Demand-Response Application in Wastewater Treatment Plants Using Compressed Air Storage System: A Modelling Approach

Abstract

:1. Introduction

2. Materials and Methods

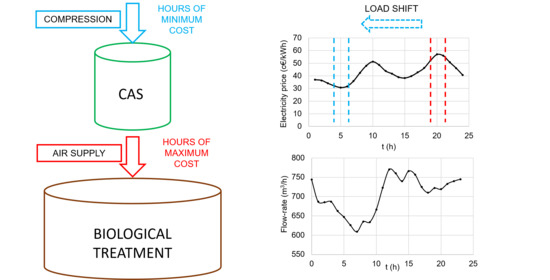

2.1. System Configuration

2.2. Input Model Data

2.3. Biological Treatment Unit

2.4. Compressed Air Storage

2.5. Anaerobic Digestion Unit

2.6. Economic Analysis

2.7. Optimization Model Implementation

3. Results

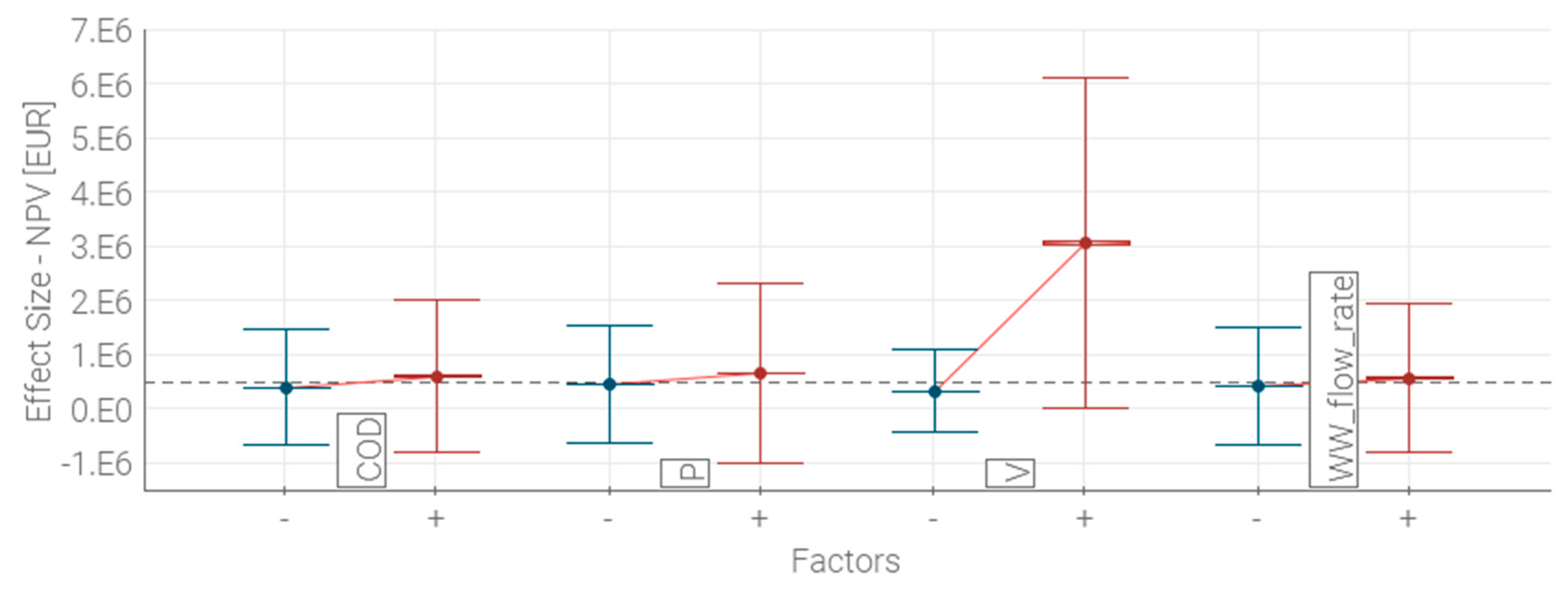

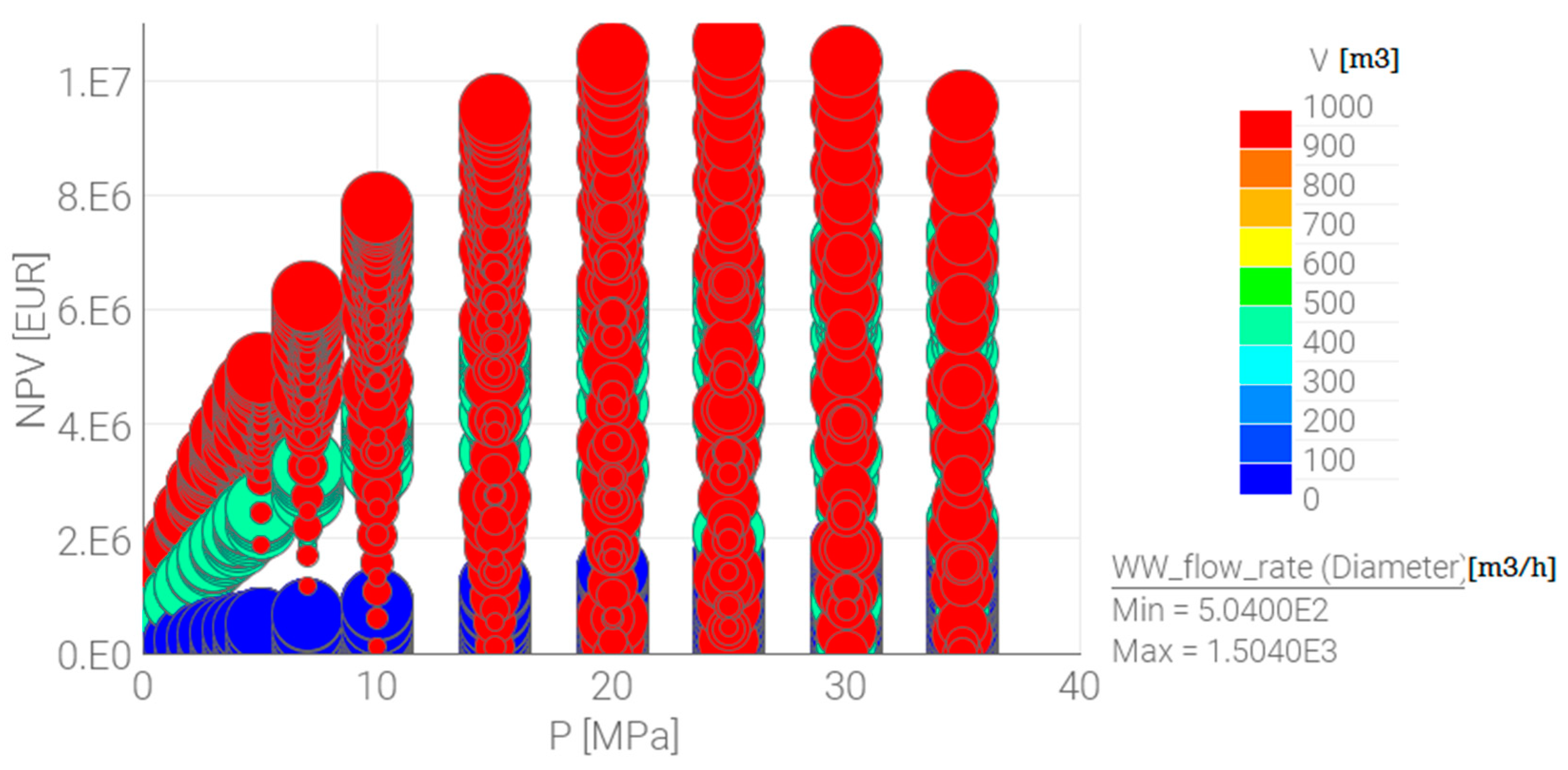

3.1. Scenario 1: Compressed Air Storage without Anaerobic Digestion

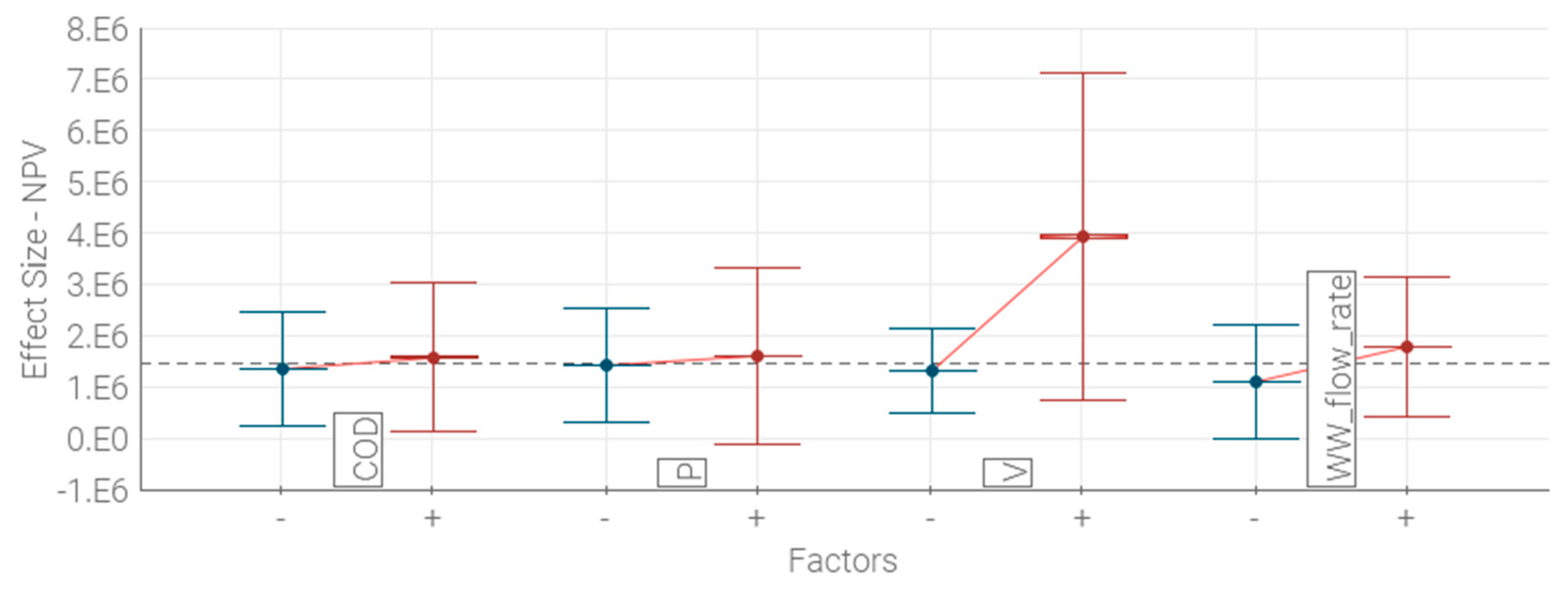

3.2. Scenario 2: Compressed Air Storage with Anaerobic Digestion

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AD | Anaerobic Digestion |

| ADM1 | Anaerobic Digestion Model No. 1 |

| AS | Activated Sludge |

| ASM1 | Activated Sludge Model No. 1 |

| CAS | Compressed air storage |

| CAES | Compressed air energy storage |

| CH4 | Methane |

| CHP | Combined Heat and Power |

| CO2 | Carbon Dioxide |

| COD | Chemical oxygen demand |

| DO | Dissolved Oxygen |

| DR | Demand Response |

| GHG | Green-House Gases |

| HRT | Hydraulic retention time |

| IWA | International Water Association |

| NZE | Net Zero Energy |

| PE | Population Equivalent |

| PLC | Programmable Logic Controller |

| TEE | White certificates |

| TN | Total Nitrogen |

| VFD | Variable Frequency Drive |

| VS | Volatile Solids |

| VSS | Volatile Suspended Solids |

| WWTP | Waste-Water Treatment Plant |

Symbols

| % VS | Volatile solid content of sludge (% w/w) |

| A | Area (m2) |

| c | Specific cost (EUR) |

| C | Cost (EUR]) |

| E | Energy |

| H | Thermal energy |

| k | Heat exchange constant |

| q | Vertical intercept of the generic equation |

| Q | Flowrate (m3/h) |

| R | Revenues (EUR) |

| t | temperature (°C) |

| V | Storage tank volume (m3) |

| X | Biomass concentration in the biological tank (g VSS/L) |

| YCH4 | Specific methane yield (NmL CH4/g VS) |

Subscripts and Superscripts

| air | air related |

| base | base digester |

| dig | digester |

| sup | superficial digester |

| av_CHP | avoided through biogas utilization |

| av_tank | avoided through air storage tank |

| compr | air compression in the tank related |

| i | generic device |

| O&M | operation and maintenance |

| loss | lost from the digester |

| in | influent |

| ope | operating |

| out | effluent |

| s0 | inlet sludge |

| sludge | sludge related |

| soil | soil related |

| TOT | total investment |

References

- Kirchem, D.; Lynch, M.Á.; Bertsch, V.; Casey, E. Modelling demand response with process models and energy systems models: Potential applications for wastewater treatment within the energy-water nexus. Appl. Energy 2020, 260, 114321. [Google Scholar] [CrossRef]

- Rodriguez, D.J.; Diego, J.; Delgado, A.; DeLaquil, P.; Sohns, A. Thirsty Energy; World Bank: Washington, DC, USA, 2013. [Google Scholar] [CrossRef]

- Lee, M.P. Assessment of Demand Response & Advanced Metering, Assessment of Demand Response & Advanced Today’s Presentation Will Discuss: Purpose of FERC’s Annual Assessment Results. December 2012. Available online: http://www.madrionline.org/wp-content/uploads/2013/09/Lee.pdf (accessed on 16 June 2020).

- Di Fraia, S.; Massarotti, N.; Vanoli, L. A novel energy assessment of urban wastewater treatment plants. Energy Convers. Manag. 2018, 163, 304–313. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the energy efficiency of a large wastewater treatment plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- Yang, X.; Wei, J.; Ye, G.; Zhao, Y.; Li, Z.; Qiu, G.; Li, F.; Wei, C. The correlations among wastewater internal energy, energy consumption and energy recovery/production potentials in wastewater treatment plant: An assessment of the energy balance. Sci. Total Environ. 2020, 714, 136655. [Google Scholar] [CrossRef]

- Mainardis, M.; Goi, D. Pilot-UASB reactor tests for anaerobic valorisation of high-loaded liquid substrates in friulian mountain area. J. Environ. Chem. Eng. 2019, 7, 103348. [Google Scholar] [CrossRef]

- Plazzotta, S.; Cottes, M.; Simeoni, P.; Manzocco, L. Evaluating the environmental and economic impact of fruit and vegetable waste valorisation: The lettuce waste study-case. J. Clean. Prod. 2020, 262, 121435. [Google Scholar] [CrossRef]

- Guerra-Rodríguez, S.; Oulego, P.; Rodríguez, E.; Singh, D.N.; Rodríguez-Chueca, J. Towards the implementation of circular economy in the wastewater sector: Challenges and opportunities. Water 2020, 12, 1431. [Google Scholar] [CrossRef]

- Kollmann, R.; Neugebauer, G.; Kretschmer, F.; Truger, B.; Kindermann, H.; Stoeglehner, G.; Ertl, T.; Narodoslawsky, M. Renewable energy from wastewater—Practical aspects of integrating a wastewater treatment plant into local energy supply concepts. J. Clean. Prod. 2017, 155, 119–129. [Google Scholar] [CrossRef]

- Mitra, S.; Grossmann, I.E.; Pinto, J.M.; Arora, N. Optimal production planning under time-sensitive electricity prices for continuous power-intensive processes. Comput. Chem. Eng. 2012, 38, 171–184. [Google Scholar] [CrossRef] [Green Version]

- Tchobanoglus, G.; Burton, F.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf and Eddy: New York, NY, USA, 2003. [Google Scholar]

- Henze, M.; Grady, C.; Gujer, W.; Marais, G.; Matsuo, T. Activated sludge model no. 1, Tech. rep. In IAWQ Scientific and Technical Report No. 1; IAWQ: London, UK, 1987. [Google Scholar]

- Póvoa, P.; Oehmen, A.; Inocêncio, P.; Matos, J.S.; Frazão, A. Modelling energy costs for different operational strategies of a large water resource recovery facility. Water Sci. Technol. 2017, 75, 2139–2148. [Google Scholar] [CrossRef]

- Hvala, N.; Vrečko, D.; Levstek, M.; Bordon, C. The use of dynamic mathematical models for improving the designs of upgraded wastewater treatment plants. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 15–31. [Google Scholar] [CrossRef]

- Simeoni, P.; Ciotti, G.; Cottes, M.; Meneghetti, A. Integrating industrial waste heat recovery into sustainable smart energy systems. Energy 2019, 175, 941–951. [Google Scholar] [CrossRef]

- Gude, V.G. Energy and water autarky of wastewater treatment and power generation systems. Renew. Sustain. Energy Rev. 2015, 45, 52–68. [Google Scholar] [CrossRef]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2014, 71, 303–308. [Google Scholar] [CrossRef]

- Mahmud, R.; Erguvan, M.; Macphee, D.W. Performance of Closed Loop Venturi Aspirated Aeration System: Experimental Study and Numerical Analysis with Discrete Bubble Model. Water 2020, 12, 1637. [Google Scholar] [CrossRef]

- Hakanen, J.; Miettinen, K.; Sahlstedt, K. Wastewater treatment: New insight provided by interactive multiobjective optimization. Decis. Support Syst. 2011, 51, 328–337. [Google Scholar] [CrossRef]

- Ramos, M.A.; Boix, M.; Montastruc, L.; Domenech, S. Multiobjective Optimization Using Goal Programming for Industrial Water Network Design. Ind. Eng. Chem. Res. 2014, 53, 17722–17735. [Google Scholar] [CrossRef] [Green Version]

- Díaz-Madroñero, M.; Pérez-Sánchez, M.; Satorre-Aznar, J.R.; Mula, J.; López-Jiménez, P.A. Analysis of a wastewater treatment plant using fuzzy goal programming as a management tool: A case study. J. Clean. Prod. 2018, 180, 20–33. [Google Scholar] [CrossRef]

- Sweetapple, C.; Fu, G.; Butler, D. Multi-objective optimisation of wastewater treatment plant control to reduce greenhouse gas emissions. Water Res. 2014, 55, 52–62. [Google Scholar] [CrossRef] [Green Version]

- Castellani, B.; Presciutti, A.; Filipponi, M.; Nicolini, A.; Rossi, F. Experimental investigation on the effect of phase change materials on compressed air expansion in CAES plants. Sustainability 2015, 7, 9773–9786. [Google Scholar] [CrossRef] [Green Version]

- Besharat, M.; Dadfar, A.; Viseu, M.T.; Brunone, B.; Ramos, H.M. Transient-flow induced compressed air energy storage (TI-CAES) system towards new energy concept. Water 2020, 12, 601. [Google Scholar] [CrossRef] [Green Version]

- Abbaspour, M.; Satkin, M.; Mohammadi-Ivatloo, B.; Lotfi, F.H.; Noorollahi, Y. Optimal operation scheduling of wind power integrated with compressed air energy storage (CAES). Renew. Energy 2013, 51, 53–59. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Smart energy systems for a sustainable future. Appl. Energy 2017, 194, 225–235. [Google Scholar] [CrossRef]

- Gestore dei Mercati Energetici (GME). Electricity Market. 2020. Available online: https://www.mercatoelettrico.org/it/ (accessed on 20 February 2020).

- Autorità di Regolazione Energia Reti e Ambiente (ARERA). Electricity Prices for Industrial Users. 2019. Available online: https://www.arera.it/it/dati/eepcfr2.htm (accessed on 21 February 2020).

- Dionisi, D.; Rasheed, A.A. Maximisation of the organic load rate and minimisation of oxygen consumption in aerobic biological wastewater treatment processes by manipulation of the hydraulic and solids residence time. J. Water Process Eng. 2018, 22, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manag. 2013, 33, 1626–1632. [Google Scholar] [CrossRef]

- Simeoni, P.; Nardin, G.; Ciotti, G. Planning and design of sustainable smart multi energy systems. The case of a food industrial district in Italy. Energy 2018, 163, 443–456. [Google Scholar] [CrossRef]

- Mainardis, M.; Flaibani, S.; Mazzolini, F.; Peressotti, A.; Goi, D. Techno-economic analysis of anaerobic digestion implementation in small Italian breweries and evaluation of biochar and granular activated carbon addition effect on methane yield. J. Environ. Chem. Eng. 2019, 7, 103184. [Google Scholar] [CrossRef]

- Zupančič, G.D.; Roš, M. Heat and energy requirements in thermophilic anaerobic sludge digestion. Renew. Energy 2003, 28, 2255–2267. [Google Scholar] [CrossRef]

- Osservatorio Meteorologico Regionale (Osmer). Data Archival. 2019. Available online: https://www.osmer.fvg.it/archivio.php?ln=&p=dati (accessed on 26 February 2020).

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-Flow Anaerobic Sludge Blanket (UASB) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering 2020, 7, 43. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Borzooei, S.; Amerlinck, Y.; Abolfathi, S.; Panepinto, D.; Nopens, I.; Lorenzi, E.; Meucci, L.; Zanetti, M.C. Data scarcity in modelling and simulation of a large-scale WWTP: Stop sign or a challenge. J. Water Process Eng. 2019, 28, 10–20. [Google Scholar] [CrossRef] [Green Version]

- Misson, G.; Mainardis, M.; Incerti, G.; Goi, D.; Peressotti, A. Preliminary evaluation of potential methane production from anaerobic digestion of beach-cast seagrass wrack: The case study of high-adriatic coast. J. Clean. Prod. 2020, 254, 120131. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. What is the best scale for implementing anaerobic digestion according to environmental and economic indicators? J. Water Process Eng. 2020, 35, 101235. [Google Scholar] [CrossRef]

- Borzooei, S.; Campo, G.; Cerutti, A.; Meucci, L.; Panepinto, D.; Ravina, M.; Riggio, V.; Ruffino, B.; Scibilia, G.; Zanetti, M. Optimization of the wastewater treatment plant: From energy saving to environmental impact mitigation. Sci. Total Environ. 2019, 691, 1182–1189. [Google Scholar] [CrossRef]

- Parker, W.J. Application of the ADM1 model to advanced anaerobic digestion. Bioresour. Technol. 2005, 96, 1832–1842. [Google Scholar] [CrossRef]

- Drewnowski, J.; Remiszewska-Skwarek, A.; Duda, S.; Łagód, G. Aeration process in bioreactors as the main energy consumer in a wastewater treatment plant. Review of solutions and methods of process optimization. Processes 2019, 7, 311. [Google Scholar] [CrossRef] [Green Version]

- Khatri, N.; Khatri, K.K.; Sharma, A. Enhanced Energy Saving in Wastewater Treatment Plant using Dissolved Oxygen Control and Hydrocyclone. Environ. Technol. Innov. 2020, 18, 100678. [Google Scholar] [CrossRef]

| Parameter | Selected Range | Modelling Step |

|---|---|---|

| Influent flowrate (m3/h) | 504 ÷ 1504 | 100 |

| Influent COD concentration (mg/L) | 150 ÷ 500 | 50 |

| Electricity consumption for aeration (% of total) | 30 ÷ 80 | 10 |

| Compressed air tank volume (m3) | 0.3 ÷ 1000 | Variable |

| Compressed air pressure (Mpa) | 0.1 ÷ 35 | Variable |

| Parameter | Objective Function |

|---|---|

| NPV (EUR) | Maximization |

| PES (toe) | Maximization |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cottes, M.; Mainardis, M.; Goi, D.; Simeoni, P. Demand-Response Application in Wastewater Treatment Plants Using Compressed Air Storage System: A Modelling Approach. Energies 2020, 13, 4780. https://doi.org/10.3390/en13184780

Cottes M, Mainardis M, Goi D, Simeoni P. Demand-Response Application in Wastewater Treatment Plants Using Compressed Air Storage System: A Modelling Approach. Energies. 2020; 13(18):4780. https://doi.org/10.3390/en13184780

Chicago/Turabian StyleCottes, Mattia, Matia Mainardis, Daniele Goi, and Patrizia Simeoni. 2020. "Demand-Response Application in Wastewater Treatment Plants Using Compressed Air Storage System: A Modelling Approach" Energies 13, no. 18: 4780. https://doi.org/10.3390/en13184780