Author Contributions

Conceptualization, A.S. and A.D.; methodology, A.S.; software, A.S., M.P. and L.M.; validation, A.S. and A.D.; formal analysis, A.S. and L.M.; investigation, A.S.; resources, A.D. and L.M.; data curation, A.S.; writing—original draft preparation, A.S. and L.M.; writing—review and editing, A.D. and M.P.; visualization, A.S.; supervision, A.D.; project administration, A.D.; funding acquisition, A.D. All authors have read and agreed to the published version of the manuscript.

Figure 1.

Block scheme of the procedure presented in this paper.

Figure 1.

Block scheme of the procedure presented in this paper.

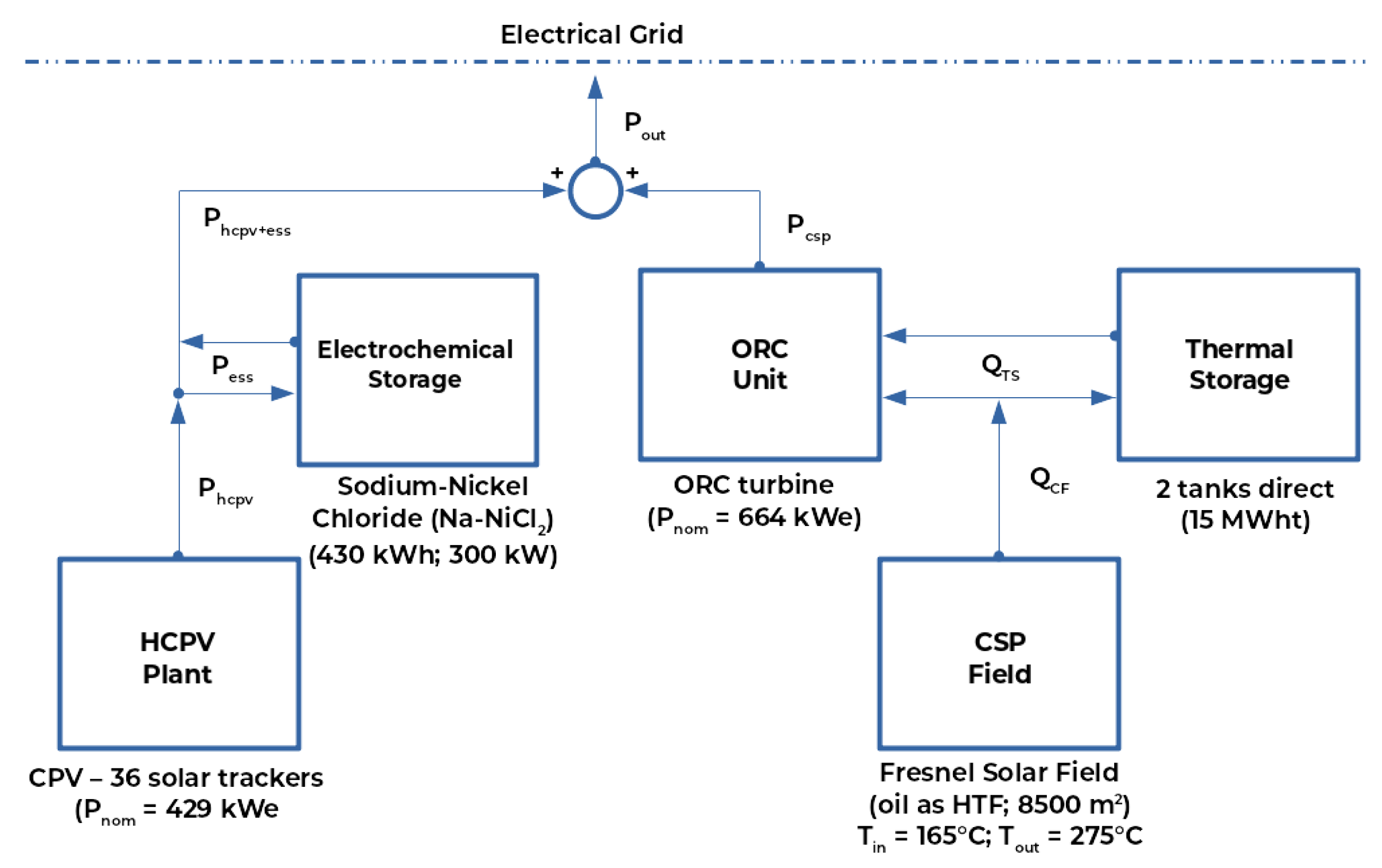

Figure 2.

Block diagram of Ottana solar facility used as a case of study.

Figure 2.

Block diagram of Ottana solar facility used as a case of study.

Figure 3.

Overview of the Ottana solar facility.

Figure 3.

Overview of the Ottana solar facility.

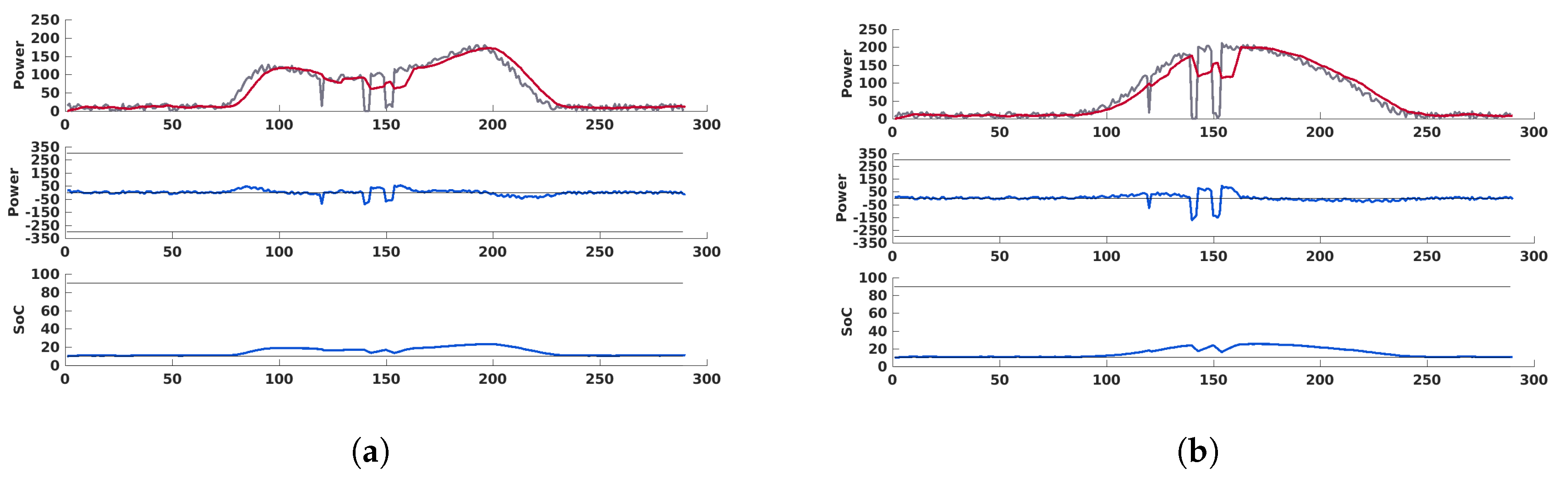

Figure 4.

(a) Top: forecast power profile (blue), filtered power profile (red). Bottom: Ideal battery power needed to let flowing to the grid a power equal to the filtered one; (b) Top: Forecast power profile (, grey), power profile after application of FBM (, red); Middle: battery power evolution (); Bottom: battery SoC.

Figure 4.

(a) Top: forecast power profile (blue), filtered power profile (red). Bottom: Ideal battery power needed to let flowing to the grid a power equal to the filtered one; (b) Top: Forecast power profile (, grey), power profile after application of FBM (, red); Middle: battery power evolution (); Bottom: battery SoC.

Figure 5.

Generic block scheme of a smoothing algorithm. The branch associated with the optional feedback is in red.

Figure 5.

Generic block scheme of a smoothing algorithm. The branch associated with the optional feedback is in red.

Figure 6.

Block scheme of the moving average algorithm. The branch associated with the feedback is in red.

Figure 6.

Block scheme of the moving average algorithm. The branch associated with the feedback is in red.

Figure 7.

Flowchart of the step-rate control algorithm.

Figure 7.

Flowchart of the step-rate control algorithm.

Figure 8.

Scatterplot of modeled GHI and DNI irradiation on a horizontal surface compared to the measured values from the ERA5 (top) and SARAH (bottom) datasets.

Figure 8.

Scatterplot of modeled GHI and DNI irradiation on a horizontal surface compared to the measured values from the ERA5 (top) and SARAH (bottom) datasets.

Figure 9.

Errors of the modeled GHI and DNI irradiation on a horizontal surface compared to the measured values from the ERA5 dataset. Histograms (first row), box-plot grouped on the hour of the day (second row), and on the month of the year (third row).

Figure 9.

Errors of the modeled GHI and DNI irradiation on a horizontal surface compared to the measured values from the ERA5 dataset. Histograms (first row), box-plot grouped on the hour of the day (second row), and on the month of the year (third row).

Figure 10.

Top: Grid power flow with RC (, red) and without RC (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 10.

Top: Grid power flow with RC (, red) and without RC (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 11.

Top: Grid power flow with MA (, red) and without MA (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 11.

Top: Grid power flow with MA (, red) and without MA (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 12.

Top: Grid power flow with SR (, red) and without SR (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 12.

Top: Grid power flow with SR (, red) and without SR (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 13.

Top: Grid power flow with RC (, red) and without RC (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 13.

Top: Grid power flow with RC (, red) and without RC (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 14.

Top: Grid power flow with FBM-MA (, red) and without FBM-MA (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 14.

Top: Grid power flow with FBM-MA (, red) and without FBM-MA (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 15.

Top: Grid power flow with FBM-SR (, red) and without FBM-SR (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Figure 15.

Top: Grid power flow with FBM-SR (, red) and without FBM-SR (, grey). Middle: Battery power evolution (, blue) and constraints (grey). Bottom: Battery SoC evolution (blue) and constraints (grey). On a cloudy day case (a), on a sunny day (b).

Table 1.

Errors for the irradiation model for GHI and DNI, for ERA5 and SARAH datasets, and for the original and optimized offset parameter.

Table 1.

Errors for the irradiation model for GHI and DNI, for ERA5 and SARAH datasets, and for the original and optimized offset parameter.

| | Offset [-] | MAE [W/m2] | RMSE [W/m2] | r [-] | ss [-] |

|---|

| GHI (ERA5) | 0.35 | 53.28 | 85.96 | 0.947 | 6.0% |

| GHI (SARAH) | 0.35 | 78.06 | 121.37 | 0.903 | 16.1% |

| DNI (ERA5) | 0.00 | 70.13 | 113.96 | 0.874 | 13.2% |

| DNI (SARAH) | 0.00 | 95.55 | 149.63 | 0.805 | 16.4% |

| GHI (ERA5) | 0.60 | 52.09 | 77.17 | 0.957 | 21.9% |

| GHI (SARAH) | 0.60 | 79.66 | 117.14 | 0.910 | 22.7% |

| DNI (ERA5) | 0.20 | 66.80 | 102.28 | 0.893 | 22.3% |

| DNI (SARAH) | 0.20 | 94.31 | 142.49 | 0.816 | 17.8% |

Table 2.

Normalized RMSE associated with each model.

Table 2.

Normalized RMSE associated with each model.

| | ASTM | Fernàndez | Modified ASTM | Modified Fernandez | Hybrid Model |

|---|

| N-RMSE [%] | | | | | |

Table 3.

Linear coefficient of the production Hybrid model adopted in this paper.

Table 3.

Linear coefficient of the production Hybrid model adopted in this paper.

| | c1 | c2 | c3 | c4 | c5 |

|---|

| 4.4699 | 0.0020 | −0.0069 | 0.0276 | - |

| 5.4941 | 0.0015 | −0.0181 | 0.0249 | −0.2040 |

Table 4.

Low-pass FIR filter characteristics.

Table 4.

Low-pass FIR filter characteristics.

| Parameter | Value | Unit |

|---|

| Typology | Low-Pass FIR | - |

| Passband Frequency | | Hz |

| Stopband Frequency | 160 | Hz |

| Passband Ripple | | dB |

| Stopband Attenuation | 60 | dB |

| Sample Rate | | mHz |

| Design Method | Kaiserwin | - |

Table 5.

Ramps’ mean values for each strategy in both cases.

Table 5.

Ramps’ mean values for each strategy in both cases.

| | No Strategy | RC | FBM-RC | MA | FBM-MA | SR | FBM-SR |

|---|

| Cloudy day | 1.99 | 1.33 | 1.27 | 0.50 | 0.35 | 1.68 | 1.62 |

| Sunny day | 2.44 | 1.35 | 1.37 | 0.57 | 0.44 | 1.80 | 1.76 |

Table 6.

Number ramp sign variations for each strategy in both cases.

Table 6.

Number ramp sign variations for each strategy in both cases.

| | No Strategy | RC | FBM-RC | MA | FBM-MA | SR | FBM-SR |

|---|

| Cloudy day | 180 | 153 | 165 | 77 | 107 | 181 | 183 |

| Sunny day | 190 | 170 | 171 | 82 | 115 | 191 | 194 |

Table 7.

Values of for each strategy in both cases.

Table 7.

Values of for each strategy in both cases.

| | No Strategy | RC | FBM-RC | MA | FBM-MA | SR | FBM-SR |

|---|

| Cloudy day | - | 4.56 | 40.06 | 13.31 | 43.86 | 5.16 | 42.00 |

| Sunny day | - | 10.85 | 40.46 | 15.28 | 45.92 | 13.06 | 45.56 |