Numerical Investigation of Injection-Induced Fracture Propagation in Brittle Rocks with Two Injection Wells by a Modified Fluid-Mechanical Coupling Model

Abstract

:1. Introduction

2. Modeling Methodology

2.1. Introduction of Particle Flow Code

2.2. Modified Fluid-Mechanical Coupling Algorithm

3. Modeling Calibration and Validation

3.1. Laboratory Test

3.2. Material Parameters Calibration

3.3. Validation of Hydraulic Fracturing Model

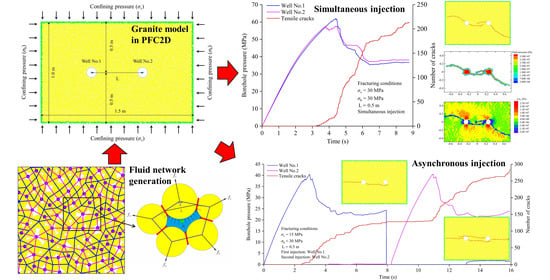

4. Hydraulic Fracturing Process in the Specimens with Two Injection Wells

4.1. Modeling Scenarios

4.2. The Influence of Injection Sequence under Different In-Situ Stress Conditions

4.3. The Influence of Well Spacing under Different In-Situ Stress Conditions

5. Analysis of Stress Shadow Effect

6. Discussion and Conclusions

- (1)

- The injection sequence and well spacing have significant effects on the fracture propagation pressure instead of the breakdown pressure. Under the condition of hydrostatic pressure, lower fracture propagation pressure is required by the simultaneous fracturing models or small well spacing models. But these effects generally decay as the vertical in-situ stress declines.

- (2)

- Adjusting the injection sequence is a feasible way to control the propagation direction of hydraulic fractures. In the state of hydrostatic pressure, simultaneous fracturing allows more fracturing fluid to penetrate into the surrounding rock and compels the fractures to deflect to the horizontal direction, which is beneficial for the formation of complex fracture networks between the injection wells. The initial expansion of the fractures in asynchronous fracturing is easily disturbed by the micro defects around the boreholes, largely engendering no fractures between these wells. When the maximum in-situ stress is in the horizontal direction, in contrast to the asynchronous fracturing, simultaneous fracturing intensifies the coalescence of horizontal fractures.

- (3)

- The reasonable well spacing in the reservoir affects the growth of fracture branches. Excessively small or large well spacing limits the generation of multiple fracture branches in fracture networks. Comparatively speaking, for getting more fractures between the injection wells, the expected well spacing under the hydrostatic pressure may be smaller than that under the in-situ differential stress.

- (4)

- The stress shadow effects of hydraulic fractures are also closely related to the injection sequence and well spacing. In the case of simultaneous fracturing or small well spacing, the superposition of the stress shadow effects in the middle of the model strengthens their impact. When the fluid injection decreases or the well spacing increases, this superposition will be suppressed.

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, B.; Wood, D.A. A holistic review of geosystem damage during unconventional oil, gas and geothermal energy recovery. Fuel 2018, 227, 99–110. [Google Scholar] [CrossRef]

- Soeder, D.J. The successful development of gas and oil resources from shales in North America. J. Pet. Sci. Eng. 2018, 163, 399–420. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Li, L.H.; Chen, B.K.; Isaka, B.L.A.; De Silva, V.R.S. Hydraulic fracturing under high temperature and pressure conditions with micro CT applications: Geothermal energy from hot dry rocks. Fuel 2018, 230, 138–154. [Google Scholar] [CrossRef]

- Li, F.; Yuan, Q.; Li, T.; Li, Z.; Sun, C.; Chen, G. A review: Enhanced recovery of natural gas hydrate reservoirs. Chin. J. Chem. Eng. 2019, 27, 2062–2073. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, K.; Zhang, L.; Sun, H.; Zhang, K.; Ma, J. Pore-scale simulation of shale oil flow based on pore network model. Fuel 2019, 251, 683–692. [Google Scholar] [CrossRef]

- Li, H.; Zhou, L.; Lu, Y.; Yan, F.; Zhou, J.; Tang, J. Changes in Pore Structure of Dry-hot Rock with Supercritical CO2 Treatment. Energy Fuels 2020, 34, 6059–6068. [Google Scholar] [CrossRef]

- Warpinski, N.R. Hydraulic fracturing in tight, fissured media. J. Pet. Technol. 1991, 43. [Google Scholar] [CrossRef]

- Osiptsov, A.A. Fluid Mechanics of Hydraulic Fracturing: A Review. J. Pet. Sci. Eng. 2017, 156, 513–535. [Google Scholar] [CrossRef]

- Patel, S.M.; Sondergeld, C.H.; Rai, C.S. Laboratory studies of hydraulic fracturing by cyclic injection. Int. J. Rock Mech. Min. Sci. 2017, 95, 8–15. [Google Scholar] [CrossRef]

- Yang, T.H.; Tham, L.G.; Tang, C.A.; Liang, Z.Z.; Tsui, Y. Influence of heterogeneity of mechanical properties on hydraulic fracturing in permeable rocks. Rock Mech. Rock Eng. 2004, 37, 251–275. [Google Scholar] [CrossRef]

- Yarushina, V.M.; Bercovici, D.; Oristaglio, M.L. Rock deformation models and fluid leak-off in hydraulic fracturing. Geophys. J. Int. 2013, 194, 1514–1526. [Google Scholar] [CrossRef] [Green Version]

- Dahi Taleghani, A.; Gonzalez, M.; Shojaei, A. Overview of numerical models for interactions between hydraulic fractures and natural fractures: Challenges and limitations. Comput. Geotech. 2016, 71, 361–368. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Zhang, F.; Dontsov, E.; Damjanac, B. Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Int. J. Solids Struct. 2019, 176–177, 207–220. [Google Scholar] [CrossRef]

- Ishida, T.; Aoyagi, K.; Niwa, T.; Chen, Y.; Murata, S.; Chen, Q.; Nakayama, Y. Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys. Res. Lett. 2012, 39. [Google Scholar] [CrossRef] [Green Version]

- Bennour, Z.; Watanabe, S.; Chen, Y.; Ishida, T.; Akai, T. Evaluation of stimulated reservoir volume in laboratory hydraulic fracturing with oil, water and liquid carbon dioxide under microscopy using the fluorescence method. Geomech. Geophys. Geo-Energy Geo-Resour. 2018, 4, 39–50. [Google Scholar] [CrossRef]

- Gonçalves da Silva, B.; Einstein, H. Physical processes involved in the laboratory hydraulic fracturing of granite: Visual observations and interpretation. Eng. Fract. Mech. 2018, 191, 125–142. [Google Scholar] [CrossRef]

- Li, B.Q.; Gonçalves da Silva, B.; Einstein, H. Laboratory hydraulic fracturing of granite: Acoustic emission observations and interpretation. Eng. Fract. Mech. 2019, 209, 200–220. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, S.; Qu, Z.; Zhou, T.; Xiao, Y.; Gao, J. Experimental study of hydraulic fracturing for shale by stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Tang, J.; Zhou, Z.; Liao, Y. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Yin, C.; Zhang, Y.; Lin, C. Propagation and characterization of the micro cracks induced by hydraulic fracturing in shale. Energy 2020, 191, 116449. [Google Scholar] [CrossRef]

- Zhuang, L.; Jung, S.G.; Diaz, M.; Kim, K.Y.; Hofmann, H.; Min, K.B.; Zang, A.; Stephansson, O.; Zimmermann, G.; Yoon, J.S. Laboratory True Triaxial Hydraulic Fracturing of Granite Under Six Fluid Injection Schemes and Grain-Scale Fracture Observations. Rock Mech. Rock Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Jing, L. A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering. Int. J. Rock Mech. Min. Sci. 2003, 40, 283–353. [Google Scholar] [CrossRef]

- Jing, L.; Hudson, J.A. Numerical methods in rock mechanics. Int. J. Rock Mech. Min. Sci. 2002, 39, 409–427. [Google Scholar] [CrossRef]

- Zhang, Y.; Wong, L.N.Y. A review of numerical techniques approaching microstructures of crystalline rocks. Comput. Geosci. 2018, 115, 167–187. [Google Scholar] [CrossRef]

- Li, J.; Dong, S.; Hua, W.; Li, X.; Pan, X. Numerical investigation of hydraulic fracture propagation based on cohesive zone model in naturally fractured formations. Processes 2019, 7, 28. [Google Scholar] [CrossRef] [Green Version]

- Liao, J.; Hou, M.Z.; Mehmood, F.; Feng, W. A 3D approach to study the interaction between hydraulic and natural fracture. Environ. Earth Sci. 2019, 78, 1–18. [Google Scholar] [CrossRef]

- Zangeneh, N.; Eberhardt, E.; Bustin, R.M.; Bustin, A. A numerical investigation of fault slip triggered by hydraulic fracturing. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, Australia, 20–22 May 2013; pp. 477–488. [Google Scholar] [CrossRef] [Green Version]

- Janiszewski, M.; Shen, B.; Rinne, M. Simulation of the interactions between hydraulic and natural fractures using a fracture mechanics approach. J. Rock Mech. Geotech. Eng. 2019, 11, 1138–1150. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Hazzard, J.F.; Young, R.P.; Maxwell, S.C. Micromechanical modeling of cracking and failure in brittle rocks. J. Geophys. Res. Solid Earth 2000, 105, 16683–16697. [Google Scholar] [CrossRef]

- Fakhimi, A.; Carvalho, F.; Ishida, T.; Labuz, J.F. Simulation of failure around a circular opening in rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 507–515. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X. Mesoscopic structure PFC∼2D model of soil rock mixture based on digital image. J. Vis. Commun. Image Represent. 2019, 58, 407–415. [Google Scholar] [CrossRef]

- Liu, G.; Sun, W.C.; Lowinger, S.M.; Zhang, Z.H.; Huang, M.; Peng, J. Coupled flow network and discrete element modeling of injection-induced crack propagation and coalescence in brittle rock. Acta Geotech. 2019, 14, 843–868. [Google Scholar] [CrossRef]

- Cundall, P.A. Fluid Formulation for PFC2D; Itasca Consulting Group: Minneapolis, MN, USA, 2000. [Google Scholar]

- Al-Busaidi, A.; Hazzard, J.F.; Young, R.P. Distinct element modeling of hydraulically fractured Lac du Bonnet granite. J. Geophys. Res. Solid Earth 2005, 110, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Yoon, J.; Backers, T.; Dresen, G. Prototype PFC2D model for simulation of hydraulic fracturing and induced seismicity. In Proceedings of the ISRM International Symposium—EUROCK, Stockholm, Sweden, 28–30 May 2012. [Google Scholar]

- Yoon, J.S.; Zimmermann, G.; Zang, A. Discrete element modeling of cyclic rate fluid injection at multiple locations in naturally fractured reservoirs. Int. J. Rock Mech. Min. Sci. 2015, 74, 15–23. [Google Scholar] [CrossRef]

- Yoon, J.S.; Zimmermann, G.; Zang, A.; Stephansson, O. Discrete element modeling of fluid injection–induced seismicity and activation of nearby fault. Can. Geotech. J. 2015, 52, 1457–1465. [Google Scholar] [CrossRef] [Green Version]

- Tomac, I.; Gutierrez, M. Coupled hydro-thermo-mechanical modeling of hydraulic fracturing in quasi-brittle rocks using BPM-DEM. J. Rock Mech. Geotech. Eng. 2017, 9, 92–104. [Google Scholar] [CrossRef]

- Tomac, I.; Gutierrez, M. Micromechanics of Hydro-Thermo-Mechanical Processes in Rock Accounting for Thermal Convection. J. Eng. Mech. 2019, 145. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Han, Z. Hydraulic fracturing process by using a modified two-dimensional particle flow code-method and validation. Prog. Comput. Fluid Dyn. 2017, 17, 52–62. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J.; Han, Z. Hydraulic fracturing process by using a modified two-dimensional particle flow code-case study. Prog. Comput. Fluid Dyn. 2017, 17, 13–26. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Braun, A.; Han, Z. Numerical Modeling and Investigation of Fluid-Driven Fracture Propagation in Reservoirs Based on a Modified Fluid-Mechanically Coupled Model in Two-Dimensional Particle Flow Code. Energies 2016, 9, 699. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Zhang, L.; Pan, Z.; Han, Z. Numerical investigation of fluid-driven near-borehole fracture propagation in laminated reservoir rock using PFC2D. J. Nat. Gas Sci. Eng. 2016, 36, 719–733. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Pan, Z.; Han, Z. Numerical studies of interactions between hydraulic and natural fractures by Smooth Joint Model. J. Nat. Gas Sci. Eng. 2017, 46, 592–602. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Braun, A.; Han, Z. Investigation of processes of interaction between hydraulic and natural fractures by PFC modeling comparing against laboratory experiments and analytical models. Energies 2017, 1001. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Zhou, J.; Braun, A.; Han, Z. Sensitivity analysis on the interaction between hydraulic and natural fractures based on an explicitly coupled hydro-geomechanical model in PFC2D. J. Pet. Sci. Eng. 2018, 167, 638–653. [Google Scholar] [CrossRef]

- Itasca Consulting Group Inc. Manual PFC2D (Particle Flow Code); Version 4.0 Users’ Guide; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2008. [Google Scholar]

- Cho, N.; Martin, C.D.; Sego, D.C. A clumped particle model for rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 997–1010. [Google Scholar] [CrossRef]

- Wu, S.; Xu, X. A Study of Three Intrinsic Problems of the Classic Discrete Element Method Using Flat-Joint Model. Rock Mech. Rock Eng. 2016, 49, 1813–1830. [Google Scholar] [CrossRef]

- Potyondy, D.O. Parallel-Bond Refinements to Match Macroproperties of Hard Rock. In Proceedings of the 2nd FLAC/DEM Symposium, Melbourne, Australia, 14–16 February 2011. [Google Scholar]

- Ding, X.; Zhang, L. A new contact model to improve the simulated ratio of unconfined compressive strength to tensile strength in bonded particle models. Int. J. Rock Mech. Min. Sci. 2014, 69, 111–119. [Google Scholar] [CrossRef]

- Yoon, J.S.; Zang, A.; Stephansson, O. Numerical investigation on optimized stimulation of intact and naturally fractured deep geothermal reservoirs using hydro-mechanical coupled discrete particles joints model. Geothermics 2014, 52, 165–184. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.; Zhou, J.; Zhang, L. Influence of grain size heterogeneity and in-situ stress on the hydraulic fracturing process by PFC2D Modeling. Energies 2018, 11, 1413. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Paul Young, R. Numerical modeling of seismicity induced by fluid injection in naturally fractured reservoirs. Geophysics 2011, 76. [Google Scholar] [CrossRef] [Green Version]

- Yoon, J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int. J. Rock Mech. Min. Sci. 2007, 44, 871–889. [Google Scholar] [CrossRef]

- Schöpfer, M.P.J.; Childs, C.; Walsh, J.J. Two-dimensional distinct element modeling of the structure and growth of normal faults in multilayer sequences: 1. Model calibration, boundary conditions, and selected results. J. Geophys. Res. Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Ajamzadeh, M.R.; Sarfarazi, V.; Haeri, H.; Dehghani, H. The effect of micro parameters of PFC software on the model calibration. Smart Struct. Syst. 2018, 22, 643–662. [Google Scholar] [CrossRef]

- Wang, Y.; Tonon, F. Modeling Lac du Bonnet granite using a discrete element model. Int. J. Rock Mech. Min. Sci. 2009, 46, 1124–1135. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Yang, D.; Braun, A.; Han, Z. Investigation of the quasi-brittle failure of alashan granite viewed from laboratory experiments and grain-based discrete element modeling. Materials 2017, 10, 835. [Google Scholar] [CrossRef]

- Zhou, J.; Lan, H.; Zhang, L.; Yang, D.; Song, J.; Wang, S. Novel grain-based model for simulation of brittle failure of Alxa porphyritic granite. Eng. Geol. 2019, 251, 100–114. [Google Scholar] [CrossRef]

- Haimson, B.; Fairhurst, C. Initiation and Extension of Hydraulic Fractures in Rocks. Soc. Pet. Eng. J. 1967, 7, 310–318. [Google Scholar] [CrossRef]

- Hubbert, M.K.; Willis, D.G. Mechanics of Hydraulic Fracturing. Pet. Trans. Aime. 1957, 210, 153–168. [Google Scholar] [CrossRef]

- Mao, R.; Feng, Z.; Liu, Z.; Zhao, Y. Laboratory hydraulic fracturing test on large-scale pre-cracked granite specimens. J. Nat. Gas Sci. Eng. 2017, 44, 278–286. [Google Scholar] [CrossRef]

- Xing, Y.; Zhang, G.; Luo, T.; Jiang, Y.; Ning, S. Hydraulic fracturing in high-temperature granite characterized by acoustic emission. J. Pet. Sci. Eng. 2019, 178, 475–484. [Google Scholar] [CrossRef]

- Germanovich, L.N.; Astakhov, D.K. Fracture closure in extension and mechanical interaction of parallel joints. J. Geophys. Res. Solid Earth 2004, 109. [Google Scholar] [CrossRef]

- Olson, J.E. Multi-fracture propagation modeling: Applications to hydraulic fracturing in shales and tight gas sands. In Proceedings of the 42nd US Rock Mechanics Symposium and 2nd US-Canada Rock Mechanics Symposium, San Francisco, CA, USA, 29 June–2 July 2008. [Google Scholar]

- Zhou, L.; Chen, J.; Gou, Y.; Feng, W. Numerical investigation of the time-dependent and the proppant dominated stress shadow effects in a transverse multiple fracture system and optimization. Energies 2017, 10, 83. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Jeffrey, R.G.; Thiercelin, M. Deflection and propagation of fluid-driven fractures at frictional bedding interfaces: A numerical investigation. J. Struct. Geol. 2007, 29, 396–410. [Google Scholar] [CrossRef]

| Micro-Parameters of the Basic Particles | Notations | Values |

|---|---|---|

| Particle density (kg/m3) | ρ | 2650.0 |

| Porosity (%) | φ | 10 |

| Effective modulus of particle (GPa) | E’ | 30.0 |

| Contact normal to shear stiffness ratio | kn/ks | 1.5 |

| Friction coefficient of particle | f | 0.8 |

| Micro-Parameters of the Parallel Bonds | Notations | Values |

| Effective modulus of the parallel bonds (GPa) | Ec | 30.0 |

| Normal to shear stiffness ratio of the parallel bonds | kn/ks | 1.5 |

| Tensile strength of the parallel bonds (MPa) | σc | 28.0 |

| Shear strength of the parallel bonds (MPa) | τc | 120.0 |

| Radius multiplier | λ | 1.0 |

| Moment contribution factor | β | 0.1 |

| Micro-Parameters of the Hydraulic Properties | Notations | Values |

| Initial hydraulic aperture (m) | e0 | 2.2 × 10−6 |

| Infinite hydraulic aperture (m) | einf | 2.2 × 10−7 |

| Model Permeability (m2) | k | 1.0 × 10−17 |

| Bulk modulus of the fracturing fluid (GPa) | Kf | 2.0 |

| Viscosity of the fracturing fluid (Pa·s) | μ | 1.0 × 10−3 |

| Macro Properties | Average of Experimental Results | Simulation Results |

|---|---|---|

| UCS (MPa) | 159.4 | 159.7 |

| UTS (MPa) | 9.5 1 | 13.8 |

| E (GPa) | 48.0 | 46.4 |

| ν | 0.23 | 0.21 |

| In-Situ Stress Conditions | Hydraulic Fracturing Characteristics | Scheme 1 | Scheme 2 | Scheme 3 | |||

|---|---|---|---|---|---|---|---|

| Well No.1 | Well No.2 | Well No.1 | Well No.2 | Well No.1 | Well No.2 | ||

| σv = 30 MPa σh = 30 MPa | Breakdown pressure (MPa) | 62.0 | 57.7 | 62.7 | 58.8 | 64.3 | 58.3 |

| Fracture extension pressure (MPa) | 36.7 | 38.1 | 45.3 | 44.8 | 46.2 | 44.6 | |

| Crack number | 214 | 145 | 149 | ||||

| Hydraulic fracture branches | 4 | 2 | 2 | ||||

| σv = 15 MPa σh = 30 MPa | Breakdown pressure (MPa) | 39.2 | 41.6 | 40.4 | 40.5 | - | 43.3 |

| Fracture extension pressure (MPa) | 20.8 | 20.7 | 22.3 | 21.7 | 16.5 | 23.6 | |

| Crack number | 192 | 285 | 186 | ||||

| Hydraulic fracture branches | 4 | 4 | 3 | ||||

| In-Situ Stress Conditions | Hydraulic Fracturing Characteristics | L = 0.3 m | L = 0.4 m | L = 0.6 m | |||

|---|---|---|---|---|---|---|---|

| Well No.1 | Well No.2 | Well No.1 | Well No.2 | Well No.1 | Well No.2 | ||

| σv = 30 MPa σh = 30 MPa | Breakdown pressure (MPa) | 62.3 | 61.6 | 60.1 | 59.2 | 61.8 | 62.4 |

| Fracture extension pressure (MPa) | 36.9 | 37.2 | 38.2 | 40.1 | 45.6 | 46.5 | |

| Crack number | 138 | 150 | 118 | ||||

| Hydraulic fracture branches | 2 | 3 | 2 | ||||

| σv = 15 MPa σh = 30 MPa | Breakdown pressure (MPa) | 39.8 | 37.4 | 40.2 | 38.7 | 40.6 | 39.9 |

| Fracture extension pressure (MPa) | 21.2 | 20.9 | 21.0 | 21.1 | 20.8 | 22.8 | |

| Crack number | 179 | 160 | 163 | ||||

| Hydraulic fracture branches | 3 | 3 | 3 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhou, J.; Zhang, L.; Han, Z. Numerical Investigation of Injection-Induced Fracture Propagation in Brittle Rocks with Two Injection Wells by a Modified Fluid-Mechanical Coupling Model. Energies 2020, 13, 4718. https://doi.org/10.3390/en13184718

Wang S, Zhou J, Zhang L, Han Z. Numerical Investigation of Injection-Induced Fracture Propagation in Brittle Rocks with Two Injection Wells by a Modified Fluid-Mechanical Coupling Model. Energies. 2020; 13(18):4718. https://doi.org/10.3390/en13184718

Chicago/Turabian StyleWang, Song, Jian Zhou, Luqing Zhang, and Zhenhua Han. 2020. "Numerical Investigation of Injection-Induced Fracture Propagation in Brittle Rocks with Two Injection Wells by a Modified Fluid-Mechanical Coupling Model" Energies 13, no. 18: 4718. https://doi.org/10.3390/en13184718