. IEEE Trans. Ind. Appl. 2014, 50, 3536–3548. [Google Scholar] [CrossRef]

- Espinoza, M.; Cárdenas, R.; Díaz, M.; Clare, J.C. An Enhanced dq-Based Vector Control System for Modular Multilevel Converters Feeding Variable-Speed Drives. IEEE Trans. Ind. Electron. 2017, 64, 2620–2630. [Google Scholar] [CrossRef]

- Kouro, S.; Rodriguez, J.; Wu, B.; Bernet, S.; Perez, M. Powering the future of industry: High-power adjustable speed drive topologies. IEEE Ind. Appl. Mag. 2012, 18, 26–39. [Google Scholar] [CrossRef]

- Diaz, M.; Cardenas, R.; Espinoza, M.; Rojas, F.; Mora, A.; Clare, J.C.; Wheeler, P. Control of Wind Energy Conversion Systems Based on the Modular Multilevel Matrix Converter. IEEE Trans. Ind. Electron. 2017, 64, 8799–8810. [Google Scholar] [CrossRef]

- Okazaki, Y.; Kawamura, W.; Hagiwara, M.; Akagi, H.; Ishida, T.; Tsukakoshi, M.; Nakamura, R. Which is more suitable for MMCC-based medium-voltage motor drives, a DSCC inverter or a TSBC converter? In Proceedings of the 9th International Conference on Power Electronics - ECCE Asia: “Green World with Power Electronics”, ICPE 2015-ECCE Asia, Seoul, Korea, 1–5 June 2015; pp. 1053–1060. [Google Scholar] [CrossRef]

- Kawamura, W.; Chiba, Y.; Hagiwara, M.; Akagi, H. Experimental verification of TSBC-based electrical drives when the motor frequency is passing through, or equal to, the supply frequency. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition, ECCE 2015, Montreal, QC, Canada, 20–24 September 2015; pp. 5490–5497. [Google Scholar] [CrossRef]

- Kawamura, W.; Chiba, Y.; Hagiwara, M.; Akagi, H. Experimental Verification of an Electrical Drive Fed by a Modular Multilevel TSBC Converter When the Motor Frequency Gets Closer or Equal to the Supply Frequency. IEEE Trans. Ind. Appl. 2017, 53, 2297–2306. [Google Scholar] [CrossRef]

- Kammerer, F.; Gommeringer, M.; Kolb, J.; Braun, M. Energy balancing of the Modular Multilevel Matrix Converter based on a new transformed arm power analysis. In Proceedings of the 2014 16th European Conference on Power Electronics and Applications, EPE-ECCE Europe 2014, Lappeenranta, Finland, 26–28 August 2014; pp. 1–10. [Google Scholar] [CrossRef] [Green Version]

- Diaz, M.; Cardenas, R.; Espinoza, M.; Hackl, C.M.; Rojas, F.; Clare, J.C.; Wheeler, P. Vector control of a modular multilevel matrix converter operating over the full output-frequency range. IEEE Trans. Ind. Electron. 2019, 66, 5102–5114. [Google Scholar] [CrossRef]

- Perez, M.A.; Bernet, S.; Rodriguez, J.; Kouro, S.; Lizana, R. Circuit topologies, modeling, control schemes, and applications of modular multilevel converters. IEEE Trans. Power Electron. 2015, 30, 4–17. [Google Scholar] [CrossRef]

- Peng, F.Z.; Qian, W.; Cao, D. Recent advances in multilevel converter/inverter topologies and applications. In Proceedings of the 2010 International Power Electronics Conference—ECCE Asia—IPEC 2010, Sapporo, Japan, 21–24 June 2010; pp. 492–501. [Google Scholar] [CrossRef]

- Korn, A.J.; Winkelnkemper, M.; Steimer, P.; Kolar, J.W. Direct modular multi-level converter for gearless low-speed drives. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011. [Google Scholar]

- Oates, C. A methodology for developing ‘Chainlink’ converters. In Proceedings of the 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–10. [Google Scholar]

- Kawamura, W.; Hagiwara, M.; Akagi, H.; Tsukakoshi, M.; Nakamura, R.; Kodama, S. AC-Inductors Design for a Modular Multilevel TSBC Converter, and Performance of a Low-Speed High-Torque Motor Drive Using the Converter. IEEE Trans. Ind. Appl. 2017, 53, 4718–4729. [Google Scholar] [CrossRef]

- Diaz, M.; Ibaceta, E.; Duran, A.; Melendez, C.; Urrutia, M.; Rojas, F. Field oriented control of a modular multilevel matrix converter based variable speed drive. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications, EPE 2019 ECCE Europe, Genova, Italy, 3–5 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Duran, A.; Ibaceta, E.; Diaz, M.; Rojas, F.; Cardenas, R.; Chavez, H. Control of a modular multilevel matrix converter for unified power flow controller applications. Energies 2020, 13, 953. [Google Scholar] [CrossRef] [Green Version]

- Urrutia, M.; Donoso, F.; Mora, A.; Espina, E.; Diaz, M.; Cardenas, R. Enhanced circulating-current control for the modular multilevel matrix converter based on model predictive control. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications, EPE 2019 ECCE Europe, Genova, Italy, 3–5 September 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Kammerer, F.; Kolb, J.; Braun, M. Fully decoupled current control and energy balancing of the Modular Multilevel Matrix Converter. In Proceedings of the 15th International Power Electronics and Motion Control Conference and Exposition, EPE-PEMC 2012 ECCE Europe, Novi Sad, Serbia, 4–6 September 2012; pp. LS2a.3-1–LS2a.3-8. [Google Scholar] [CrossRef] [Green Version]

- Kawamura, W.; Hagiwara, M.; Akagi, H. Control and experiment of a 380-V, 15-kW motor drive using modular multilevel cascade converter based on triple-star bridge cells (MMCC-TSBC). In Proceedings of the 2014 International Power Electronics Conference, IPEC-Hiroshima—ECCE Asia 2014, Hiroshima, Japan, 18–21 May 2014; pp. 3742–3749. [Google Scholar] [CrossRef]

- Kammerer, F.; Gommeringer, M.K.J.B.M. Overload Capability of the Modular Multilevel Matrix Converter for Feeding High Torque Low Speed Drives. In Proceedings of the PCIM South America, Sao Paulo, Brazil, 14–15 October 2014; pp. 20–27. [Google Scholar] [CrossRef]

- Espinoza-B, M.; Cárdenas, R.; Clare, J.; Soto-Sanchez, D.; Diaz, M.; Espina, E.; Hackl, C.M. An Integrated Converter and Machine Control System for MMC-Based High-Power Drives. IEEE Trans. Ind. Electron. 2019, 66, 2343–2354. [Google Scholar] [CrossRef]

- Kolb, J.; Kammerer, F.; Gommeringer, M.; Braun, M. Cascaded control system of the modular multilevel converter for feeding variable-speed drives. IEEE Trans. Power Electron. 2015, 30, 349–357. [Google Scholar] [CrossRef]

- Diaz, M.; Rojas, F.; Espinoza, M.; Mora, A.; Wheeler, P.; Cardenas, R. Closed loop vector control of the modular multilevel matrix converter for equal input-output operating frequencies. In Proceedings of the 2017 IEEE Southern Power Electronics Conference, SPEC 2017, Puerto Varas, Chile, 4–7 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Diaz, M.; Espinosa, M.; Rojas, F.; Wheeler, P.; Cardenas, R. Vector control strategies to enable equal frequency operation of the modular multilevel matrix converter. J. Eng. 2019, 2019, 4214–4219. [Google Scholar] [CrossRef]

- Fan, B.; Wang, K.; Wheeler, P.; Gu, C.; Li, Y. A Branch Current Reallocation Based Energy Balancing Strategy for the Modular Multilevel Matrix Converter Operating Around Equal Frequency. IEEE Trans. Power Electron. 2018, 33, 1105–1117. [Google Scholar] [CrossRef]

- Urrutia, M.; Mora, A.; Angulo, A.; Lezana, P.; Cardenas, R.; Diaz, M. A novel Capacitor Voltage Balancing strategy for Modular Multilevel Converters. In Proceedings of the 2017 IEEE Southern Power Electronics Conference, SPEC 2017, Puerto Varas, Chile, 4–7 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Mora, A.; Urrutia, M.; Cardenas, R.; Angulo, A.; Espinoza, M.; Diaz, M.; Lezana, P. Model-predictive-control-based capacitor voltage balancing strategies for modular multilevel converters. IEEE Trans. Ind. Electron. 2019, 66, 2432–2443. [Google Scholar] [CrossRef]

- Kammerer, F.; Brackle, D.; Gommeringer, M.; Schnarrenberger, M.; Braun, M. Operating performance of the modular multilevel matrix converter in drive applications. In Proceedings of the PCIM Europe 2015; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 19–20 May 2015. [Google Scholar]

- Kawamura, W.; Chen, K.L.; Hagiwara, M.; Akagi, H. A Low-Speed, High-Torque Motor Drive Using a Modular Multilevel Cascade Converter Based on Triple-Star Bridge Cells (MMCC-TSBC). IEEE Trans. Ind. Appl. 2015, 51, 3965–3974. [Google Scholar] [CrossRef]

- Kawamura, W.; Chiba, Y.; Akagi, H. A Broad Range of Speed Control of a Permanent Magnet Synchronous Motor Driven by a Modular Multilevel TSBC Converter. IEEE Trans. Ind. Appl. 2017, 53, 3821–3830. [Google Scholar] [CrossRef]

- Erickson, R.; Angkititrakul, S.; Almazeedi, K. A New Family of Multilevel Matrix Converters for Wind Power Applications: Final Report; NREL/SR-500-40051; Technical Report for National Renewable Energy Lab: Golden, CO, USA, 2006. [Google Scholar]

- Erickson, R.W.; Al-Naseem, O.A. A new family of matrix converters. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Denver, CO, USA, 29 November–2 December 2001; Volume 2, pp. 1515–1520. [Google Scholar] [CrossRef]

- Angkititrakul, S.; Erickson, R.W. Control and implementation of a new modular matrix converter. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition—APEC, Anaheim, CA, USA, 22–26 February 2004; Volume 2, pp. 813–819. [Google Scholar] [CrossRef]

- Fan, B.; Wang, K.; Wheeler, P.; Gu, C.; Li, Y. An Optimal Full Frequency Control Strategy for the Modular Multilevel Matrix Converter Based on Predictive Control. IEEE Trans. Power Electron. 2018, 33, 6608–6621. [Google Scholar] [CrossRef]

- Soto, D.; Borquez, J. Control of a modular multilevel matrix converter for high power applications. Stud. Inform. Control 2012, 21, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, Y.; Takeshita, T.; Muneshima, M.; Tadano, Y. Independent control of input current and output voltage for Modular Matrix Converter. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Vienna, Austria, 10–13 November 2013; pp. 888–893. [Google Scholar] [CrossRef]

- Kammerer, F.; Gommeringer, M.; Kolb, J.; Braun, M. Benefits of operating Doubly Fed Induction Generators by Modular Multilevel Matrix Converters. In PCIM Europe Conference Proceedings; VDE-Verl: Nuremberg, Germany, 2013; pp. 1149–1156. [Google Scholar]

- Fan, B.; Wang, K.; Zheng, Z.; Xu, L.; Li, Y. Optimized Branch Current Control of Modular Multilevel Matrix Converters under Branch Fault Conditions. IEEE Trans. Power Electron. 2018, 33, 4578–4583. [Google Scholar] [CrossRef]

- Yao, W.; Liu, J.; Lu, Z. Distributed Control for the Modular Multilevel Matrix Converter. IEEE Trans. Power Electron. 2019, 34, 3775–3788. [Google Scholar] [CrossRef]

- Nakamori, T.; Sayed, M.A.; Hayashi, Y.; Takeshita, T.; Hamada, S.; Hirao, K. Independent Control of Input Current, Output Voltage, and Capacitor Voltage Balancing for a Modular Matrix Converter. IEEE Trans. Ind. Appl. 2015, 51, 4623–4633. [Google Scholar] [CrossRef]

- Miura, Y.; Mizutani, T.; Ito, M.; Ise, T. Modular multilevel matrix converter for low frequency AC transmission. In Proceedings of the International Conference on Power Electronics and Drive Systems, Kitakyushu, Japan, 22–25 April 2013; pp. 1079–1084. [Google Scholar] [CrossRef]

- Miura, Y.; Mizutani, T.; Ito, M.; Ise, T. A novel space vector control with capacitor voltage balancing for a multilevel modular matrix converter. In Proceedings of the 2013 IEEE ECCE Asia Downunder—5th IEEE Annual International Energy Conversion Congress and Exhibition, IEEE ECCE Asia 2013, Melbourne, VIC, Australia, 3–6 June 2013; pp. 442–448. [Google Scholar] [CrossRef]

- Khalid, H.A.; Al-Emadi, N.A.; Ben-Brahim, L.; Gastli, A.; Cecati, C. A novel control scheme for three-phase seven-level packed U-Cell based DSTATCOM. Electr. Power Syst. Res. 2020, 182, 106201. [Google Scholar] [CrossRef]

- Hagiwara, M.; Maeda, R.; Akagi, H. Negative-sequence reactive-power control by a PWM STATCOM based on a modular multilevel cascade converter (MMCC-SDBC). IEEE Trans. Ind. Appl. 2012, 48, 720–729. [Google Scholar] [CrossRef]

- Kawamura, W.; Hagiwara, M.; Akagi, H. A broad range of frequency control for the modular multilevel cascade converter based on triple-star bridge-cells (MMCC-TSBC). In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, ECCE 2013, Denver, CO, USA, 15–19 September 2013; pp. 4014–4021. [Google Scholar] [CrossRef]

- Díaz, M.; Cárdenas, R.; Mauricio Espinoza, B.; Mora, A.; Rojas, F. A novel LVRT control strategy for modular multilevel matrix converter based high-power wind energy conversion systems. In Proceedings of the 2015 10th International Conference on Ecological Vehicles and Renewable Energies, EVER 2015, Monte Carlo, Monaco, 31 March–2 April 2015; pp. 1–11. [Google Scholar] [CrossRef]

- Diaz, M.; Rojas, F.; Donoso, F.; Cardenas, R.; Espinoza, M.; Mora, A.; Wheeler, P. Control of modular multilevel cascade converters for offshore wind energy generation and transmission. In Proceedings of the 2018 13th International Conference on Ecological Vehicles and Renewable Energies, EVER 2018, Monte-Carlo, Monaco, 10–12 April 2018; pp. 1–10. [Google Scholar] [CrossRef]

- Hagiwara, M.; Akagi, H. Control and Experiment of Pulsewidth-Modulated Modular Multilevel Converters. IEEE Trans. Power Electron. 2009, 24, 1737–1746. [Google Scholar] [CrossRef]

- Espinoza, M.; Espina, E.; Diaz, M.; Mora, A.; Cardenas, R. Improved control strategy of the modular multilevel converter for high power drive applications in low frequency operation. In Proceedings of the 2016 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Ota, J.I.; Shibano, Y.; Niimura, N.; Akagi, H. A phase-shifted-PWM D-STATCOM using a modular multilevel cascade converter (SSBC) - Part I: Modeling, analysis, and design of current control. IEEE Trans. Ind. Appl. 2015, 51, 279–288. [Google Scholar] [CrossRef]

- Mora, A.; Espinoza, M.; Diaz, M.; Cardenas, R. Model Predictive Control of Modular Multilevel Matrix Converter. In Proceedings of the 2015 IEEE 24th International Symposium on Industrial Electronics (ISIE), Buzios, Brazil, 3–5 June 2015; pp. 1074–1079. [Google Scholar] [CrossRef]

- Buccella, C.; Cecati, C.; Cimoroni, M.G.; Razi, K. Analytical method for pattern generation in five-level cascaded H-bridge inverter using selective harmonic elimination. IEEE Trans. Ind. Electron. 2014, 61, 5811–5819. [Google Scholar] [CrossRef]

- Diaz, M.; Cárdenas, R.; Espinoza, M.; Mora, A.; Wheeler, P. Modelling and control of the modular multilevel matrix converter and its application to wind energy conversion systems. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Florence, Italy, 23–26 October 2016; pp. 5052–5057. [Google Scholar] [CrossRef]

- Korn, A.J.; Winkelnkemper, M.; Steimer, P. Low output frequency operation of the Modular Multi-Level Converter. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 3993–3997. [Google Scholar] [CrossRef]

- Hagiwara, M.; Hasegawa, I.; Akagi, H. Start-up and low-speed operation of an electric motor driven by a modular multilevel cascade inverter. IEEE Trans. Ind. Appl. 2013, 49, 1556–1565. [Google Scholar] [CrossRef]

- Li, B.; Zhou, S.; Xu, D.; Xu, D.; Wang, W. Comparative study of the sinusoidal-wave and square-wave circulating current injection methods for low-frequency operation of the modular multilevel converters. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition, ECCE 2015, Montreal, QC, Canada, 20–24 September 2015; pp. 4700–4705. [Google Scholar] [CrossRef]

- Mauricio Espinoza, B.; Mora, A.; Diaz, M.; Cárdenas, R. Balancing energy and low frequency operation of the modular multilevel converter in back to back configuration. In Proceedings of the 2015 10th International Conference on Ecological Vehicles and Renewable Energies, EVER 2015, Monte Carlo, Monaco, 31 March–2 April 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Du, S.; Wu, B.; Tian, K.; Zargari, N.R.; Cheng, Z. An Active Cross-Connected Modular Multilevel Converter (AC-MMC) for a Medium-Voltage Motor Drive. IEEE Trans. Ind. Electron. 2016, 63, 4707–4717. [Google Scholar] [CrossRef]

- Du, S.; Wu, B.; Zargari, N.R. A Star-Channel Modular Multilevel Converter for Zero/Low-Fundamental-Frequency Operation Without Injecting Common-Mode Voltage. IEEE Trans. Power Electron. 2018, 33, 2857–2865. [Google Scholar] [CrossRef]

- Cárdenas, R.; Peña, R. Sensorless vector control of induction machines for variable-speed wind energy applications. IEEE Trans. Energy Convers. 2004, 19, 196–205. [Google Scholar] [CrossRef]

- Yang, R.; Li, B.; Wang, G.; Cecati, C.; Zhou, S.; Xu, D.; Yu, W. Asymmetric Mode Control of MMC to Suppress Capacitor Voltage Ripples in Low-Frequency, Low-Voltage Conditions. IEEE Trans. Power Electron. 2017, 32, 4219–4230. [Google Scholar] [CrossRef]

- Li, B.; Zhou, S.; Xu, D.; Yang, R.; Xu, D.; Buccella, C.; Cecati, C. An Improved Circulating Current Injection Method for Modular Multilevel Converters in Variable-Speed Drives. IEEE Trans. Ind. Electron. 2016, 63, 7215–7225. [Google Scholar] [CrossRef]

- Yang, S.; Bryant, A.; Mawby, P.; Xiang, D.; Ran, L.; Tavner, P. An Industry-Based Survey of Reliability in Power Electronic Converters. IEEE Trans. Ind. Appl. 2011, 47, 1441–1451. [Google Scholar] [CrossRef]

- Miura, Y.; Yoshida, T.; Fujikawa, T.; Miura, T.; Ise, T. Operation of modular matrix converter with hieralchical control system under cell failure condition. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Karwatzki, D.; Von Hofen, M.; Baruschka, L.; Mertens, A. Operation of modular multilevel matrix converters with failed branches. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Dallas, TX, USA, 29 October–1 November 2014; pp. 1650–1656. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, Y.; Liu, Z. Robust Sensor Fault Reconstruction for Modular Multilevel Converter Based on Sliding Mode Observer. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 1835–1840. [Google Scholar]

- Luo, J.; Zhang, X.; Xue, Y.; Gu, K.; Wu, F. Harmonic Analysis of Modular Multilevel Matrix Converter for Fractional Frequency Transmission System. IEEE Trans. Power Deliv. 2020, 35, 1209–1219. [Google Scholar] [CrossRef]

- Meng, Y.; Li, S.; Zou, Y.; Li, K.; Wang, X.; Wang, X. Stability analysis and control optimisation based on particle swarm algorithm of modular multilevel matrix converter in fractional frequency transmission system. Iet Gener. Transm. Distrib. 2020, 14, 2641–2655. [Google Scholar] [CrossRef]

| Example | Decoupled | CCV Oscillations | Compactness | Linear Transformations | |

|---|---|---|---|---|---|

| Natural Frame | [7] | No | Mixed | Low | 0 |

| Double | [24] | Yes | 2 frequencies per CCV term | Medium | 1 |

| Double | [31] | Yes | 1 frequencies per CCV term | Medium | 2 |

| Vector Double | [32] | Yes | 1 frequencies per CCV term | High | 2 |

| Ref. | Paper Title | Journal/Conference | CCV Control | Local Cell Balancing | Mode |

|---|---|---|---|---|---|

| [13] | A novel cascaded vector control scheme for the Modular Multilevel Matrix Converter. | IECON Proceedings | CCR | Sorting PWM | Balancing Control |

| [24] | Control and Experiment of a Modular Multilevel Cascade Converter Based on Triple-Star Bridge Cells | IEEE Trans. on Industry Applications | CCR | PS-PWM | Balancing Control |

| [27] | Control of Wind Energy Conversion Systems Based on the Modular Multilevel Matrix Converter | IEEE Trans. on Industrial Electronics | CCR | PS-PWM | Balancing Control |

| [30] | Experimental Verification of an Electrical Drive Fed by a Modular Multilevel TSBC Converter When the Motor Frequency Gets Closer or Equal to the Supply Frequency | IEEE Trans. on Industry Applications | CCR | PS-PWM | Mitigation Control |

| [31] | Energy balancing of the Modular Multilevel Matrix Converter based on a new transformed arm power analysis | EPE-ECCE | CCR | Sorting PWM | Balancing Control |

| [32] | Vector Control of a Modular Multilevel Matrix Converter Operating Over the Full Output-Frequency Range | IEEE Trans. on Industrial Electronics | CCR | PS-PWM | Mitigation Control |

| [38] | Control of a Modular Multilevel Matrix Converter for Unified Power Flow Controller Applications | Energies | CCR | PS-PWM | Mitigation Control |

| [41] | Fully decoupled current control and energy balancing of the Modular Multilevel Matrix Converter | EPE/PEMC | CCR | SVM | Balancing Control |

| [47] | Vector control strategies to enable equal frequency operation of the modular multilevel matrix converter | Journal of Engineering | CCR | PS-PWM | Mitigation Control |

| [48] | A Branch Current Reallocation Based Energy Balancing Strategy for the Modular Multilevel Matrix Converter Operating Around Equal Frequency | IEEE Trans. on Power Electronics | CCR | PWM | Balancing Control |

| [52] | A Low-Speed, High-Torque Motor Drive Using a Modular Multilevel Cascade Converter Based on Triple-Star Bridge Cells (MMCC-TSBC) | IEEE Trans. on Industry Applications | CCR | PS-PWM | Mitigation Control |

| [53] | A Broad Range of Speed Control of a Permanent Magnet Synchronous Motor Driven by a Modular Multilevel TSBC Converter | IEEE Trans. on Industry Applications | CCR | PS-PWM | Mitigation Control |

| [54] | A new family of matrix converters for Wind Power Applications. | IECON Proceedings | CCR | SVM | Balancing Control |

| [57] | An Optimal Full Frequency Control Strategy for the Modular Multilevel Matrix Converter Based on Predictive Control | IEEE Trans. on Power Electronics | CCR | PS-PWM | Balancing Control |

| [58] | Control of a Modular Multilevel Matrix Converter for High Power Applications | Studies in Informatics and Control | NSCR | PS-PWM | Balancing Control |

| [59] | Independent Control of Input Current, Output Voltage, and Capacitor Voltage Balancing for a Modular Matrix Converter | IEEE Trans. on Industry Applications | NSCR | PS-PWM | Balancing Control |

| [60] | Benefits of operating Doubly Fed Induction Generators by Modular Multilevel Matrix Converters | PCIM Europe Conference Proceedings | CCR | Sorting PWM | Balancing Control |

| [61] | Optimized Branch Current Control of Modular Multilevel Matrix Converters under Branch Fault Conditions | IEEE Trans. on Power Electronics | CCR | PS-PWM | Balancing Control |

| [62] | Distributed Control for the Modular Multilevel Matrix Converter | IEEE Trans. on Power Electronics | CCR | PS-PWM | Balancing Control |

| Control Loop | Type | Advantage | Disadvantage | DFM | EFM | |

|---|---|---|---|---|---|---|

| CCV Balancing Control | NSCR | Simple | Negative-sequence currents in the grid | Adequate | No | |

| CCR | Double | Decoupled CCV Control | Complexity | Excellent | Good | |

| CCR | Double | Decoupled CCV Control | Complexity | Excellent | Excellent | |

| Control Loop | Type | Advantage | Disadvantage |

|---|---|---|---|

| LCB Control | SVM | Use of redundancy for balancing purposes | Impracticable for a large number of cells |

| PS-PWM | Simplicity of implementation in digital platforms | Multiple P controllers and closed-loop tuning | |

| LS-PWM | Simplicity of implementation in digital platforms | High computational burden due to sorting algorithms | |

| MPC | Formulation of a constrained optimal control problem | Implementation of approximated solution approaches |

| m-Harmonic | |||

|---|---|---|---|

| 1 | 0 | 0 | |

| 3 | 0 | ||

| 5 |

| Control Loop | Approach | Advantages | Disadvantages | CCV Control | Complexity | |

|---|---|---|---|---|---|---|

| CCV Mitigation Control | Section 4.5.1A | Double | No CMV | High CC, Op. restrictions, open loop control | Good | Moderate |

| Section 4.5.1B | Double | No operational restrictions | Injection of CMV, open loop control | Good | Moderate | |

| Section 4.5.1C | Double | No CC No CMV | Op. restrictions, open loop control, reactive current | Moderate | Low | |

| Section 4.5.2 | Double | No operational restrictions | Injection of CMV | Excellent | High | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diaz, M.; Cardenas, R.; Ibaceta, E.; Mora, A.; Urrutia, M.; Espinoza, M.; Rojas, F.; Wheeler, P. An Overview of Modelling Techniques and Control Strategies for Modular Multilevel Matrix Converters. Energies 2020, 13, 4678. https://doi.org/10.3390/en13184678

Diaz M, Cardenas R, Ibaceta E, Mora A, Urrutia M, Espinoza M, Rojas F, Wheeler P. An Overview of Modelling Techniques and Control Strategies for Modular Multilevel Matrix Converters. Energies. 2020; 13(18):4678. https://doi.org/10.3390/en13184678

Chicago/Turabian StyleDiaz, Matias, Roberto Cardenas, Efrain Ibaceta, Andrés Mora, Matias Urrutia, Mauricio Espinoza, Felix Rojas, and Patrick Wheeler. 2020. "An Overview of Modelling Techniques and Control Strategies for Modular Multilevel Matrix Converters" Energies 13, no. 18: 4678. https://doi.org/10.3390/en13184678